4

one-minute warm-up and self-zeroing sequence

when it is first turned on in fresh air. The alarm of

the instrument may very loud without contact any

gas. That is caused by the high Tic Rate preset in

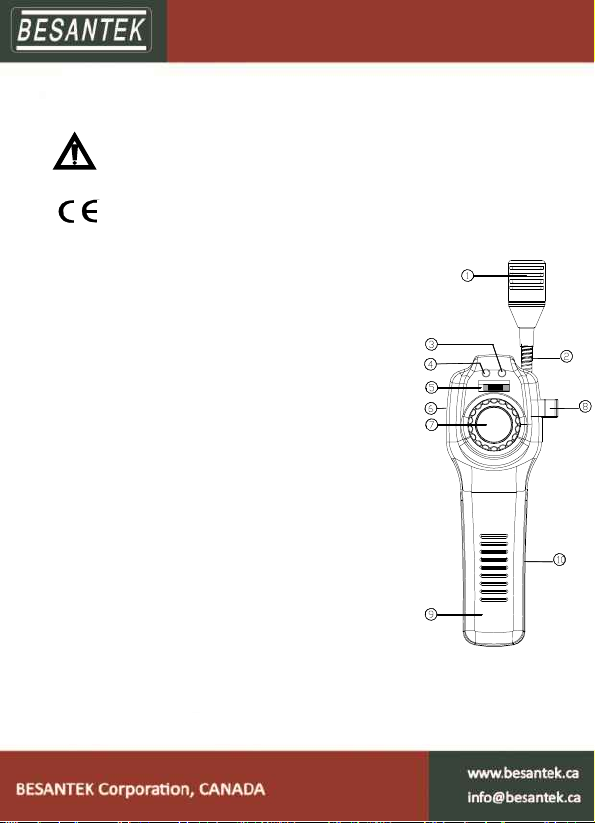

rotary wheel.

Rate (Sensitivity) Adjustment

Each time the instrument is put into service, you

should conduct a quick functional test. Adjust the

Tic Rate to non-alarm level. Then, simply expose

the sensor to a known leak, like a cigarette lighter,

or pass the probe over a drop of combustible fluid.

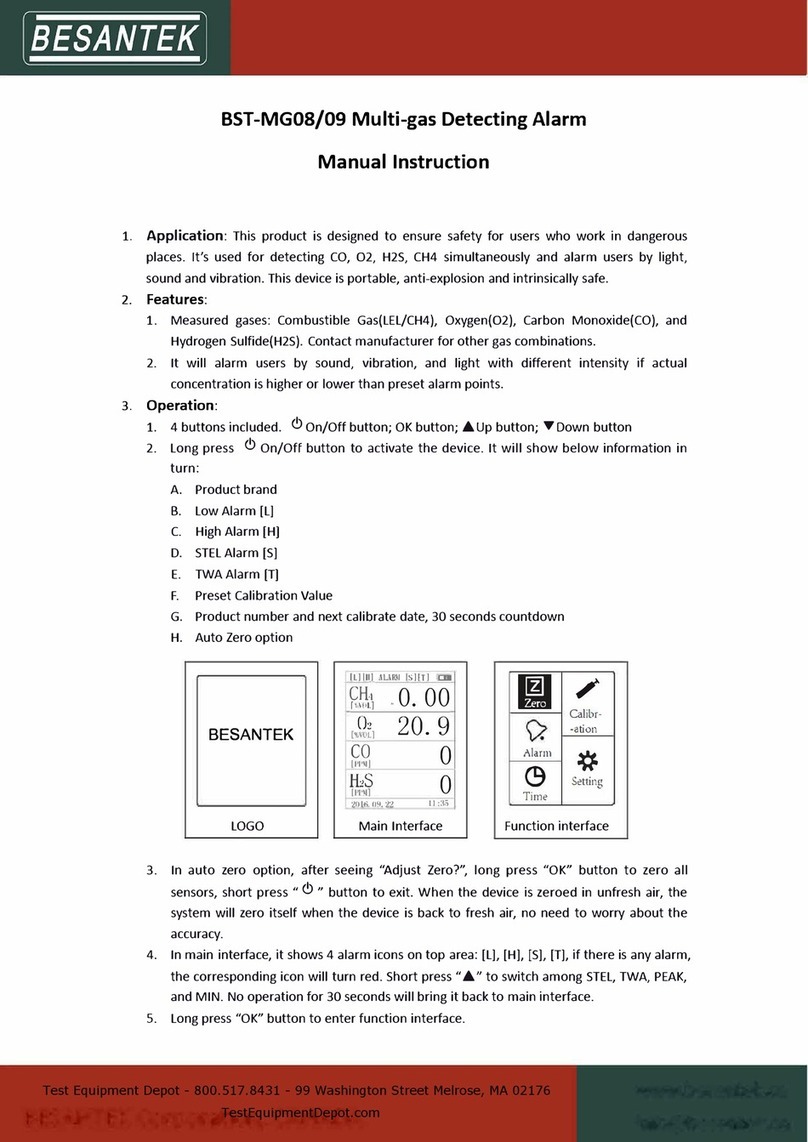

After the initial warm-up, the instrument can be used

to detect combustible gasses. When the sensor in

the probe tip detects a combustible gas, the tic rate

will increase and the instrument sounds a warbling

tone while the ALARM light. As the concentration of

gas increases so does the tic rate.

If the situation calls for quiet operation, or if

background noise makes it difficult to hear the

built-in speaker, you can use an earphone. The jack

is at the top of the instrument. Note that listening to

the alarm or tic through the earphone is very loud.

If the READY light is off, the batteries are low. They

should be replaced immediately. Low batteries will

adversely affect the instrument’s reliability. See the

replacement procedures.