© 2005 - Bernard Burton DRAFT 8

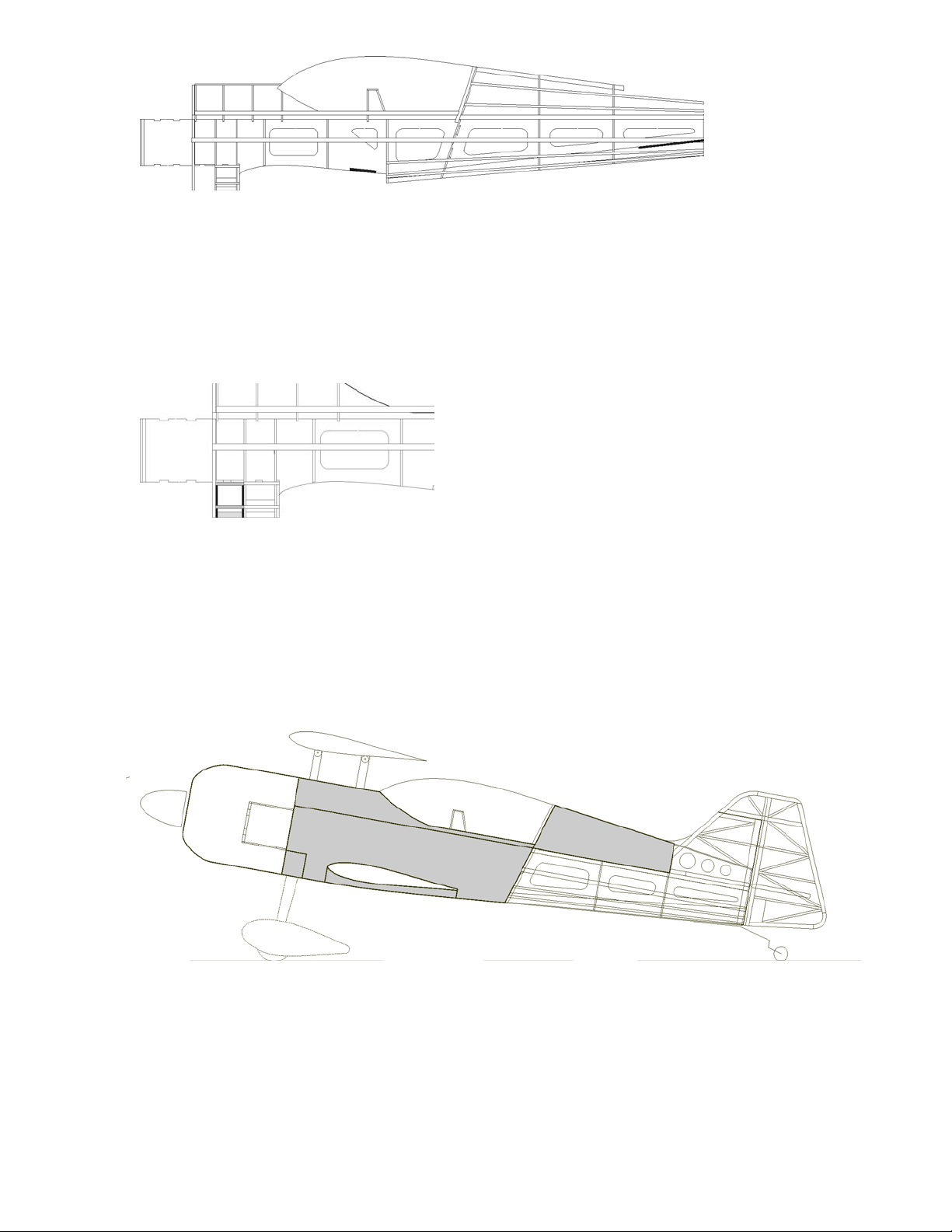

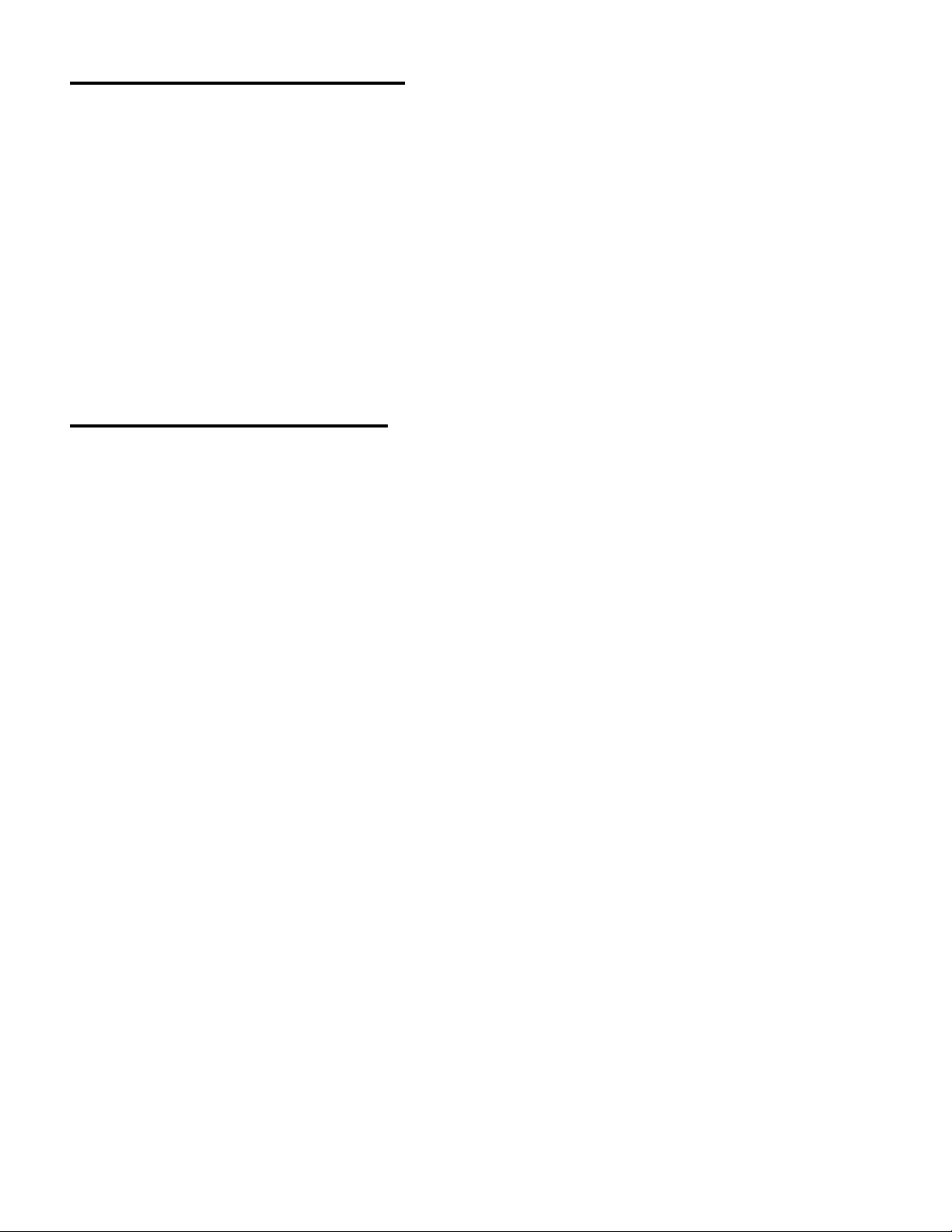

Upper wings:

Step 1: Prepare the top left wing:

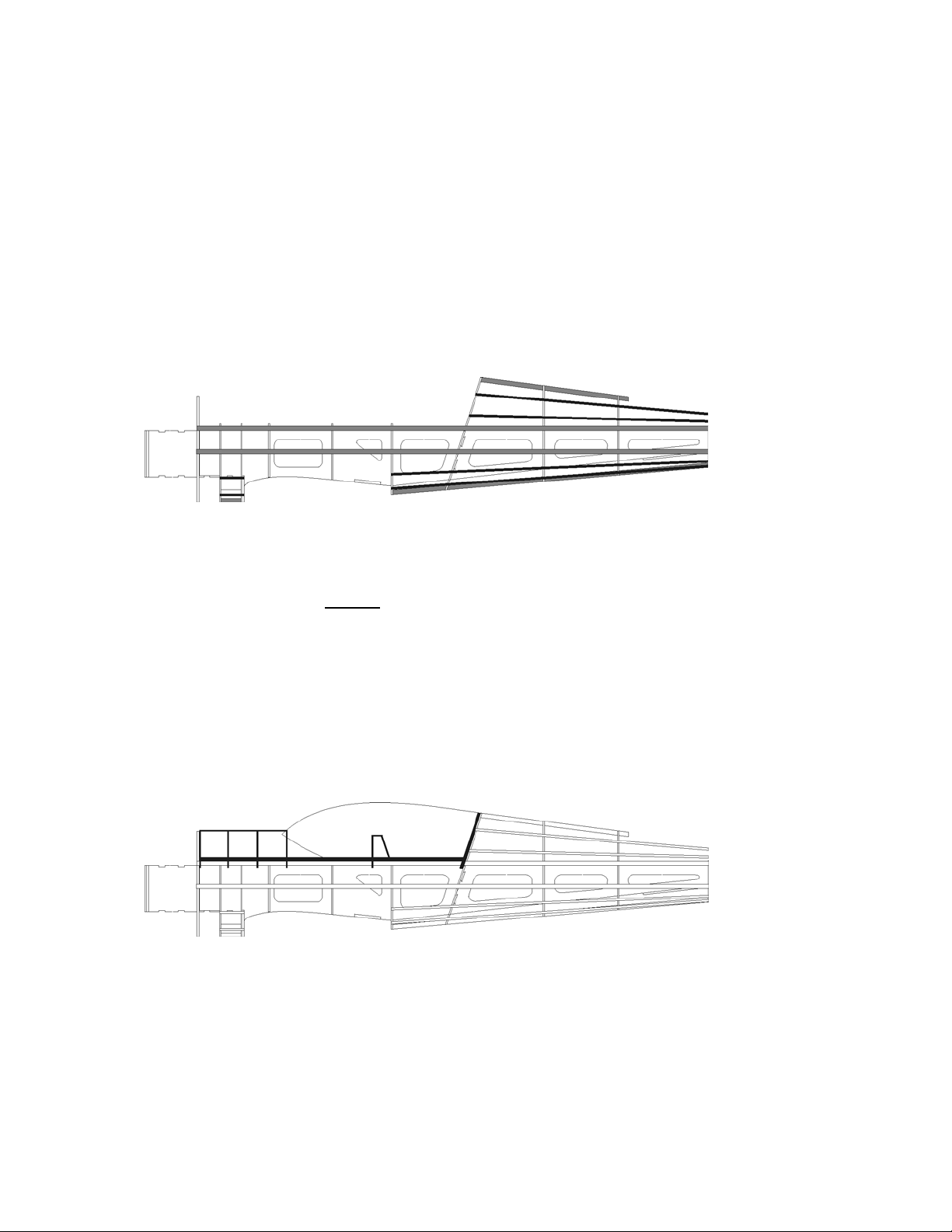

- On a flat workbench, prepare & protect your plan.

- Pin the lower main spar on the plan

- Glue all the wing ribs on the lower main spar (Hard wood 10x10 mm) according the

plan. W1-W2-W3-W4-W9 should be glued with 30’ epoxy. Other ribs can be glued

with polyurethane glue. Pin the rear rib alignment tabs on the workbench to

guarantee a straight wing trailing edge

- Proceed with the upper main spar (Hard wood 10x10 mm) as well as with the top 5x5

mm balsa spars

- Glue the 10x10 mm Balsa leading edge and the balsa trailing edge

- Proceed with all remaining 5x5 mm balsa spars (upper & lower)

- To prevent wing torsion, glue 2 mm balsa re-enforcement between the upper and

lower main spars (vertical fiber direction)

- Cover the wing with 2 mm balsa sheet according the plan

- Glue the rib caps.

- Prepare the servo support assembly and glue it in place. Consider that the servo arm

is on the lower side of the wing

- Install the optional wing tip if required. Use the small balsa square triangles to re-

enforce the wing tip fixation.

- Prepare the aileron: pin a 2mm balsa sheet according the plan. Glue the aileron ribs

(small & long triangles). Re-enforce at the position of the control horn. Put the leading

edge spars (square & triangle) and cover the top with a 2 mm balsa sheet.

- Put a wire in the wing to ease the servo wires installation at a later stage.

- When the glue is fully cured, remove the wing & aileron from the workbench

- Glue W9a & W9b plywood ribs on W3 & W9 with 30’ epoxy. The tabs should be

placed on the lower side of the wing

- Remove the rib alignment tabs. Except the W1 & W9 alignment tabs.

- If your job is well done, the wing should rest on the four wing fixation tabs and stay

perfectly straight.

- Continue to cover the wing with 2 mm balsa sheet according the plan but ensure that

you can still access W1-W2-W3-W4 ribs to glue the wing tubes at a later stage.

Step 2: Prepare the top right wing following the same instructions as here above.

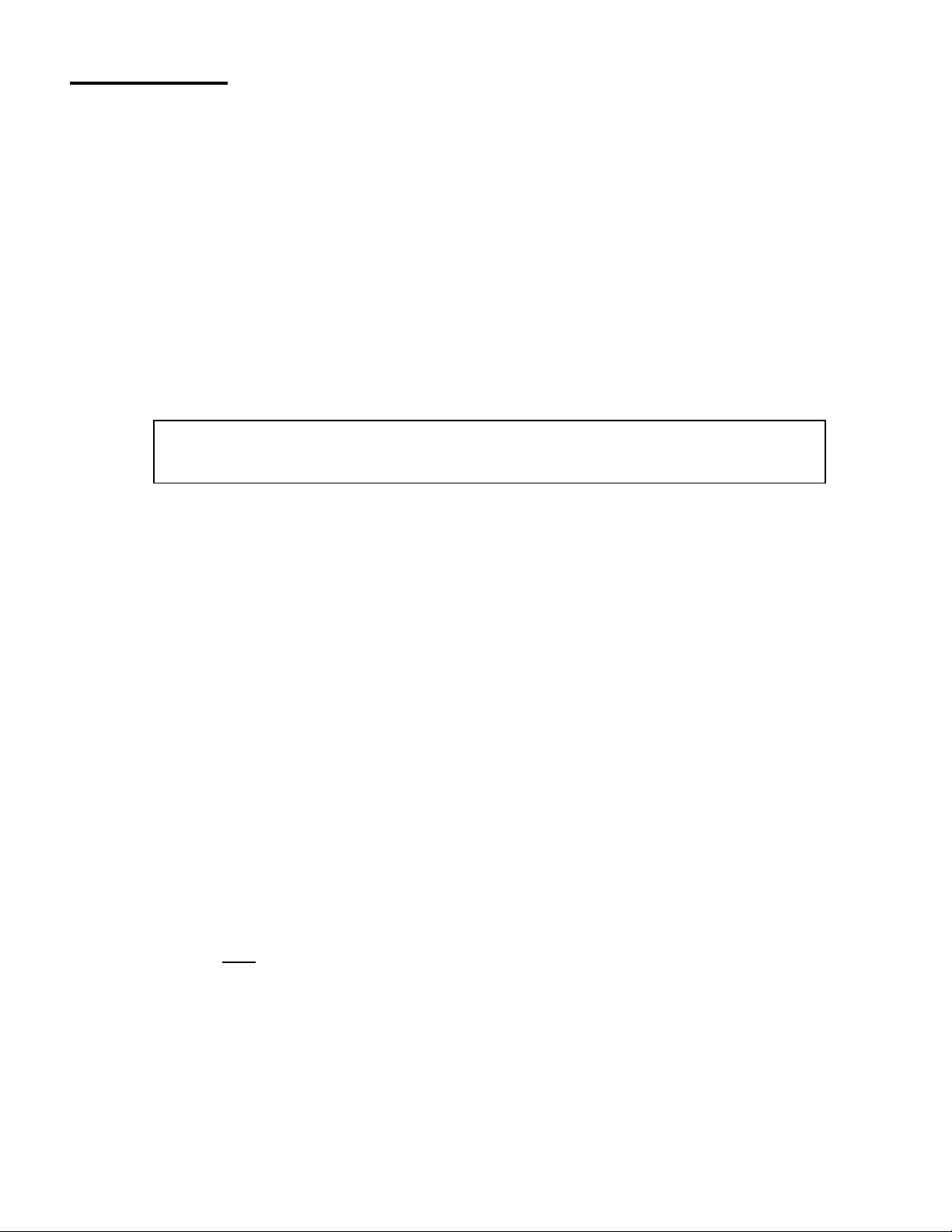

Step 3: When the right & left upper wings are ready, proceed as follow:

- On a flat workbench, align the wings and glue the right & left half wing tube sockets in

place with the aluminum tube inside. Do not glue the aluminum tube in their sockets.

Note: a dry assembly could be required to ensure a perfect alignment before gluing.

- Verify and eventually adjust the alignments before the glue cures

- Close the right & left wings with the remaining 2mm balsa sheeting

- Remove the remaining alignment tabs.

-

- Glue the remaining rib caps

- At this stage, the wings alignment should be perfect: straight & not twisted. The eight

wing fixations tabs should rest on the workbench without any constrains.

- Sand the leading edges.

- Your top wing is ready.

Note: During the previous steps, always verify and eventually adjust the

alignments before the glue cures.