Bentone BF 1 KSV RME Technical specifications

Providing sustainable energy solutions worldwide

CR00174 178 156 35-3 2021-07-09

Installation- and maintenance instruction

BF 1 KSV RME

LMO14.113C2E

ANV47C

Translation of the original instructions.

2Bentone

example Beispielexempel

352011030141

Designation

Type

Model

Serial no.

Motor supply

Main supply

MADE IN SWEDEN BY

LIGHT OIL 35-90kW 1,25-6,0 cSt 7-14bar

BF 1 KS 76-24

BF 1

BF 1 KS 76-24

1234567

1~230V 1,0A 50Hz IP 20

Man.Year 2019

Cap. Min-Max

3

?

1

-sv

1. Manualer på övriga språk

2. www.bentone.com\

nedladdning

eller scanna QR-koden.

3. Skriv in brännarens

artikelnummer som finns på din

typskylt (se bild) och välj ditt

språk.

Detaljerad ecodesign information

kan laddas ner på:

www.bentone.com/ecodesign.

-en

1. Manuals in other languages

2. www.bentone.com\download

or scan QR-code.

3. Enter the burner`s article

number on your data plate (see

picture) and select language.

Detailed ecodesign information

can be downloaded at:

www.bentone.com/ecodesign.

-da

1. Manualer på andre sprog

2. www.bentone.com\download

eller scan QR-koden.

3. Indtast brænderens

artikelnummer, der findes på

typeskiltet (se billede), og vælg

dit sprog.

Detaljerede oplysninger om

ecodesign kan downloades på:

www.bentone.com/ecodesign.

-fr

1. Manuels dans d’autres

langues

2. www.bentone.com\download

ou scannez le code QR.

3. Saisir le numéro d’article

du brûleur sur votre plaque

signalétique (consultez

l’illustration) et sélectionnez la

langue.

Des informations détaillées

sur l’écodesign peuvent être

téléchargées à l’adresse:

www.bentone.com/ecodesign.

-de

1. Gebrauchsanweisungen in

anderen Sprachen

2. www.bentone.com\download

oder scannen Sie den QR-Code.

3. Geben Sie die Artikelnummer

des Brenners auf Ihrem

Typenschild ein, (siehe Bild) und

wählen Sie die Sprache aus.

Detaillierte Informationen zum

Ecodesign können unter

www.bentone.com/ecodesign

heruntergeladen werden.

2

3Bentone

Table of contents

1. Safety Information____________________________________ 4

2. Technical data _______________________________________ 8

2.1 Model BF 1 KS/KSV 76-24 _________________________ 9

2.2 Recommended nozzles and pressures ______________ 10

2.3 Description______________________________________ 11

3. Installation _________________________________________ 13

3.1 Delivery checks __________________________________ 13

3.2 Preparations for installation ________________________ 13

3.3 Oil supply _______________________________________ 13

3.4 Electrical connection______________________________ 13

3.5 Choice of nozzle _________________________________ 13

3.6 Brake plate and airflow setting _____________________ 13

3.7 Burner installation ________________________________ 14

4. Basic settings ______________________________________ 15

4.1 Example of basic setting __________________________ 15

5. Burner servicing ____________________________________ 18

5.1 Warning ________________________________________ 18

6. Pump Instructions___________________________________ 27

6.1 Suntec ANV47C _________________________________ 27

7. Preheater___________________________________________ 31

8. Oil Burner Control ___________________________________ 32

8.1 Wiring diagram _________________________________ 32

8.2 Function LMO14/24 ______________________________ 33

8.3 Colour codes LMO14/24 __________________________ 34

8.4 Fault codes LMO14/24 ___________________________ 34

9. Fault Location ______________________________________ 35

9.1 Burner will not start_______________________________ 35

9.2 Burner will not start after normal use ________________ 35

9.3 Delayed ignition__________________________________ 36

9.4 Noise in pump ___________________________________ 36

9.5 Pump pressure __________________________________ 37

10. Log of flue gas analysis____________________________ 38

11. Oil burners maintenance instructions _______________ 39

4Bentone

1. Safety Information

This Installation and Maintenance manual:

• is to be regarded as part of the burner and must always be kept near

the installation site

• is intended for use by authorised personnel

• must be read prior to installation

• must be observed by all who work with the burner and associated

system components

• work with the burner may only be carried out by certified installers/

personnel

• Enertech AB is not liable for any typographical errors and reserves the

right to make design changes without prior notice.

• The burner may only be used for its intended purpose in accordance

with the product’s technical data.

• The burner may only be installed and operated by authorised

personnel.

• The product is packaged to prevent damage from occurring during

handling. Handle the product with care. Lifting equipment must be

used to lift larger packages.

• The products must be transported/stored on a level surface in a dry

environment, max. 80% relative humidity, no condensation.

Temperature -20 to +60 °C.

• Check that the burner is compatible with the boiler’s output range.

• The label information on the rating plate refers to the burner’s minimum

and maximum power.

• All components must be installed without being bent, twisted or

subjected to mechanical or thermal forces which can affect the

components.

• The burner must be installed so that it complies with local regulations

for fire safety, electrical safety, and fuel distribution.

• Make sure when installing the equipment that there is enough space to

service the burner.

• Permitted ambient temperature during operation 0 to +60°C. Max

80% relative humidity, no condensation.

• The installer must ensure that the room has adequate air supply.

• The room must comply with local regulations pertaining to its intended

use.

• The installation site must be free of chemicals.

• Burner tubes, fan wheels and air dampers may contain sharp edges.

• The surface temperature of the burner’s components can exceed

60°C.

• Caution: The burner has moving parts, and there is risk of crushing

injuries.

• The electrical installation must be professionally carried out in

accordance with applicable high voltage regulations, as per Enertech’s

recommendations.

165 105 85

5Bentone

• Before service, shut off the fuel supply and turn off the power to the

burner.

• Leak checks must be performed during installation and service to

prevent fuel leakage.

• Care should be taken by the installer to ensure that no electrical cables

or fuel lines are crushed or otherwise damaged during installation or

service.

• If the boiler is equipped with an access hatch, this must be equipped

with a hatch opening switch connected to the burner's safety system.

• When in operation, the burner’s noise level can exceed 85 dBA.

Use hearing protection.

• The burner must not be put into operation without proper safety and

protection devices.

• Fire extinguisher with Class BE recommended.

• Modifying the design or using accessories that have not been

approved by Enertech in writing is strictly prohibited.

• Prior to operation, the following points must be checked:

-fitting and installation work has been completed and approved

-electrical installation has been correctly performed

-flue gas ducts and combustion air ducts are not blocked

-all actuators and control and safety devices are in working order and

correctly set

• After commissioning

-If the gas burner control has a solid red light, contact your installer.

6Bentone

General requirements RME

This is a burner designed for FAME, B-100 (RME) fuel. The fuel must meet

the requirements of standard EN 14214 for FAME.

The fuel must be stored and used according to the manufacturer’s

instructions. It should typically be used within 6 months of manufacture. Fuel

that is allowed to age loses its oxidation stability and produces aggressive

constituents. These cause oxidation damage to components in the oil

system. The fuel should be stored in a cool area to minimise these problems.

The RME cistern must be made of metal or dark coloured plastics approved

for the fuel.

The design of the equipment on the burner permits the use of EO1 type

oil without modification, although with appropriate adjustments to the

combustion after changing the fuel type.

Oil burners must be installed in accordance with local regulations. The

installer must therefore be knowledgeable of the regulations pertaining to oil

and combustion.

Installation should be carried out as a one-pipe system and used together

with the bleeder to vent the system, and an appropriate filter must also be

in place. Copper should be avoided in RME fuel systems since the fuel and

copper have an oxidising effect on each other.

Only oil suitable for the burner must be used and then in combination with

a suitable oil filter designed for FAME, B-100 (RME) and installed before the

burner’s oil pump.

The tank should be cleaned and the water should be checked regularly to

prevent problems related to corrosion and microorganisms. This should be

done once a year.

If the burner is replacing an existing burner, ensure that the oil filter is

changed to a filter designed for FAME, B-100 (RME). Installation may only be

performed by qualified personnel.

Care should be taken by the installer to ensure that no electrical cables or oil/

gas pipelines are crushed or damaged during installation or service.

Burners that run on FAME, B-100 (RME) fuel are and must be equipped with

parts designed for this fuel. This applies in particular to oil-related parts such

as the pump, solenoid valve, oil filter and hoses with fire-retardant sleeves. It

is very important when carrying out a service to replace old parts with new

parts of the same quality.

Maintenance

The boiler/burner must be checked regularly for faults or leakage. Any boiler/

burner that uses FAME (RME) fuel must be serviced at least twice a year. It is

very important that worn parts are replaced at the time of servicing with new

parts of the same quality.

Oil hoses must be of high-quality fluoride rubber or PTFE intended for FAME,

B-100 (RME).

The hoses must be fitted with fire-retardant sleeves in order to satisfy

requirements according to EN-ISO 6806.

7Bentone

Components Service life – Recommended

replacement

Service life – Recommended

replacement Operating cycles

Control system 10 years 250,000 cycles

Pressure switch 10 years 250,000 cycles

Ignition system with flame guard 10 years 250,000 cycles

UV flame sensor 10,000 h N/A

Damper motor 500,000 cycles

Contactor 10 years 500,000 cycles

Burner Twice a year 3,000 h

Filter Twice yearly replacement 3,000 h replacement

Oil hose Once yearly replacement

Nozzle Twice yearly replacement 3,000 h replacement

Electrodes Replace/Clean twice a year Replace/Clean 3,000 h

Brake disc Replace/Clean twice a year Replace/Clean 3,000 h

Motor Twice a year 3,000 h

Drive shaft Check/replace in the event of

damage

Check/replace in the event of

damage

Fan wheel Twice a year

Replace if

need for cleaning/imbalance

3,000h

Replace if

need for cleaning/imbalance

Tank Check for water once a year

Clean tank once a year

Oil filter Twice a year 3,000 h replacement

Oil valve Tightness check twice a year Replace if leaky

The burner and its components must be recycled according to applicable regulations.

Burner service schedule

Servicing must be carried out twice a year or after 3,000 hours of operation.

Component replacement intervals

Delivery check

• Make sure everything is delivered and the goods have not been damaged during transit.

• If something is wrong with a delivery, report it to the supplier.

• Transport damage must be reported to the shipping company.

8Bentone

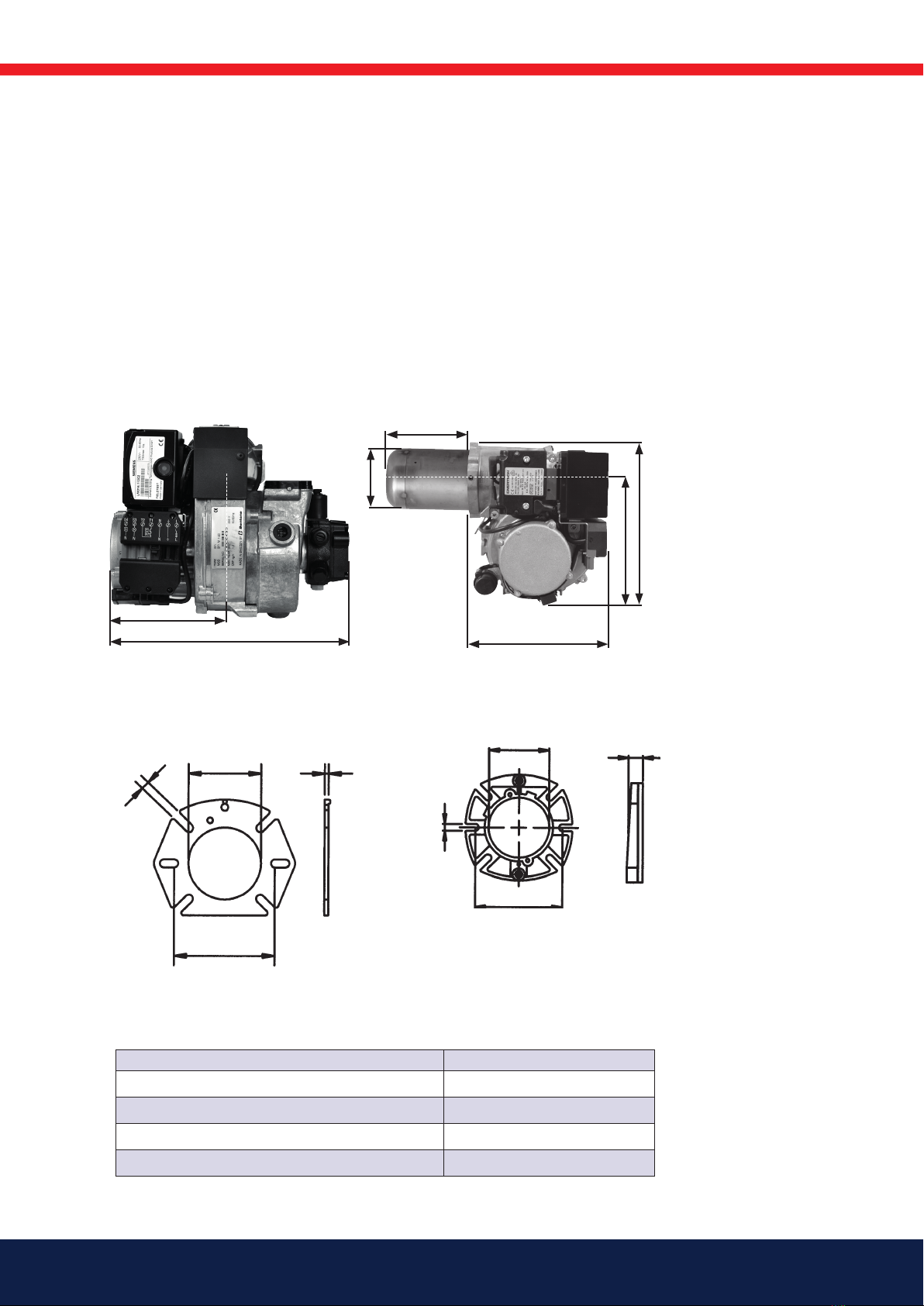

165 305 56

ø89

172

B

190

226

278

145

Dimensions, flanges

Flange 2

10,3

25

130–150

ø89,7

Flange 1

125–150

ø90 5

10,3

Electrical specification EN 60335-2-102

Type BF 1

Electrical data, Control power 230V 1~ 1,1/1,5A 50/60Hz IP20

Electrical data, Motor -

Max fuse rating 10A

Noise level 70 dBA

Max operating current, see data plate.

2. Technical data

The burner is intended for:

• Light oil, B10 heating oil/biofuel blend, FAME, B-100 (RME) (as defined in DIN V51603-6).

and is used for:

• Water heating generators.

• Hot air generators (these require LMO 24 255 C2E).

Dimensions BF 1

9Bentone

ø73

ø24

ø76

10,0-11,0

2,3-3,1 0,5-1,5

Length of blast tube

Protrusion from flange, measurement B

Flange 1 Flange 2

147 130 114

224 207 191

Working area/Basic settings

!Do not exceed the

working area.

!Scale value applies

to 0 mbar furnace

pressure.

0,0

2,0

4,0

6,0

8,0

10,0

12,0

14,0

16,0

18,0

20,0

22,0

35 40 45 50 55 60 65 70 75 80 85 90

160302-781-2

kW

Air settings

Nozzle assembly

Scale

Burner output

-

0,5

0,0

0,5

1,0

1,5

2,0

2,5

3,0

3,5

4,0

30 35 40 45 50 55 60 65 70 75 80 85 90 95

mbar

kW

3.0-7.6 kg/h

35-90 kW

160303-296

2.1 Model BF 1 KS/KSV 76-24

10 Bentone

2.6 Recommended nozzles and pressures

Because of the different types of boiler in existence, with varying furnace

geometries and furnace loads, it is not possible to commit to any given spray

angle or spay pattern. Note that spray angles and spray patterns change

with pump pressures.

Nozzle 60° Solid/Hollow cone

80° Solid/Hollow conel

Pump pressure 10 bar (8–14 bar) Fuel oil 1

10 bar (7–12 bar) Kerosene

Nozzle table, 8-15 bar

Pump pressure, bar

Gph 8 9 10 11 12 13 14 15

kg/h kW kg/h kW kg/h kW kg/h kW kg/h kW kg/h kW kg/h kW kg/h kW

0,40 1,33 16 1,41 17 1,49 18 1,56 18 1,63 19 1,70 20 1,76 21 1,82 21

0,50 1,66 20 1,76 21 1,86 22 1,95 23 2,04 24 2,12 25 2,20 26 2,28 27

0,60 2,00 24 2,12 25 2,23 26 2,34 28 2,45 29 2,55 30 2,64 31 2,73 32

0,65 2,16 26 2,29 27 2,42 29 2,54 30 2,65 31 2,75 33 2,86 34 2,96 35

0,75 2,49 29 2,65 31 2,79 33 2,93 35 3,08 36 3,18 38 3,30 39 3,42 40

0,85 2,83 33 3,00 36 3,16 37 3,32 39 3,47 41 3,61 43 3,74 44 3,87 46

1,00 3,33 39 3,53 42 3,72 44 3,90 46 4,08 48 4,24 50 4,40 52 4,56 54

1,10 3,66 43 3,88 46 4,09 48 4,29 51 4,48 53 4,67 55 4,84 57 5,01 59

1,20 3,99 47 4,24 50 4,47 53 4,68 55 4,89 58 5,09 60 5,29 63 5,47 65

1,25 4,16 49 4,40 52 4,65 55 4,88 58 5,10 60 5,30 63 5,51 65 5,70 68

1,35 4,49 53 4,76 56 5,02 59 5,27 62 5,50 65 5,73 68 5,95 70 6,15 73

1,50 4,98 59 5,29 63 5,58 66 5,85 69 6,11 72 6,36 75 6,60 78 6,83 81

1,65 5,49 65 5,82 69 6,14 73 6,44 76 6,73 80 7,00 83 7,27 86 7,52 89

1,75 5,82 69 6,18 73 6,51 77 6,83 81 7,14 85 7,42 88 7,71 91 7,97 94

2,00 6,65 79 7,06 84 7,45 88 7,81 93 8,18 97 8,49 101 8,81 104 9,12 108

2,25 7,49 89 7,94 94 8,38 99 8,78 104 9,18 109 9,55 113 9,91 117 10,26 122

The table applies to oils with a viscosity of 4.4 mm2/s (cSt) at a density of 830 kg/m3.

Burner with preheater

Allow for a reduction in oil quantity of 5–20% with preheating owing to:

• Temperature increases at the nozzle.

• Nozzle design.

• Capacity (the higher the capacity the lower the difference).

2.2 Recommended nozzles and pressures

11Bentone

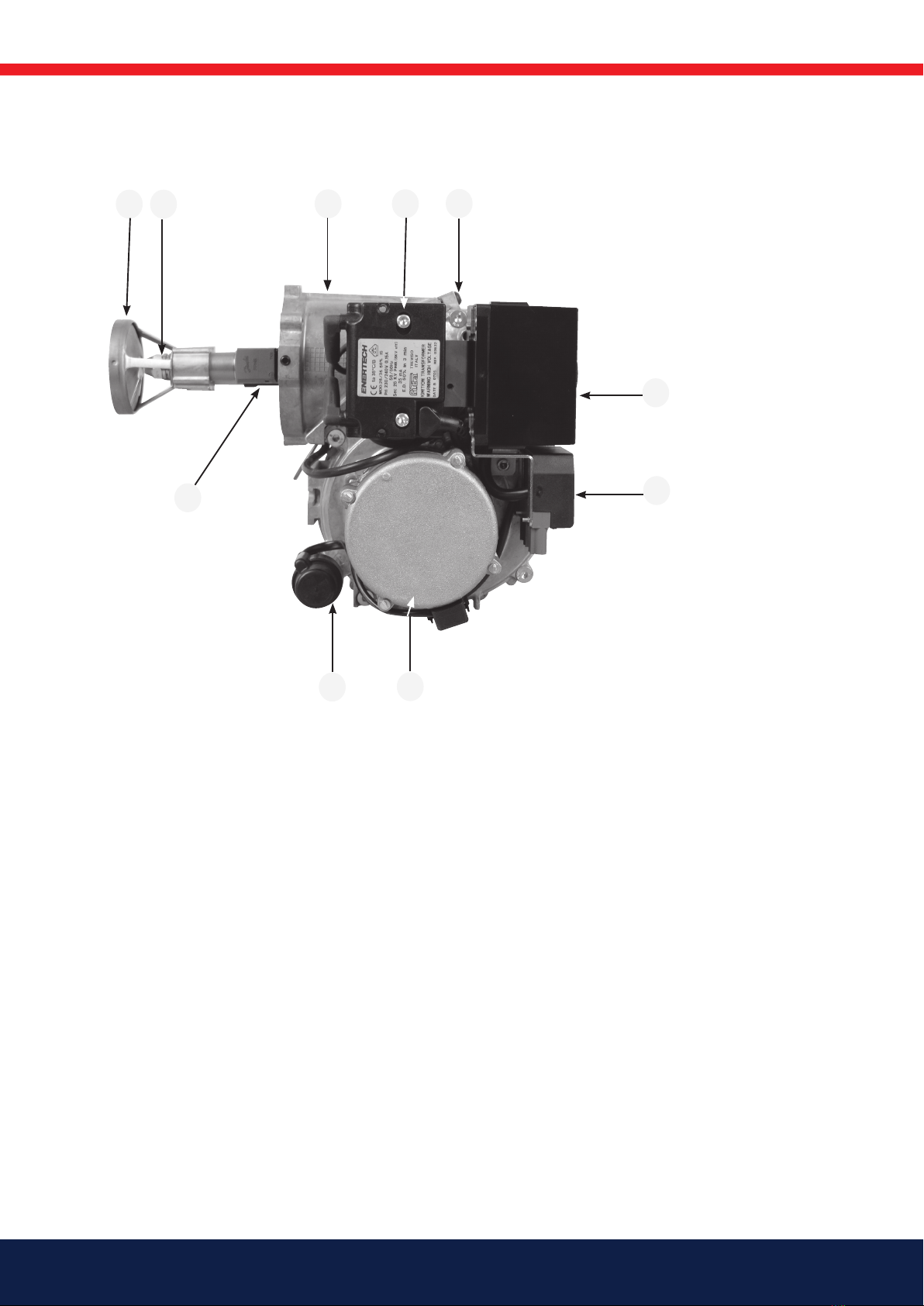

23 4

7

1

10

5

6

8

9

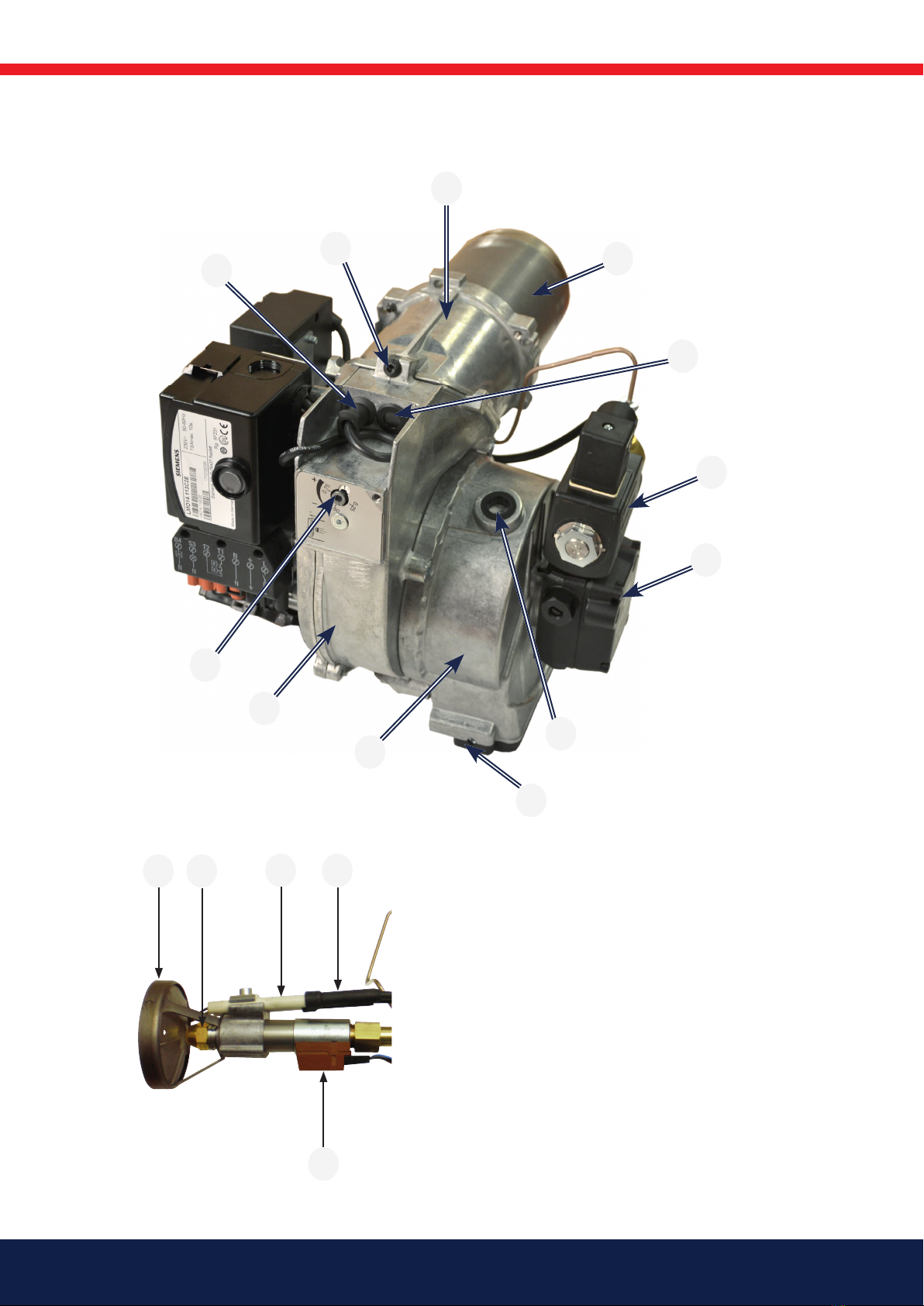

2.3 Description

Components

1. Brake plate

2. Nozzle

3. Fan housing, front

4. Ignition transformer

5. Separating screw

6. Oil burner control

7. Electrical contact X1 (refer to wiring diagram)

8. Motor

9. Capacitor

10. Preheater, where fitted

11. Ignition electrode

12. Ignition cable

13. Photoresistor

14. Inspection glass

15. Nozzle assembly adjustment

16. Cover plate

17. Blast tube

18. Grid

19. Solenoid valve

20. Oil pump

21. Air regulator

22. Air intake

23. Air flow indicator

24. Fan housing, rear

12 Bentone

211 12

1

10

5

15

24

22

21

23

13

3

17

14

19

20

13Bentone

165 305 18

3. Installation

3.1 Delivery checks

Check that everything has been delivered and that the goods are not

transport damaged. Any delivery faults must be reported to the supplier.

Transport damage must be reported to the forwarder.

3.2 Preparations for installation

Check that the burner’s measurements and capacity range is suitable for

the boiler in question. The power information on the data plate refers to the

burner’s max. and min. power.

3.3 Oil supply

In order to achieve good operational reliability it is important that the oil

supply system is laid out correctly.

Observe the following:

• Choice of pipe diameters, pipe lengths and height differences (refer to

pump instructions).

• Piping should be run with a minimum of joints/compression fittings.

• Pipework must be laid out so that oil hoses are not subjected to

tension or overbending when the burner is swung out or removed for

service.

• The oil filter should be installed so that the filter cartridge can easily be

replaced

3.4 Electrical connection

Before electrical installation is begun, electricity must be switched off at

the main switch. If the boiler has a 7-pole or a 4-pole Eurostecker (only on

2-stage burners), these often fit directly to the burner. Otherwise use the

connectors supplied. The operating thermostat, the max. thermostat and the

inspection hatch (where fitted) interlock can then be wired in series on the

incoming phase connected to L1 or connected between T1 and T2. In the

first mentioned case a jumper is installed between T1 and T2.

(Refer to connection in the section Electrical equipment).

3.5 Choice of nozzle

(Technical data): Recommended nozzle and nozzle table.

3.6 Brake plate and airflow setting

Before operations basic burner setting may be made according to the

diagram. (Refer to basic settings). Note that this only refers to the basic

setting; the setting must be adjusted after the burner has been started.

At this time flue gas analysis and soot measurement must be carried out.

!If any electrical connection is used other than that recommended by Enertech,

there may be a risk of equipment damage and personal injury.

14 Bentone

E

Return Inlet

E

X1

X2

3.7 Burner installation

3.7.1 Hole pattern

Check that the hole pattern matches the flange supplied.

(Refer to Technical data.)

3.7.2 Burner installation

1. Install the flange and the gasket on the boiler.

2. Attach the front piece to the flange.

3. Insulate between the burner register and the boiler cover for reduced

heat radiation.

4. Install the selected nozzle. (Refer to Technical data.)

5. Install the brake plate and check the ignition electrodes (refer to Burner

service.).

6. Install the burner body to the front piece and lock with screw (E).

3.7.3 Oil pipes

1. Check the oil pipe dimensions. (Refer to Pump Instructions.)

2. The oil filter should be installed in the oil supply line. If an air separator is

fitted, the oil filter should be installed before the air filter to increase the

life span of the filter.

3. For one-pipe systems the return plug must be removed. (Refer to

Pump Instructions.)

4. When installing oil hoses, check that the supply and return hoses are

connected to the correct connections on the oil pump. The hoses

must be run so that they are not bent or tensioned.

5. Purge the oil system. The oil pump will be damaged if it is run dry.

6. The vacuum should not be lower than 0.3 bar depression in the suction

line at start up.

3.7.4 Electrical connection

If the boiler lacks ready-connected plugs, connect using the supplied plug,

X2 in accordance with the wiring diagram.

1. Disconnect the power at the main switch.

2. Wire the Eurostecker X2 as in alt. 1–3 (refer to Electrical equipment).

3. Connect the Eurostecker X2 to the burner.

4. Switch on the power at the main switch.

15Bentone

165 305 19

4. Basic settings

4.1 Example of basic setting

4.1.1 Choice of nozzle

BF1 FU 63-16

Burner output 30 kW

Estimated nozzle output: 30 / 11,86* = 2,53 kg/h

Choice of nozzle according to table. (Refer to Technical data.)

According to the nozzle table, the following nozzle is indicated:

Nozzle: 0,65 Gph

Pump pressure: 11,0 bar

BF1 FU 63-16/FUV 63-16

Burner output 30 kW

Because of preheater, output is adjusted upward for choice of nozzle

according to table.

Estimated nozzle output: 30 x 1,06 = 31,8 kW

31,8 / 11,86* = 2,68 kg/h

Choice of nozzle according to table. (Refer to Technical data).

According to the nozzle table, the following nozzle is indicate

Nozzle: 0,75 Gph

Pump pressure: 9,5 bar

* Calorfic value Light oil = 11,86 kWh/kg

4.1.2 Basic setting

Setting values for 30 kW according to basic settings tables.

(Refer to Technical data FU 63-16).

Air setting = 11,0

Insert setting = 4,0

16 Bentone

Ι

Π

M

4.1.3 Nozzle assembly adjustment

The burner is fitted with a regulator which changes the brake plate position

in the blast tube. This is used to set the correct pressure drop across the

combustion assembly and thereby achieve good combustion without

pulsation.

The setting to be chosen is dependent among other things on set output

and furnace pressure.

Brake plate setting

• Less diffusion: turn screw to left.

• More diffusion: turn to right.

Setting brake plate position affects air flow. It is therefore always

necessary to adjust the air with the burner air regulator afterwards.

4.1.4 Air intake adjustment

Air settings are very important for achieving good combustion with neither

too much, nor too little, air. Adjustment of combustion airflow is carried out

by turning the air regulator with an Allen key. How far open the air regulator

must be is determined by output, furnace pressure and other burner settings

such as blast tube position.

4.1.5 Method of adjusting air quantity

Setting the air regulator is dependent on how the screw (with which air

regulation is adjusted) is installed. If the air intake is installed underneath

as shown in illustration Ι, turning the screw clockwise will reduce airflow,

and anticlockwise increase it. If the air intake is installed on top as shown

in illustration Π, clockwise adjustment increases airflow, and anticlockwise

reduces it.

4.1.6 Inlet cone, air adjustment

Airflow is also affected by the position of the inlet cone. However, it is

extremely rare that this needs to be adjusted; it should be left in the

standard STD position to achieve good starts and operations. (A cast-in

arrow on the fan housing indicates the position of the inlet cone. In addition

to the scale on the inlet cone casting, there is also a mark (M) indicating the

factory setting.)

17Bentone

D

4.1.7 Air intake rotation

It is possible to rotate the air intake to adapt the burner to different

surroundings. It is possible to rotate the air intake to a number of positions,

not just the positions shown to the left.

To rotate the air intake, undo the three screws that fasten the air intake and

the two screws which retain the pump. Then rotate the air intake to the

desired position and tighten the screws.The position of the air intake affects

the airflow through the burner somewhat.

The position which provides best airflow is with the air intake pointing

downwards.

4.1.8 Air duct

A hose connection air duct is available in three different dimensions: 48, 68,

and 78 mm outer diameter (D). The air duct is installed on the air intake at

the place where the grille is attached in the standard model

18 Bentone

165 305 51

!

Warning

!When servicing or replacing components that affect combustion, analyses and

soot tests must be carried out on the installation.

5. Burner servicing

5.1 Warning

Service must be carried out after 3,000 operating hours, or at least once per

year.

Only authorized personnel may perform service.

Before any type of service work is begun, switch of the power at the main

switch and shut off the oil.

Exercise caution as parts which are exposed when the burner is taken apart

can be hotter than 60°C. The installation engineer must be especially careful

to ensure that no electrical wiring or oil lines are pinched or damaged during

installation or service.

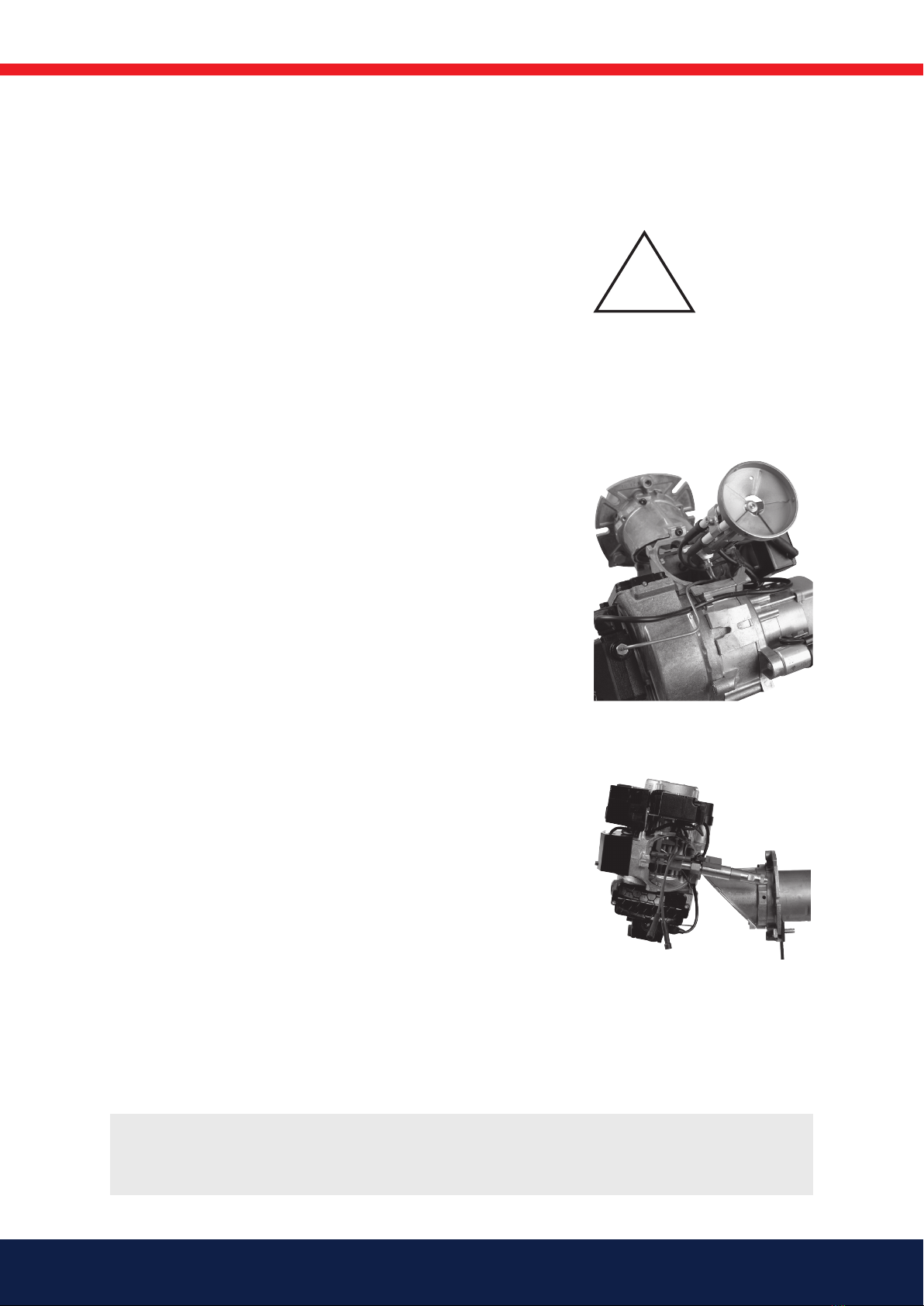

5.1.1 Service position

5.1.1.1 Service position 1

1. Switch off the power at the main switch and disconnect the Eurostecker

from the burner.

2. Undo the screw which fastens the burner front piece to the fan housing,

but only so much as to allow the fan housing to be removed from the

burner front piece.

3. Remove the fan housing from the burner front piece and pull it

backwards until the combustion assembly is free of the burner front

piece.

4. Suspend the fan housing by the fan housing attachment point (for

joining the front piece to the fan housing) on the screw (for joining the

front piece to the fan housing) as illustrated to the left. If necessary,

tighten the screw somewhat to ensure that the burner is suspended

safely.något för att få brännaren att hänga säkrare.

5.1.1.2 Service position 2

1. Switch off the power at the main switch and disconnect the Eurostecker

from the burner.

2. Undo the screw which fastens the burner front piece to the fan housing,

but only so much as to allow the fan housing to be removed from the

burner front piece.

3. Remove the fan housing from the burner front piece and pull it

backwards until the combustion assembly is free of the burner front

piece.

4. Turn the screw into the front piece until there is a gap of approx. 5 mm

between the metal and the screw head.

5. Suspend the fan housing by the fan housing service attachment on

the screw used for joining the front piece to the fan housing, with the

motor upwards, as shown in the illustration to the left.

19Bentone

!When servicing or replacing components that affect combustion, analyses and

soot tests must be carried out on the installation.

5.1.1.3 Service position 3

1. Switch off the power at the main switch and disconnect the Eurostecker

from the burner.

2. Undo the screw which fastens the burner front piece to the fan

housing, but only so much as to allow the fan housing to be removed

from the burner front piece.

3. Remove the fan housing from the burner front piece and pull it

backwards until the combustion assembly is free of the burner front

piece.

4. Turn the screw into the front piece until there is a gap of approx. 5 mm

between the metal and the screw head.

5. Suspend the fan housing by the fan housing service attachment on the

screw used for joining the front piece to the fan housing, with the air

intake upwards, as shown in the illustration to the left.

5.1.2 Combustion assembly service

1. Switch off the power at the main switch and disconnect the Eurostecker

from the burner.

2. If so desired, service position 1 may be used.

3. Carry out a visual inspection of the combustion assembly and check

the various parts for defects.

4. Undo and remove the brake plate and the electrode package from the

oil pipe. Clean the brake plate as necessary.

5. Screw off the nozzle.

6. Install the nozzle. The nozzle may not be cleaned; it must be replaced

with a new nozzle if the existing one is considered defective.

7. Check the ignition electrodes. Replace as necessary (refer to Technical

data for electrode settings).

8. Install the brake plate and electrode package. Check that the distance

between the nozzle and brake plate is correct

(refer to Technical data).

9. Undo the screw that the fan housing is suspended from. Reassemble

the front piece and the fan housing and fasten them together.

10. Connect the Eurostecker and switch on the power at the main switch.

11. Start the burner and check the combustion.

20 Bentone

!When servicing or replacing components that affect combustion, analyses and

soot tests must be carried out on the installation.

5.1.3 Preheater replacement

1. Switch off the power at the main switch and disconnect the Eurostecker

from the burner.

2. If so desired, service position 1 may be used.

3. Remove the brake plate and electrode package.

4. Disconnect the preheater cable from the preheater.

5. Screw off the nozzle.

6. Undo the nut that connects the oil pipe to the preheater.

7. Install the new preheater. Check the condition of the O-ring; replace

as necessary.

8. Connect the preheater cable.

9. Install the nozzle.

10. Install the brake plate and electrode package. Check that the distance

between the nozzle and brake plate is correct

(refer to Technical data).

11. Re-assemble the burner.

12. Connect the Eurostecker and switch on the power at the main switch.

13. Start the burner and check the combustion.

Table of contents

Other Bentone Portable Generator manuals