BERMAD M10 User manual

Instruction Manual

ELECTROMAGNETIC FLOW METERS

M10

INSTRUCTION MANUAL

CAREFULLY READ THESE INSTRUCTIONS AND KEEP THEM IN A SAFE PLACE

M10

Instruction Manual

2

This document must be delivered to the user before machine installation and commissioning.

Symbols used in this manual

In order to draw the attention of all personnel working with the equipment supplied by BERMAD, the points

of particular importance described in this manual are highlighted with graphic signs and dierent colors

that will make them easily identifiable.

Legend

CAUTION! This sign indicates a risk of electric shock! All operations marked with this sign must be performed

exclusively by qualified technical personnel.

CAUTION/WARNING. This symbol indicates vital information and points to be observed. Please refer to

the related documents.

NOTE. This symbol indicates information and points of particular importance to be observed.

READ THE INSTRUCTIONS CAREFULLY AND KEEP THEM IN A SAFE PLACE

This manual can be downloaded from the web site www.euromag.com in the Area Download section. We

want you to save time and money!

We assure you that, having read this manual thoroughly, you will be able to perform correct installation

and fully use the product in total safety.

Instruction Manual

33

1 INTRODUCTION 5

1.1 MANUFACTURER’S STATEMENT 5

1.2 PACKAGING VERIFICATION 5

1.3 PRELIMINARY NOTES 6

1.4 PRODUCT IDENTIFICATION 7

1.5 APPLICATIONS 8

2 PRODUCT DESCRIPTION 9

2.1 OPERATING PRINCIPLE 9

2.2 POWER SUPPLY 9

2.3 DATA SAFETY 10

3 TECHNICAL SPECIFICATIONS 11

3.1 OVERALL DIMENSION 11

3.2 CERTIFICATES AND APPROVALS 12

3.3 GENERAL TECHNICAL FEATURES 13

3.4 MEASURING ACCURACY 14

3.4.1 Reference conditions: 14

3.4.2 Accuracy class 14

3.4.3 MID Annex III (MI-001) - (Directive 2014/32/EU) 15

4 INSTALLATION 16

4.1 STORAGE AND MOVING 16

4.1.1 Storage 16

4.2 GENERAL INSTALLATION REQUIREMENTS 16

4.2.1 Vibrations 16

4.2.2 Magnetic fields 17

4.2.3 Negative pressure 17

4.2.4 Protection from direct sunlight 17

4.2.5 Operating temperatures 17

4.3 INSTALLATION CONDITIONS 18

4.3.1 Positioning in relation to the plant 18

4.3.2 Important guidelines for correct installation 18

4.4 INSTALLATION 22

4.4.1 Important instructions on installation 22

4.4.2 Sensor support 23

4.5 HOW TO AVOID AIR POCKETS IN THE PIPELINES 24

4.6 ELECTRICAL CONNECTION 28

4.6.1 Wiring diagram 28

4.6.2 Connection options I/O 30

4.6.2.1 Pulse output 30

4.6.2.2 RS485 - 2 wire interface 30

4.6.3 Electrical grounding of the meter 32

4.6.3.1 Plastic Pipe Installation using Grounding Rings 32

4.6.3.2 Metal Pipe Installation 33

4.6.4 Connection to the power supply 33

4.7 BATTERY INSTALLATION 34

M10

Instruction Manual

4

5 METER PROGRAMMING 36

5.1 DISPLAY 36

5.2 FIRST ACTIVATION 37

5.3 USER INTERFACE 38

5.4 DISPLAY TEST 39

5.5 FUNCTIONS 39

5.5.1 List of functions available through display interface 41

5.6 BATTERY 42

5.7 ACCESS VIA MAG-NET APP 43

5.8 ACCESS VIA EUROMAG-LINK 44

5.8.1 Access via RS485 44

5.8.2 Access via Bluetooth 45

5.9 FIRMWARE UPDATE 47

5.10 DEVICE RESET 49

5.10.1 Reboot 49

5.11 METERS SUBJECT TO LEGAL METROLOGY 50

5.11.1 Metrological seals 50

5.11.2 Utility seals 50

6 MAINTENANCE 51

6.1 CABLE GLAND CLOSING AND GASKET CONDITION CHECK 51

6.2 BATTERY INSTALLATION/REPLACEMENT 51

7 TROUBLESHOOTING 52

7.1 MALFUNCTIONING AND POSSIBLE SOLUTIONS 52

7.2 SELF DIAGNOSTIC 53

8 PRODUCT DISPOSAL 55

Instruction Manual

55

1 INTRODUCTION

IMPORTANT WARNING! It is very important that all personnel working with the equipment have read and

understood the instructions and indications provided in this manual, and that they follow them prior to

using the equipment itself. The manufacturer assumes no responsibility for the consequences resulting

from improper use by the worker.

The worker will be responsible for the suitability of the device for particular purposes.

The warranty will be considered void in case of improper installation and use of devices (systems).

The manufacturer shall bear no responsibility for any damage caused by improper use, improper

installation or tampering of own products. Installation, connection, commissioning and maintenance

must be carried out by personnel who are qualified and authorized for this purpose. The personnel in

charge of the installation must make sure that the measurement system is properly connected as per

the wiring diagram indicated in this document.

The manufacturer shall bear no responsibility for any damages or injuries resulting from any misunderstanding

of this manual. In order to avoid possible accidents to persons or things caused by incorrect interpretation

of the instructions, the user must not proceed with operations and/ or interventions on the meter if

there are uncertainties or doubts regarding the operation(s) to be performed. We recommend contacting

Assistance Service for clarifications in this regard for more precise instructions.

The manufacturer will be held responsible only if the meter will be used in its original configuration.

For applications that require high working pressures or use of substances that may be dangerous for

people, the environment, equipment or anything else: In case of pipe breakage, BERMAD recommends to

take the necessary precautions such as adequate positioning, protection or installation of a guard or safety

valve, before installing the meter.

The device contains live electrical components, therefore installation, checks and maintenance must be

carried out by experienced and qualified personnel who are aware of all necessary precautions to be taken.

Before opening any internal part, please disconnect the power supply.

1.1 MANUFACTURER’S STATEMENT

Stresses and loads possibly caused by earthquakes, strong winds, fire damage, vibrations and natural

disasters were not taken into account in the phase of product designing.

Do not install the product in such a way that it acts as a focus for stresses on the pipes. External loads

were not taken into account in the device configuration.

While the device is working, the pressure, supply voltage and/or temperature values indicated on the

label or in this Operating Manual must not be exceeded.

1.2 PACKAGING VERIFICATION

At the moment of purchase and/or upon receipt of the product, the buyer is strongly advised to check the

quality of the packaging which must be intact, without visible dents and completely and correctly closed.

When opening the packaging, also check that the product complies with the information on the packing

list in terms of completeness of components/accessories.

NOTE: All BERMAD software packages are available on the USB flash drive key that accompanies the product.

The software can also be downloaded from the website www.euromag.com by accessing the Download

Area. A free registration will be required after which you can download the configuration software for

your product.

M10

Instruction Manual

6

1.3 PRELIMINARY NOTES

The M10 is a reduced bore electromagnetic flowmeter, made of thermoplastic material equipped with grooved

connection system, available in sizes DN50/2” - DN150/6”, and with an integrated electronic converter.

Like other electromagnetic flowmeters it has many important advantages compared to its mechanical

counterparts, such as: exceptional long-term stability, maximum process reliability and zero maintenance.

As a result, these sensors can provide accurate and reliable long-term measurements.

See the following paragraphs for more detailed information on correct installation.

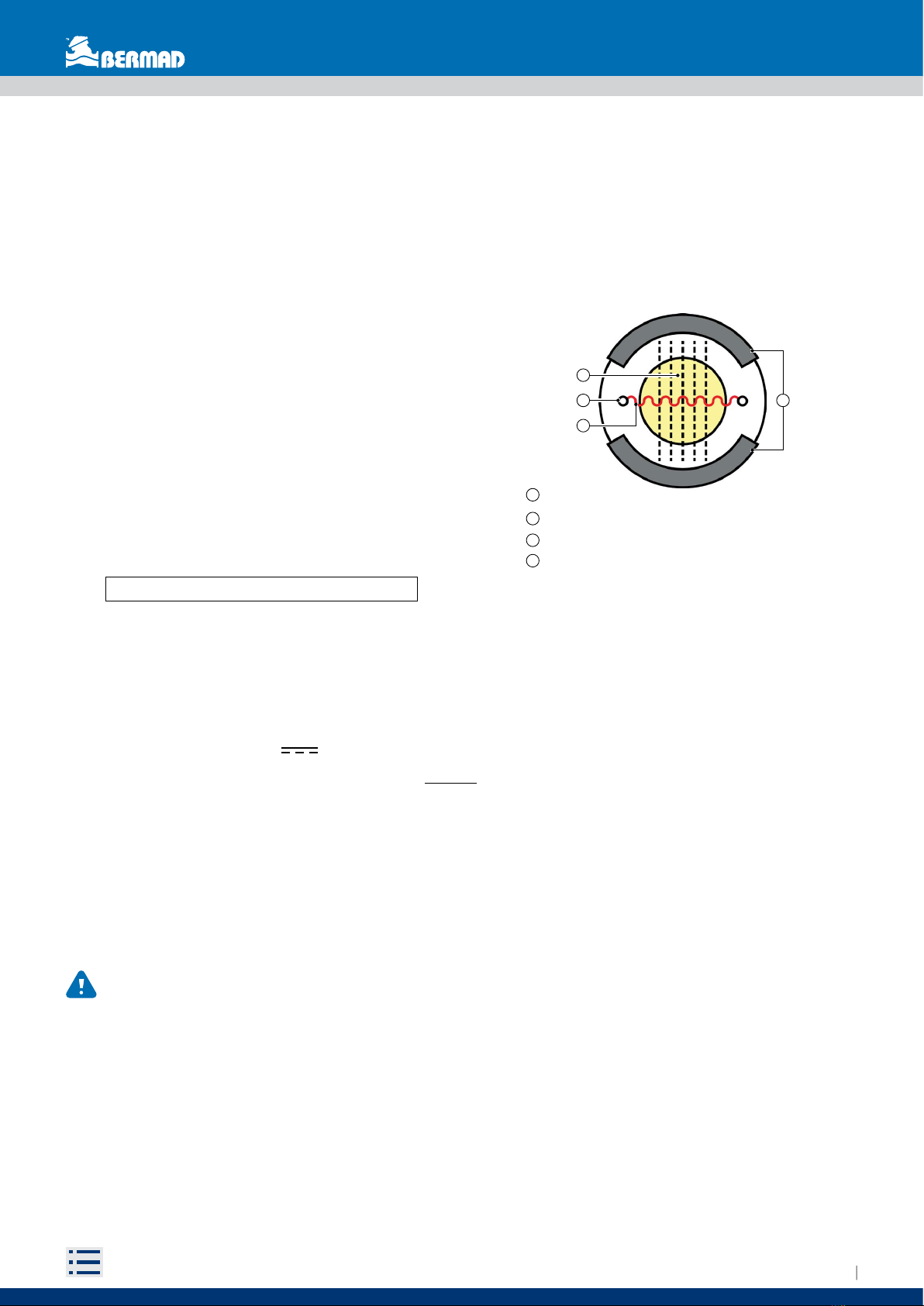

Main parts of the M10 meter are:

Flow tube

Meter enclosure

Battery compartment

Label

Grounding stud

Connection cable/connector

Protective cover

Display

Battery Holder

Grounding Stud

Connection Cable Connector

Flow Tube

Label

FRONT BACK

(Connection cable confiiguration)

BACK

(Connector confiiguration)

Meter Enclosure

Battery Compartment

Positive flow direction Victaulic OGS connection system

Display

Protective cover

TOP SIDE

Instruction Manual

77

The M10 meter is equipped with a magnet for magnetic reed operation.

NOTES:

Electromagnetic flowmeters are designed specifically to operate under the following basic

conditions:

1. The liquid must be conductive

2. The tube must always be completely full

3. The input and output distances must be according to the recommended settings

4. The grounding instructions must be followed

1.4 PRODUCT IDENTIFICATION

Each M10 manufactured by BERMAD has a STANDARD identification plate

(Fig. 1) or MID (Fig. 2), that displays the following information:

STANDARD PLATE:

CE conformity mark.

MODEL: Instrument Model

S/N: Meter Serial Number

Size: Nominal diameter

PN: Pressure class

Qmax: Max flow rate

IP: Degree of protection

12Vdc / Battery: power supply, to be selected during

commissioning

This symbol means that the product must be

disposed of according to the legal requirements.

Fig. 1 STANDARD Identification Plate

Model: M10

S/N: N7K0056

Size: DN80/3”

PN: 16 bar

Qmax: 100 m

3

/h

IP: 68

12VDC

BATTERY

PN: M070080G16PF2AB

M10

Instruction Manual

8

MID IDENTIFICATION PLATE:

CE conformity mark

Model: Instrument Model

S/N: Meter Serial Number

DN80/3”. PN16: Nominal diameter and MAP

Q3: permanent flow rate

R: ratio

∆p: pressure loss class.

M1 O: Environmental Class

E2: Electromagnetic class

T: Non resettable totalizers

P: Resettable totalizers

12Vdc / Battery: power supply, to be selected during

commissioning

Rep.: Date within battery must be replaced

This symbol means that the product must be

disposed of according to the legal requirements.

The identification plate must never be removed, damaged or changed. It must also be kept clean from

any dirt deposits, as the data contained are the only safe and unambiguous way to recognize the type of

flowmeter and it allows to complete the repair request form attached to this manual.

1.5 APPLICATIONS

M10 is widely used for purposes in which it is important to measure the flow rate of electrically

conductive liquids. Examples of typical applications for the M10 meter are:

Irrigation

Greenhouses

Waterworks

DMA District Metered Areas

Leak detection systems

Remote applications without access to electrical grid

Building and Cooling Systems

Fig. 2 MID

M10

S/N: N7K0059

DN80/3” - PN16

R400

T50

∆p16

M1

E1

IP68

PN: M070080G16PF2AB

T: Noon resettable P: Resettable

12VDC

BATTERY

- Rep. mm/aaaa

M21

0122

Instruction Manual

99

2 PRODUCT DESCRIPTION

2.1 OPERATING PRINCIPLE

M10 has been designed with the aim of fulfillment of all the requirements of modern water management

systems, through a flexible and hybrid electronics which, depending on the model, oers various power

supply solutions.

An electromotive force is induced at the ends of a

conducting fluid that moves with velocity v in a magnetic

induction field B and can be expressed as:

e = kBDv

Where it is:

Bis constant by construction;

Dis constant and represents the distance between

the electrodes E1 and E2 (equivalent to the diameter

of the flowmeter);

vis the fluid velocity;

kis the calibration constant;

emf «e» is proportional to the velocity «v»

2.2 POWER SUPPLY

The M10 meter is available with three dierent power supply setup:

Battery-powered via a lithium battery (LiSOCL2)

Mains powered 12Vdc

Mains powered 12Vdc with backup lithium battery

It the case of lithium battery power supply is used; it is necessary to consider the following cautions:

Lithium batteries are the primary energy source because of their high-energy density, and are made to

meet the highest safety standards. However, they can be potentially hazardous if they are exposed to

electrical or mechanical abuse. In many cases, this is associated with excessive heat production in which

the increased internal pressure could lead to cell rupture.

These basic precautions need to be followed when handling and using lithium batteries:

IMPORTANT INSTRUCTIONS!

Do not short-circuit, recharge, overload or reverse-connect the battery

Do not expose the battery to temperatures higher than those specified, as it will incinerate

Do not crush, puncture or open the cells or disassemble the battery packs

Do not weld or solder the battery body or battery packs

Do not expose the contents to water

The use of lithium batteries is regulated under the United Nations Model Regulations on the Transport of

Dangerous Goods (UN Model Regulations on the Transport of Dangerous Goods), document ST/SG/ AC.10/1/

Rev.22.

1 - Electromotive force (proportional to the velocity);

2 - Electrodes;

- Magnetic field;

3

4 - Coils;

1

2 4

3

M10

Instruction Manual

10

These are basic precautions that should be followed during the transport of lithium batteries:

IMPORTANT NOTES!

Transport only in special packages with labels and special transport documents specific to current regulations.

Be careful when handling, transporting and packing the batteries so as to avoid short- circuiting.

The batteries comply with the requirements set out in the “UN Manual of Tests and Criteria, Part III,

subsection 38.3” for air transport and with the provisions of the ADR regulations for transport by truck/ship.

Remove the battery from the transmitter before sending the flow meter to BERMAD in case of maintenance

or of any intervention under warranty.

2.3 DATA SAFETY

The M10 meter guarantee the security of the collected and processed data as a result of the internal

memory (EEPROM) on which the data are saved.

The integrated memory allows the storage of data with 100,000 log lines (the data are kept for more than 6

years with factory settings); when the memory is full, the new data will automatically overwrite the old data.

In order to prevent the loss of saved data, and to be able to better manage it on its management systems,

the unit is supplied with a specialized software that allows users to communicate with the electronics of

the M10 via Bluetooth or RS485 communication interfaces, that can be connected to any PC, laptop and/or

tablet with a Windows operating system, it is also possible to interface with the “Mag-Net” mobile software

in iOS and Android smartphones and tablets.

Fast download, data management, easy programming and an advanced self-diagnosis system, that

automatically perform a wide range of essential checks, make the M10 converter a highly ecient and

irreplaceable tool for fluid detection in water management systems.

A multi-level password system also allows controlled access to the data collected and guarantees confidentiality.

Instruction Manual

1111

3 TECHNICAL SPECIFICATIONS

3.1 OVERALL DIMENSION

The overall dimensions of M10 are shown below.

L2

Di

L3L4

De

L1

L2

Size De L1 L2 L3 L4

DN50 / 2” 60.3 230 100 150 200

DN80 / 3” 88.6 230 100 150 225

DN100 / 4” 114.3 230 100 150 250

DN150 / 6” * 168.3 300 100 210 300

* DN150/6” Version are indicative

M10

Instruction Manual

12

3.2 CERTIFICATES AND APPROVALS

MARKING

The device complies with the requirements of the applicable EU directives.

These are listed together with the applied standards in the relevant

EU Declaration of Conformity.

Electromagnetic compatibility

Directive 2014/30/EU

Harmonised standards: EN 61326-1

Radio Equipment

Directive 2014/53/EU

Harmonised standards:

ETSI EN 301 489-1

ETSI EN 301 489-17

Measurement Instrument Directive

2014/32/EU

Harmonised standards: EN ISO 4064 (OIML 49)

RoHS

Directive 2011/65/EU

Harmonised standards: EN IEC 63000

Other certification and

international standards

ISO 20456: Measurement of fluid flow in closed conduits

OIML R49: Water meters for cold potable water and hot water

OIML D11: General requirements for measuring instruments

EN IEC 60529: Degrees of protection provided by enclosures

Instruction Manual

1313

3.3 GENERAL TECHNICAL FEATURES

The table below contains the technical data of the M10.

Features M10

Structure

Integral Flow meter

DN Range

DN50/2” ÷ DN150/6”

Nominal Pressure

16 bar

Process Connection

Victaulic OGS

Fluid Conductivity

> 20 µS/cm

Process Temperature Range

0 ÷ 80 °C (32 ÷ 176 °F)

Materials in contact with

water

Flow tube: Glass fibre reinforced plastic

Electrodes: AISI316L

Power supply

Battery Powered: 3.6 V Lithium Battery

Mains Powered: 12Vdc (10.8 ÷ 13.2V), max 100mA

Consumption

0,25W÷1W (Mains powered)

Outputs

2 passive outputs (1 programmable), SSR Type (dry contact), galvanically insulated

Max. load +/- 35VDC, 100 mA protected against short circuits, minimum pulse

duration 5ms.

RS458 2 wire /half-duplex

Communication

Modbus RTU Slave

Bluetooth

Display

LCD Segment display, with dedicated status icons, 8+6 digits

User Interfaces

Magnetic reed

Bluetooth Mobile App

Euromag Link Software

Process memory

100,000 data lines

Programmable frequency 1 ÷ 120 minutes (15 minutes factory standard)

Metrological certificate

OIML R49-1:2013 / MID 2014/32/EU - Class 2 (if requested)

Temperature range

Ambient: -20 ÷ 60 °C (-4 ÷ +140 °F)

Process: 0 ÷ 80 °C (32 ÷ 176 °F)

Storage: -40 ÷ 70 °C (-40 ÷ +158 °F)

Technical units

m, m3, l, ML, ft3, gal

Totalizers

5 (2 Positive, 2 Negative, 1 Net)

Alarms and status icons

Status icons displayed and alarms recorded in the data logger

Self diagnostic

Excitation failure

Excessive ambient temperature

Wet electronic board

Low battery level / Mains voltage out of range

Pulses overlapping

Bluetooth communiccation error

Empty pipe

Measurement error

Software/memory malfunction

Mains power interruption

Software for communication

and programming

Bluetooth Mobile App - Mag-Net

Euromag Link Software (trough Bluetooth dongle, or RS485 interface)

Data Protection

Customizable password protection

EEPROM Memory with safe data storage management

M10

Instruction Manual

14

3.4 MEASURING ACCURACY

3.4.1 Reference Conditions:

Measuring liquid: water

Conductivity: >200 µs/cm

Temperature: 20°C

Pressure: 1 bar / 10Mpa

Upstream diameters: ≥ 5 DN

Downstream diameters: ≥ 3 DN

3.4.2 ACCURACY CLASS

ISO 20456: Q1÷Q2: ±0,45mm/s

Q2÷Q4: ±0,5% ±0.35mm/s

ISO 4064/OIML R49: R400 - Class 2

Instruction Manual

1515

3.4.3 MID ANNEX III MI001 DIRECTIVE 2014/32/EU

Flow characteristics

Water temperature class

T50 (+0,1 °C / +50 °C)

Maximum admissible pressure (MAP)

1,6 MPa (16 bar)

Orientation limitation

The sensor can be used in horizontal, vertical or diagonal position.

Flow profile sensitivity class

U0 and D0 (0 x DN upstream and 0 x DN downstream)

Reverse flow

The water meter is designed to measure reverse flow. The reverse flow is recorded on a separate volume

totalization. Also for reverse flow another pulse output is used.

Pressure loss class

∆p 16 (0,016 MPa or 0,16 bar)

Temperature range ambient

0°C/+55°C

Size Ø In and

Outlet [mm]

Flow rates [m3/h]

Minimum

Q1

Transitional

Q2

Permanent

Q3

Overload

Q4

Ratio

Q3/Q1

DN50 / 2” 50 0,10 0,16 40 50 400

DN80 / 3” 80 0,25 0,40 100 125 400

DN100 / 4” 100 0,40 0,64 160 200 400

DN150 / 6” 150 1,00 1,60 400 500 400

M10

Instruction Manual

16

4 INSTALLATION

4.1 STORAGE AND MOVING

4.1.1 Storage

To ensure the correct maintenance of the device while waiting for its installation, it is necessary to comply

with the storage provisions below:

1) Store the device in a dry place and protected from dust

2) Keep away from direct and continued sunlight

3) Keep the device in the original packaging until it is used

4) Temperature of the storage place: -40 ÷ +70 °C (-40 ÷ +158 °F)

4.2 GENERAL INSTALLATION REQUIREMENTS

IMPORTANT NOTE! THE SENSOR MUST ALWAYS BE COMPLETELY FULL OF LIQUID!

4.2.1 Vibrations

DO NOT expose the flowmeter to vibrations and/or movements that could aect its performance and

duration.

Install a suitable anti-vibration protection if vibrations occur.

AVOID EXCESSIVE

VIBRATIONS

AVOID EXCESSIVE

VIBRATIONS

AVOID EXCESSIVE

VIBRATIONS

Fig. 3 The pipe must always be completely full of liquid

Fig. 4 Avoid vibrations

Fig. 5 Installation with anti-vibration protections

Instruction Manual

1717

4.2.2 Magnetic fields

AVOID exposing the flowmeter to strong or nearby magnetic fields.

Fig. 6 Avoid magnetic fields

4.2.3 Negative pressure

Avoid vacuum conditions in the pipe. They can damage the coating of the flowmeter and move the electrodes

from their correct position.

4.2.4 Protection from direct sunlight

Protect the flowmeter if exposed to direct sunlight.

Fig. 7 Avoid direct exposure to sunlight

4.2.5 Operating temperatures

For normal and ecient operating of the flowmeter:

The ambient temperature must be limited within the range of (-25 ÷ +60) °C, (-13 ÷ +140) °F.

Fig. 8 Environment and fluid temperature limits

The process temperature must be limited within the range of (0÷ +80) °C, (32 ÷ +176) °F.

N S

N S

N S

M10

Instruction Manual

18

4.3 INSTALLATION CONDITIONS

4.3.1 Positioning in relation to the plant

To ensure optimal working conditions, the flowmeter must be installed correctly inside the system.

Correct and incorrect installation positions are described and illustrated below.

The flowmeter must remain below the hypothetical blue line (level line), which connects the two levels of

fluid to be measured (Fig. 9).

NOTE: Avoid placing the flowmeter above the piezometric level line (Fig. 10).

4.3.2 Important guidelines for correct installation

The M10 meter is designed to have the IP68 protection degree only when properly closed and tightened.

The manufacturer does not assume any responsibility for an improper closing by third parties.

For correct working conditions, please follow the important guidelines shown in the following figures.

Improper installation may result in an inaccurate measurement.

For partially filled pipes or with downward flow and free exit, the flowmeter should be placed in a

U-shaped tube (Fig. 11).

Fig. 9 Correct position Fig. 10 Incorrect position

Ideal installation

Fig. 11 Installation on U-shaped tube

Installation in limited spaces

Instruction Manual

1919

“T” connection upstream of the flowmeter

Fig. 12 Installation near "T" connection

Three-dimensional curves

Fig. 13 Installation near three-dimensional bends

IMPORTANT NOTE: THE SENSOR MUST ALWAYS BE COMPLETELY FULL OF LIQUID!

To ensure that the sensor is always completely filled with liquid, it is important to install it in the correct

position () and avoid all possible incorrect positions ().

This installation ensure that the

sensor is full of liquid.

This installation DOES NOT guarantee a

pipe full of liquid.

Fig. 14 Correct installation Fig. 15 Incorrect installation

M10

Instruction Manual

20

We recommend installing the sensor on a vertical/sloped pipe with an upward flow direction (Fig. 16) to

minimize the wear and deposits in the sensor. Avoid the installation on vertical pipes with free exit (Fig. 17).

Fig. 18 Correct (LH) and incorrect installation (central and RH)

Fig. 16 Correct position Fig. 17 Incorrect position

The position on the left ensure

that the sensor is full of liquid.

Central and right positions DO NOT

guarantee a pipe full of liquid.

Table of contents

Other BERMAD Measuring Instrument manuals