Berges ACM-D2 Series User manual

Operating manual

ACM

D2/S2

Table ofcontents

1.General information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.Safetyinstructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .3

2.1.General safetyinstructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2.Intended use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.3.Transport,storage, installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4.Electrical connection.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.5.Operating instructions. . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. .4

2.6.Miscellaneous.. . . .. . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. .5

3.Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .6

4.Technical data(input voltage1x220...240V).. . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. . 7

5.Technical data(input voltage3x380...460V).. . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. . 8

6.Technical data(input voltage3x380...460V).. . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. . 9

7.Power-derating in function ofthe switching frequency.. . . . . . . . . . . . . . . . . . . . . . . .. 10

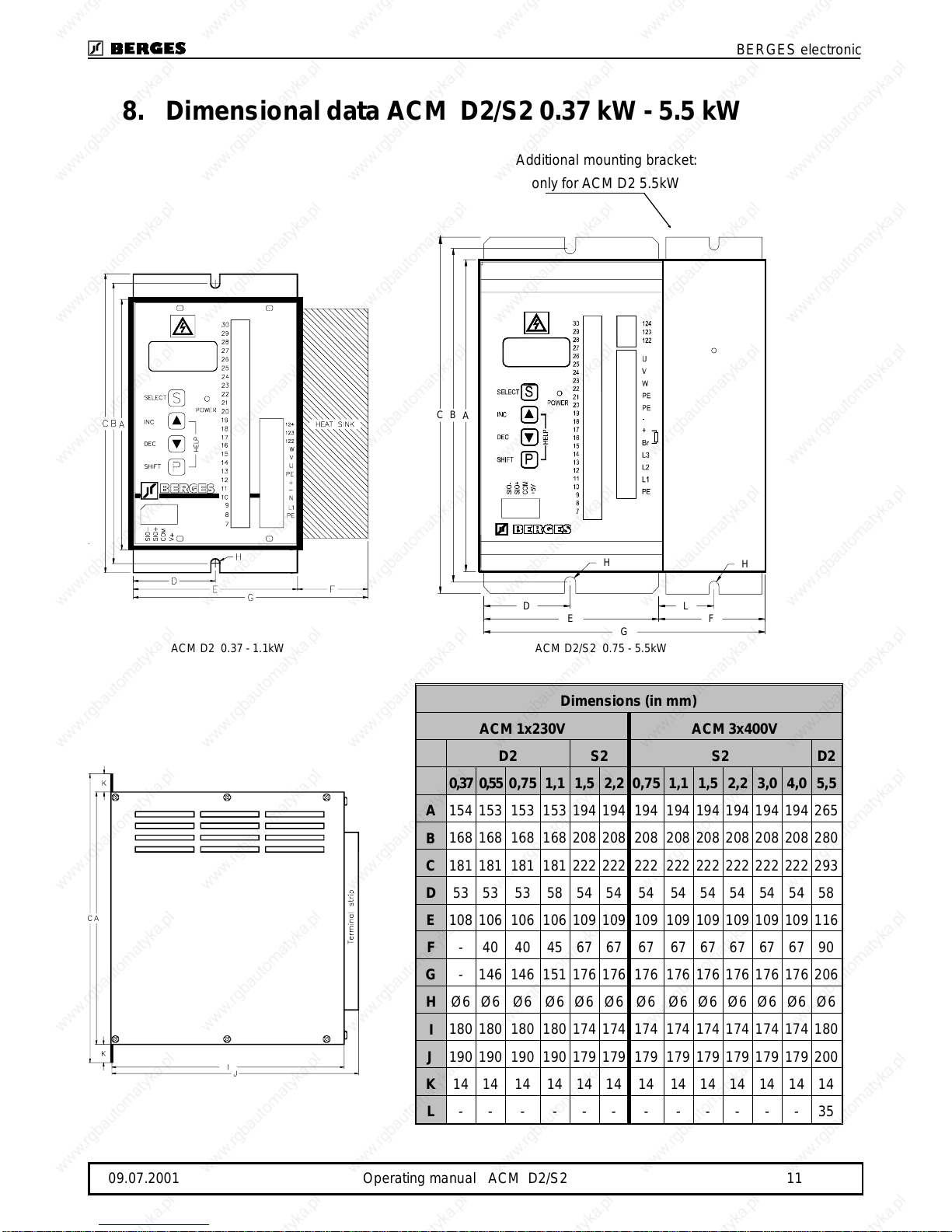

8.Dimensional data ACM D2/S2 0.37kW-5.5 kW.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

9.Dimensional data ACMD27.5kW -22.0 kW.. . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. 12

10. Dimensional data ACMD230.0 kW-37.0 kW. . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. 13

11. Installationexamples.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

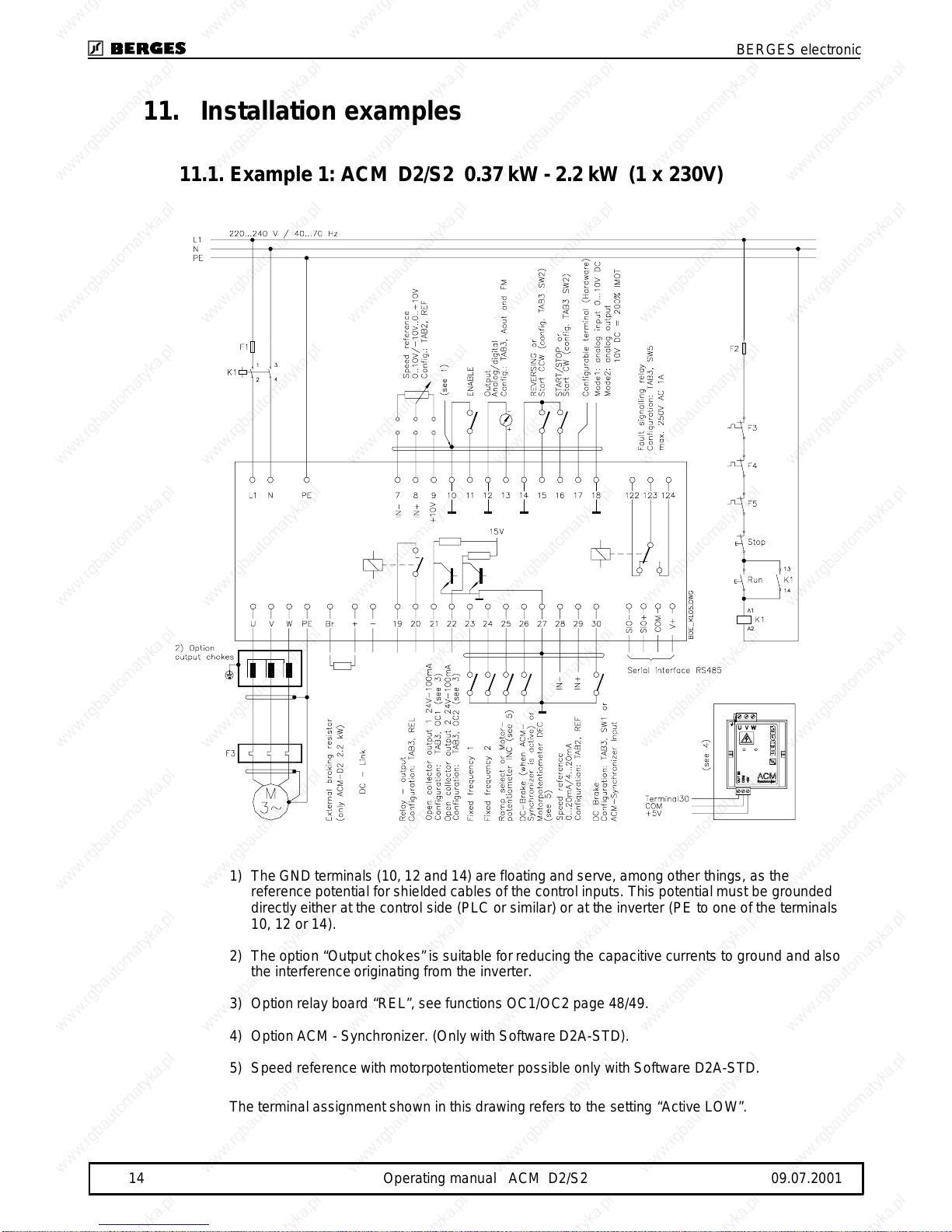

11.1.Example 1:ACM D2/S2 0.37 kW-2.2kW (1 x230V). . .. . . . . . . . . . . . . . . .. 14

11.2.Example 2:ACM D2/S2 0.75 kW-37.0 kW (3 x 400V). . . . . . . . . . . . . . . . . .. 15

12. Installation.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

12.1.Installation.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

12.2.Mainspowerconnection.. . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. 16

12.3.Motorconnection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

12.4.Interference suppressionmeasures / EMC(electromagneticcompatibility).... . 17

12.4.1.General information.. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. 17

12.4.2.Installation notes. . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. 17

12.5.Mainsback-upfuses.. . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. 18

12.6.Ventilation.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

12.7.Controlterminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

12.8.Power terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

BERGES electronic

09.07.2001 Operating manual ACM D2/S2 1

13. Commissioning and settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

13.1. General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

13.2. Adaptionto operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

14. Operating functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

14.1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

14.2. Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

14.3. Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

14.4. Help - function and language - select. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

14.5. Inverter status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

14.6. Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

14.7. Operating error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

14.8. Hardware error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

15. Programming ACM D2/S2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

15.1. Program structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

15.2. Program level TAB1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

15.3. Program level TAB2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

15.4. Program level TAB3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

16. Braking chopper ACM D2/S2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

16.1. Braking chopper 0.37 kW - 1.1 kW (1 x 230V). . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

16.2. Braking chopper 0.75 kW - 37.0 kW (3 x 400V). . . . . . . . . . . . . . . . . . . . . . . . . . . 51

16.2.1. Minimum values for braking resistors (accessory) . . . . . . . . . . . . . . . . . . 51

16.2.2. Assembling the braking resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

17. Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

17.1. Programming key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

17.2. Telecomander RC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

17.3. DVM - PLUS MP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

17.4. ACM - Synchronizer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

18. Faults and remedies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

19. Functions of ACM D2/S2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

20. Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . 58

Operating manual ACM D2/S2

Document: ACM/D2A-STD-E/A07

Edition: 09.07.2001

© 2001 BERGES electronic s.r.l. All rights reserved.

ArtNr: 38005000EN

BERGES electronic

2 Operating manual ACM D2/S2 09.07.2001

1.General information

Beforeyou startwiththeinstallationandthestartingupof theinverter,pleaseread this manual carefully

andpay special attentiontothenotes and suggestions.

This manualmust bemadeavailable toeveryuser.Beforeworkingwiththe unittheuser must become

familiarwith it.This specially appliestothe knowledgeand observanceof the following safety and

warningindications.

Used symbols:

Danger,warning

Thissymbolis usedwhenthelifeorhealthoftheuserisindangeroraconsiderable damagetoproperty

can occur.

Attention, essential measure

This symbol is shownon placesofthe manual, whicharetobeparticularlyconsidered for safeand

disturbance-free operationof the inverter.

2.Safetyinstructions

Allinstructionsstated in this chapter are important forthesecurity ofusers and machines orsystems

andshould absolutely beconsidered.

2.1.Generalsafety instructions

Invertersworkwithhigh voltages,whichcancausedeathorseriousinjurybytouchingthem. Depending

on thedegree of protectionofthe inverter, inoperationthey may have live, uninsulated andpossibly

alsomovingorrotatingparts,aswellashotsurfaces.Incaseofaninadmissibleremoval oftherequired

covers,an improperuse anda wronginstallationor operation,thereisa danger of seriouspersonal

injuryand damage toproperty.

All operations servingtransport,installation andcommissioning as well asmaintenance are to be

carriedoutbyskilledtechnicalpersonnel(observeIEC 364orCENELECHD384and nationalaccident

prevention rules!).Forthe purposesofthese basic safetyinstructions,"skilledtechnical personnel"

meanspersons who arefamiliar with theinstallation,mounting, commissioning and operationof the

productandhavethequalificationsneededforthe performance oftheirfunctions.

2.2.Intended use

The applicationof theinverterdescribedin this operating manualexclusivelyserves forthe purpose

ofcontinuously variable speed controlofthree-phase motors.

Invertersarecomponentsdesigned tobeusedinelectricalinstallationsormachinery.

Commissioningofthe inverter(e.g.the startingof normaloperation) isprohibited until the systemhas

been provedto conform to theprovisions ofthedirective89/392/EEC(Machinery Safety Directive -

MSD)andthe 89/336/EEC (EMC directive).

The invertermeetsthe requirementsofthe low-voltagedirective73/231/EEC. Theyare subject tothe

harmonizedstandardsoftheseriesEN50178.

The operatorof thesystemis solelyliable fordamage resultingfromimproper use oftheinverter.

ATTENTION!

BERGES electronic

09.07.2001 Operating manual ACM D2/S2 3

2.3.Transport, storage,installation

The invertermustbe protectedagainst inadmissible mechanical loads.Nocomponentsmust be

bentand no insulatingdistances mustbe altered duringtransportation or handling. The inverters

are containingelectrostaticsensitive components which are liabletodamage through improper

use.Do nottouch electroniccomponents andelectricalcontacts. Donot switchoninverters with

mechanicaldamaged electrical orelectronic components,the accordancewiththe applied directi-

vesis nolongerguaranteedinthiscase.With theinstallationofthe inverter attentionis tobepaid

to the prescribed minimum distancesaswellas toasufficientcooling.Theclimatic conditionsshall

be in conformity withEN 50178.

2.4.Electrical connection

Before performing anyinstallationworkthe system mustbe insulatedfrom themains supplyand

protected accordingly.

Afterswitchingoff the linevoltage, wait for atleast5minutes until the DC-link capacitors are

discharged. Onlythen itis allowed toworkonthedevice. Incaseofmalfunctions, the discharge

time could be exceeded substantially.

Becauseofapossibleleakagecurrent>3.5mAfromtheinstalledEMC-filter,the inverterisdesigned

only forpermanentconnection.For sizeandlayoutoftheGND(earth)conductor also see EN

50178.

The invertersare designed to beinstalled in a switchgear cabinet and may onlyoperate when

connected with earth-potential.

Foratrouble-freeoperationoftheinverter,the installation requirements and notes in this manual

are to beconsidered.

Whenusingresidual-current-operatedcircuit-breakerspay attention tothe compatibilitywiththe

inverter.Depending on thetypeofthedevicethe following rules apply:

•Single-phase inverters:pulse-currentsensitive(typeA) or all-currentsensitive(type B)residual-

current-operated circuit-breakers are admissible.

•Three-phase inverters:onlyall-current sensitive (type B) residual-current-operated circuit-brea-

kers are admissible.

Otherwiseanotherprotective measure such as separationfrom the environment by double or

reinforcedinsulation,disconnection from the mainsorsimilararetobeused(EN50178). Thetrigger

currentoftheresidual-current-operated circuit-breakers mustbesufficientlydimensioned since

capacitive leakage currents (cable screens, filters)can easilylead to falsetriggering.

2.5.Operating instructions

The invertercanbe configured to restartautomaticallyincaseofan error.If necessary, thesystem

mustbeequippedwithadditionalmonitoring or protective featurestoavoidresulting dangers(see

accident prevention rules etc.).

The motorcan be stoppedby switching off thesetpointordeactivating theenable input. Ifrequired

forsafetyreasons,aninadvertent restartcanbepreventeddisconnectingtheinverter from the

mains supply.

BERGES electronic

4Operating manual ACM D2/S2 09.07.2001

2.6. Miscellaneous

We point out that we do not take the responsibility fordamage and operationaldisturbances resulting

from the neglect of this operating manual.

Technical changes may be carried out to improve the device and its functions.

Before you continue reading, please check whether technical amendments are attached

in the annex to this operating manual!

BERGES electronic

09.07.2001 Operating manual ACM D2/S2 5

3.Introduction

The presentoperatingmanualcontains specifications,installationinstructions and troubleshooting

proceduresforACM D2/S2inverters.

The information inthismanual mustbeknown beforeinstallation oftheinverter in orderto

guaranteefault-freeinstallation and thus maximum performance.

The informationcontainedin this manual refersto thesoftwareversions D2A-STD-020Aand

D2A-1300-021.

BERGES electronic

6Operating manual ACM D2/S2 09.07.2001

4. Technical data (input voltage 1 x 220...240V)

Inverter ACM D2 ACM S2

0.37kW 0.55kW 0.75kW 1.1kW 2.2kW

Motor output kW 0.37 0.55 0.75 1.1 2.2

Output power kVA 0.75 1.0 1.5 1.9 3.2

Rated device current A 2.0 2.6 3.4 4.5 9.0

Overload capacity % 200% ×180 s (+/-15%)

Output voltage

(max. = mains voltage) V3x0...U

IN

Output frequency Hz 0...650 Hz (0...1300Hz vers. D2A-1300-xxx)

Electrical efficiency % > 95%

Operating mode 4-quadrant operation (with braking chopper)

Mains voltage V 1 x 220...240V, +/−15% 1x220...240V

or

3x220...240V

Mains frequency Hz 40...70 Hz

Modulation method PWM

Modulation frequency kHz 8 4

Speed reference

0...10V DC; (10...0V DC); -10V...0...10V DC

0...20mA; 4...20mA

External potentiometer (4K7); Keypad (JOG mode)

Motorpotentiometer ((mode JOG MPt) only with softw. D2A-STD)

RS485 (CAN on request)

Frequency resolutions Hz 9 Bit of maximum frequency

Acceleration/

deceleration time Sec. 0.01...1000 sec.

Maximum frequency Hz 0...650 Hz (0...1300Hz vers. D2A-1300-xxx)

Minimum frequency 0...Fmax

DC brake Standard

Braking chopper Standard

Undervoltage trip level V 170...175V AC / 240...250V DC

Overvoltage trip level V 280...285V AC / 395...405V DC

Short circuit Electronically controlled

Overcurrent Electronically controlled

Overtemperature Monitoring of heat sink temperature

Programming block Definable security code

Start block Definable AUTOSTART function

Ambient temperature °C From −5 °C to 45 °C

Storage temperature °C From −20 °C to 60 °C

Humidity % < 90% RH, non-condensing

EMC Installed EMC-filter; limit class "A" according to EN 61800-3

(See page 17)

Degree of protection IP IP 20

Weight, approx. kg 1.6 2.5 2.5 2.7 4.9

Inverter output

data

Mains

input

Control dataProtective

functions

Ambient

conditions

BERGES electronic

09.07.2001 Operating manual ACM D2/S2 7

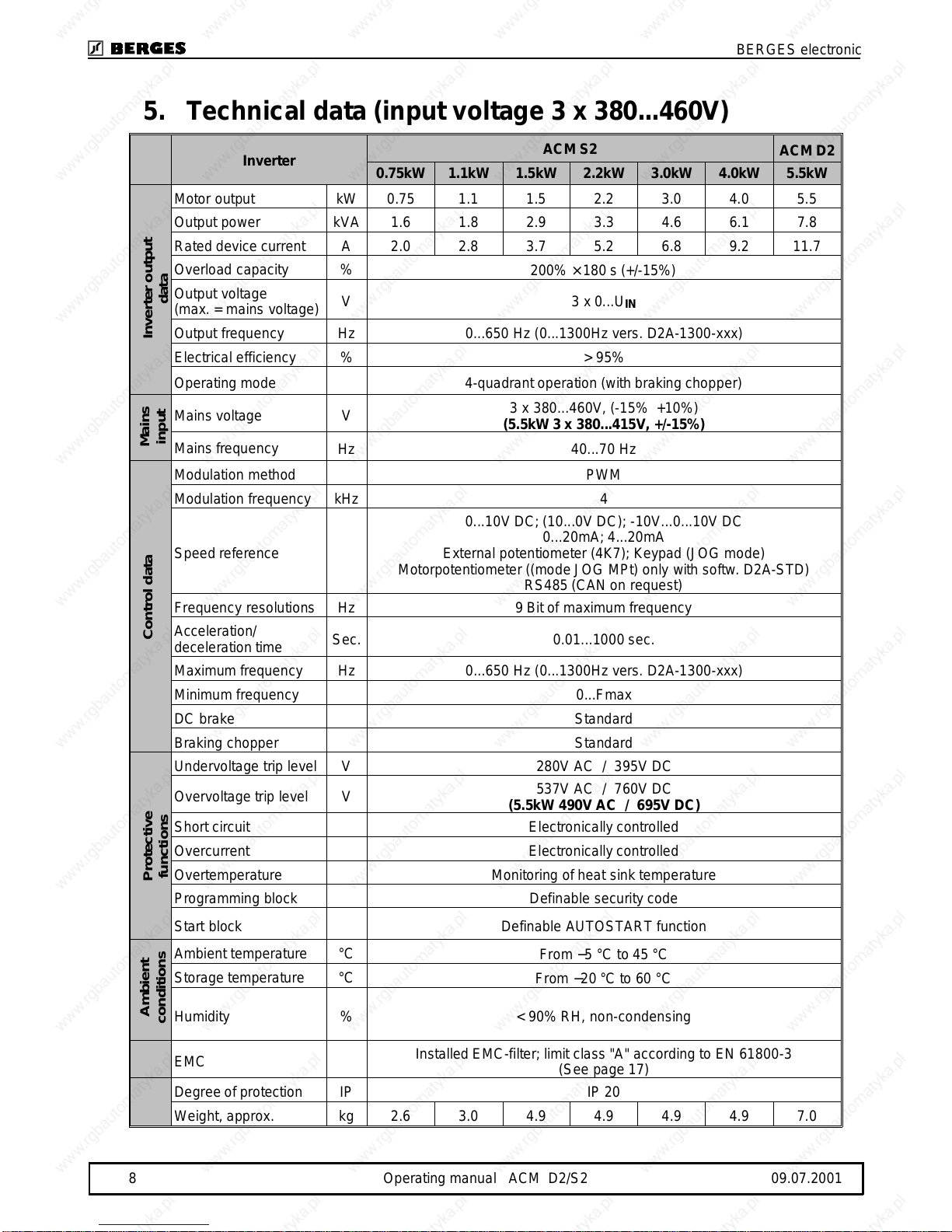

5. Technical data (input voltage 3 x 380...460V)

Inverter ACM S2 ACM D2

0.75kW 1.1kW 1.5kW 2.2kW 3.0kW 4.0kW 5.5kW

Motor output kW 0.75 1.1 1.5 2.2 3.0 4.0 5.5

Output power kVA 1.6 1.8 2.9 3.3 4.6 6.1 7.8

Rated device current A 2.0 2.8 3.7 5.2 6.8 9.2 11.7

Overload capacity % 200% ×180 s (+/-15%)

Output voltage

(max. = mains voltage) V3x0...U

IN

Output frequency Hz 0...650 Hz (0...1300Hz vers. D2A-1300-xxx)

Electrical efficiency % > 95%

Operating mode 4-quadrant operation (with braking chopper)

Mains voltage V 3 x 380...460V, (-15% +10%)

(5.5kW 3 x 380...415V, +/-15%)

Mains frequency Hz 40...70 Hz

Modulation method PWM

Modulation frequency kHz 4

Speed reference

0...10V DC; (10...0V DC); -10V...0...10V DC

0...20mA; 4...20mA

External potentiometer (4K7); Keypad (JOG mode)

Motorpotentiometer ((mode JOG MPt) only with softw. D2A-STD)

RS485 (CAN on request)

Frequency resolutions Hz 9 Bit of maximum frequency

Acceleration/

deceleration time Sec. 0.01...1000 sec.

Maximum frequency Hz 0...650 Hz (0...1300Hz vers. D2A-1300-xxx)

Minimum frequency 0...Fmax

DC brake Standard

Braking chopper Standard

Undervoltage trip level V 280V AC / 395V DC

Overvoltage trip level V 537V AC / 760V DC

(5.5kW 490V AC / 695V DC)

Short circuit Electronically controlled

Overcurrent Electronically controlled

Overtemperature Monitoring of heat sink temperature

Programming block Definable security code

Start block Definable AUTOSTART function

Ambient temperature °C From −5 °C to 45 °C

Storage temperature °C From −20 °C to 60 °C

Humidity % < 90% RH, non-condensing

EMC Installed EMC-filter; limit class "A" according to EN 61800-3

(See page 17)

Degree of protection IP IP 20

Weight, approx. kg 2.6 3.0 4.9 4.9 4.9 4.9 7.0

Inverter output

data

Mains

input

Control dataProtective

functions

Ambient

conditions

BERGES electronic

8 Operating manual ACM D2/S2 09.07.2001

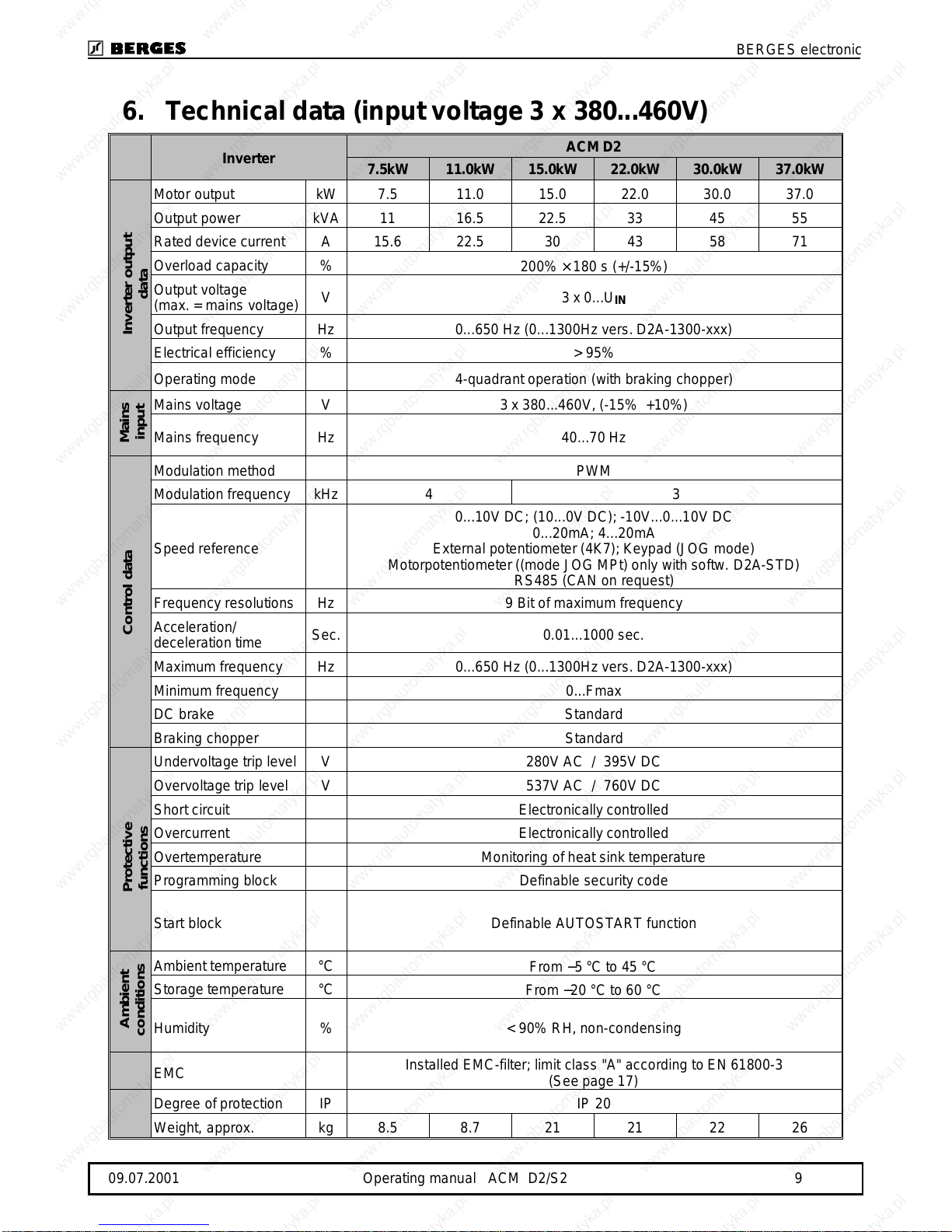

6. Technical data (input voltage 3 x 380...460V)

Inverter ACM D2

7.5kW 11.0kW 15.0kW 22.0kW 30.0kW 37.0kW

Motor output kW 7.5 11.0 15.0 22.0 30.0 37.0

Output power kVA 11 16.5 22.5 33 45 55

Rated device current A 15.6 22.5 30 43 58 71

Overload capacity % 200% ×180 s (+/-15%)

Output voltage

(max. = mains voltage) V3x0...U

IN

Output frequency Hz 0...650 Hz (0...1300Hz vers. D2A-1300-xxx)

Electrical efficiency % > 95%

Operating mode 4-quadrant operation (with braking chopper)

Mains voltage V 3 x 380...460V, (-15% +10%)

Mains frequency Hz 40...70 Hz

Modulation method PWM

Modulation frequency kHz 4 3

Speed reference

0...10V DC; (10...0V DC); -10V...0...10V DC

0...20mA; 4...20mA

External potentiometer (4K7); Keypad (JOG mode)

Motorpotentiometer ((mode JOG MPt) only with softw. D2A-STD)

RS485 (CAN on request)

Frequency resolutions Hz 9 Bit of maximum frequency

Acceleration/

deceleration time Sec. 0.01...1000 sec.

Maximum frequency Hz 0...650 Hz (0...1300Hz vers. D2A-1300-xxx)

Minimum frequency 0...Fmax

DC brake Standard

Braking chopper Standard

Undervoltage trip level V 280V AC / 395V DC

Overvoltage trip level V 537V AC / 760V DC

Short circuit Electronically controlled

Overcurrent Electronically controlled

Overtemperature Monitoring of heat sink temperature

Programming block Definable security code

Start block Definable AUTOSTART function

Ambient temperature °C From −5 °C to 45 °C

Storage temperature °C From −20 °C to 60 °C

Humidity % < 90% RH, non-condensing

EMC Installed EMC-filter; limit class "A" according to EN 61800-3

(See page 17)

Degree of protection IP IP 20

Weight, approx. kg 8.5 8.7 21 21 22 26

Inverter output

data

Mains

input

Control dataProtective

functions

Ambient

conditions

BERGES electronic

09.07.2001 Operating manual ACM D2/S2 9

7.Power-derating in function of the switching

frequency

PNNominal power

POUTOutput power

fPWMSwitching frequency

Ambient conditions: Tamb = 45°C

0,0

0,2

0,4

0,6

0,8

1,0

0481216

f(kHz)

Pout / P N

ACMD2/S2 0,37-2,2kW/230V

ACMS20,75-4,0kW/400V

ACM D2 5,5kW/400V

ACM D2 7,5kW/400V

ACM D2 11kW/400V

ACMD222-37kW/400V

ACMD215kW/400V

N

/ P

out

P

(kHz)

PWM

f

1230

1,2

1,0

0,8

0,6

0,4

0,2

0,06

BERGES electronic

10 Operating manual ACM D2/S2 09.07.2001

8.Dimensional data ACM D2/S2 0.37 kW - 5.5 kW

Additional mounting bracket:

onlyforACMD25.5kW

Dimensions (in mm)

ACM 1x230V ACM 3x400V

D2S2 S2 D2

0,370,550,751,11,52,20,751,11,52,23,04,05,5

A154153153153194194194194194194194194265

B168168168168208208208208208208208208280

C181181181181222222222222222222222222293

D5353 53 585454 54 545454545458

E108106106106109109109109109109109109116

F-404045676767676767676790

G-146146151176176176176176176176176206

HØ6Ø6Ø6Ø6Ø6Ø6Ø6Ø6Ø6Ø6Ø6Ø6Ø6

I180180180180174174174174174174174174180

J190190190190179179179179179179179179200

K1414 14 141414 14 141414141414

L------------35

ACMD2 0.37 - 1.1kW

C B A

F

G

L

E

D

H

H

ACMD2/S20.75 -5.5kW

BERGES electronic

09.07.2001 Operating manual ACM D2/S2 11

9.Dimensional data ACM D2 7.5 kW- 22.0 kW

Dimensions(inmm)

ACM D2 (3x400V)

7.5 11.015.0 22.0

A317317 330330

B344344 375375

C367367 390390

D54.2554.25 48 48

G209209 250250

HØ7 Ø7Ø6 Ø6

I186186 310310

J198198 325325

K25 2530 30

L154.75 154.75 205205

ACMD27.5 - 11.0kW ACMD2 15.0 - 22.0kW

BERGES electronic

12 Operating manual ACM D2/S2 09.07.2001

10. Dimensional data ACM D2 30.0 kW - 37.0 kW

Dimensions (in mm)

ACM D2 (3x400V)

30.0 37.0

A442 442

B343 408

C422 422

D242 242

E35.5 67

F65.5 98.5

GØ7 Ø7

H255 255

ACM D2 30.0 - 37.0kW

ACM D2 30.0 -37.0kW

BERGES electronic

09.07.2001 Operating manual ACM D2/S2 13

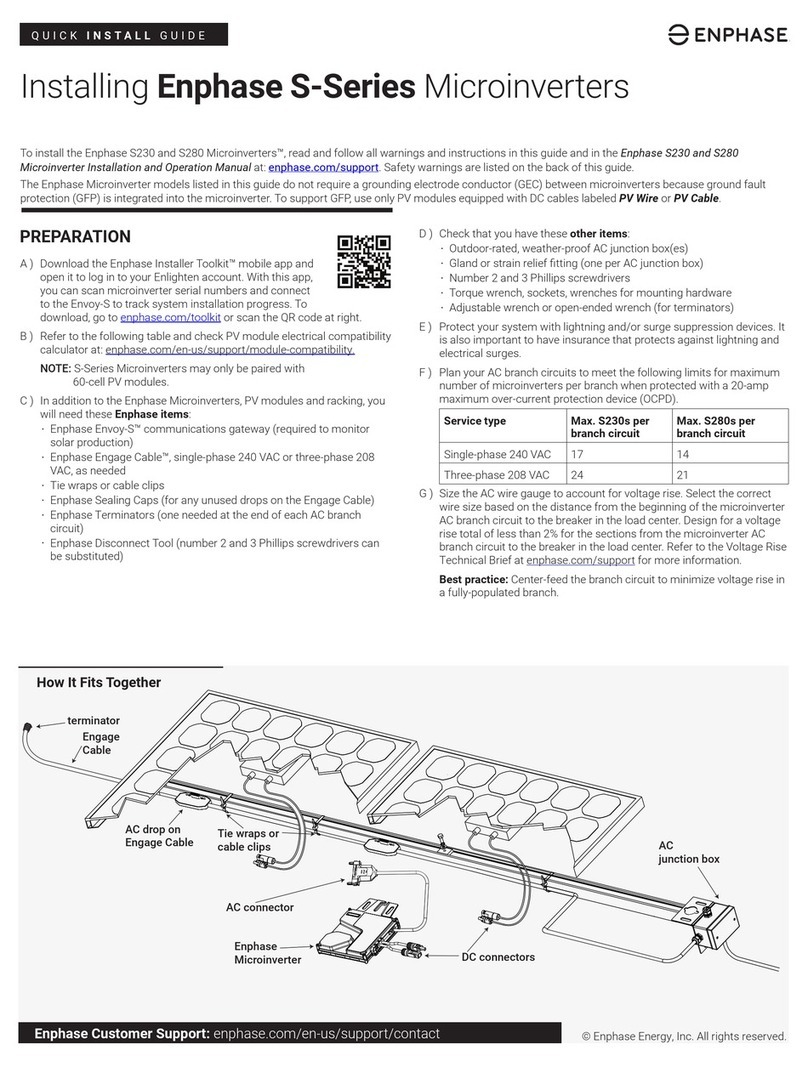

11.Installation examples

11.1.Example1: ACM D2/S20.37kW -2.2kW (1 x 230V)

1)TheGNDterminals (10,12and14)arefloating andserve,amongother things, as the

referencepotentialforshieldedcablesofthe controlinputs. Thispotentialmust be grounded

directlyeither atthe control side(PLC orsimilar)orat the inverter(PEto oneofthe terminals

10, 12 or14).

2)Theoption “Output chokes” issuitable forreducingthecapacitivecurrents to ground and also

the interferenceoriginatingfrom the inverter.

3)Optionrelayboard“REL”,seefunctions OC1/OC2 page48/49.

4)OptionACM-Synchronizer. (OnlywithSoftwareD2A-STD).

5)Speed reference with motorpotentiometerpossibleonlywith SoftwareD2A-STD.

Theterminalassignmentshown inthisdrawingrefersto the setting“Active LOW”.

BERGES electronic

14 Operating manual ACM D2/S2 09.07.2001

11.2.Example2: ACM D2/S20.75kW- 37.0kW (3 x 400V)

1)TheGNDterminals(10,12and14)arefloatingandserve,among other things, as the

referencepotentialforshieldedcablesofthecontrolinputs.Thispotentialmust be grounded

directlyeither at thecontrol side(PLC orsimilar)or at theinverter (PE to oneofthe terminals

10,12or 14).

2)Theoption “Output chokes” issuitablefor reducing thecapacitivecurrents to ground and also

the interference originating fromthe inverter.

3)Optionrelayboard“REL”,seefunctionsOC1/OC2 page48/49.

4)OptionACM-Synchronizer. (OnlywithSoftwareD2A-STD).

5)Speed referencewithmotorpotentiometerpossible onlywithSoftware D2A-STD.

6)Inputsnon-insulated.

Theterminalassignmentshown inthisdrawingrefersto the setting“Active LOW”.

BERGES electronic

09.07.2001 Operating manual ACM D2/S2 15

12.Installation

12.1.Installation

The frequencyinverters aredesigned for installation inaswitchgearcabinet and for

permanentconnection.

The inverter must be installedso that the heat sinkis facing to theright.Onlyin this waysufficient

cooling is guaranteed.

Ifthe inverterhas to beinstalledin adifferent position, externalcooling is required forfull capacity

utilization.

BERGES invertersare generallydesignedsothattheycan be operatedat ambient temperatures

from −5 °C to +45 °C and atarelative humidityof up to 90%.

Formation of condensationmust beavoided!

Please contactBERGES ifthe above values areexceeded. Aheat build-upatthe inverter during

operation mustbe prevented.Theinternal air circulation maypossibly be insufficient if theunit is

installed in a control cabinet with a small volume.

The units should never be installedintheproximityof corrosiveor flammablegases, conductive

dustorlarge magnetic and electric fields.

The inverter should be installed in alocationthat is largely freeofdust,steam and vibrations.

Operationofthe unitsinthepresenceof abrasivedust,steam, condensate, oil mist or aircontaining

saltwillreducetheirusefullife.

Paycloseattentionduringinstallationtoensuringthatnoobjects(such asdrilling swarf,wireor

anythingelse)fallintotheunit.Otherwise adevicefault cannot beexcluded, even after longer

periods of operation.

12.2.Mainspower connection

Toguaranteelastingoperatingsafetyand reliability, the invertermustbeconnected expertly in

accordancewith the valid electricstandards. Attentionmust be paid togoodinsulation from earth

potential onthe power terminals.

Connectasinglephase mainspowersupplywitha ratedvoltagebetween220V and 240V or a

three-phasemainspower supplywith aratedvoltagebetween380Vand 460V (5.5kW 380...415V)

40..70Hztothemainspowerconnectionterminals L1,NorL1,L2,L3and PErespectively(TN-C

System).

L1 (phase)- N 220...240V 40...70Hz PE = earth

L1 L2 L3(phases) 380...460V (5.5 kW 380...415V)40...70Hz PE= earth

Ensureavoltage balance toearth whenfeedinginthe mainspowerthrough an insulating

transformer (star pointearthed)oruse thevector group “DY5”in the case of single-phase inverter

power supply.

BERGES electronic

16 Operating manual ACM D2/S2 09.07.2001

12.3.Motor connection

Connectthe motorcable tothe U, V, W and PE terminals.

The inverter willbedeactivated in theevent of ashort circuitat the terminals U, V, W.

We recommendPTCevaluation using commercially availabledevices toachieveeffective protection

of the motor.

Ifinterruptingcontacts(e.g. contactorsormotorprotectionswitchesetc.) haveto be installedbetween

themotorandinverter,thecircuitmustbeconfiguredsoastoensurethatthe ENABLE signal(terminals

10/11) isdeactivated beforeseparationofthe inverter/motor connection.A relay switching time of

approx. 30ms suffices.

Longmotor cables(>20m) in connection with high voltage peakscausedby thefast switching output

stages oftheinvertermay endangerthe motorinsulation.Insuch cases werecommend tousesuitable

filtermeasures (e.g.motor chokesor dU/dt filters) toprotect themotor.

12.4.Interferencesuppression measures / EMC

(electromagneticcompatibility)

12.4.1.Generalinformation

Invertersare electronic deviceswhich areused in industrialand commercialsystems. In accordance

withthe EMC-directives89/336/EECthe invertersarenotdesignedfor independentoperation.Thus

invertersshould beusedforfurtherprocessingthroughcompetent machine/systemmanufacturers.

Bythis,the devices donot require a CE-marking. Theproofofthe conformityofthe machine/system

with the required EMC-directives must be furnished by themanufacturer or operator ofthesystem.

The invertersofthe ACM series areequipped withan internal filter and designed to be used in class

"A"environments(firstenvironment,restricteddistribution)accordingtotheproduct standard EN

61800-3.

The evaluationofthe conformitytook place inapracticalstructurehavingtaken into accountthe

following installationnotes.

Voltage peaks producedbyotherdevicesconnected atthemains supplycan possibly disturb or even

damage the inverter.Inputchokes(option)can be usedtoprotect the inverteragainst these voltage

peaks (causede.g.byswitching offof highloadsfrom themains).

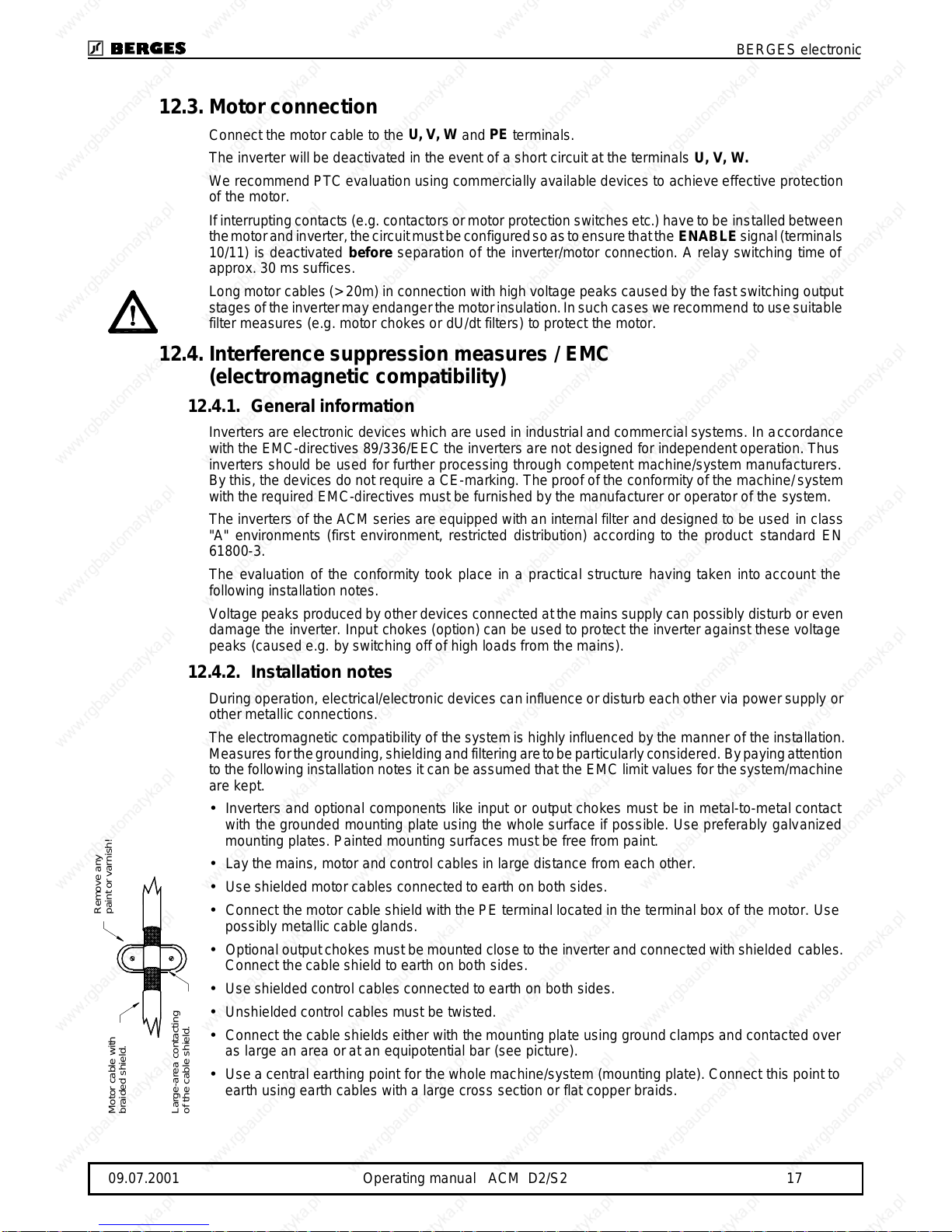

12.4.2.Installation notes

Duringoperation, electrical/electronicdevices caninfluence ordisturbeachother via powersupply or

othermetallic connections.

The electromagnetic compatibilityof thesystemis highly influenced bythe manner of the installation.

Measuresforthegrounding,shieldingand filteringaretobeparticularlyconsidered. Bypayingattention

tothefollowinginstallationnotesitcan beassumed that the EMC limit values for thesystem/machine

are kept.

•Invertersand optional components likeinput oroutputchokes mustbe inmetal-to-metal contact

withthegrounded mounting plateusing the wholesurface ifpossible. Usepreferablygalvanized

mounting plates. Painted mounting surfacesmustbe free from paint.

•Laythemains, motor andcontrol cablesin large distance from each other.

•Useshieldedmotorcablesconnectedtoearth onboth sides.

•Connect themotor cable shieldwiththePE terminallocatedinthe terminalbox ofthe motor. Use

possibly metalliccableglands.

•Optionaloutputchokesmust bemounted closeto the inverterand connectedwith shielded cables.

Connect thecableshield toearth on both sides.

•Useshieldedcontrol cablesconnectedtoearth on both sides.

•Unshielded control cables must be twisted.

•Connectthecableshieldseitherwith themounting plate using groundclampsandcontacted over

as large an area oratan equipotential bar(see picture).

•Useacentral earthing point for thewholemachine/system (mounting plate).Connect this pointto

earth usingearth cables witha large crosssection or flat copperbraids.

Remove any

paint or varnish!

Motor cable with

braided shield.

Large-area contacting

of the cable shield.

BERGES electronic

09.07.2001 Operating manual ACM D2/S2 17

•Do not extend the shields with single wiresand do notinterrupt themif possible.

•Whenconstructingthe switchgearcabinetorthesystem,separatethepower sectionfrom the

controlsection. Eventuallyprovide a shieldbetween power and control section.

•Wireinductiveswitchingelements (coilsof contactorsorrelays)withRC-elements,free-wheeling

diodes or varistors.

12.5.Mainsback-up fuses

External upstream fusesare requiredtoprotectthecablesandthe unititself. Thefuses mustbe

dimensionedso asto permitstarting up andnormaloperationofmotors.To guarantee this,we

recommendthe useofthe followingsslow-blow fuses:

Mains input 1 x 230V

0.37kW0.55kW0.75kW 1.1kW2.2kW

4A 8A 8A 8A 16A

Mains input 3 x 400V

0.75kW 1.1kW 1.5kW2.2kW3.0kW 4.0kW5.5kW

4A6A 6A 8A 10A 16A 20A

Mains input 3 x 400V

7.5kW 11.0kW 15.0kW 22.0kW 30.0kW 37.0kW

35A 35A 63A 63A 80A100A

12.6.Ventilation

Forall inverters,thepermissibleambient temperatureof 45°Cmustnotbeexceeded. This

particularly appliesifthe inverter isinstalledin acontrol cabinet,because operationoftheinverter

mayincreasethe ambienttemperature substantially.Appropriatemeasures, e.g.installationofa

fan,mustbe taken if thepermissibleambienttemperature isalmost reached or exceeded under

full loading of theinverter.

BERGES electronic

18 Operating manual ACM D2/S2 09.07.2001

Other manuals for ACM-D2 Series

1

This manual suits for next models

1

Table of contents

Other Berges Inverter manuals