Bertolini Australasia EZI-SPOT User manual

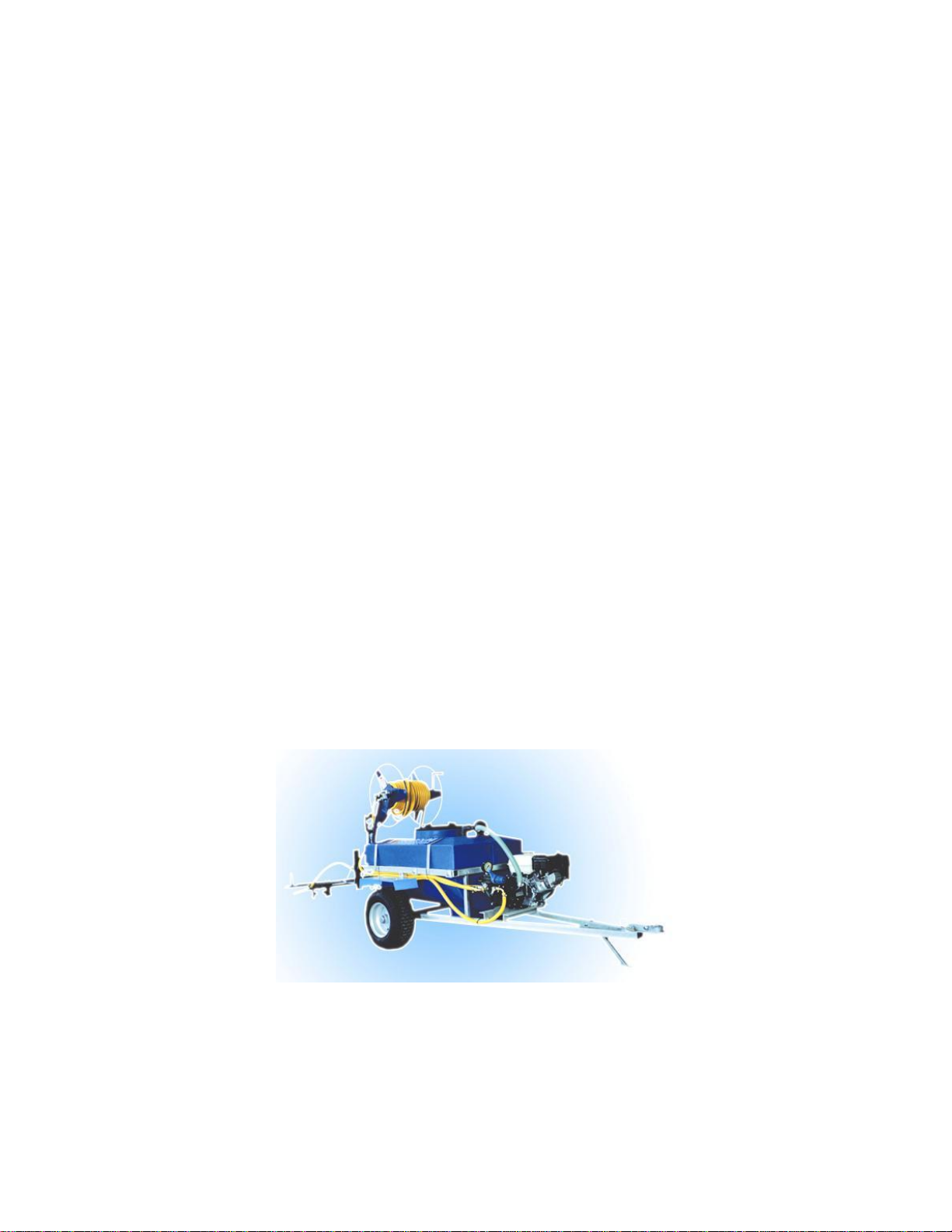

EZI-SPOT

TRAILED

SPRAYER

Bertolini Australasia Warranty Policy

Bertolini Australasia warrants the owner that it will repair or replace without charge parts found

defective or malfunctioning in accordance with the warranty limitation and adjustment schedule below.

This Warranty covers

Only conditions resulting from defects in workmanship or material under normal use and service.

This warranty does not cover

Conditions resulting from misuse, negligence, alteration, accidental damage or failure to perform

normal maintenance services.

Any product which has been repaired by an unauthorised Bertolini Australasia service outlet which

adversely affects its performance and reliability in any way is the sole and absolute judgment of

Bertolini Australasia.

The replacement of lubricating oil, filters and belts made in connection with normal maintenance

services.

Lost time, inconvenience, loss of use of the product or other consequential damages.

The repair of defective products qualifying under this warranty will be performed by any authorised

Bertolini Australasia service outlet within a reasonable time following the delivery of the product at the

cost of the owner, to the service outlets place of business. The product will be repaired or replaced

using new parts sold by Bertolini Australasia.

The owner is responsible for the performance of regular maintenance services as specified in the

owner’s operator manual applicable to the product.

This warranty is the only warranty applicable to Bertolini Australasia’s new products and, to

the maximum extent permitted by law, is expressly in lieu of any other warranties expressed

or implied, including any implied warranty of merchantability or fitness for a particular

purpose.

Bertolini Australasia does not authorise any person to create for it any other obligation or

liability in connection with these products.

Bertolini Australasia shall not be liable for incidental or consequential damages resulting from

a product performing in breach of the written warranty.

Given continuous product development, Bertolini Australasia reserves the right to change

specifications and design without notice.

All products

Private Domestic Use 12 months

Private and Commercial Agriculture 12 months

Agricultural Contractors 6 months

All Non-Agricultural Applications 3 months

This warranty period will begin on the date the product is delivered to the first retail

purchaser.

EZI-SPOT TRAILED SPRAYERS

By Bertolini Australasia

Bertolini Ezi-spot portable sprayers are available in 30, 50, 100 and 200 litre versions

Whether you are a commercial grower or home gardener, you will find many uses for this unit. The

tank, pump and wand fittings are corrosion resistant and are suitable for applying weedicides,

herbicides, insecticides, fungicides, miticides, and green formulations. The unit is designed for spot-

spraying but may be used in conjunctions with a boom for boom spraying.

Please read the safety instructions on page 2 before installing or operating the Ezi-spot sprayer

Specifications

Pump

Shur-flo 8000 series, 12 DC electric, 6.8 litres per

minute open flow, on demand electric pressure

switch.

Hose

6 metre delivery hose standard.

Lance

Lightweight lance with adjustable nozzle pattern.

Tank

The 30, 50 and 100 litre blue translucent tanks are

made from UV stabilized and impact resistant

polyethylene. The screw on lid incorporates an

anti-spill breather.

Filtration

Teejet AA122 line strainer.

Controls

On/Off power switch. The pump is fitted with an

automatic electric pressure sensing switch which

automatically starts the pump when the pressure falls

below 40 psi and stops the pump when the pressure

reaches 60 psi.

Regulator and tap

Three way for operator to choose gun or boom

spraying. Pressure regulator to enable correct

pressure setting when boom spraying

Trailer

Robust steel construction, Powdercoated (BAT100)

or galvanised finish. Large pneumatic wheels,

mudguards and 1 7/8” to coupling (excludes

BAT100)

Connection to 12 volt DC supply

The sprayer requires 12 volt DC power source.

A 2 metre loom is provided to allow the sprayer to

be connected to the 12 volt DC available. The red

wire is positive and the black is negative. An on/off

switch is fitted to the sprayer to allow the sprayer to

be disconnected from the 12 volt source to prevent

accidental drain of power. The switch also allows

the pump to be shut down when the tank is empty

preventing overheating and damage to the pump. It

is recommended that if installing the sprayer on an

ATV or any vehicle that a 10 amp fuse be installed

to prevent any potential damage to the electrical

system on the vehicle. Consult your vehicle

instruction manual for the correct electrical

connection.

Fitting instructions

Position the sprayer so as to minimize contamination

of the operator. With the pump away from the

operator the risk of contamination due to hose failure

can be minimized. It is recommended that the

sprayer be securely attached to any ATV or other

vehicle with the tie down straps provided (BAM30

and BAM50 models only). When fitted, these

should be firmly secured to approved attachment

points on the ATV or other vehicle. The sprayer

should be mounted centrally as near to the centre of

the gravity of the ATV as possible. It should

protrude so as to not cause an obstruction. Refer to

manufacturer’s instructions for appropriate load

limits and fitting instruction. Never fill the tank to

beyond the vehicle’s weight limits.

Ezi-Spot Installation and Instruction Sheet

Operating Instructions

Fill the sprayer with clean water.

Check suction line strainer for dirt or damage.

Connect pump and ensure it primes correctly,

holding the spray lance trigger on until it sprays

steadily.

Check all pipes, hoses, hose clamps and connections

for leaks or damage.

Gun Spraying

When gun spraying ensure the three way tap is

turned to hand gun position, turn on pump. While

gun spraying the pump operates on a pressure

switch. When outlet pressure drops (gun trigger

open) below the preset limit, the switch will close

and the pump operates until the shut-off (gun trigger

closed) high pressure is achieved. Depending on

nozzle setting, cone pattern or straight jet the pump

may cycle on and off, this is normal pressure switch

operation. The shut-off pressure is set to factory

calibrated standards and should not be re-adjusted.

Shutdown and Storage

Check the chemical manufacturer’s label for

disposal of chemical. Drain the excess material

from the tank. Select an appropriate place (one that

will not endanger animals or the environment) for

cleaning and flushing the system.

Flush tank, pump and hose until they flow clean.

This prevents build up of residues in hoses and

pump valves. If heavy frosts are experienced, run

the pump to make sure pump and spray lines are dry.

This will prevent water freezing in the pump or

spray lines and damaging the sprayer.

Boom Spraying

To apply chemical accurately is the key to getting

the job done correctly without under or over

applying, and thus saves you money.

Step one is knowing your real vehicle speed. To

measure your real vehicle speed do the following

Measure a distance of 50 metres using a tape

measure.

Mark these points so they can be clearly seen

when driving past in your vehicle. The starting

point should be far enough so that you are at

spraying speed as you pass the start point.

Time how long it takes in seconds to travel

between the start and finish points.

Divide 180 by the number of seconds it took to

pass between the start and finish points, this last

figure is your speed.

Eg. 180 18 seconds = 10 Your spraying speed

is 10 kmp/h.

Once you know your correct spraying speed you

can look at the nozzle chart.

To read the chart look first along the top to

select your vehicle speed. Eg 10kmp/h

Then come straight down the column below the

selected speed to the volume in litres per hectare

you wish to apply eg. 115 l/ha.

Look to the left of this figure (eg115) till you

are below the column marked “Bar”, you will

see that you need to spray at 2 bar pressure

(30psi).

Look left again and you are looking at a box

with nozzle types (DG, TP, XR etc). For this

example it works out that any of these nozzles

in size ….03 is the correct nozzle to use at this

required rate per hectare at 10 kmp/h.

For normal pasture spraying the nozzle should

be 500mm (1/2 metre) off the ground.

The lower pressuer the better as you will get

less spray drift –2 bar (30psi) is standard

practice.

Remember that 10 % difference in speed means

either under or over applying chemical.

Nozzles should be replaced as routine

maintenance at the end of the spraying season.

For information on spray drift, droplet size, or

specialist spray information please ask your

Bertolini Dealer for a current TeeJet Spray

Products Catalogue. Assistance on how to read

the chart will be given if required. If you don’t

have a Bertolini Dealer close by please call

Bertolini on 07 847 7950 and ask for a

catalogue to be sent out.

Care and Maintenance

Always fill the sprayer from a clean water source.

The line strainer should be checked and cleaned if

necessary each time the tank is filled. Appropriate

protective equipment should be used whenever

maintenance is carried out.

Shutdown and Storage

Check the chemical manufacturer’s label for

disposal of chemical. Drain the excess material

from the tank. Select an appropriate place (one that

will not endanger animals or the environment) for

cleaning and flushing the system. Flush tank, pump

and hose until they flow clean. This prevents build

up of residues in hoses and pump valves. If heavy

frosts are experienced, run the pump to make sure

pump and spray lines are dry. This will prevent

water freezing in the pump or spray lines and

damaging the sprayer.

General Guidance

Do Spray:

Only after reading this instruction manual

carefully and following the advice given.

With pump pressures as low as possible

consistent with chemical container label

conditions and nozzle type.

With nozzles that reduce spray drift to a

minimum.

With booms as close to the ground as

practicable.

With the wind at right angle to the direction of

travel and turn into the wind so as to reduce

spray drift to a minimum.

Using the correct personal protective equipment

specified on the chemical containers label.

Don’t Spray:

With booms higher than is necessary, and no

more than about one metre above the ground.

In a figure eight or similar pattern.

Unless you have been trained to spray using an

ATV.

Holding the spray lance while driving the ATV.

Warnings

You need to read carefully and take note of the

following warnings before attempting to operate or

install this sprayer. Failure to comply with these

warnings may result in serious injury or death.

Warning!!! This sprayer is designed and

manufactured solely for the purpose of applying

agricultural chemicals to crops. Under no

circumstances may it be used for any other purpose.

Warning!!! Prior to sprayer usage, all users and

operators must have read and fully understood the

contents of this operator’s manual.

Warning!!! Refer to the chemical manufacture

labels for correct use and safe handling instructions

of chemicals before use.

Warning!!! Never allow inadequately trained

personnel to attach or operate the sprayer.

Warning!!! Read this entire instruction manual

together with the installation procedures before

attempting to install or operate the sprayer.

Warning!!! Before carrying out any maintenance

work wash the sprayer thoroughly. Remove all toxic

chemicals that may contaminate the machine.

Warning!!! Do not exceed the vehicle or tractor

manufacturer’s specific safe load carrying and

towing capacities.

Warning!!! Do not point the spray gun at a

human’s body as high pressure spray may cause

serious bodily harm.

Bertolini Australasia

32-36 Ellis St

P O Box 5272

Hamilton

NEW ZEALAND

Phone: (07) 847 7950

Fax: (07) 847 7960

TROUBLE SHOOTING FOR 12 VOLT SHURFLO DIAPHRAGM PUMPS

Problem

Probable Cause

Remedy

Pump starts but doesn’t prime

Low Voltage

No liquid / low liquid

Check electrical connection

Food filter (if fitted) not fully

submerged.

Check liquid level

Check suction hose for kinks

Air leak in inlet line

Damaged / sticky valves

Debris in pump

Check fittings and o ring

Replace / clean valves

Clean filter

Check for debris in bottom of

tank

Blocked Filter

Worn or dislodged valve

Suction / delivery line

Clean / replace

Replace o rings

Fit lines to correct ports or fitted

vice-versa.

External leak from pump head

Ruptured diaphragm

Piston screw loose

Piston screw cross threaded

Replace diaphragm

Tighten piston screws

Re-thread and fit new screw

Suction Leak

Pinched diaphragm

Cracked upper housing

Inlet fitting loose

Cracked valve housing

Replace diaphragm

Replace upper housing

Tighten fitting

Replace valve housing

Pump running rough or noisy

Faulty motor

Loose body screws

Broken magnet inside motor

housing

Damaged bearing

Replace motor

Tighten screws

Replace motor

Replace bearing

Low Performance

Blocked filter

Improper voltage

Worn / damaged valves

Loose fasteners

Clean / replace

Check wiring and connections

Replace valves

Tighten fasteners

Pump will not start

Motor faulty

Loose / contaminated connection

Failed pressure switch

Damaged / worn brushes /

broken brush spring

Blown main fuse

No power to pump

Replace motor

Check all connections

Replace broken pressure switch

Replace brush housing assembly

Replace fuse

Check power source and all

connections

SERVICE BULLETIN

SHURFLO PUMPS

A number of 12 volt diaphragm pumps are being returned to Bertolini for repair and / or suspected

warranty replacement.

In many instances the problems identified were minor and could be easily rectified.

To facilitate on the spot assessments and rectifications, the above Trouble Shooting information has

been provided for your use.

These checks need to be performed prior to submission of suspected warranty claims or requests for

replacement pumps.

If further assistance is required please contact our customer service staff on 07 847 7950.

OTHER USEFUL INFORMATION

PRESSURE OPERATION SWITCH (IF EQUIPPED)

The pressure switch reacts to outlet pressure and interrupts power at the preset shut-off pressure

indicated on the pump label. When outlet pressure drops below the preset limit, the switch will close

and the pump operates until the shut-off (high) pressure is achieved. The shut-off pressure is set to

factory calibrated standards and shouldn’t be re-adjusted.

MOUNTING

The pump may be mounted in any position. However, if mounting the pump vertically the pump head

should be in the down position so that in the unlikely event of a leak, fluid will not enter the motor.

Table of contents