Siemens V20_EN_rev01-08032019.docx 0-1

Sommario

0................................................................................................................................................................ 0-0

1INTRODUCTION....................................................................................................................................1-1

2SAFETY INSTRUCTIONS AND PRECAUTIONS..................................................................................2-1

2.1 SAFETY INSTRUCTIONS..............................................................................................................2-1

2.2 PRECAUTIONS..............................................................................................................................2-1

3POWER MODULE.................................................................................................................................. 3-1

3.1 POWER MODULE V20 ..................................................................................................................3-1

3.1.1 Description.............................................................................................................................. 3-1

3.1.2 Warnings.................................................................................................................................3-1

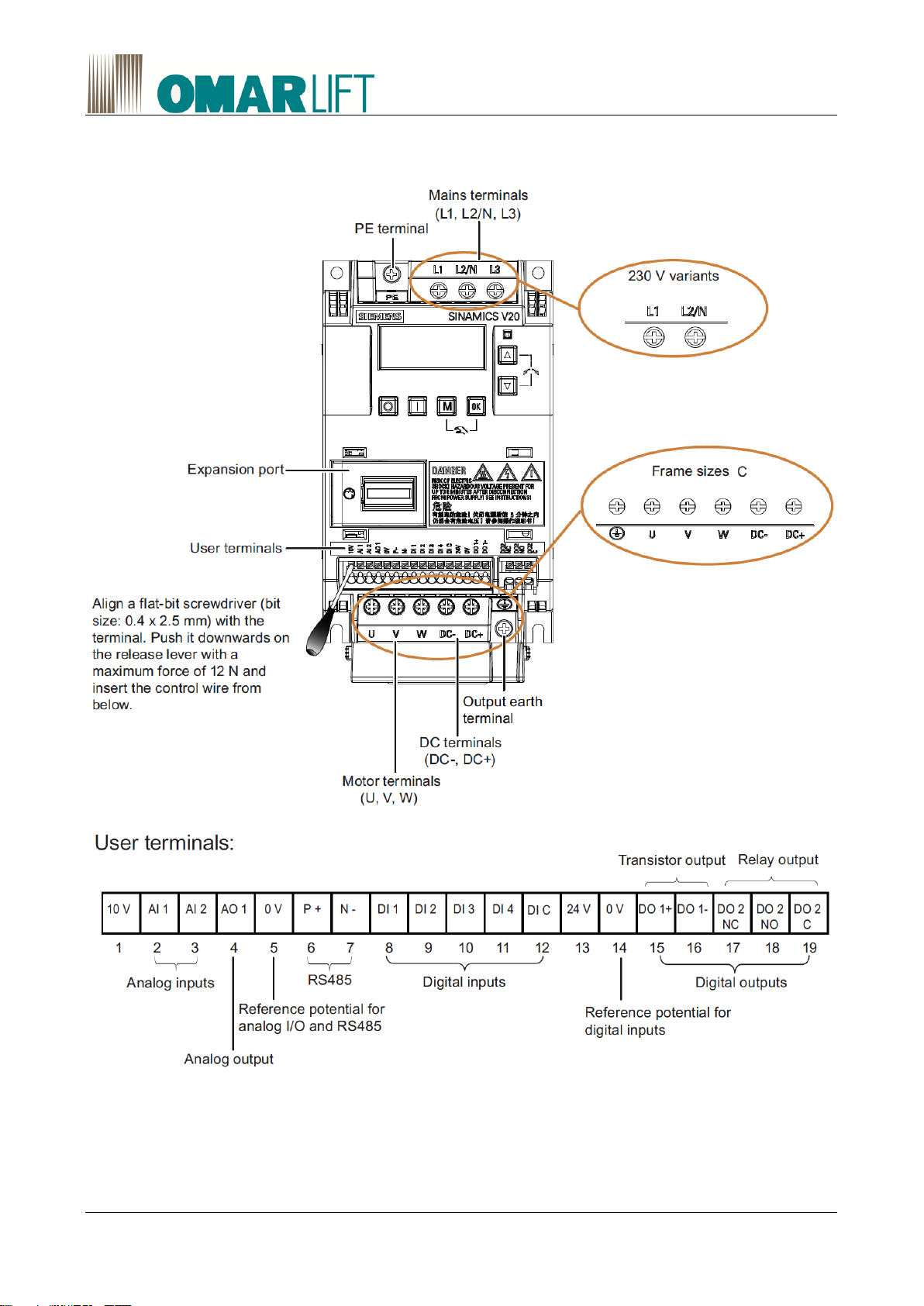

3.1.3 Terminal description ............................................................................................................... 3-2

3.1.4 Dimension drawings ............................................................................................................... 3-3

3.1.5 Wiring......................................................................................................................................3-4

3.1.6 Technical data......................................................................................................................... 3-5

4EMC-COMPLIANT INSTALLATION (EMC) ........................................................................................... 4-6

5BRAKING RESISTORS.......................................................................................................................... 5-8

6CONTROL UNIT.....................................................................................................................................6-1

6.1 DESCRIPTION ............................................................................................................................... 6-1

6.2 SAFETY WARNING ....................................................................................................................... 6-1

6.3 USER TERMINALS........................................................................................................................6-1

6.4 TECHNICAL DATA.........................................................................................................................6-1

7POWER WIRING.................................................................................................................................... 7-3

7.1 POWER CIRCUIT CONNECTION .................................................................................................7-3

7.2 SAFETY INSTRUCTIONS..............................................................................................................7-3

7.3 RULES FOR EMC COMPLIANT MOTOR - INVERTER WIRING..................................................7-3

7.4 SIEMENS V20 ELECTRICAL WIRING ..........................................................................................7-5

8PROGRAMMING THROUGH PC ..........................................................................................................8-1

9PROGRAMMING THROUGH KEYBOARD AND MENU....................................................................... 9-1

9.1 EXPANSION PORT (Optional)....................................................................................................... 9-1

9.2 THE BUILT-IN BASIC OPERATOR PANEL (BOP) .......................................................................9-1

9.2.1 Inverter menu.......................................................................................................................... 9-3

9.2.2 Viewing inverter status............................................................................................................9-4

9.2.3 Editing of parameters..............................................................................................................9-4

9.2.4 Screen displays.......................................................................................................................9-5

9.2.5 LED warnings..........................................................................................................................9-6

9.3 QUICK COMMISSIONING .............................................................................................................9-6

9.3.1 Quick commissioning through the Setup menu...................................................................... 9-6

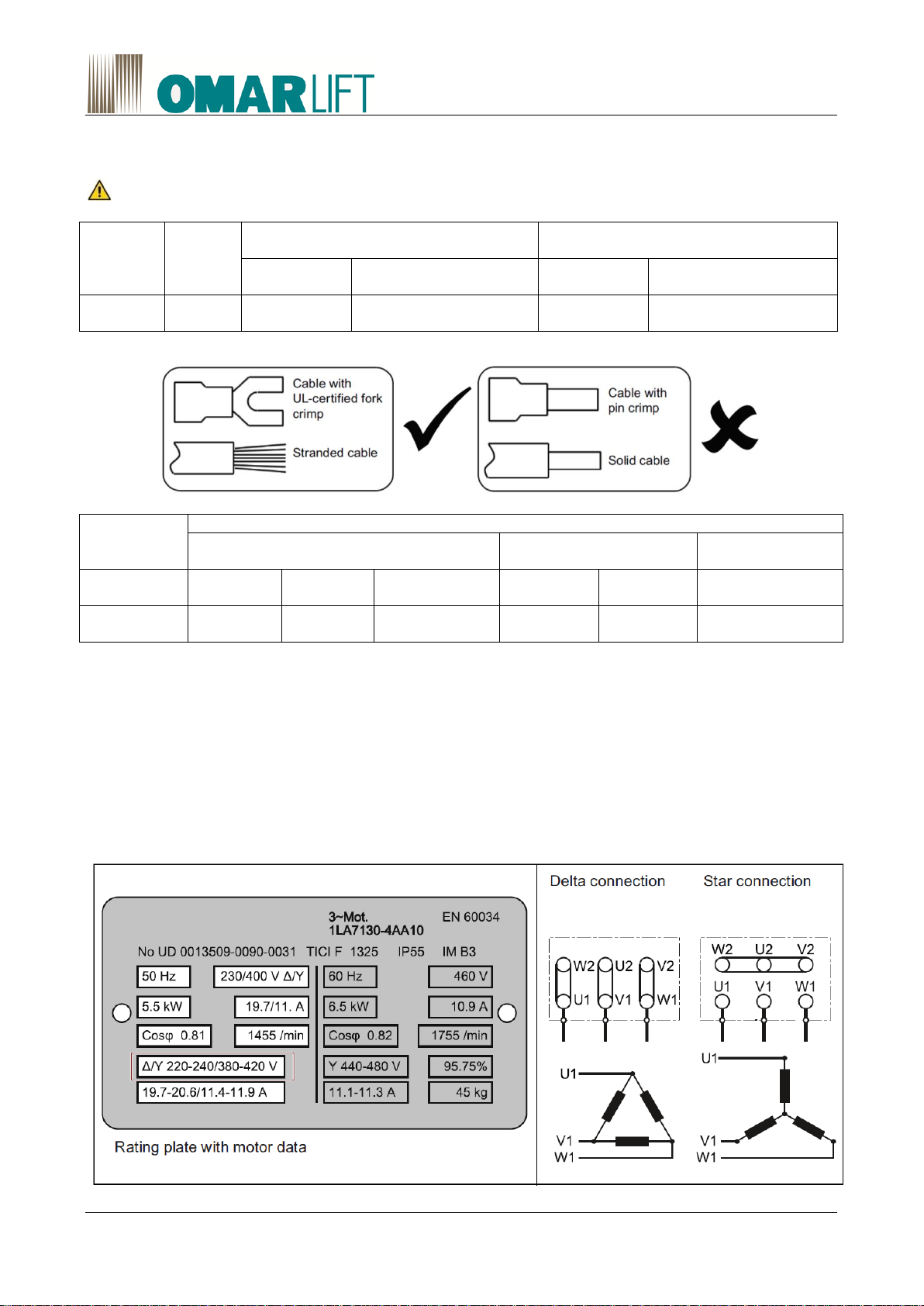

9.3.2 Setting motor data .................................................................................................................. 9-7

9.3.3 Setting connection-macros.....................................................................................................9-8

9.3.4 Setting application macros...................................................................................................... 9-8

10 PARAMETERS.................................................................................................................................10-9