Berges ACM-D2 Series User manual

Operating manual

ACM

Table of contents

1. Safety notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1. Explanation of symbols and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2. General safety notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Use of the inverter in accordance with its intended purpose. . . . . . . . . . . . . . . . . . . . . . . 5

3. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4. Technical data (input voltage 1 x 220...240V). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5. Technical data (input voltage 3 x 380...415V). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6. Technical data (input voltage 3 x 380...460V). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7. Power-derating in function of the switching frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

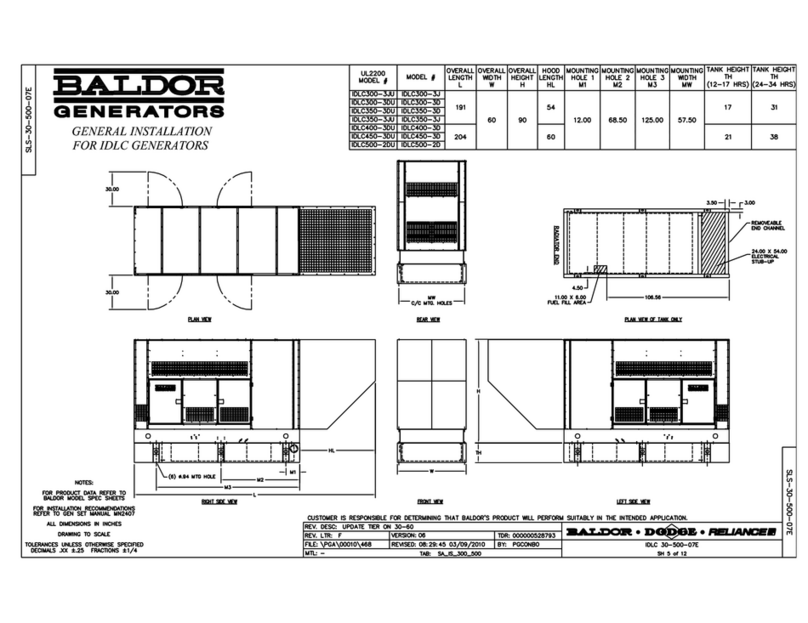

8. Dimensional data ACM-D2 0.37 kW - 5.5 kW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

9. Dimensional data ACM-D2 7.5 kW - 22.0 kW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

10. Dimensional data ACM-D2 30.0 kW - 37.0 kW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

11. Installation examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

11.1. Exemple 1: ACM-D2 0.37 kW - 2.2 kW (1 x 230V). . . . . . . . . . . . . . . . . . . . . . . 13

11.2. Exemple 2: ACM-D2 0.75 kW - 37.0 kW (3 x 400V). . . . . . . . . . . . . . . . . . . . . . 14

12. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

12.1. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

12.2. Mains power connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

12.3. Motor connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

12.4. Interference suppression measures/EMC (electromagnetic compatibility). . . . . . 17

12.5. Mains back-up fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

12.6. Series autotransformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

12.7. Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

12.8. Control terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

12.9. Power terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

13. Commissioning and settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

13.1. General information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

13.2. Adaption to operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

BERGES electronic

29.05.98 Operating manual ACM-D2 1

14. Operating functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

14.1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

14.2. Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

14.3. Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

14.4. Help - function and language - select. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

14.5. Inverter status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

14.6. Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

14.7. Operating error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

14.8. Hardware error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

14.9. Input circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

15. Programming ACM-D2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

15.1. Program structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

15.2. Program level TAB1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

15.3. Program level TAB2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

15.4. Program level TAB3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

16. Braking chopper ACM - D2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

16.1. Braking chopper 0.37 kW - 1.1 kW (1 x 230V). . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

16.2. Braking chopper 0.75 kW - 37.0 kW (3 x 400V). . . . . . . . . . . . . . . . . . . . . . . . . . . 52

16.2.1. Minimum values for braking resistors (accessory) . . . . . . . . . . . . . . . . . . 52

16.2.2. Assembling the braking resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

17. Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

17.1. Programming key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

17.2. Software KEYSOFT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

17.3. Telecomander RC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

17.4. DVM - PLUS MP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

17.5. ACM - Synchronizer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

18. Faults and remedies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

19. Functions of ACM-D2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

20. Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Operating manual ACM-D2

Document: ACM/D2A-STD-E/A07

Edition: 29.05.1998

© 1998 BERGES electronic s.r.l. All rights reserved.

ArtNr: 38005000EN

BERGES electronic

2Operating manual ACM-D2 29.05.98

1. Safety notes

1.1. Explanation of symbols and notes

Work safety symbol

You will find this symbol next to all work safety notes in this instruction manual if there is a risk of injury

or death for persons involved. Pay attention to these notes and observe particular caution in such

cases. Also pass on all work safety instructions to other users.

Voltage warning

This symbol is shown wherever particular caution is necessary owing to occurring or applied voltages

(e.g. DC voltages up to 800 V) and where special precautionary measures have to be taken. The

inverter must always be isolated from the mains when working on it.

Caution note

This note is shown in all parts of this instruction manual to which particular attention must be paid to

ensure that the guidelines, specifications, notes and the correct sequence of work are obeyed to

prevent damage or destruction of the inverter and/or systems.

1.2. General safety notes

You must read and observe the instruction manual and safety notes before commencing

assembly and commissioning work!

Besides paying attention to the notes given in this instruction manual, also observe the

generally valid safety and accident prevention regulations!

The inverters must always be isolated from the mains voltage before all work on the electrical or

mechanical parts of the system.

The inverter are designed for installation in a switchgear cabinet and for permanent connection.

Installation, maintenance and repair work must only be carried out by instructed, technically suitable

and qualified personnel.

Conversions or changes carried out on or in the inverter and its components and accessories without

express authority render all warranty claims null and void.

Please contact BERGES if any conversions or changes are necessary, particularly in relation to the

electric components.

BERGES electronic

29.05.98 Operating manual ACM-D2 3

The components of the power section and specific elements of the control section are connected

to the voltage mains when the inverter is connected to the mains voltage.

Touching these components involves mortal danger!

Isolatetheinverterfromthemainsbeforeremovingthefront panel or the housing (e.g. by removing

or deactivating on-site fuses or by deactivating a master switch isolating all poles etc.).

After switching off the mains voltage, wait for at least 5 minutes before beginning work on or in

the inverter (the DC voltage in the DC link capacitors must first of all discharge through discharge

resistors). DC voltages of up to 800 V are possible. In the event of malfunctions, the discharge

time of 5 minutes may be exceeded substantially.

The inverter contains protective facilities that deactivate it in the event of malfunctions, as the result

of which the motor is de-energized and comes to a standstill (so-called ‘‘coasting’’ of the motor is

possible depending on the flywheel or the type of drive involved). Standstill of the motor can,

however, also be produced by mechanical blockage. Voltage fluctuations, and particularly mains

power failures may also lead to deactivation. In certain circumstances the drive may start up

automatically once the cause of the fault has been remedied. As the result of this, certain systems

may be damaged or destroyed and there may be a risk for operators working on the system. For

such operating cases, the user must take precautions to reliably prevent automatic starting

of the motor. For example, this can be done by using a speed monitor that deactivates the power

supply to the inverter if the motor should come to an unscheduled standstill.

The motor may stop during operation due to a disabling protection circuit operation or by loss of

the control signal. Resetting these systems can result in the motor restarting. If automatic starting

ofthemotormustbepreventedtoprotectoperatingpersonnel,interlocksmustbeprovidedtoisolate

the mains supply to the inverter.

The inverter must always be earthed when operated.

Measuringinstrumentsmustonlybeconnected anddisconnectedafterremovingthepower supply.

The responsible operating personnel must read, understand and observe the instruction manual.

Wedrawattentionto thefactthatno liabilitycanbe assumedfordamageand malfunctionsresulting

from failure to observe the instruction manual.

Technical data and illustrations given in this operating manual may be amended to comply with

modifications of the units which may be made to improve their functions.

BERGES electronic

4Operating manual ACM-D2 29.05.98

2. Use of the inverter in accordance with its intended

purpose

The application of the inverter described in this operating manual exclusively serves the purpose of

continuously variable speed control of three-phase motors.

Theinverteraredesignedforinstallationinaswitchgearcabinetandforpermanentconnection.

The operator of the system is solely liable for damage resulting from improper use of the inverter.

Theoperatorofthesystemisresponsibleforobeyingtheoperating,maintenanceandrepairconditions.

Only personnel informed about the functions and hazards of the inverter may be employed for the

purposes of operation, maintenance and repair.

Only items expressly approved by BERGES (e.g. mains filters and chokes etc.) may be used as

accessories.

The installer of the system is liable for any damage resulting from the use of accessories that have not

been approved expressly by BERGES. Please consult us in the event of uncertainty.

Before you continue reading, please check whether technical amendments are attached

in the annex to this operating manual!

3. Introduction

The present operating manual contains specifications, installation instructions and troubleshooting

procedures for ACM-D2 inverters.

The information in this manual must be known before installation of the inverter in order to guarantee

fault-free installation and thus maximum performance.

The information contained in this manual refers to the software versions D2A-STD-014 and

D2A-1300-012.

BERGES electronic

29.05.98 Operating manual ACM-D2 5

4. Technical data (input voltage 1 x 220...240V)

Inverter ACM-D2

0.37kW 0.55kW 0.75kW 1.1kW 2.2kW

Motor output kW 0.37 0.55 0.75 1.1 2.2

Output power kVA 0.75 1.0 1.5 1.9 3.2

Rated device current A2.0 2.6 3.4 4.5 9.0

Overload capacity %200% ×180 s (+/-15%)

Output voltage

(max. = mains voltage) V3 x 0...UIN

Output frequency Hz 0...650 Hz (0...1300Hz vers. D2A-1300-xxx)

Electrical efficiency %> 95%

Operating mode 4-quadrant operation (with braking chopper)

Mains voltage V1 x 220...240V, +/−15% 1x220...240V

or

3x220...240V

Mains frequency Hz 40...70 Hz

Modulation method PWM

Modulation frequency kHz 8 4

Speed reference

0...10V DC; (10...0V DC); -10V...0...10V DC

0...20mA; 4...20mA

External potentiometer (4K7); Keypad (JOG mode)

Motorpotentiometer ((mode JOG MPt) only with softw. D2A-STD)

RS485 (CAN on request)

Frequency resolutions Hz 9 Bit of maximum frequency

Acceleration/

deceleration time Sec. 0.01...1000 sec.

Maximum frequency Hz 0...650 Hz (0...1300Hz vers. D2A-1300-xxx)

Minimum frequency 0...Fmax

DC brake Standard

Braking chopper Standard

Undervoltage trip level V170...175V AC / 240...250V DC

Overvoltage trip level V280...285V AC / 395...405V DC

Short circuit Electronically controlled

Overcurrent Electronically controlled

Overtemperature Monitoring of heat sink temperature

Programming block Definable security code

Start block Definable AUTOSTART function

Ambient temperature °C From −5 °C to 45 °C

Storage temperature °C From −20 °C to 60 °C

Humidity %< 90% RH, non-condensing

Degree of protection IP IP 20

Weight, approx. kg 1.6 2.5 2.5 2.7 4.9

Inverter output

data

Mains

input

Control dataProtective

functions

Ambient

conditions

BERGES electronic

6Operating manual ACM-D2 29.05.98

5. Technical data (input voltage 3 x 380...415V)

Inverter ACM-D2

0.75kW 1.1kW 1.5kW 2.2kW 3.0kW 4.0kW 5.5kW

Motor output kW 0.75 1.1 1.5 2.2 3.0 4.0 5.5

Output power kVA 1.6 1.8 2.9 3.3 4.6 6.1 7.8

Rated device current A2.0 2.8 3.7 5.2 6.8 9.2 11.7

Overload capacity %200% ×180 s (+/-15%)

Output voltage

(max. = mains voltage) V3 x 0...UIN

Output frequency Hz 0...650 Hz (0...1300Hz vers. D2A-1300-xxx)

Electrical efficiency %> 95%

Operating mode 4-quadrant operation (with braking chopper)

Mains voltage V3 x 380...415V, (+/-15%)

Mains frequency Hz 40...70 Hz

Modulation method PWM

Modulation frequency kHz 4

Speed reference

0...10V DC; (10...0V DC); -10V...0...10V DC

0...20mA; 4...20mA

External potentiometer (4K7); Keypad (JOG mode)

Motorpotentiometer ((mode JOG MPt) only with softw. D2A-STD)

RS485 (CAN on request)

Frequency resolutions Hz 9 Bit of maximum frequency

Acceleration/

deceleration time Sec. 0.01...1000 sec.

Maximum frequency Hz 0...650 Hz (0...1300Hz vers. D2A-1300-xxx)

Minimum frequency 0...Fmax

DC brake Standard

Braking chopper Standard

Undervoltage trip level V280V AC / 395V DC

Overvoltage trip level V490V AC / 695V DC

Short circuit Electronically controlled

Overcurrent Electronically controlled

Overtemperature Monitoring of heat sink temperature

Programming block Definable security code

Start block Definable AUTOSTART function

Ambient temperature °C From −5 °C to 45 °C

Storage temperature °C From −20 °C to 60 °C

Humidity %< 90% RH, non-condensing

Degree of protection IP IP 20

Weight, approx. kg 2.6 3.0 4.9 4.9 4.9 4.9 7.0

Inverter output

data

Mains

input

Control dataProtective

functions

Ambient

conditions

BERGES electronic

29.05.98 Operating manual ACM-D2 7

6. Technical data (input voltage 3 x 380...460V)

Inverter ACM-D2

7.5kW 11.0kW 15.0kW 22.0kW 30.0kW 37.0kW

Motor output kW 7.5 11.0 15.0 22.0 30.0 37.0

Output power kVA 11 16.5 22.5 33 45 55

Rated device current A15.6 22.5 30 43 58 71

Overload capacity %200% ×180 s (+/-15%)

Output voltage

(max. = mains voltage) V3 x 0...UIN

Output frequency Hz 0...650 Hz (0...1300Hz vers. D2A-1300-xxx)

Electrical efficiency %> 95%

Operating mode 4-quadrant operation (with braking chopper)

Mains voltage V3 x 380...460V, (-15% +10%)

Mains frequency Hz 40...70 Hz

Modulation method PWM

Modulation frequency kHz 4 3

Speed reference

0...10V DC; (10...0V DC); -10V...0...10V DC

0...20mA; 4...20mA

External potentiometer (4K7); Keypad (JOG mode)

Motorpotentiometer ((mode JOG MPt) only with softw. D2A-STD)

RS485 (CAN on request)

Frequency resolutions Hz 9 Bit of maximum frequency

Acceleration/

deceleration time Sec. 0.01...1000 sec.

Maximum frequency Hz 0...650 Hz (0...1300Hz vers. D2A-1300-xxx)

Minimum frequency 0...Fmax

DC brake Standard

Braking chopper Standard

Undervoltage trip level V280V AC / 395V DC

Overvoltage trip level V537V AC / 760V DC

Short circuit Electronically controlled

Overcurrent Electronically controlled

Overtemperature Monitoring of heat sink temperature

Programming block Definable security code

Start block Definable AUTOSTART function

Ambient temperature °C From −5 °C to 45 °C

Storage temperature °C From −20 °C to 60 °C

Humidity %< 90% RH, non-condensing

Degree of protection IP IP 20

Weight, approx. kg 8.5 8.7 21 21 22 26

Inverter output

data

Mains

input

Control dataProtective

functions

Ambient

conditions

BERGES electronic

8Operating manual ACM-D2 29.05.98

7. Power-derating in function of the switching frequency

PNNominal power

POUT Output power

fPWM Switching frequency

Ambient conditions: Tamb = 45°C

0,0

0,2

0,4

0,6

0,8

1,0

1,2

04812 16

fPWM (kHz)

P

out/PN

ACM-D2 0,37-2,2kW/230V

ACM-D2 1,1-4,0kW/400V

ACM-D2 5,5kW/400V

ACM-D2 7,5kW/400V

ACM-D2 11kW/400V

0,0

0,2

0,4

0,6

0,8

1,0

1,2

03612

fPWM (kHz)

P

out/PN

ACM-D2 15kW/400V

ACM-D2 22-37kW/400V

BERGES electronic

29.05.98 Operating manual ACM-D2 9

8. Dimensional data ACM-D2 0.37 kW - 5.5 kW

Additional mounting bracket:

Only for ACM-D2 5,5kW

Dimensions (in mm)

ACM-D2 (1x230V) ACM-D2 (3x400V)

0.37 0.55 0.75 1.1 1.5 2.2 0.75 1.1 1.5 2.2 3.0 4.0 5.5

A153 153 153 153 193 193 193 193 193 193 193 193 265

B168 168 168 168 208 208 208 208 208 208 208 208 280

C181 181 181 181 221 221 221 221 221 221 221 221 293

D53 53 53 58 58 58 58 58 58 58 58 58 58

E108 106 106 106 116 116 116 116 116 116 116 116 116

F-40 40 45 90 90 4 27 90 90 90 90 90

G-146 146 151 206 206 120 143 206 206 206 206 206

HØ6 Ø6 Ø6 Ø6 Ø6 Ø6 Ø6 Ø6 Ø6 Ø6 Ø6 Ø6 Ø6

I180 180 180 180 180 180 180 180 180 180 180 180 180

J190 190 190 190 195 195 195 195 195 195 195 195 200

K14 14 14 14 14 14 14 14 14 14 14 14 14

L------------35

ACM-D2 0.37 - 2.2kW ACM-D2 0.75 - 5.5kW

BERGES electronic

10 Operating manual ACM-D2 29.05.98

9. Dimensional data ACM-D2 7.5 kW - 22.0 kW

Dimensions (in mm)

ACM-D2 (3x400V)

7.5 11.0 15.0 22.0

A317 317 330 330

B344 344 375 375

C367 367 390 390

D54.25 54.25 48 48

G209 209 250 250

HØ7 Ø7 Ø6 Ø6

I186 186 310 310

J198 198 325 325

K25 25 30 30

L154.75 154.75 205 205

ACM-D2 7.5 - 11.0kW ACM-D2 15.0 - 22.0kW

BERGES electronic

29.05.98 Operating manual ACM-D2 11

10. Dimensional data ACM-D2 30.0 kW - 37.0 kW

Dimensions (in mm)

ACM-D2 (3x400V)

30.0 37.0

A442 442

B343 408

C422 422

D242 242

E35.5 67

F65.5 98.5

GØ7 Ø7

H255 255

ACM-D2 30.0 - 37.0kW

ACM-D2 30.0 - 37.0kW

BERGES electronic

12 Operating manual ACM-D2 29.05.98

11. Installation examples

11.1. Exemple 1: ACM-D2 0.37 kW - 2.2 kW (1 x 230V)

1) The GND terminals (10, 12 and 14) are floating and serve, among other things, as the

reference potential for shielded cables of the control inputs. This potential must be grounded

directly either at the control side (PLC or similar) or at the inverter (PE to one of the terminals

10, 12 or 14).

2) The option ‘‘Output chokes’’ is suitable for reducing the capacitive currents to ground and also

the interference originating from the inverter.

3) Option relay board ‘‘REL’’, see functions OC1/OC2 page 49/50.

4) Option ACM - Synchronizer. (Only with Software D2A-STD)

5) Speed reference with motorpotentiometer possible only with Software D2A-STD

The terminal assignment shown in this drawing refers to the setting ‘‘Active LOW’’.

Inverters can be operated via residual-current-operated circuit-breakers if special

conditions are satisfied (see chapter 12, page 16)!

BERGES electronic

29.05.98 Operating manual ACM-D2 13

11.2. Exemple 2: ACM-D2 0.75 kW - 30 kW (3 x 400V)

1) The GND terminals (10, 12 and 14) are floating and serve, among other things, as the

reference potential for shielded cables of the control inputs. This potential must be grounded

directly either at the control side (PLC or similar) or at the inverter (PE to one of the terminals

10, 12 or 14).

2) The option ‘‘Output chokes’’ is suitable for reducing the capacitive currents to ground and also

the interference originating from the inverter.

3) Option relay board ‘‘REL’’, see functions OC1/OC2 page 49/50.

4) Option ACM - Synchronizer. (Only with Software D2A-STD)

5) Speed reference with motorpotentiometer possible only with Software D2A-STD

6) Inputs Non-Isolated.

The terminal assignment shown in this drawing refers to the setting ‘‘Active LOW’’.

Inverters can be operated via residual-current-operated circuit-breakers if special

conditions are satisfied (see Chapter 12, Page 16)!

BERGES electronic

14 Operating manual ACM-D2 29.05.98

12. Installation

12.1. Installation

The frequency inverters are designed for installation in a switchgear cabinet and for permanent

connection.

The inverter must be installed so that the heat sink is facing to the right . Only in this way natural

convection is guaranteed.

If the inverter has to be installed in a different position, external cooling is required for full capacity

utilization.

BERGES inverters are generally designed so that they can be operated at ambient temperatures from

−5 °C to +45 °C and at a relative humidity of up to 90%.

Formation of condensation must be avoided!

Please contact BERGES if the above values are exceeded. A heat build-up at the inverter during

operation must be prevented. The internal air circulation may possibly be insufficient if the unit is

installed in a control cabinet with a small volume.

The units should never be installed in the proximity of corrosive or flammable gases, conductive dust

or large magnetic and electric fields.

The inverter should be installed in a location that is largely free of dust, steam and vibrations.

Operation of the units in the presence of abrasive dust, steam, condensate, oil mist or air containing

salt will reduce their useful life.

Paycloseattentionduringinstallationtoensuringthatnoobjects(suchasdrillingswarf,wireoranything

else) fall into the unit. Otherwise a device fault cannot be excluded, even after longer periods of

operation.

12.2. Mains power connection

To guarantee lasting operating safety and reliability, the inverter must be connected expertly in

accordance with the valid electric standards. Attention must be paid to good insulation from earth

potential on the power terminals.

Connect an AC mains power supply with a rated voltage between 220V and 240V or a three phase

mains power supply with a rated voltage between 380V and 460V (40..70Hz) to the mains power

connection terminals L1, N or L1,L2,L3 and PE respectively. (TN-C System)

L1 (phase) -- N 220...240V 40...70 Hz; PE = Ground

L1, L2, L3 (phases) 380...415V (380...460V) 40...70 Hz; PE = Ground

Ensure a voltage balance to earth when feeding in the mains power through an isolating transformer

(star point earthed) or use the vector group ‘‘DY5’’ in the case of single-phase inverter power supply.

The inverter must always be earthed.

BERGES electronic

29.05.98 Operating manual ACM-D2 15

Frequency inverters must not be connected via a residual-current-operated circuit-

breaker as the sole protective measure!

The single exception below permits connection of a frequency inverter via a residual-cur-

rent-operated circuit-breaker as the sole protective measure:

Installation of a residual-current-operated circuit-breaker of the newest design for frequency in-

verters up to 4kVA (input voltage 1x230V) with MOBILE connection.This residual-current-

operated circuit-breaker must be suitable for alternating and pulsating DC leakage current.

Residual-current-operated circuit-breakers of this type bear the symbol .

Reliable tripping of the residual-current-operated circuit-breaker is not ensured in the

case of frequency inverters up to 4 kVA (input voltage 3x400V) with MOBILE connection;

an additional protective measure must be used for this reason. Also see the diagramm be-

low.

In the case of frequency inverters with PERMANENT connection (input voltage 1x230V

and 3x400V), another protective measure must always be used in addition to the residual-

current-operated protective device. Also see the diagramm below.

The protective function of the residual-current-operated circuit-breaker is no longer ensured due

to leakage currents from interface suppression capacitors in the inverter and DC-components in

the fault current. All devices connected to this residual-current-operated circuit-breaker (and per-

son touching them) are no longer protected in the event of a fault.

The pluggable terminal strips on the inverter (power connection terminals) must not be

plugged or removed when alive (DIN VDE 0160/pr EN50178).

The inverter will be destroyed if the mains feeder is confused with the motor cable.

The DC link capacitors must be reformed if the inverter you wish to connect has been out of ope-

ration more than a year. To do this, connect the inverter to voltage for approx. 30 minutes.The in-

verter should not be loaded by connected motors during forming.

12.3. Motor connection

Connect the motor cable to the U, V, W and PE terminals.

The inverter will be deactivated in the event of a short circuit at the terminals U, V, W.

We recommend PTC evaluation using commercially available devices to achieve effective protecti-

on of the motor.

If interrupting contacts (e.g. contactors or motor protection switches etc.) have to be installed

between the motor and inverter, the circuit must be configured so as to ensure that the ENABLE

signal (terminals 10/11) is deactivated before separation of the inverter/motor connection. A relay

switching time of approx. 30 ms suffices.

We recommend using output chokes for motor cable lengths over 20 m.

Connection of the electrical

equipment to the mains

Rated power

The compatibility of the electrical

equipment with the residual-current-

operated protectiv device must be

checked

Additional protection

besides residual-current-

operated protective device

is always necessary

Plugged in Permanent connection

>> 4kVA≤≤ 4kVA

BERGES electronic

16 Operating manual ACM-D2 29.05.98

12.4. Interference suppression measures/EMC (electromagnetic

compatibility)

Electrical/electronic devices are capable of influencing or disturbing each other through connecting

cables or other metallic connections. Electromagnetic compatibility consists of the factors interference

resistance and interference emission. Correct installation of the inverter in conjunction with any

possible local interference suppression measures has a crucial effect on minimizing or

suppressing mutual interference.

The following note refer to a mains power supply that is not ‘‘contaminated’’ by high frequency

interference.Othermeasuresmaybenecessarytoreduceorsuppressinterferenceifthemainsvoltage

is ‘‘contaminated’’. No generally valid recommendations can be given in such cases. Please consult

BERGES if all recommended interference suppression measures should not produce the desired

result.

•When secured on metal (control panels or control cabinets etc.), the inverter should be installed

usingscrewswithadditionalserratedwashers (tolinktheinvertermetallicallyto theearthedbase

surface).

•Usea shieldedmotor cable(earthing onboth sides).The shield shouldbe laidwithout interruption

fromthe inverter’s PEterminal to the motor’sPE terminal .If a shielded motorcable cannot be used,

the unshielded motor cable should be laid in a metal duct. This metal duct must not be interrupted

and must be adequately earthed.

Thefollowing pointsmust beobserved if radiointerference suppressionis to be realizedinaccordance

with EN 55011, EN 55014 and EN 50081-1 :

•Line-side connection of a mains filter and a output choke (the mains filter and output choke are not

contained in the scope of delivery).

•Lay the motor cable so that it is shielded.

•Lay the control cable so that it is shielded.

•Observe the general measures for radio interference suppression (also refer to the whole chapter

‘‘Interference suppression measures/EMC (electromagnetic compatibility)’’.

•When connecting the shield to cables leading further, the cross section of the shield should not be

tapered.

•Lay motor, mains power and signal cables separately and, as far away from each other as possible

and separately.

•When using a mains filter, place it at the shortest possible distance from the inverter to be able to

connect both devices by means of short connecting cables.

•When using an output choke (option), place it in the direct proximity of the inverter and connect it

with the inverter using a shielded cable which is earthed at both ends.

•Shielded signal cables should be laid at a minimum distance of 10 cm from power cables running

parallel. A separate earthed metal cable duct is advisable for such signal cables. If signal cables

intersect with a power cable, they should do so at an angle of 90°.

We recommend that control cables with a length of more than 1 m be twisted or laid in a shielded

configuration and earthed at both sides.

BERGES electronic

29.05.98 Operating manual ACM-D2 17

Other loads connected to the mains may produce voltage spikes that may interfere with functioning

of the inverter or may even damage it. Chokes or main filters can be used on the mains side to

protect the inverter against voltage spikes (resulting from switching large loads to the mains, for

example). Such chokes and filters are available as accessories.

If inverters are operated in a switchgear or in their close proximity (e.g. in one common control

cabinet) in connection with the same power mains, we recommend the following precautionary

measures to suppress interference in the switchgear:

•Wire the coils of contactors, switchgear devices and relay combinations with RC elements or

with free-wheeling diodes.

•Use shielded cables for external control and measuring cables.

•Lay disturbing cables (e.g. power and contactor control circuits) separately and at a distance

from the control cables.

12.5. Mains back-up fuses

External upstream fuses are required to protect the cables and the unit itself. The fuses must be

dimensioned so as to permit starting up and normal operation of motors. To guarantee this, we

recommend the use of the followings slow-blow fuses :

Mains input 1 x 230V

0.37kW 0.55kW 0.75kW 1.1kW 2.2kW

4A 8A 8A 8A 16A

Mains input 3 x 400V

0.75kW 1.1kW 1.5kW 2.2kW 3.0kW 4.0kW 5.5kW

4A 6A 6A 8A 10A 16A 20A

Mains input 3 x 400V

7.5kW 11.0kW 15.0kW 22.0kW 30.0kW 37.0kW

35A 35A 63A 63A 80A 100A

BERGES electronic

18 Operating manual ACM-D2 29.05.98

Other manuals for ACM-D2 Series

1

This manual suits for next models

14

Table of contents

Other Berges Inverter manuals

Popular Inverter manuals by other brands

KEHUA TECH

KEHUA TECH SPI-B2S Series user manual

Generac Power Systems

Generac Power Systems Guardian 004188-1 owner's manual

Huawei

Huawei SUN2000-50KTL-JPM0 user manual

Turbo Energy

Turbo Energy Hybrid Series instruction manual

Black & Decker

Black & Decker BDI750 instruction manual

GT POWER

GT POWER GT3500i Operating instruction