Smart Sensor AS8800L User manual

AS8800L

1

3

1. Introduction

This instrument provide combustible gas detection.

It is excellent apply on any situation of combustible

gas or vapour or residue for pinpointing known leaks,

checking for leaks and verifying safety of potential

hazardous locations.

Some application are:

A. Gas lines and pipes

B. Propane gas refill station

C. Fuel in marine bilges

D. Exhaust and fuel leaks

E. Check manholes for safety

Note:

Although the unit will respond to high level of

Carbon Monoxide, it should not be used as a a detector

for this gas in normal room or working atmospheres.

It used to pinpoint a leak as described in the

Operation Instructions.

2. How it works

After the automatic warm up, when the sensor of

the instrument detected vaporous & gas-form

combustible compound, the signal variate as the

increase tick rate with LED will light up to located

the combustible leaks. That help the user to take

effective reaction to clear potential hazard.

3. Features

3.1 Adjustable sensitivity

3.2 Auto fast warm-up

3.3 Alarm indication

3.4 Low battery indication

3.5 Leak size indication (Audio and Visible)

3.6 Instant response and pinpoint leak position

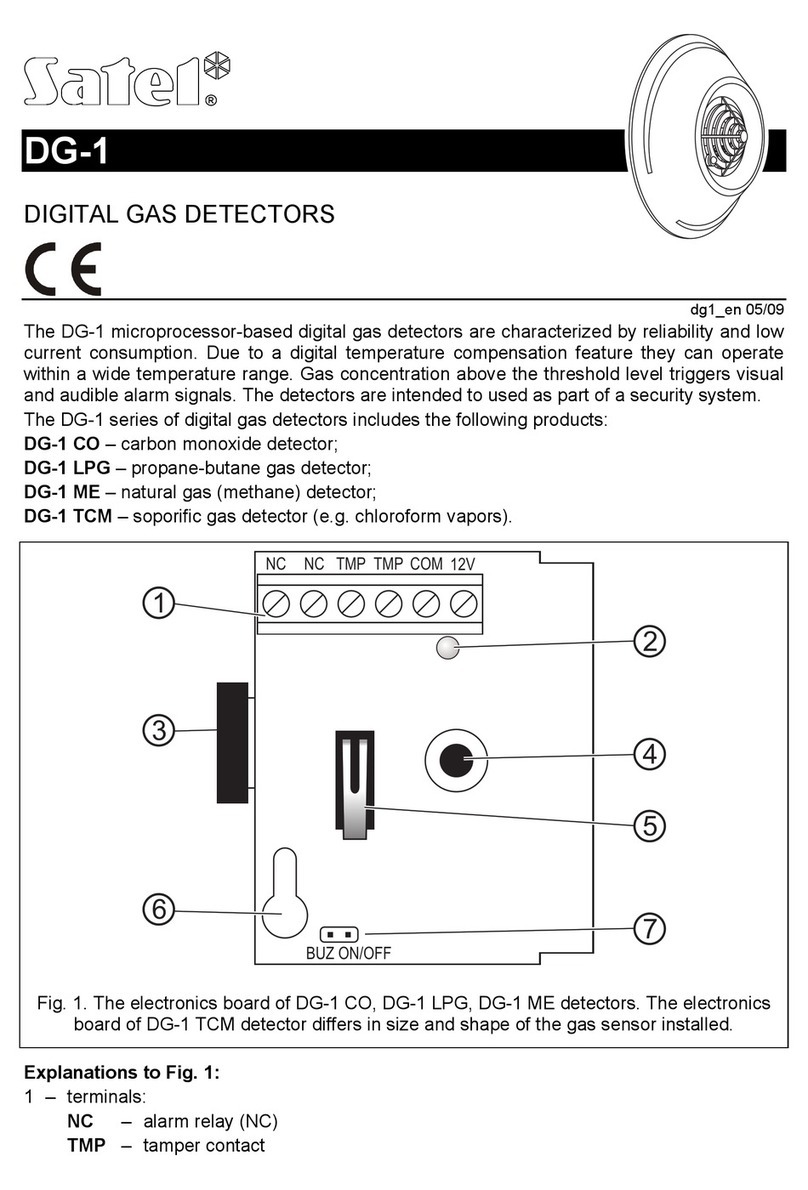

4. Diagram and description

① ON/OFF switch

② Power indicator

③ Leak size indicator

④ Speaker

⑤ Sensitivity adjust knob

⑥ Battery compartment

⑦ Flex probe

⑧ Probe knob

2

Combustible Gas Detector

Instruction Manual

AS8800L

1

3

1. Introduction

This instrument provide combustible gas detection.

It is excellent apply on any situation of combustible

gas or vapour or residue for pinpointing known leaks,

checking for leaks and verifying safety of potential

hazardous locations.

Some application are:

A. Gas lines and pipes

B. Propane gas refill station

C. Fuel in marine bilges

D. Exhaust and fuel leaks

E. Check manholes for safety

Note:

Although the unit will respond to high level of

Carbon Monoxide, it should not be used as a a detector

for this gas in normal room or working atmospheres.

It used to pinpoint a leak as described in the

Operation Instructions.

2. How it works

After the automatic warm up, when the sensor of

the instrument detected vaporous & gas-form

combustible compound, the signal variate as the

increase tick rate with LED will light up to located

the combustible leaks. That help the user to take

effective reaction to clear potential hazard.

3. Features

3.1 Adjustable sensitivity

3.2 Auto fast warm-up

3.3 Alarm indication

3.4 Low battery indication

3.5 Leak size indication (Audio and Visible)

3.6 Instant response and pinpoint leak position

4. Diagram and description

① ON/OFF switch

② Power indicator

③ Leak size indicator

④ Speaker

⑤ Sensitivity adjust knob

⑥ Battery compartment

⑦ Flex probe

⑧ Probe knob

2

Combustible Gas Detector

Instruction Manual

4 5

6

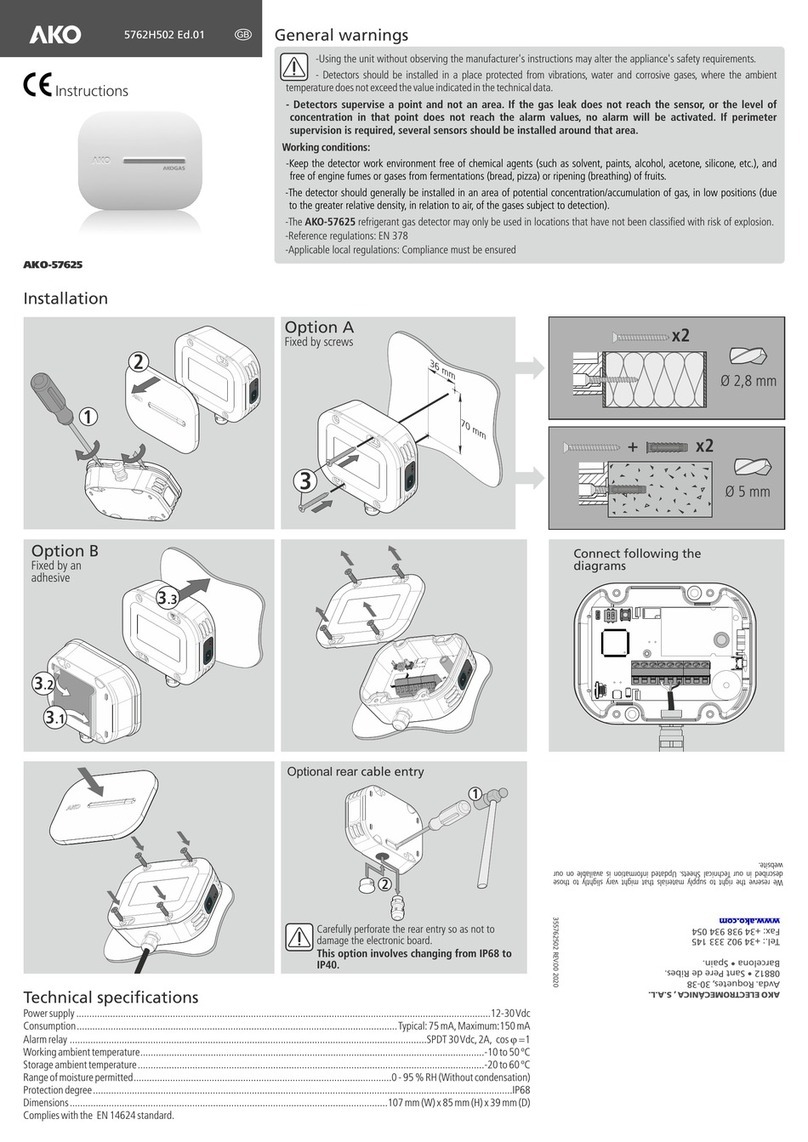

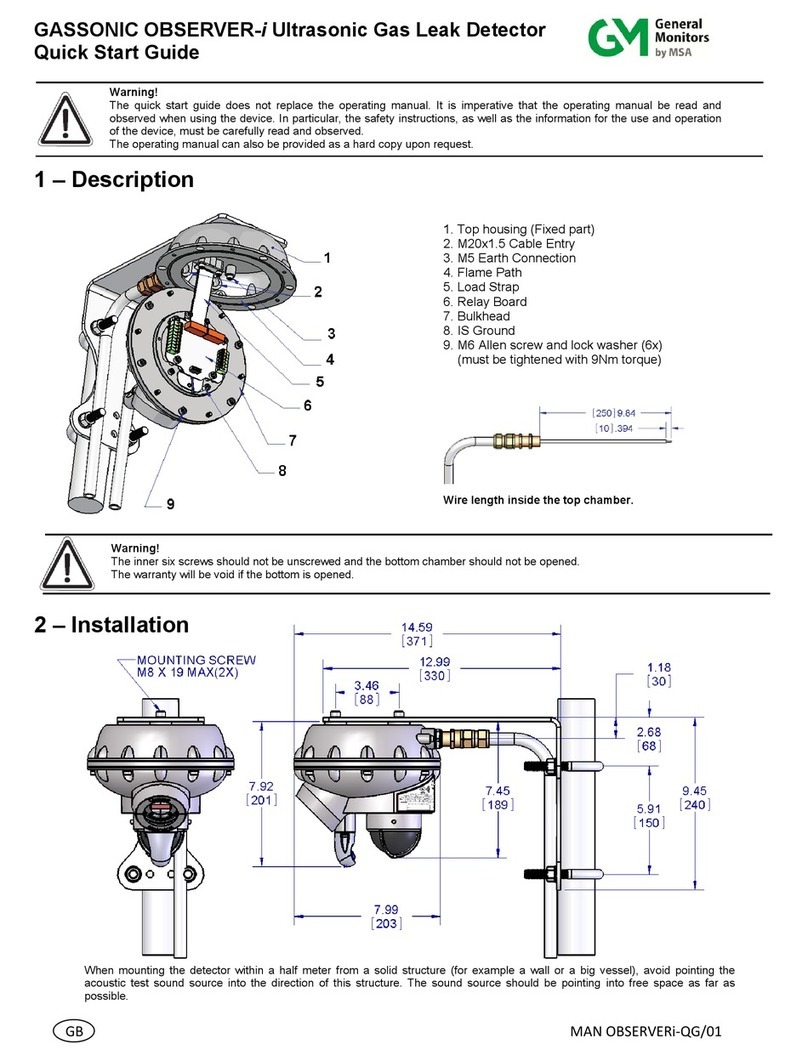

5. Operation instruction

5.1 Turn the unit off and the sensitivity knob fully

counter clockwise.

5.2 Turn the unit on in a non-contaminated atmosphere

by slide the switch to ON, the power indicator

will be lit. Power indicator keep on light show

the battery power is sufficient, it ensure the

unit precise detection.

5.3 After turn on, the unit will auto warm-up within

20 sec, a ticking sound will be heard.

5.4 Adjust the sensitivity control until the first

leak indicator light up, the ticking speed up.

5.5 Approached the sensor to a known leak source,

the leak size indicate lights will increase with

the rapid ticking. Above steps to ensure the unit

working correctly, now the unit are ready to use.

If the battery power in sufficient state but the

sensor approach a known leaks without any

responds, do not use the instrument, please

return for repair.

5.6 In conjunction with the increased tick rate,

the leak size indicator will light from down to

top as a larger combustible concentrations.

5.7 Search the general area of the leak. When

a detectable compound enters the sensor, the

ticking speed up.

5.8 If you are searching for a heavy leak source,

please lower the sensitivity in a clear air by

turning the adjustable knob (until the leak size

indicator turn off).

6. To change batteries

6.1 During operation, if the power indicator is

blinking, it is necessary to change batteries.

6.2 Change the batteries properly, cover battery

door.

Note:

A. Battery must only be replaced in an area known

to be no-hazardous.

B. Turn off the unit when replace the battery.

C. Do not short circuit the metal pieces of the battery.

D. Do not clean the sensor probe to avoid the water,

oil stain, dust entering into probe. (important)

Detect Item

Sensitivity

Response time

Warm-up time

Continuous

operation time

Low battery

indication

Power supply

Working Condition

Storage Condition

7. Specifications

Combustible gas

Variable, minimum 50 PPM

(methane)

Instantaneous

<20 seconds

9 hours (slightly vary with

working condition)

Replace batteries while

power indicator blinks

3*1.5V AA batteries

0 to 50°C; ≤80% RH(Non gel)

10 to 60°C; 0% to 90% RH

8. Cautions

8.1 Do not use the instrument in an area of extremely

high level of combustible gas.

8.2 The gas/vapor of organic solvent might interfere

the function of the unit. During detection, please

eliminate the influence of the organic solvent.

8.3 In order to ensure correct operation and indication,

the unit should be switched on and warm-up in

non-contaminated atmosphere.

4 5

6

5. Operation instruction

5.1 Turn the unit off and the sensitivity knob fully

counter clockwise.

5.2 Turn the unit on in a non-contaminated atmosphere

by slide the switch to ON, the power indicator

will be lit. Power indicator keep on light show

the battery power is sufficient, it ensure the

unit precise detection.

5.3 After turn on, the unit will auto warm-up within

20 sec, a ticking sound will be heard.

5.4 Adjust the sensitivity control until the first

leak indicator light up, the ticking speed up.

5.5 Approached the sensor to a known leak source,

the leak size indicate lights will increase with

the rapid ticking. Above steps to ensure the unit

working correctly, now the unit are ready to use.

If the battery power in sufficient state but the

sensor approach a known leaks without any

responds, do not use the instrument, please

return for repair.

5.6 In conjunction with the increased tick rate,

the leak size indicator will light from down to

top as a larger combustible concentrations.

5.7 Search the general area of the leak. When

a detectable compound enters the sensor, the

ticking speed up.

5.8 If you are searching for a heavy leak source,

please lower the sensitivity in a clear air by

turning the adjustable knob (until the leak size

indicator turn off).

6. To change batteries

6.1 During operation, if the power indicator is

blinking, it is necessary to change batteries.

6.2 Change the batteries properly, cover battery

door.

Note:

A. Battery must only be replaced in an area known

to be no-hazardous.

B. Turn off the unit when replace the battery.

C. Do not short circuit the metal pieces of the battery.

D. Do not clean the sensor probe to avoid the water,

oil stain, dust entering into probe. (important)

Detect Item

Sensitivity

Response time

Warm-up time

Continuous

operation time

Low battery

indication

Power supply

Working Condition

Storage Condition

7. Specifications

Combustible gas

Variable, minimum 50 PPM

(methane)

Instantaneous

<20 seconds

9 hours (slightly vary with

working condition)

Replace batteries while

power indicator blinks

3*1.5V AA batteries

0 to 50°C; ≤80% RH(Non gel)

10 to 60°C; 0% to 90% RH

8. Cautions

8.1 Do not use the instrument in an area of extremely

high level of combustible gas.

8.2 The gas/vapor of organic solvent might interfere

the function of the unit. During detection, please

eliminate the influence of the organic solvent.

8.3 In order to ensure correct operation and indication,

the unit should be switched on and warm-up in

non-contaminated atmosphere.