BERMAD FP 400E Owner's manual

BERMAD Fire Protection

400 Series

FP 400E Deluge Valve Data

Description

BERMAD FP 400E Deluge Valves are elastomeric- type

globe valves that are rolling-diaphragm actuated, with an

integral, solid, resilient seal. These automatic water

control valves are designed for vertical or horizontal

installation and are available in diameter sizes from 1½” to

14” (DN40 to DN350).

The BERMAD FP 400E valves are used for water flow

control in Deluge, Combination Pressure Control Deluge,

Preaction or Water/Foam systems, and are manufactured

from various materials and coatings to suit all kind of

industrial specifications.

The FP 400E Deluge Valve is held closed by system water

pressure trapped in the control chamber. When the

releasing system operates, pressure is released from the

control chamber, and the seal disc opens to allow water

to flow into the system.

The design of the FP 400E valve body includes a single,

full bore seat with unobstructed flow path, free of any

in-line ribs, supporting cage, or shafts.

The unique hydro-dynamic globe design provides high

flow capabilities with minimum head loss. The cover is

removable via four (4) fastening bolts (up to 10”) for quick

in-line inspection and servicing.

The internal design of the FP 400E valve is based on

innovative technology using advanced rubber-based

materials to achieve a solid, one-piece, elastomeric

assembly including flexible fiber reinforced diaphragm,

vulcanized with a rugged radial seal disk, and together

providing resilient, drip-tight sealing. The elastomeric

assembly is carefully balanced and peripherally supported

to avoid tension and protect the elastomer, resulting in

long-life, controlled actuation, even under harsh

conditions.

The elastomeric assembly can be easily removed from the

valve body with no need for disassembling the valve from

the line.

Accessories

The BERMAD FP 400E Deluge Valve are trimmed with

the original components and accessories per

specification and in accordance with valve functions and

applications.

Where additional specifications and/or signaling devices

are required for a specific application, refer to system

data for the system used, and to the BERMAD data

sheet and Installation, Operation & Maintenance for

specific model required.

Main Features

■One-piece molded elastomeric moving part –

No maintenance required

■In-line serviceable, field replaceable internal parts

■Obstacle free, full bore

■Available in corrosion resistant materials

■Designed to be reset without opening the valve

■Compatible with electric/hydraulic/pneumatic release

and pressure control trim systems

Approvals

■UL Listed to UL 260 from 5 to 250 psi (0.3 to 17.2 bar)

Working Pressure, 1-½” through 10”

(DN40 through DN250)

■ABS Approved for 300 psi (21 bar) maximum working

pressure, 1-½” through 14” (DN40 through DN350)

■Lloyd’s Register Type Approval for 300 psi (21 bar)

maximum working pressure, 1-½” through 14”

(DN40 through DN350)

■Fire Test Certified to ISO 6182 part 5, 1-½”

through 12” (DN40 through DN300)

Notes:

1. The FP 400E valve shall be trimmed with specific

components & accessories.

2. The FP 400E valve must be installed and maintained in

compliance with the most recent BERMAD publications.

1

BERMAD Fire Protection

400 Series

FP 400E Materials Specifications

Construction Materials

The BERMAD FP 400E valves are available in a variety of materials to

ensure optimal suitability for a wide range of applications. When the

valve is designed for external corrosive environments and/or internal

corrosive fluid, an adequate Body and Cover resistant material shall be

used.

It is recommended to apply the “High Build Epoxy Fusion-Bonded with

UV Protection, Anti-Corrosion” specification (as shown below) when

the valve is used in corrosive environments such as seashore,

chemical environments or petrochemicals and other industrial

processing plants.

Note: in case of Seawater service, brackish/ desalinated water or if

Foam Concentrate is used please refer to BERMAD FS 400E series

engineering data.

Standard Configurations

Item

Number Description Code

FP-C-PR FP-C-ER FP-S-ER

1 Cover Ductile Iron Ductile Iron Cast Steel

2 Valve Body Ductile Iron Ductile Iron Cast Steel

3 Elastomeric Assembly NR with VRSD* NR with VRSD* NR with VRSD*

4 External Bolts / Nuts S.S. 316 S.S. 316 S.S. 316

5 Coating Polyester H.B. Epoxy H.B. Epoxy

* VRSD - Vulcanized Radial Seal Disk

Specifications

Castings

■Ductile Iron to ASTM A536 65-45-12 (coated)

■Cast Steel ASTM A216 Grade WCB (coated)

■Nickel Aluminum Bronze ASTM B148 C95800

■Stainless Steel 316 ASTM A351 Grade CF8M

■Hastelloy C-276

Standard Bolting:

■Stainless Steel 316 to ASTM A320 Gr.B8F

Option: Internal Spring - S.S. 302 or Inconel

Elastomer

■NR, Polyamide fabric reinforced Polyisoprene,

Temperature Rating 50°C

■NBR, Polyamide fabric reinforced Nitrile (Buna-N),

Temperature Rating 80°C

■EPDM, Polyamide fabric reinforced Ethylene-

Propylene, Temperature Rating 90°C

Coating

■Electrostatic Powder Coating Polyester

■High Built Epoxy Fusion-Bonded with UV

Protection, Anti-Corrosion

■Color: Fire Red to RAL 3002

Note: Internal & External coating applied on Ductile Iron

or Cast Steel Castings only.

Material

End Connection

Standard Inlet &

Outlet

Class

& Type

Max. working

Pressure

psi bar

Ductile Iron

Flanged ANSI B16.42 #150RF 250 17.4

Flanged ISO 7005-2 PN16 235 16

Grooved ANSI C606 250 250 17.4

Threaded ISO-7-RP/NPT

250 250 17.4

Cast Steel Flanged ANSI B16.5 #150RF 250 17.4

Flanged ISO 7005-2 PN16 235 16

Stainless

Steel

Flanged ANSI B16.5 #150RF 250 17.4

Flanged ISO 7005-2 PN16 235 16

Ni-Al

Bronze

Flanged ANSI B16.24 #150RF 250 17.4

Flanged ISO 7005-2 PN16 235 16

Pressure Rating

Notes:

1. To attach a grooved valve to flanged line or vice versa, apply a grooved-

flange adapter suited to the designated conditions.

2. Factory pressure testing: Each valve is tested at 375 psi (26 bar)

3. Water Temperature: 0.5 - 50ºC (33 - 122ºF) for standard construction.

4. Standard flange facing: Raised Face (RF), Serrated Finish.

Flat Face (FF) flanges available on request.

2

3

1

4

2

5

BERMAD Fire Protection

400 Series

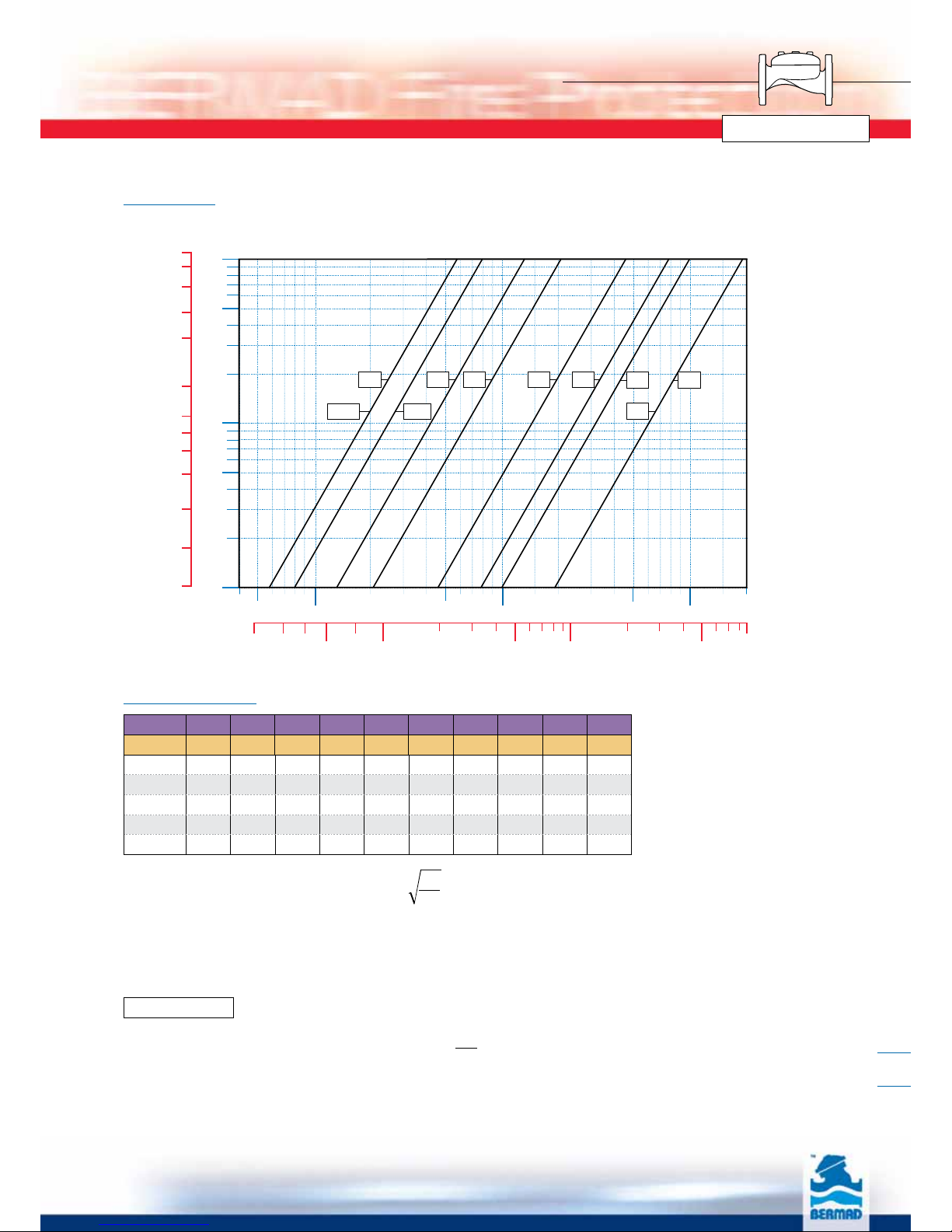

FP 400E Flow &Hydraulic Data

5678

10

15

20

30 440050 60 80

100

15020020 3000300500600800

1000

2000

0.01

0.05

0.1

0.5

1.0

2

1/2

"

3" 4" 6" 8" 10"

12"

bar

m3/h

psi

1.5

2.5

5.0

7.5

10.0

12.5

15.0

0.15

0.25

0.5

0.75

1.0

1.25

20 30 40 50 75 100 500 1,000 5,000

gpm

Pressure Loss

11/2"

14"2"

Flow Chart

Flow Properties

DN 40 50 65 80 100 150 200 250 300 350

Inch 1½" 2" 2½" 3" 4" 6" 8" 10" 12" 14"

Kv 57 57 78 136 204 458 781 829 1,932 1,932

Cv 66 66 90 157 236 529 902 957 2,231 2,231

K3.2 3.2 4.2 2.9 4.0 4.0 4.4 3.9 3.6 3.6

Leq-m 9.1 9.1 12.1 13.7 14 27.4 45.8 108 57 57

Leq-feet 30 30 40 45 46 90 150 354 187 187

Valve flow coefficient, Kv or Cv Equivalent Pipe Length, Leq

Flow resistance or Head loss coefficient,

Cv = 1.155 Kv

Where:

Kv = Valve flow coefficient (flow in m3/h at 1bar Diff. Press.)

Cv = Valve flow coefficient (flow in gpm at 1psi Diff. Press.)

Q = Flow rate (m3/h ; gpm)

∆P = Differential pressure (bar ; psi)

Gf = Liquid specific gravity (Water = 1.0)

Kv(Cv)=Q Gf

∆P

Leq=Lk.D

K=∆H2g

V2

Where:

K = Flow resistance or Head loss coefficient (dimensionless)

∆H = Head loss (m ; feet)

V = Nominal size flow velocity (m/sec ; feet/sec.)

g = Acceleration of gravity (9.81 m/sec2; 32.18 feet/sec2)

Where:

Leq = Equivalent nominal pipe length (m ; feet)

Lk = Equivalent length coefficient for turbulent

flow in clean commercial steel pipe (SCH 40)

D = Nominal pipe diameter (m; feet)

Note:

The Leq values given are for general consideration only.

Actual Leq may vary somewhat with each of the valve sizes.

3

BERMAD Fire Protection

400 Series

FP 400E Dimensions &Weights

Size DN mm (inch) 40 (1½”) 50 (2”) 65 (2½”) 80 (3”) 100 (4”) 150 (6”) 200 (8”) 250 (10”) 300 (12”) 350 (14”)

ANSI #150, ISO PN 16

LF (mm) 205 205 205 257 320 415 500 605 725 741

W (mm) 155 155 178 200 223 306 365 405 610 597

H (mm) 74 74 86 110 130 205 256 256 373 373

RF (mm) 64 78 89 100 115 140 172 204 242 267

a (1) (inch) ½ ½ ½ ½ ½ ½ ½ ½ ½ ½

b (1) (inch) ¼¼¼¼¼¼¼¼¼¼

c (1) (inch) ½½½½½½½½½½

d (2) (inch) ¾ ¾ 1.5 1.5 2 2 2 2 2 2

Control Vol.(3) (Lit.) 0.12 0.12 0.18 0.29 0.67 1.94 3.86 3.86 13.8 14

Weight (Kg) 8 9 10.5 19 28 68 125 140 220 235

Metric

Si

Flanged

Grooved Threaded

LG

a

d

a

RG

H

LT

a

d

a

RT

H

a

d

LF

RF

H

a

b

Cb

b

W

Flanged Grooved

Threaded

Size DN mm (inch) 50 (2”) 80 (3”) 100 (4”) 150 (6”) 200 (8”)

Grooved

LG (mm) 205 250 320 415 500

W (mm) 120 175 200 306 365

H (mm) 74 110 130 205 256

RG (mm) 30.2 44.5 57.2 84.2 110

a (1) (inch) ½ ½ ½ ½ ½

b (1) (inch) ¼ ¼ ¼ ¼ ¼

c (1) (inch) ½ ½ ½ ½ ½

d (2) (inch) ¾ 1½ 2 2 2

Control Vol.(3) (Lit.) 0.12 0.29 0.67 1.94 3.86

Weight (Kg) 5 10.6 16.2 49 108

Size DN mm (inch) 40 (1½”) 50 (2”) 65 (2½”)

ISO-7-Rp or NPT(F)

LT (mm) 180 180 210

W (mm) 120 120 129

H (mm) 74 74 87

RT (mm) 30 37.5 40

a (1) (inch) ½ ½ ½

b (1) (inch) ¼ ¼ ¼

c (1) (inch) ½ ½ ½

d (2) (inch) ¾ ¾ 1½

Control Vol.(3) (Lit.) 0.12 0.12 0.18

Weight (Kg) 4 4 5.7

(1) (a), (b), (c) are NPT Thread ports

(2) (d) is BSPT threaded drain port

(3) (Control Volume) is Control Chamber Displacement Volume of Liquid pushed when valve opens

4

BERMAD Fire Protection

400 Series

FP 400E Dimensions &Weights

Size 1½ 22½ 346810 12 14

ANSI #150, ISO PN 16

LF (inch) 81/881/881/8101/8125/8163/8195/82313/16 284/8291/8

W (inch) 61/861/87 77/886/812 143/816 24 234/8

H (inch) 27/827/833/843/851/881/8101/8101/8145/8145/8

RF (inch) 24/831/834/837/844/854/866/88 94/8104/8

a (1) (inch) ½ ½ ½ ½ ½ ½ ½ ½ ½ ½

b (1) (inch) ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ 3/83/8

c (1) (inch) ½½½½½½½½½½

d (2) (inch) ¾ ¾ 1.5 1.5 2 2 2 2 2 2

Control Vol.(3) (Gal.) 0.03 0.03 0.05 0.08 0.18 0.51 1.02 1.02 3.65 3.70

Weight (Lbs.) 18 20 23 42 62 150 276 309 485 518

English

US

Flanged

Grooved Threaded

LG

a

d

a

RG

H

LT

a

d

a

RT

H

a

d

LF

RF

H

a

b

Cb

b

W

Flanged Grooved

Threaded

Size (inch) 2 3 4 6 8

Grooved

LG (inch) 81/16 913/16 125/8165/16 195/8

W (inch) 4¾ 67/877/8121/16 143/8

H (inch) 215/16 45/16 51/8129/16 101/8

RG (inch) 13/16 1¾ 2¼ 3¼ 43/8

a (1) (inch) ½ ½ ½ ½ ½

b (1) (inch) ¼ ¼ ¼ ¼ ¼

c (1) (inch) ½ ½ ½ ½ ½

d (2) (inch) ¾ 1½ 2 2 2

Control Vol.(3) (Gal.) 0.03 0.08 0.18 0.51 1.02

Weight (Lbs.) 11 23 36 108 238

Size (inch) 1½ 22½

ISO-7-Rp or NPT(F)

LT (inch) 71/16 71/16 81/4

W (inch) 43/443/451/16

H (inch) 27/8215/16 37/16

RT (inch) 13/619/16 19/16

a (1) (inch) ½ ½ ½

b (1) (inch) ¼ ¼ ¼

c (1) (inch) ½ ½ ½

d (2) (inch) ¾ ¾ 1½

Control Vol.(3) (Gal.) 0.03 0.03 0.05

Weight (Lbs.) 9 9 13

(1) (a), (b), (c) are NPT Thread ports

(2) (d) is BSPT threaded drain port

(3) (Control Volume) is Control Chamber Displacement Volume of Liquid pushed when valve opens

5

BERMAD Fire Protection

400 Series

FP 400E Installation, Operation &Maintanence

Installation

Proper operation of the FP 400E Deluge Valves depends

upon their trim being installed in accordance with the

appropriate trim configuration.

Notes:

■Wet pilot height should not exceed “Maximum

Elevation Above Valve" (see data for specific model).

■Any deviation in trim size or arrangement may

adversely affect the proper operation of the deluge

valve.

■All the pilot system devices, must be UL Listed and

compatible with the particular deluge system. Refer

to current “UL Listed Fire Protection Equipment

Directory”.

Warning: The deluge valve and trim must be installed

only in areas where they will not be subject to freezing

temperatures.

Installation Instructions

1. Allow enough room around the valve assembly for

any adjustments and future maintenance.

2. Before the valve is installed, flush the pipeline to

remove any dirt, scale, debris, etc. Not flushing the

line may result in the valve being rendered

inoperable.

3. Install the valve in the pipeline so that the valve flow

arrow appearing on the body casting is pointing in

the desired direction. Ensure that the valve is

positioned so that the cover can be easily removed

for future maintenance.

4. Ensure that the Control Trim is mounted properly

and all other components are positioned correctly

as per illustration.

5. After installation in the main line, carefully inspect/

correct any damaged accessories, piping, tubing, or

fittings. Ensure that there are no leaks.

6. Install the components comprising the Deluge Trim

Package in their proper positions in compliance with

all instructions, drawings, and technical

specifications describing the BERMAD Deluge

Valve, according to the relevant illustration.

7. All additional accessories, although not packed

together with the BERMAD Deluge Valve, must be

installed as shown in the relevant P&ID and other

illustrations.

Operation

Principle of Operation

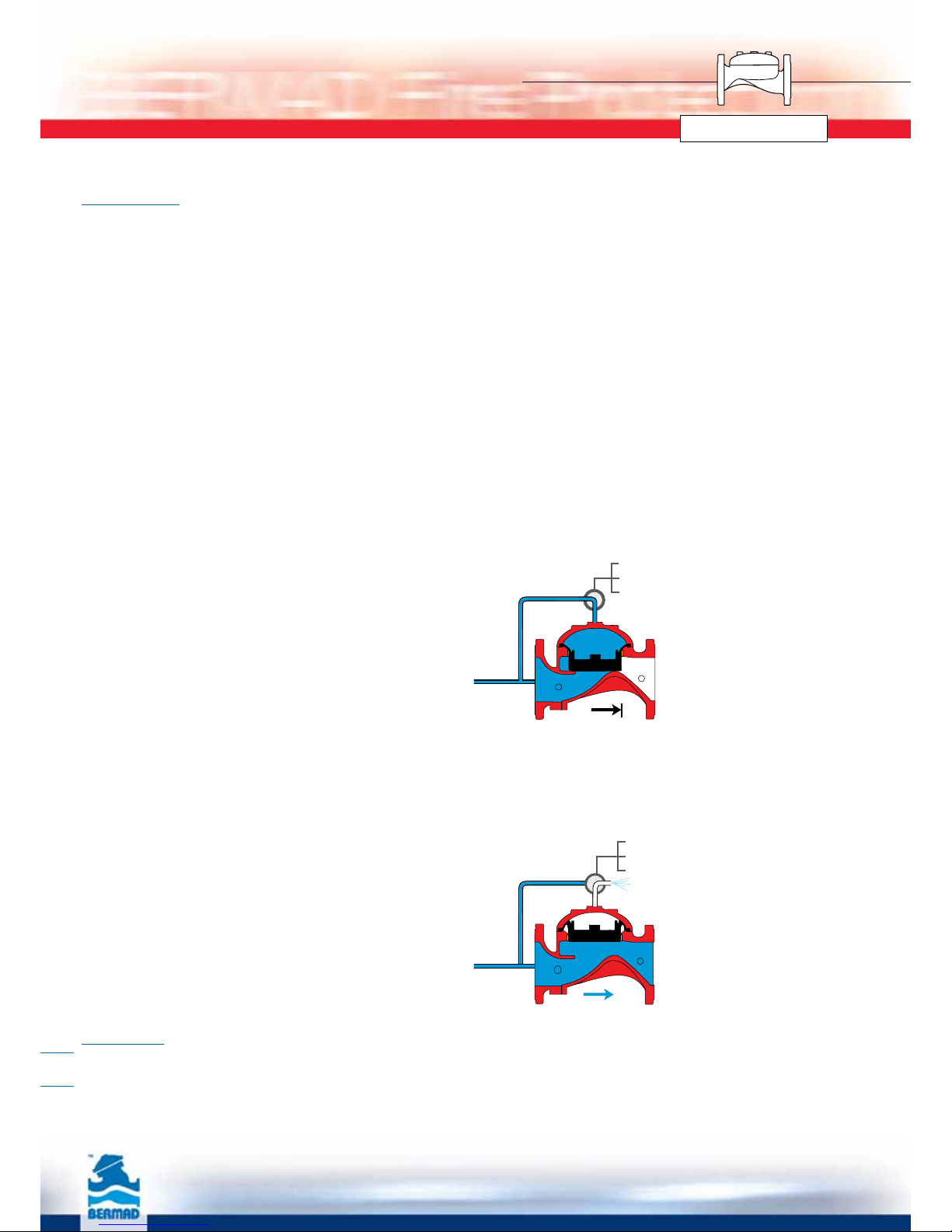

The BERMAD FP 400E Deluge Valve (assembled with

specific trim) is suitable for systems that include

adequate detecting and piping systems with open

nozzles. The deluge valve prevents water from entering

system piping until required. The deluge valve is kept

closed by pressure applied to the control chamber

through a restricted priming line.

In the SET position, the water pressure supplied through

the priming line is trapped in the control chamber of the

deluge valve by a check valve, and by the normally

closed release device.

The pressure trapped in the control chamber of the

deluge valve presses the valve seal disc down, thereby

sealing the valve and keeping the system piping dry.

Under Test or Fire conditions, when the pressure is

released from the control chamber by the opening of the

automatic releasing device or by manual release, the

deluge valve opens and allows the inlet supply water to

flow through the valve and into the system piping and

alarm devices.

Warning: Whenever the handle of the Manual

Emergency Release is pulled, pressure is released from

the control chamber, the deluge valve will open, and

water will flow into system piping and alarm devices.

Electric

Pneumatic

Hydraulic

Electric

Pneumatic

Hydraulic

Valve Closed (Set Position)

Line pressure applied to the control chamber of the

valve creates a superior force that moves the valve to

the closed position and provides drip tight sealing.

Valve Open (Operating Conditions)

Releasing the pressure from the control chamber to

atmosphere or some other lower pressure zone causes

the line pressure acting on the seal disc to move the

valve to the open position.

6

BERMAD Fire Protection

400 Series

FP 400E Installation, Operation &Maintanence

Placing in Service/Resetting

The deluge valve and the control trim shall be Place in

Service with accordance to the most recent IOM

procedures for the specific model.

After all relevant instructions are performed, slowly open

the supply-isolating valve and check that no water flows

into the system.

The system is now operational and in stand-by mode.

Maintenance

Bermad Deluge Valves require no lubrication, no packing

tightening, and require minimum maintenance.

Removing the System from Service

Warning: When taking a deluge system out of service,

a fire patrol should be established in the system area.

If automatic fire alarm signaling equipment is utilized,

the proper authority should be notified that the system

is being removed from service. The insuring body and

owner’s representative should also be notified when the

system is being taken out of service.

WARNING:

Do not turn off the water supply to make repairs without

placing a roving fire patrol in the area covered by the

system. The patrol should continue until the system is

back in service.

Prior to turning off any valves or water supply, notify local

site fire officials.

Removal Instructions

1. Shut off the main supply-isolating valve.

2. Close the priming line valve to the deluge valve

control chamber.

3. Open all drain valves.

4. Release the water pressure from the control chamber

of the deluge valve by pulling the manual emergency

release.

5. Place “Fire Protection System Out of Service” signs in

the area protected by the system.

Inspection and Testing

1. Warning: Do not turn the water supply off to make

repairs without placing a roving fire patrol in the area

covered by the system. The patrol should continue

until the system is back in service.

2. Prior to turning off any valves or activating any

alarms, notify local security guards and the central

alarm station, if used, to avoid signaling a false alarm.

3. The deluge valve and the control trim shall be

maintained with accordance to the most recent IOM

procedures for the specific model. A periodic test

schedule should be established also with accordance

to the site conditions and owner regulations.

4. Take all additional measures as required by NFPA-25

“standard for the inspection, testing, and

maintenance of water-based fire protection systems”.

5. The system should be checked weekly for “Normal

Conditions”.

6. Clean the priming strainer prior to any resetting of the

deluge valve.

7. The deluge valve must be activated at full flow at

least annually. Take all necessary precautions to drain

water and prevent damage in the area protected by

the system.

8. After about five years of operation, replacement of the

diaphragm assembly is recommended. Remove the

cover, clean the valve body from sediments, clean the

control tubing entry holes, and install a new

diaphragm assembly in place.

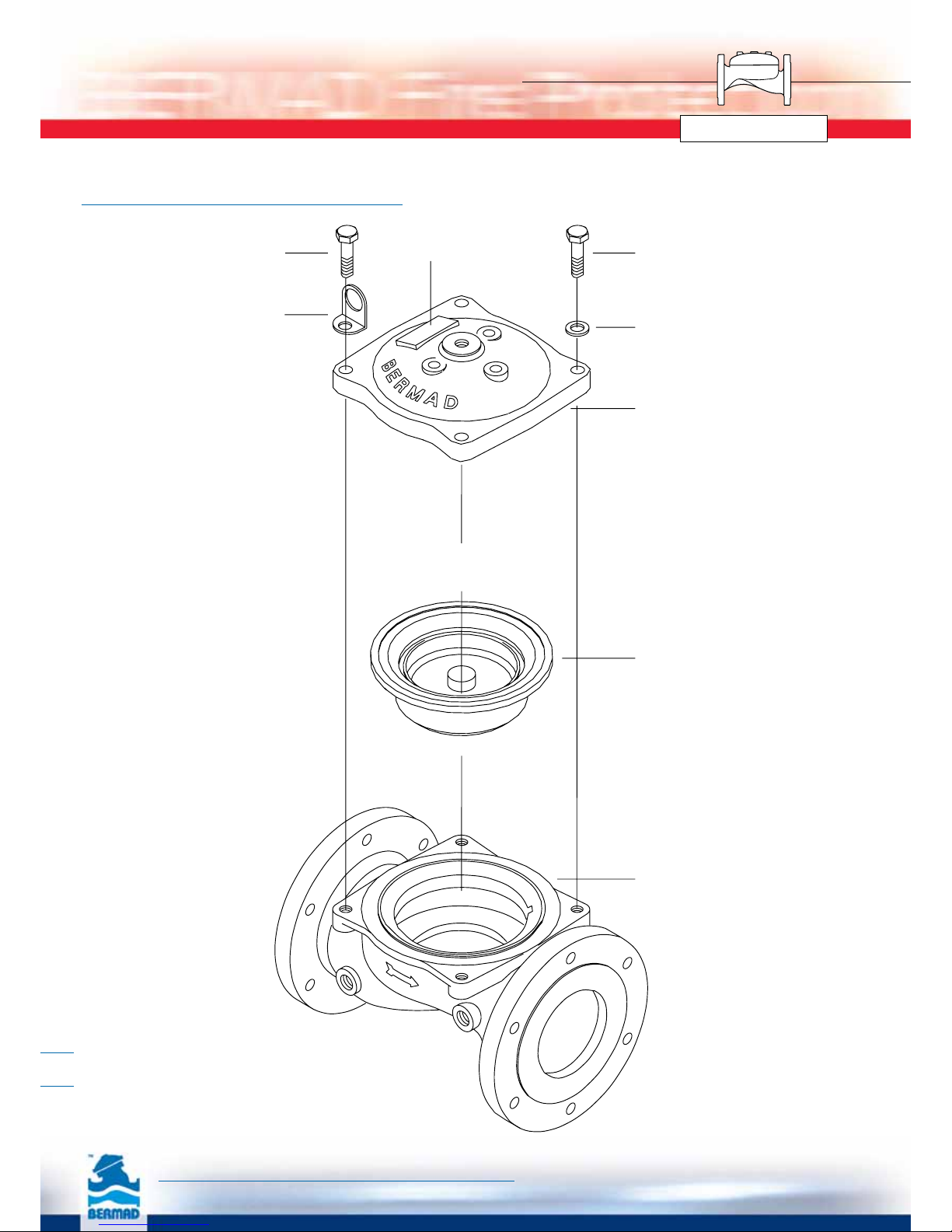

Spare Parts

1. The Diaphragm Assembly is the only spare part

needed for the main deluge valve, see attached

“Valve Disassembly and Parts Breakdown Illustration”.

2. It is not recommended to store spare rubber parts for

long periods (rubber in improper storage conditions

can harden and crack).

3. Contact your Bermad representative and order new

rubber parts when required.

7

BERMAD Fire Protection

400 Series

FP 400E Installation, Operation &Maintanence

Valve Disassembling Parts Breakdown

Lifting Ring

Body

Diapragm

Assembly

Cover

Disk

Bolt

Bolt Va lve name plate

The information herein is subject to change without notice. BERMAD shall not be held

liable for any errors. All rights reserved. © Copyright by BERMAD. PT4PE08-DATA

8

This manual suits for next models

1

Table of contents

Popular Lawn And Garden Equipment manuals by other brands

Sunforce

Sunforce SOLAR user manual

GARDEN OF EDEN

GARDEN OF EDEN 55627 user manual

Goizper Group

Goizper Group MATABI POLMINOR instruction manual

Rain Bird

Rain Bird 11000 Series Operation & maintenance manual

Cub Cadet

Cub Cadet BB 230 brochure

EXTOL PREMIUM

EXTOL PREMIUM 8891590 Translation of the original user manual

Vertex

Vertex 1/3 HP Maintenance instructions

GHE

GHE AeroFlo 80 manual

Land Pride

Land Pride Post Hole Diggers HD25 Operator's manual

Yazoo/Kees

Yazoo/Kees Z9 Commercial Collection System Z9A Operator's & parts manual

Premier designs

Premier designs WindGarden 26829 Assembly instructions

Snapper

Snapper 1691351 installation instructions