CGS TFT Owner's manual

Installation, Operation & Maintenance Manual Merlin Detector-TFT

IOM Iss: 1 05-21 1

Gas Detector TFT

Addressable Safe Area Fixed Gas Detector

Installation, Operation & Maintenance

Please read this manual carefully and retain for future use.

CGS supply a range of remote gas detectors including carbon monoxide (CO), natural gas/methane (NG), liquid

petroleum gas (LPG) and also oxygen (O2) that are compatible with our range of Merlin control panels connecting up

to 16 detectors (control panel dependant) per cable run to monitor gas levels/hazards in safe areas.

The information contained within this manual should be referenced for typical installation and operation only.

For specific requirements that may deviate from the information in this manual –contact your supplier.

Installation, Operation & Maintenance Manual Merlin Detector-TFT

IOM Iss: 1 05-21 2

Contents

Important Warning Statements ...........................................................................................3

Installation.............................................................................................................................4

Typical Location & Positioning..........................................................................................................4

Access & Mounting ............................................................................................................................5

Internal Board Overview ....................................................................................................................5

Wiring a Detector (GDP2X or GDPX+ Control Panel)....................................................................6

Creating a Detector Chain.................................................................................................................6

Detector ID Switches .........................................................................................................................7

120ohm Termination Resistance ......................................................................................................7

Wiring a Detector (GDP2 or GDP4 Control Panel).........................................................................8

Wiring your Detector (Merlin ‘S’ Control Panels) ...........................................................................8

Audible Alarm Switch.........................................................................................................................8

Factory Set Condition ........................................................................................................................8

Installation Tips ...................................................................................................................................9

Operation ..............................................................................................................................9

Initial Power-Up (Commissioning) ....................................................................................................9

Digital Indication ...............................................................................................................................10

Alarm Set Points ...............................................................................................................................10

General Maintenance .........................................................................................................10

Cleaning.............................................................................................................................................10

Manual Circuit Simulation Test.......................................................................................................11

Bump Test (Gas Response Check) ................................................................................................11

Service & Field Calibration ................................................................................................12

Overview............................................................................................................................................12

Annual Service Message .................................................................................................................12

Service Mode (GDP2X & GDPX+)..................................................................................................13

Field Calibration................................................................................................................................13

End of Operational Life (EOL).........................................................................................................14

Specification .......................................................................................................................15

Installation, Operation & Maintenance Manual Merlin Detector-TFT

IOM Iss: 1 05-21 3

Important Warning Statements

Please take the time to thoroughly read these instructions which should be retained for future reference.

Detectors are shipped pre-calibrated and configured.

The expected lifetime of a gas sensor is 3-10 years upon initial power up dependant on your target gas and environmental

factors. The device will display a message to indicate this time and should immediately be replaced.

It is recommended that this device be commissioned upon installation and serviced annually by a competent person.

Do not apply lighter gas or other aerosols to the device –this will cause extreme damage to the sensors.

High concentrations of alcohol found in many products may damage, deteriorate or affect the gas sensing elements.

This device is designed to detect the gas type displayed on the screen only.

It is not designed to detect smoke, fire or other gases and should not be used as such.

This device provides early warning of the presence of gas, usually before a healthy adult would experience symptoms. This

warning is possible provided your alarm is installed and maintained in accordance with this manual.

Never ignore your device when in alarm.

This device requires a continual supply of electrical power –it will not work without power.

This device should not be used to substitute proper installation, use and/or maintenance of fuel burning appliances

including appropriate ventilation and exhaust systems.

Multiple detectors may be required to adequately protect property and persons.

This device does not prevent dangerous gasses from occurring or accumulating.

Actuation of your alarm indicates the presence of dangerous levels of gas.

The device is not intended for use in potentially explosive atmospheres.

Seek fresh air supply and contact your local gas emergency service should you suspect a gas leak.

This unit may not fully safeguard individuals with specific medical conditions. If in doubt, consult a doctor/physician.

Your product should reach you in perfect condition, if you suspect it is damaged, contact your supplier.

Manufacturer’s Warranty

Warranty coverage: The manufacturer warrants to the original consumer purchaser, that this product will be free of defects in

material and workmanship for a period of three (3) years from date of purchase or one (1) years for oxygen detectors.

The manufacturer’s liability hereunder is limited to replacement of the product with repaired product at the discretion of the

manufacturer. This warranty is void if the product has been damaged by accident, unreasonable use, neglect, tampering or other

causes not arising from defects in material or workmanship. This warranty extends to the original consumer purchaser of the

product only. Warranty disclaimers: Any implied warranties arising out of this sale, including but not limited to the implied

warranties of description, merchantability and intended operational purpose, are limited in duration to the above warranty period. In

no event shall the manufacturer be liable for loss of use of this product or for any indirect, special, incidental or consequential

damages, or costs, or expenses incurred by the consumer or any other user of this product, whether due to a breach of contract,

negligence, strict liability in tort or otherwise. The manufacturer shall have no liability for any personal injury, property damage or any

special, incidental, contingent or consequential damage of any kind resulting from gas leakage, fire or explosion. This warranty does

not affect your statutory rights. Warranty Performance: During the above warranty period, your product will be replaced with a

comparable product if the defective product is returned together with proof of purchase date. The replacement product will be in

warranty for the remainder of the original warranty period or for six months –whichever is the greatest.

Information on waste disposal for consumers of electrical & electronic equipment.

When this product has reached the end of its life it must be treated as Waste Electrical & Electronics Equipment (WEEE). Any

WEEE marked products must not be mixed with general household waste, but kept separate for the treatment, recovery and

recycling of the materials used. Please contact your supplier or local authority for details of recycling schemes in your area.

At the end of their working life, electrochemical sensors for oxygen and carbon monoxide detectors should be disposed of in an

environmentally safe manner. Alternatively they can be securely packaged and returned to CGS clearly marked for disposal.

Electrochemical sensors should not be incinerated as this may cause the cell to emit toxic fumes.

Installation, Operation & Maintenance Manual Merlin Detector-TFT

IOM Iss: 1 05-21 4

Installation

Typical Location & Positioning

Our detectors should be installed in safe areas only at risk of gas leaks e.g. over boilers, valves or meters. Take in to

account the design of the air flow patterns within the zone area.

Detectors should be installed in the correct orientation, as recommended, and ease of access should be accounted

for to allow for any servicing, recalibration and other forms of maintenance.

Consider the coverage required, application and function of the area. Emphasis should be placed on airflow patterns,

correct placement and not perceived detection ranges. The target gas will only be identified when contact is made

with the sensing element itself.

Maximum Gas Detectors per Merlin Panel

Merlin ‘S’ Range

1 Detector

Merlin GDP2

Merlin GDP4

6 Detectors (2 Zone Panel –LED Indication)

12 Detectors (4 Zone Panel –LED Indication)

Merlin GDP2X

Merlin GDPX+

8 Detectors (2 Zone Panel –Digital Indication)

16 Detectors (4 Zone Panel –Digital Indication)

Avoid conditions of any other environmental factors that could potentially impede the accuracy and operation of the

detectors such as; condensation; vibration; temperature, pressure, the presence of other gases, electromagnetic

interference and draft/splash zones i.e. doors, fans, sinks, ovens etc.

Locations for detectors will vary based on the intended application and target gas, they should be located near

identified sources of a potential gas leaks/pockets where gas could quickly accumulate and areas of identified

consequential risk to detect gas. The composition of the target gas and its density relative to air are used as the basis

for the recommended height of sensors. Generally, the installation height of a sensor for a heavy gas (such as

propane) would be close to the lowest point in the area, and for a light gas (such as methane) would be close to the

highest point in the area. These recommended heights may vary based on air flow and temperature conditions in

addition to the proposed application and location –this is particularly apparent with oxygen depletion sensors, and the

target gas that they are used for.

Target Gas

Typical Position

Natural Gas/Methane (NG)

High Level - 300mm (1ft) from ceiling

Liquid Petroleum Gas (LPG)

Low Level - 300mm (1ft) from ground level

Carbon Monoxide (CO)

Breathing Zone - 1700mm (5ft 6”) from ground level

Hydrogen (H)

High Level - 300mm (1ft) from ceiling

Oxygen (O2)

*Breathing Zone - 1000-1500mm (3 - 5ft) from ground level

* If you are installing and monitoring Oxygen depletion –consider the density of gas for its application and position

the detector accordingly i.e. ground level for high density gases.

The detectors are designed around a centralised control panel of which the location also needs to be considered.

The control panel should be located away from the area that it is monitoring and accessible is for both status

observation and alarm purposes.

Where cable runs may exceed 100 yards from a control panel –Contact your supplier!

Installation, Operation & Maintenance Manual Merlin Detector-TFT

IOM Iss: 1 05-21 5

Access & Mounting

Unpack all the parts.

The detectors are designed for surface mounting and must be installed by a licensed,

insured contractor or competent person. A deeper back enclosure is supplied to

accommodate wiring where required.

Carefully remove the rear cover from the unit by releasing the two latching clips located at

the bottom of the case. To do this –use a small flat head screwdriver.

Using the rear cover - mark the screw holes to the wall and ensure the wall surface is flat to

prevent base distortion. There are two pre-fractured areas for cable entry provided on the

inside of the rear cover which may be cut away as required. After executing the mounting

and the connections –replace the rear cover ensuring the two clips are latched.

Make a note of the installation date on the label located on the side of the unit.

We recommend all Merlin gas detection equipment is commissioned by a competent/trained engineer to

ensure correct installation and operation. Contact CGS for more information.

Internal Board Overview

Note: Terminal blocks are plug/socket type and may be removed to ease wiring.

Be careful when creating access for cables –Damage to circuit boards will void any warranty!

Any damage attempting to remove the circuit board parts may void any warranty!

Detectors must be earthed/grounded for electrical safety and to limit the effects of EMC or R/F interference!

For MODBUS communications, a shielded cable is used!

Installation, Operation & Maintenance Manual Merlin Detector-TFT

IOM Iss: 1 05-21 6

Wiring a Detector (GDP2X or GDPX+ Control Panel)

24vdc power supply from the control panel and communication cables are wired to control panels (GDP2X or

GDPX+). Both control panel and detector terminals are marked as [DETECTOR CHAIN + - D+ D-].

[SHEILD WIRE] detector terminals should be used for earthing/grounding and shield wires connected to any

Earth/Ground terminal on the control panel. Twist the shield wire to avoid stray shield wires,

A shielded and twisted 2 or 4 core cable is used to wire the MODBUS

terminals [D+ & D-). The shielding can be of 2 types: braided [mesh of thin

conducting wires] or foil (consisting of a thin sheet of metal covering the

twisted wires). One example of such cable is BELDEN 3082A. Any cable with

similar characteristics can be used to connect all the devices together.

If you are encountering noise or irregular problems with a bus link, the problem is likely related to grounding,

incorrect shielding or wiring mains power cables next to data cables.

The detector must be earthed/grounded for electrical safety and limit the effects of R/F & EMC interference!

Where cable runs may exceed 100 yards from one control panel –Contact your supplier!

Ensure the 120-ohm termination resistance switch is turned on at each end of a cable run!

Creating a Detector Chain

Create a detector chain by connecting detectors in a parallel (daisy chain) method.

Any other way may cause issues or damage to the overall system. Resistor switches should be turned on at each end

of a chain –see section ‘120ohm Termination Resistance’.

Single Detector Chain from

Control Panel example.

Installation, Operation & Maintenance Manual Merlin Detector-TFT

IOM Iss: 1 05-21 7

Split Detector Chain from Control Panel example.

Reversing the [D+] and [D-] connections of any device can lead to the whole system to stop working owing to reverse

polarity found on the terminals. In order to avoid this problem, it is recommended that the cable of same colour

should be used to connect all [D+] terminals together and similarly cable of same colour to be used to connect all [D-]

terminals together.

The detector must be earthed/grounded for electrical safety and limit the effects of R/F & EMC interference!

Where cable runs may exceed 100 yards from one control panel –Contact your supplier!

Ensure the 120ohm termination resistance switch is turned on at each end of a cable run!

Detector ID Switches

When wiring multiple detectors it is important to identify each detector installed for

the control panel to receive and display accurate data corresponding with the

correct device.

The ID configuration diagram is printed onto detector boards for quick

reference as shown opposite. All detectors are factory set to ID1.

We recommend a plan, map and/or marking the detector enclosures detailing ID and location!

ID Switches must be configured for each detector connected to receive and display accurate data!

120ohm Termination Resistance

Signal communication issues may occur where the bus length is too long, high baud rates are

used or signal reflections are occurring. To avoid this, terminating at each end of a chain

may help the quality of the data signal by turning on the 120-ohm terminal resistor switch.

If a split chain is used, terminate the last detector in each chain.

If a single chain is used, terminate the first device (Panel) and last device (Detector).

Split chain Single chain

Installation, Operation & Maintenance Manual Merlin Detector-TFT

IOM Iss: 1 05-21 8

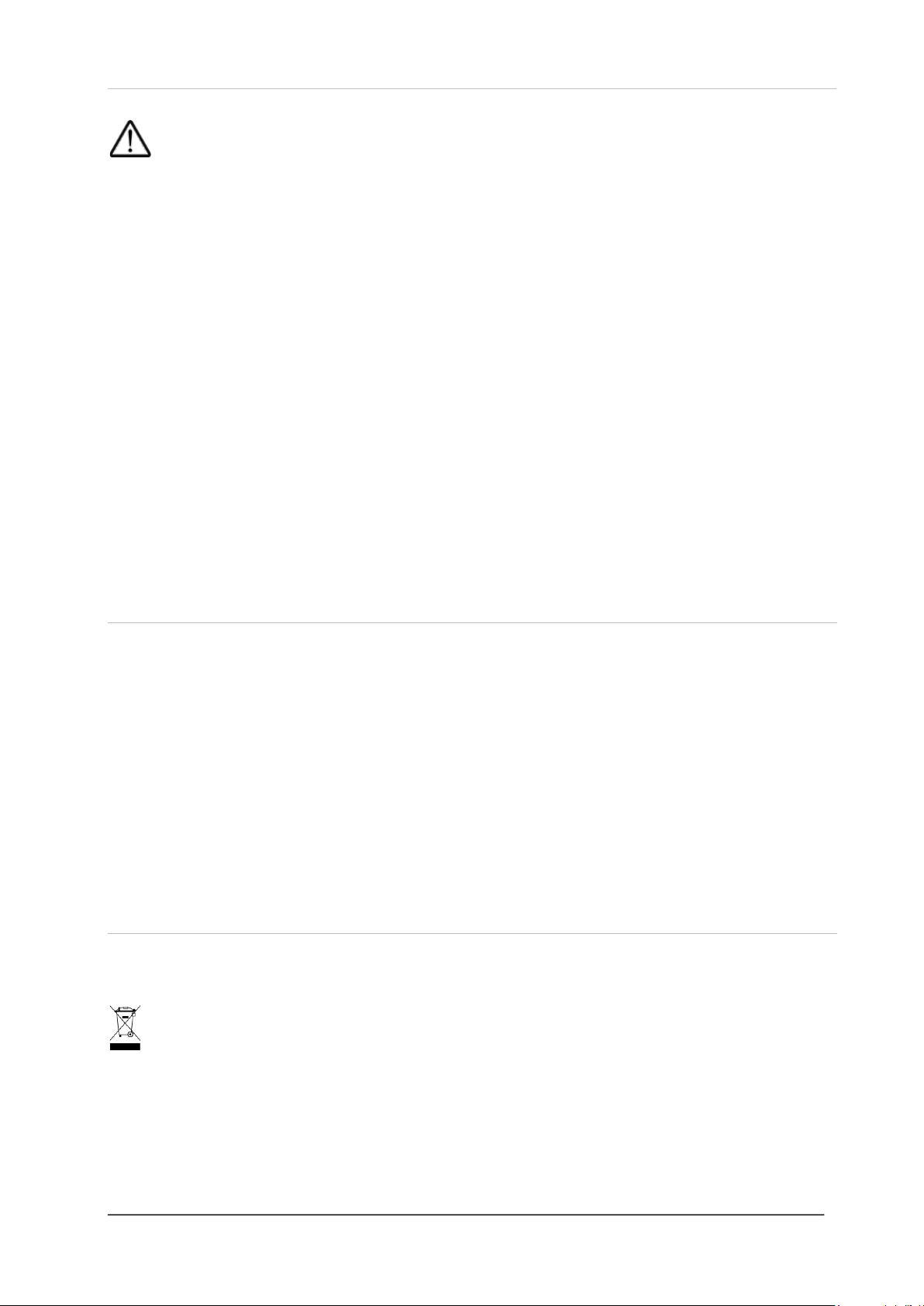

Wiring a Detector (GDP2 or GDP4 Control Panel)

Power is supplied to a detector via the GDP terminal [+ / -] and using the panel [GAS DETECTION ZONE] terminal.

If you are using a GDP panel you will need to use the detector [C/L] terminal as an alarm relay.

BMS terminals can be used in conjunction with

other external relays that affect other devices

and controls such as purge fans or audible

alarms etc.

Wiring your Detector (Merlin ‘S’Control Panels)

Power is supplied to a detector via the GDP terminal [+ / -] and using the ‘S’ panel [GAS DETECTOR] terminal [+ / -].

For a BMS alarm relay use [COM] and [NC] on the detector and the [open/close] switch terminal on the panel.

BMS are volt free connections.

A relay will change state when in alarm or

when gas is detected.

BMS terminals can be used in conjunction with

other external relays that affect other devices

and controls such as purge fans and audible

alarms etc.

Audible Alarm Switch

There is a switch on the detector board identified as [Buzzer On/Off].

The detector can be configured to have an audible alarm or not when gas levels reach the alarm

set points. The alarm will continuously sound –there are no provisions to silence the alarm, gas

levels must drop to a safe value for the alarm to stop.

Factory Set Condition

Buzzer On/Off Switch

ON

Chain Termination Resistor

OFF

Detector ID Switches

ID 1

Detectors are shipped pre-calibrated and configured.

Installation, Operation & Maintenance Manual Merlin Detector-TFT

IOM Iss: 1 05-21 9

Installation Tips

Wiring detector chains

The best way to connect devices in a MODBUS RTU communication is a parallel DAISY CHAIN method.

Cable distance

You may encounter problems when powering detectors beyond 100 yards from one control panel, in this instance,

contact your supplier.

Resistance to interference

Signal communication issues may occur where the bus length is too long, high baud rates are used or signal

reflections are occurring. To avoid this, terminating at each end of a chain may help the quality of the data signal by

turning on the 120ohm terminal resistor switch of the first and last device in the chain.

Earthing/Grounding

If you are encountering noise or irregular or abnormal problems, the problem is likely related to grounding, incorrect

shielding or wiring mains power cables next to data cables. If using a shielded cable –ensure the shielding or

equivalent is wired to the [Shield Wire] terminal on the detectors and connected to a mains powered earth/ground

point on the control panel.

Cable characteristics

For MODBUS communications, a shielded and twisted pair cable is used. The shielding can be of 2 types: braided

[like a mesh of thin conducting wires] or like a foil [consisting of a thin sheet of metal covering the twisted wires].

Detector protection

High concentrations of alcohol found in many products may damage, deteriorate or affect the gas sensing elements of

the detectors –such as; wine; deodorants; stain removers; thinners etc.

Detector identification

Remember to individually ID each connected detector by configuring the ID switches on the circuit board. Make a

plan, map and/or note of the location of all connected detectors for tracing and locality purposes.

Buzzer on alarm

There are no provisions to silence the alarm buzzer when high gas levels are detected. Gas levels must return to safe

level for the buzzer to stop. The audible buzzer is optional via a switch on the circuit board.

Operation

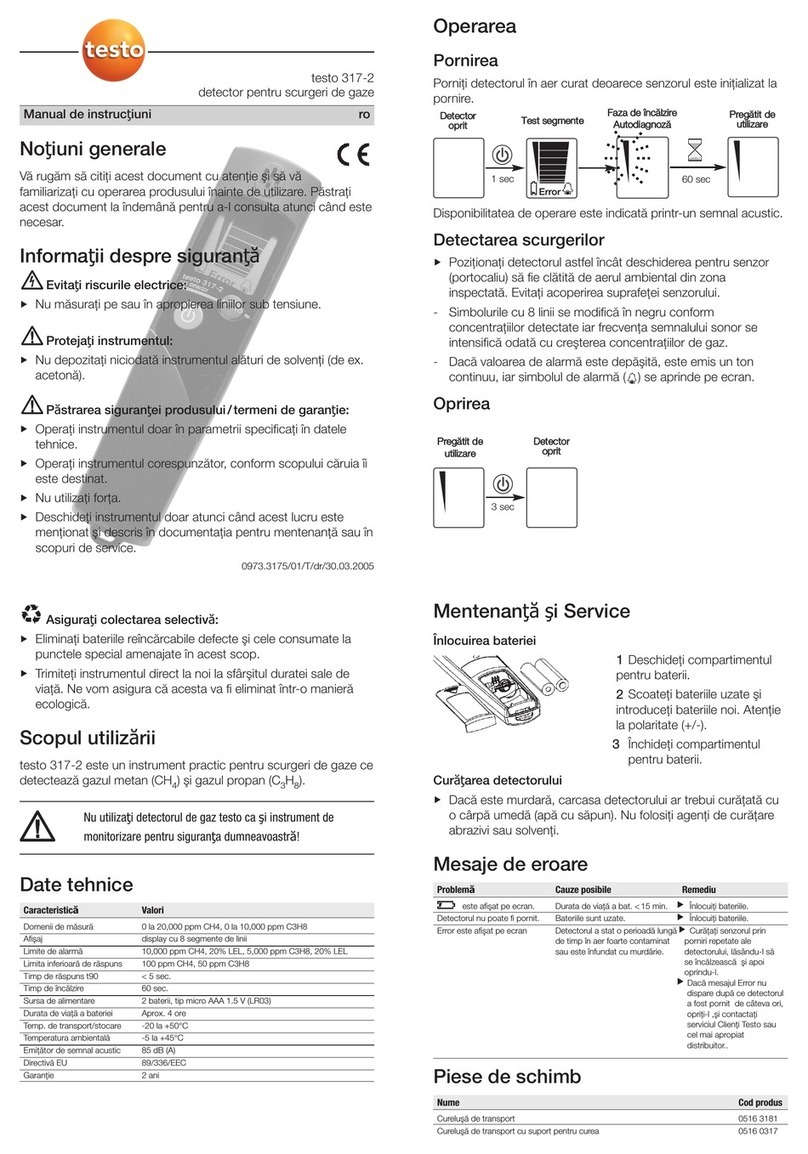

Initial Power-Up (Commissioning)

On connecting power, the detector enters ‘sensor stabilisation’ phase for approximately 60 seconds –during this

period the screen will display an ‘initialisation’ message indicating that the device is not yet ready for gas detection.

After the sensor has stabilised –the screen will display;

a. Target gas.

b. Target gas value.

c. Target gas measurement (parts per million or % LEL).

d. Unique detector serial/batch number.

e. Configured ID number.

We recommend all gas detection systems be commissioned by a competent/trained engineer to ensure

correct installation and operation!

Installation, Operation & Maintenance Manual Merlin Detector-TFT

IOM Iss: 1 05-21 10

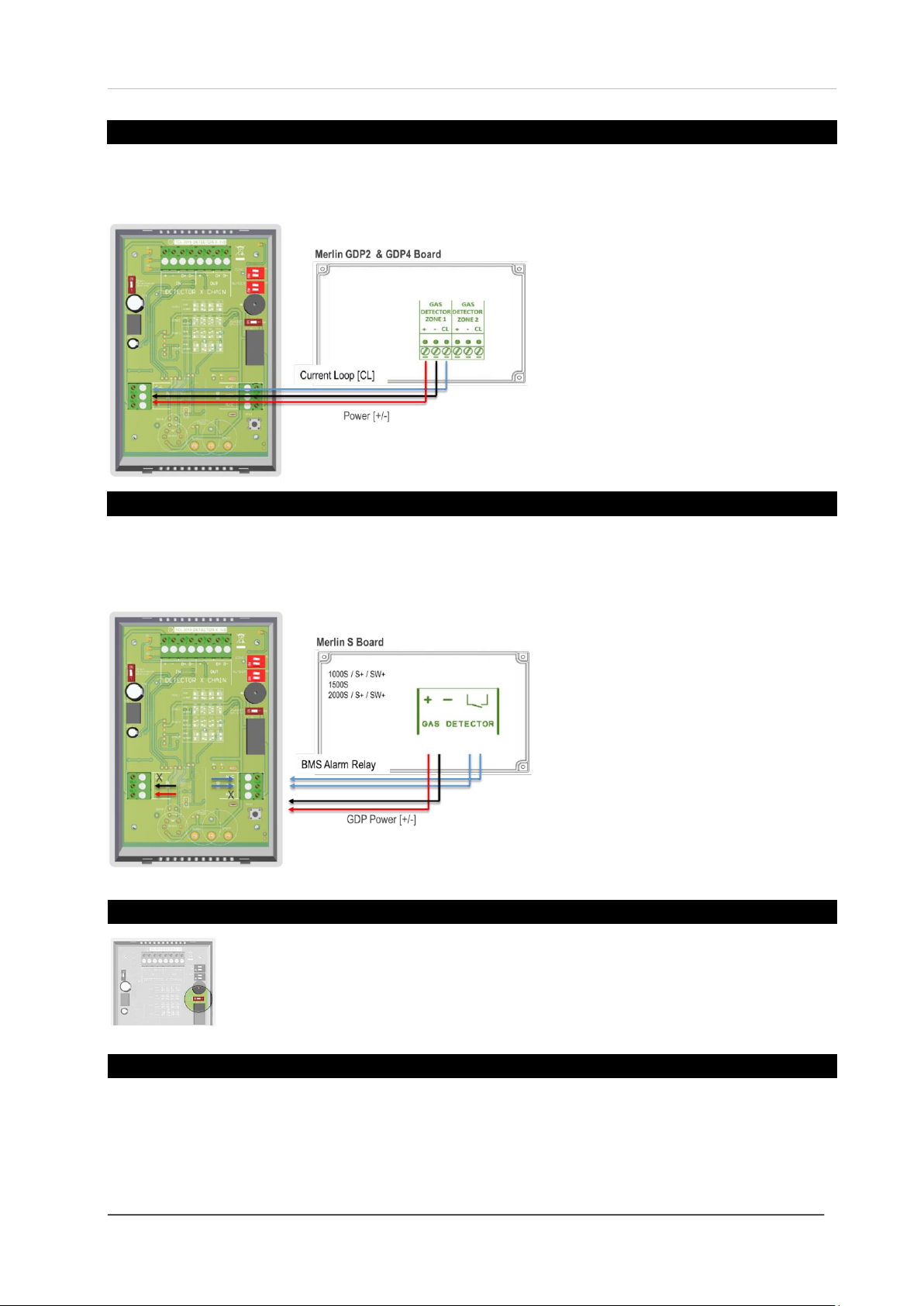

Digital Indication

Alarm Set Points

▲Rising alarm ▼Falling alarm LEL (Lower Explosive Limit) PPM (Parts per Million)

Gas Detector

Pre-Alarm

Buzzer

Alarm State

Buzzer

Methane/Natural Gas (NG)

▲8% LEL

No Sound

▲ 10% LEL

Continuous

sound

Liquid Petroleum Gas (LPG)

▲8% LEL

▲10% LEL

Hydrogen Gas (H)

▲8% LEL

▲10% LEL

Oxygen (O2)

N/A

▼18.5% ▲23%

Carbon Monoxide (CO)

▲ 20 PPM

▲ 20ppm after two (2) hours

▲50ppm after One (1) hour

▲100ppm after Ten (10) minutes

▲ 300ppm after One (1) minute

An audible buzzer will sound if the buzzer switch on the circuit board is on!

General Maintenance

Cleaning

Keep your gas detector in good working order - follow these basic principles;

Remove any dust/debris from the outer enclosure regularly using a slightly damp cloth.

Never use detergents or solvents to clean your device.

Never spray air fresheners, hair spray, paint or other aerosols near the device.

Never paint the device. Paint will seal vents and interfere with the device.

Concentrations of alcohol found in many products may damage, deteriorate or affect the gas sensing elements

such as; wine; deodorants; stain removers and thinners. Other gases and substances to avoid are; corrosives

(i.e. chlorine & hydrogen chloride); alkali metals; basic or acidic compounds; silicones; tetraethyl lead;

halogens and halogenated compounds!

Installation, Operation & Maintenance Manual Merlin Detector-TFT

IOM Iss: 1 05-21 11

Manual Circuit Simulation Test

When the test button on the circuit board is pressed and held the detector will simulate an open

circuit to ensure configured systems, outputs, alarms, indications and other external devices operate

as intended in response to gas. When the test button is released –the test sequence will terminate

and return to normal operation.

Access to the interior of the detector, when carrying out any work, must be conducted by a competent person!

This test does not check the gas sensing element itself!

Bump Test (Gas Response Check)

What is a Bump Test?

Gas response checks are often referred to as a ‘bump test’. Bump tests are important to make sure a device is able to

detect a release of gas as early as possible. The aim of the bump test is to make sure a detector is working at its

optimum by briefly exposing the unit to a known concentration of the target gas that usually exceeds the highest

alarm point. If the detector goes into alarm and all signals/outputs activate, then the system is working safely. If the

system fails to operate as intended in an alarm state, the gas detector must not be used until a full inspection and

service has been conducted.

Why is it important?

A detector may visually appear in good working order, but its sensitivity can be inhibited by external factors. Dust,

humidity, temperature fluctuations, cleaning products, contaminants or sensor drift (ageing) can cause a decline in

sensitivity and eventual failure.

How often?

Regular bump tests are important to make sure the detector is able to detect a release of gas as early as possible and

usually takes seconds (gas type dependant i.e. CO sensors will take over a minute) and is often completed alongside

a scheduled fire alarm test, however the frequency should be determined following an appropriate risk assessment by

the end user. Remember, bump testing does not remove the need to have gas detectors inspected, calibrated and

serviced periodically by a competent person.

What do I need?

Contact your CGS representative for details of suitable bump testing kits and gases. Kits usually consist of a certified

gas cylinder; flow control regulator, tube pipe and applicator cone. We recommend only using CGS calibration gas

kits to ensure correct flow rates meet CGS technical requirements. A bump testing gas is usually a concentration mix

that exceeds the highest alarm set-point.

See below for recommended gas concentrations for bump testing your detector.

Detector Type

Bump Test Gas

Response Time

CO - Carbon Monoxide

400 - 500ppm (balance in air).

<120s

NG - Methane

0.6 - 0.8% BV (balance in air)

<30s

LPG - Liquid Petroleum Gas

0.3 –0.4% BV (balance in air)

<30s

H - Hydrogen

5000 - 6000ppm (balance in air)

<30s

O2- Oxygen

15% (balance in Nitrogen).

<60s

All certified test gases supplied by CGS are classified as non-flammable and non-toxic, however, they do contain gas

under pressure and may explode if heated to extreme temperatures and cause asphyxiation in high concentrations.

Installation, Operation & Maintenance Manual Merlin Detector-TFT

IOM Iss: 1 05-21 12

How to perform a Bump Test?

1. Ensure you have the correct gas for the device type prior to application.

2. Screw and seal the regulator/valve into the gas cylinder outlet.

3. Once sealed, the regulator pressure gauge will indicate cylinder pressure.

4. Offer up the applicator hose/cone to the lower vents.

5. Open the valve/regulator to allow the gas to be delivered at a pre-set flow rate.

7. Wait for the device to enter alarm status and energise configured outputs/relays.

At this point…

9. Remove applicator hose/ cone and turn the gas cylinder regulator/valve off.

10. Wait for the device to return to normal.

11. Reset the system.

Record your test details. There is a provision for this in your control panel manual.

To increase reaction time, cover the escape vents at the top of the device.

Alternatively, enclose the device and apply gas i.e. in an air tight bag or container.

For more help and advice on bump testing –contact us.

Always remove the regulator/valve from cylinder after use!

Always check cylinder pressure upon sealing valve –there may not be a sufficient amount of gas!

All CGS cylinders will re-seal upon removal of the regulator/valve!

Always give at least five (5) minutes between testing the same unit or until gas has fully dispersed!

Always consider safety and use equipment in accordance with Safety Data Sheets!

Service & Field Calibration

Overview

Detectors are pre-calibrated at the time of manufacture, therefore a field calibration is only required periodically

(usually annually) to compensate for its sensitivity and accuracy that can be inhibited by external factors. Dust,

humidity, temperature fluctuations, cleaning products, contaminants or sensor drift (ageing) can cause a decline in

sensitivity, accuracy and eventual failure. Servicing and field calibration is important to prolong the operational life and

ensure the detector is able to detect a concentration of gas as accurately and as early as possible to optimise

protection. Typical accuracy of a detector is ± 10-20% of the standard field gas concentration.

Service and field calibration should coincide with the annual service message prompted on the detection system after

each year of service/operation. The annual timer for service will begin after 5 hours of continuous power irrespective

of whether the system is then used intermittently. Depending on the application and environmental factors, field

calibration can be conducted at a higher frequency determined by the end user following an appropriate risk

assessment but must be executed by a competent person.

Contact your CGS representative for details of suitable field calibration kits and gases to ensure any equipment and

flow rates meet CGS technical requirements.

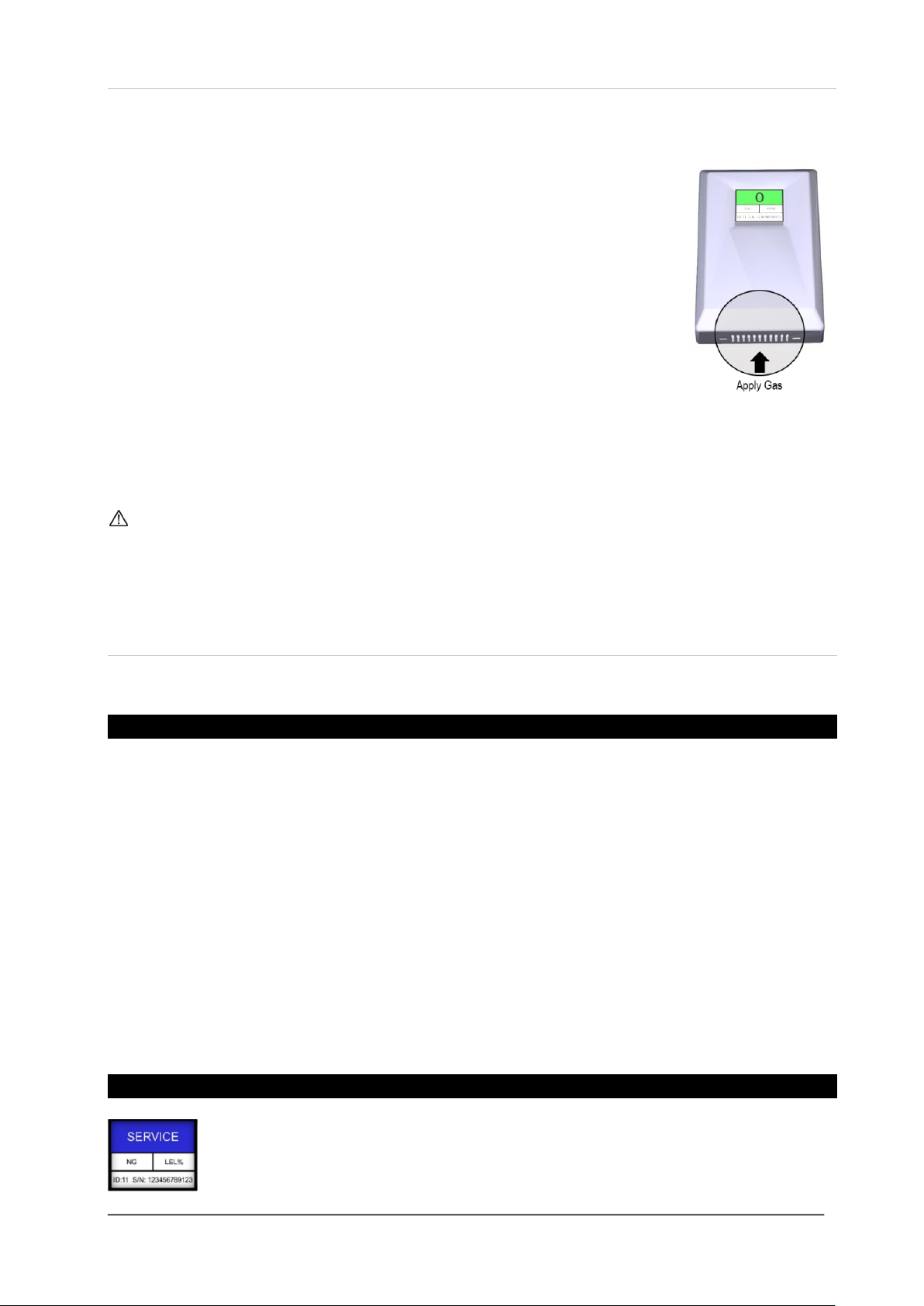

Annual Service Message

A service screen will intermittently flash every 30 seconds after one year of operation. The annual

message reminder will begin after five (5) hours of continuous power irrespective of whether the

system is then used intermittently. The detector will still operate as intended during this time.

Installation, Operation & Maintenance Manual Merlin Detector-TFT

IOM Iss: 1 05-21 13

Service Mode (GDP2X & GDPX+)

Access service mode by pressing the CGS logo on the control panel home screens only. The screen will display a

service prompt. Press Yes. (Note: All alarm signals/outputs will be inhibited for fifteen (15) minutes. Proceed to

service and re-calibrate detectors if required. Upon completion –exit service mode by pressing the ‘Exit’ button on

screen. If you need more time, exit and re-enable service mode. The system returns to a normal state after fifteen (15)

minutes automatically if the ‘exit’ button is not pressed.

When service mode is enabled, the control panel will ignore all alarm signals/outputs and the gas valve will

remain active. The panel will return to a normal operational state after fifteen minutes automatically unless

service mode is disabled manually by pressing the [EXIT] button on screen!

Field Calibration

1. Carefully remove the detector cover to access the circuit board.

2. Ensure that service mode has been enabled on the control panel.

3. Short out the unmarked service headers for ~3s.

4. A calibration prompt will appear for a limited time on the detector screen.

5. Offer up the applicator hose/cone and cover the gas sensor fully.

6. Open the valve/regulator and deliver the gas at a pre-set flow rate.

7. Wait for a ‘successful’ message to appear on the detector screen.

8. Remove applicator hose/cone and turn the gas cylinder regulator/valve off.

9. After ~5s the detector will return to normal operation.

(Note: the annual service reminder is automatically reset)

10. Carefully replace the back cover.

See below for calibrated gas concentrations that must be used to calibrate your detector.

Detector Type

Calibration Gas

CO - Carbon Monoxide

120ppm (balance in air).

NG - Methane

0.5% BV (balance in air)

LPG - Liquid Petroleum Gas

0.2% BV (balance in air)

H - Hydrogen

4000ppm (balance in air)

O2- Oxygen

20.9% (balance in Nitrogen).

Installation, Operation & Maintenance Manual Merlin Detector-TFT

IOM Iss: 1 05-21 14

Gas sensor location, types and response times

The time for sensors to respond to their target gas will vary

on the type of gas sensing element. You should always refer

to the specification for information on sensor type and alarm

levels i.e. electro-mechanical sensors (such as CO and O2)

will react to its target gas slower than semi-conducting

sensor types (such as methane and LPG).

Failed Field Calibration

If field calibration is unsuccessful a screen text ‘Fail’ will appear.

After ~5s the detector will return to a normal state as it was pre-service but the service reminder

message will remain flashing. Check that the correct gas and concentration has been applied and

gas was applied before contacting your supplier.

Access to the interior of the detector, when carrying out any work, must be conducted by a competent person!

Before carrying out any work ensure local regulations and site procedures are followed!

Always give at least five (5) minutes between testing the same unit or when gas has fully dispersed!

Do not conduct calibration of sensors in conditions outside of any recommended ranges!

To recalibrate a detector, the following procedure and gases must be used!

Calibrated gases must be mixed in accordance with recognised standards such as EN 6142.

If a gas sensor is exposed to a concentration significantly above the measuring range, it should be

recalibrated as soon as possible afterwards!

Contact CGS for more information.

End of Operational Life (EOL)

The typical life of a gas detector depends on its application and intended target gas, in addition the operational life

can be prolonged if the system and equipment is installed and maintained in accordance the instructions stated within

this manual.

At the end of its predicted operational life –the detector will display an ‘End of Life’ screen. This

message indicates that the detector has reached its expected operational lifecycle and no gas

levels will be displayed. You must contact your supplier immediately for replacement.

The EOL is approximate from the first five (5) hours of continuous power!

The EOL will depend on the type of gas your detector is targeting and may vary depending on its application

and environmental conditions such as the frequency of exposure to the target gas, poisons or inhibitors!

Installation, Operation & Maintenance Manual Merlin Detector-TFT

IOM Iss: 1 05-21 15

Specification

General

Product:

Gas Detector-TFT

Model(s):

CO (Carbon Monoxide) NG (Methane/Natural Gas) LPG (Liquid Petroleum Gas) H (Hydrogen) O2 (Oxygen)

Use:

Indoor, Safe Areas (not to be used in potentially explosive atmospheres)

Indicators (1.8” TFT Screen)

Green (Safe), Yellow (Special State) & Red (Alarm). Gas Type & Detected Concentration Level. Measured

Value Detector ID No. Serial No. End of Life. Sensor Fault. Service.

Screen Brightness

Non- adjustable

Mounting

Wall Mounting

Electrical

Max. Power Consumption

90mA Max @ 24vdc

Power Voltage Input Range

12-32Vdc (24vdc Nominal)

Communication

RS485, Modbus RTU

BMS Terminal

Volt Free (Normally Closed / Common / Normally Open)

GDP Terminal

24Vdc Power Input (+ - ) & Current Loop (CL)

Relay(s)

1x 30vdc 2A (Non-Latching)

Terminal Wire ratings

Copper 18AWG (0.75mm2) Min. 14 x screw terminals.

Construction

Dimensions (H x W x D)

140 x 95 x 30mm / 5.51 x 3.74 x 1.18”

Unit Weight (Approx.)

0.05kg / 1.77oz

Housing Material

Polylac - PA765

Environmental

Ingress Protection

IP40

Storage Conditions

Dry. Temp: -10 ~ 50°C / 14~ 122°F : 30 ~ 80% rh

Compliance

CE / UKCA

BS EN 50270 / BS EN 61010-1

Sensor Specification

Factory Calibration Conditions

25° ± 5°C - 77° ± 41°F (40-70% RH)

Sensor Operating Temperature

-20C° ~ 50°C (14 ~ 122°F)

Sensor Operating Humidity

Continuous 30-80% rh Non-Condensing

Sensor Operating Pressure

Normal Atmospheric Pressure ± 10%

Gas

Sensor

Indicating

Range

Steps

Calibration

Gas

Response

(t90)

Recovery

(t10)

Alarm: 1

(Pre alarm warning)

Alarm: 2

*EOL

(Years)

Electrochemical Sensors

Carbon

Monoxide

(CO)

0-999ppm

1

120ppm CO

<60s

<60s

▲20ppm

Exposure time.

▲20ppm (after two hours)

▲50ppm (after one hour)

▲100ppm (after ten minutes)

▲300ppm (after one minute)

5

Oxygen

(O2)

0-30% V/V

0.1

Clean Air

(20.9%)

<30s

<60s

N/A

▼18.5% V/V

▲23% V/V

3

Semiconductor Sensors

Methane

(CH4)

0-20% LEL

0.1

0.5% BV

methane

<30s

<30s

▲8% LEL

▲10% LEL

10

Propane

(LPG)

0-20% LEL

0.1

0.2% BV

Propane

<30s

<30s

▲8% LEL

▲10% LEL

10

Hydrogen

(H)

0-20% LEL

0.1

4000ppm

Hydrogen

<30s

<30s

▲8% LEL

▲10% LEL

10

▲ Rising Alarm ▼Falling alarm

*EOL –Expected Operational Life

Installation, Operation & Maintenance Manual Merlin Detector-TFT

IOM Iss: 1 05-21 16

Installation Details

Please pass this manual to the system owner / user.

Date of Installation:

Installation Location:

Organisation:

Stamp/Signature of the installer:

We recommend all Merlin gas detection equipment be commissioned by competent/trained engineers to ensure

correct installation and operation. The Merlin range of gas detectors are calibrated when manufactured, however, we

strongly recommend the detectors response and alarm signals are tested and validated once installed. This will

ensure the equipment performs as intended and is free from any unforeseen damage caused by transit/installation.

Every effort is made to ensure the accuracy of this document; however, CGS can assume no responsibility for any

errors or omissions in this document or their consequences. CGS would greatly appreciate being informed of any

errors or omissions that may be found in the content of this document. For information not covered in this document,

or if there is a requirement to send comments/corrections, please contact CGS using the contact details given below.

Canadian Gas Safety

Telephone: 647-577-1500

Canadian Gas Safety is the owner of this document and reserves all rights of modification without prior notice.

Table of contents

Other CGS Gas Detector manuals

Popular Gas Detector manuals by other brands

Riken Keiki

Riken Keiki GD-84D-EX Series operating manual

Duomo

Duomo BX150 manual

SyxthSense

SyxthSense RGI-CO0-L42 Product sheet

HSS Hire

HSS Hire Safe and Sure 34074 Operating & safety guide

Crowcon

Crowcon Xsafe Bright Installation, operation and maintenance instructions

WatchGas

WatchGas AirWatch Mk 1.0 Quick reference card