Beumer stretch hood S User manual

BEUMER stretch hood® S

BA-6090103-EN

19.08.09 1

Operating instructions

Machine type

BEUMER stretch hood®S

Machine no.

6090103.10 - 210

Project

BECTON DICKINSON

Document no.

BA-6090103-EN

BEUMER stretch hood® S Table of Contents

BA-6090103-EN

19.08.09 3

Table of Contents

Introduction ..................................................................................7

Where can I find what I am looking for?..................................................... 8

Addresses.....................................................................................9

Germany..................................................................................................... 9

America...................................................................................................... 9

Declaration by the manufacturer ..............................................11

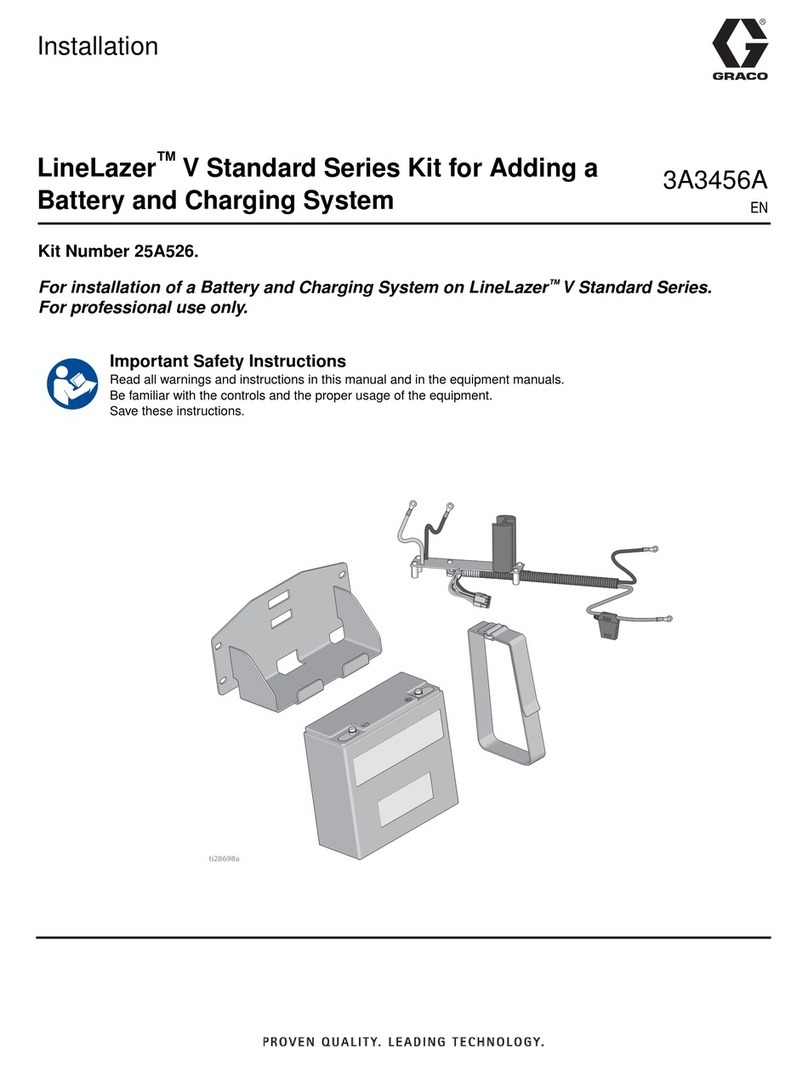

1Intended use.......................................................................13

Use........................................................................................................... 13

Danger zone............................................................................................. 13

Access area ........................................................................................ 13

Working area....................................................................................... 13

Maintenance area ............................................................................... 13

Owner's responsibility .............................................................................. 14

Qualification of personnel......................................................................... 14

Operating personnel............................................................................ 14

Skilled personnel................................................................................. 14

Skilled electrician ................................................................................ 14

Unauthorised use..................................................................................... 15

2Technical data....................................................................17

Requirements on the place of installation................................................ 17

Building ............................................................................................... 17

Foundation.......................................................................................... 17

Lighting................................................................................................ 17

Power supply............................................................................................ 17

Electrical energy.................................................................................. 17

Pneumatic energy............................................................................... 18

Material/items transported........................................................................ 18

Pallets ................................................................................................. 18

Film specification................................................................................. 19

Performance data..................................................................................... 19

3Technical description........................................................21

System description................................................................................... 21

BEUMER stretch hood®...................................................................... 21

Description of modules............................................................................. 22

BEUMER stretch hood®...................................................................... 22

Hood applicator head.......................................................................... 23

Hoist with stretch frame....................................................................... 24

Crimping and stretching unit............................................................... 25

Table of Contents BEUMER stretch hood® S

4 BA-6090103-EN

19.08.09

Maintenance platform.......................................................................... 26

Chain conveyor................................................................................... 27

Pallet positioning device ..................................................................... 28

Pallet roller conveyor........................................................................... 29

4Safety..................................................................................31

Safety instructions.................................................................................... 31

Safety devices.......................................................................................... 31

Protective structure............................................................................. 31

5Installation..........................................................................33

Safety instructions.................................................................................... 33

Lifting equipment................................................................................. 33

Welding work....................................................................................... 33

Preparation of installation......................................................................... 34

Foundation.......................................................................................... 34

Tools ................................................................................................... 34

Torque list ........................................................................................... 35

Preassembly............................................................................................. 36

Transport route.................................................................................... 36

Final installation........................................................................................ 36

How to install the BEUMER stretch hood®.......................................... 36

Hoist.................................................................................................... 37

Maintenance platform.......................................................................... 38

Hood applicator head.......................................................................... 41

Film releasing trestle........................................................................... 42

Pallet transport system........................................................................ 43

Check of installation................................................................................. 44

How to check screw and bolt connections.......................................... 44

6Commissioning..................................................................45

Safety instructions.................................................................................... 45

First start-up............................................................................................. 45

Basic requirements ............................................................................. 45

How to switch on the power supply..................................................... 46

Electrical energy ............................................................................ 46

Pneumatic energy.......................................................................... 46

7Operation............................................................................47

Safety instructions.................................................................................... 47

Emergency stop.................................................................................. 48

General information.................................................................................. 49

Safety photocell and CPSET-M12 muting device............................... 50

Control unit..................................................................................... 50

Restart or reset .............................................................................. 51

Safety photocell CPSET M13 for protection against access .............. 52

Control unit..................................................................................... 52

Control cabinet.................................................................................... 53

Control elements............................................................................ 53

BEUMER stretch hood® S Table of Contents

BA-6090103-EN

19.08.09 5

Display elements............................................................................ 53

Visualisation............................................................................................. 54

Functions in the visual display system................................................ 55

Structure of the user interfaces........................................................... 55

Function keys which are not related to a certain display.................... 56

Function keys which are related to a certain display.......................... 56

How to enter parameters .................................................................... 57

Input keys....................................................................................... 57

Password protection............................................................................ 59

Access authorisation........................................................................... 59

User log in........................................................................................... 59

How to assign a password.................................................................. 61

User log out......................................................................................... 61

Operation of system................................................................................. 62

Basic screen........................................................................................ 62

Structure of the operator functions...................................................... 63

List of all icons for the F keys.............................................................. 64

Presets................................................................................................ 65

Modes of operation ............................................................................. 66

Automatic return to starting position (starting position)....................... 69

Interrupt pallet..................................................................................... 69

Film insertion plan............................................................................... 70

How to insert the film........................................................................... 70

Parameters.......................................................................................... 71

Parameters for the operating personnel ............................................. 72

Parameters for service personnel....................................................... 74

Status display...................................................................................... 82

Display of operation sequences.......................................................... 83

Error messages................................................................................... 84

Fault messages.............................................................................. 84

Fault buffer..................................................................................... 85

Reset of fault buffer........................................................................ 86

System messages.......................................................................... 86

Identifier system....................................................................................... 87

Equipment identifier ............................................................................ 87

Numbering of the terminal boxes/terminal strips ................................ 87

8Trouble shooting................................................................89

Safety instructions.................................................................................... 89

Malfunctions............................................................................................. 89

What to do if ............................................................................................ 90

Before start-up .................................................................................... 90

Failures ............................................................................................... 90

Malfunctions........................................................................................ 93

9Maintenance.......................................................................95

Safety instructions.................................................................................... 95

Inspection................................................................................................. 96

Maintenance............................................................................................. 99

General maintenance instructions ...................................................... 99

Table of Contents BEUMER stretch hood® S

6 BA-6090103-EN

19.08.09

How to maintain motors ...................................................................... 99

How to maintain gear units ................................................................. 99

How to order spare parts .................................................................... 99

Chain drive.......................................................................................... 99

How to maintain the sealing rail........................................................ 100

Lubrication.............................................................................................. 101

Change of lubricant of geared motors............................................... 101

Anti-friction bearings.................................................................... 101

How to lubricate the chain drive........................................................ 102

How to lubricate the linear guide....................................................... 102

Table of lubricants............................................................................. 103

10 De-commissioning...........................................................105

Safety instructions.................................................................................. 105

Disassembly........................................................................................... 105

Waste disposal....................................................................................... 105

Lubricant ........................................................................................... 105

Motors and gear units ....................................................................... 106

Machine actuators............................................................................. 106

Pneumatic parts................................................................................ 106

Electric parts ..................................................................................... 106

11 Transport..........................................................................107

Safety instructions.................................................................................. 107

Transport instructions............................................................................. 108

Packaging ......................................................................................... 108

Means of transport............................................................................ 108

Storage.............................................................................................. 109

Transport units ....................................................................................... 109

Long-term storage.................................................................................. 110

General information........................................................................... 110

Anti-friction bearings ......................................................................... 110

12 Index .................................................................................111

13 Annex................................................................................117

Spare parts lists...................................................................................... 117

Annexes ................................................................................................. 117

Drawings ................................................................................................ 117

BEUMER stretch hood® S Introduction

BA-6090103-EN

19.08.09 7

Introduction These operating instructions help you to familiarise yourself with the ma-

chine/system and to make use of its designated applications. They contain im-

portant information on how to operate the machine/system safely, correctly and

most efficiently.

The operating instructions are subdivided into chapters so as to facilitate finding

the information desired. The order of chapters and subject areas can be seen

from the list of chapters. The introduction of these operating instructions con-

tains the following notes:

• Table of contents

• Introduction

• Where can I find what I am looking for?

• Addresses

• EC declaration by the manufacturer

Introduction BEUMER stretch hood® S

8 BA-6090103-EN

19.08.09

Where can I find what I am looking for?

The following aids facilitate finding the information desired:

Search for chapters

• Selecting the desired chapter in the list of chapters

Table of contents

• Complete table of contents at the beginning of the operating instructions

Index

• Index at the end of the operating instructions

Should you have any questions, please indicate the document number so as to

enable us to help you.

1 Machine type

2 Title of chapter

3 Date of issue

4 Document number

5 Page number

Header

The header is located in the upper section of the page. The machine type is

indicated in the inside margin of the header, the relevant chapter of the operat-

ing instructions in the outside margin.

Footer

The footer is located in the lower section of the page. The document number is

indicated in the inside margin of the footer. The document number consists of

the letters BA, the order number and the language identifier. The date of issue is

indicated below the document number. The page number is indicated in the

outside margin of the footer. It consists of the number of the chapter and a con-

secutive number.

BEUMER stretch hood® S Addresses

BA-6090103-EN

19.08.09 9

Addresses

Germany

BEUMER Maschinenfabrik GmbH & Co. KG

Postfach 12 54 · D - 59267 Beckum

Oelder Str. 40 · D - 59269 Beckum

Phone:

Fax:

E-Mail:

Internet:

+49 (25 21) 24 0

+49 (25 21) 24 280

www.BEUMER.com

Technical After-Sales Service

Phone: +49 (25 21) 24 444

Spare Parts Department

Phone: +49 (25 21) 24 343

America

BEUMER Corporation

191Chambers Brook Rd.

Branchburg, NJ 08876

USA

Phone:

Fax:

E-Mail:

Internet:

+1 732 5608222

+1 732 5630905

www.BEUMER.com

BEUMER stretch hood® S Declaration by the manufacturer

BA-6090103-EN

19.08.09 11

Declaration by the manufacturer

as defined by the EC Machine Directive 98/37/EC, Annex II B

Manufacturer: BEUMER Maschinenfabrik GmbH & Co. KG

Oelder Str. 40 D-59269 Beckum

The design and construction of the machine mentioned below - up to the interfaces and as far as possible

regarding the scope of supply - correspond to the fundamental requirements with regard to safety and

health according to Annex I of the EC Machine Directive as well as to the requirements laid down in the

EC directives listed below.

Machine: Packaging system

Number: 6090103.10 - 210

EC directives complied with:

98/37/EC Directive of the European Parliament and of the Council of 22 June 1998 on the ap-

proximation of the laws of the Member States relating to machinery

2006/95/EC Directive 2006/95/EC of the European Parliament and of the Council of 12 December

2006 on the harmonisation of the laws of Member States relating to electrical equip-

ment designed for use within certain voltage limits

2004/108/EC Directive 2004/108/EC of the European Parliament and of the Council of 15 Decem-

ber 2004 on the approximation of the laws of the Member States relating to electro-

magnetic compatibility and repealing Directive 89/336/EEC Text with EEA relevance

Harmonised standards applied:

EN ISO 12100-1 EN ISO 12100-2 EN ISO 13850 EN ISO 13857 EN ISO 14121-1

EN 619 EN 953 EN 954 EN 983 EN 60204-1

This machine is designed for being mounted on other machines. Commissioning this machine is prohib-

ited unless it has been established that the machine to which it is to be mounted complies with the re-

quirements of the directive.

Beckum, 4 August, 2009

BEUMER Maschinenfabrik

BEUMER stretch hood® S Intended use

BA-6090103-EN

19.08.09 13

1 Intended use

Use The packaging system comprising the BEUMER stretch hood® prepares stretch

hoods which are pulled over palletised load units for the purpose of securing

loads. The stretch hoods are formed from a gusseted film tube. The palletised

load units are transported by roller conveyors and/or chain conveyors. Using the

packaging system for other purposes than those mentioned above is considered

as unauthorised use.

Operate the machine/system only in technically perfect working order in accor-

dance with its intended use. The safe operation requires awareness of possible

risks and observing the operating instructions. Eliminate immediately any func-

tional disorders, especially those affecting safety!

As regards the electromagnetic compatibility, the machine/system has been

designed for the use in industrial environment. If the machine/system is used in

other environments, a special permit issued by the relevant authorities of the

country of use is required.

An intended use also involves observing the operating instructions. Special at-

tention is to be paid to the inspection and maintenance instructions.

Any modifications, additions or conversions to the machine/system which could

affect safety must not be carried out without the manufacturer's approval. This

also applies to the installation and adjustment of safety devices and valves as

well as to welding work on load-bearing elements.

Danger zone According to the level of hazards involved when operating the machine/system,

three different areas are distinguished. Only persons authorised by the owner

have access to the individual areas.

Access area

The access area, which is defined by the manufacturer, may be entered or

reached by any persons without opening guards, activating protective devices

with sensors or using additional tools.

Working area

The working area, which is defined by the manufacturer, is the area where per-

sons work on the machine/system or operate it in normal operation (inspection,

maintenance and cleaning are excluded).

Maintenance area

The maintenance area, which is defined by the manufacturer, may only be en-

tered by authorised personnel for carrying out maintenance work. Since health

and safety of the personnel are at risk in this area, it may be entered only if the

machine/system is switched off and secured against unintentional re-start.

Intended use BEUMER stretch hood® S

14 BA-6090103-EN

19.08.09

Owner's responsibility

The user has to ensure the following:

• Any work on and with the machine/system is carried out by authorised per-

sonnel only.

• Work on the electrical equipment of the machine/system are carried out only

by skilled electricians in accordance with the electrical engineering rules and

regulations.

• Only trained or instructed personnel is employed! Set out clearly the individ-

ual responsibilities of the personnel for operation, set-up, maintenance and

servicing!

Qualification of personnel

Operating personnel

Operating personnel includes all persons who have been employed by the

owner to operate the machine/system. In order to be able to carry out work with

the machine/system without further assistance, the operating personnel must

have completed the theoretical and practical training.

Training measures are offered to familiarise the operating personnel with special

features of the machine.

Skilled personnel

Skilled personnel includes all persons who have been employed by the owner of

the machine/system to perform special tasks such as maintenance or trouble

shooting. In order to be able to fulfil these tasks without further assistance, the

skilled personnel must have completed the theoretical and practical training.

The skilled personnel has to fulfil the following requirements:

• Completed vocational training in the mechanical engineering or metal trade

• Six-month experience of maintaining conveying systems

• Supplementary training for work to be carried out on hydraulic or pneumatic

systems

Skilled electrician

Skilled electricians are persons having an adequate technical education, knowl-

edge and experience to recognise and avoid risks which may be caused by elec-

tricity. A skilled electrician has to fulfil the following requirements:

• Electrotechnical education

• Knowledge and experience

• Knowledge of the relevant standards

• Ability to assess entrusted tasks

• Ability to recognise risks

BEUMER stretch hood® S Intended use

BA-6090103-EN

19.08.09 15

Unauthorised use

An unauthorised use of the machine includes:

• Transport of materials which are not laid down in the contract and in these

operating instructions.

• Non-compliance with the permissible parameters of the material/items trans-

ported.

• Use of materials, e.g. operating resources, films, pallets etc., which are not

specified.

• Maintenance work on a machine which is not secured.

• Non-observance of the operating instructions.

• Non-utilisation of genuine spare parts

We explicitly point out that only spare parts which have been released by us are

to be used. This also applies analogously to subassemblies by our subsuppliers.

In addition, the stipulations agreed by contract are valid.

Danger!

An unauthorised use of the machine/system could result in severe per-

sonal injury or death and damage to the system.

The machine/system must not be switched on if defects jeopardise the opera-

tional reliability.

BEUMER stretch hood® S Technical data

BA-6090103-EN

19.08.09 17

2 Technical data

Requirements on the place of installation

Designation Data

Installation height < 1,000 m

Ambient temperature 0 °C to +40 °C

Building

For a trouble-free operation of the system, the following conditions have to be

fulfilled:

• minimum ambient temperature -5 °C

• max. wind velocity 15 m/min.

Foundation

The foundation must be designed as monolithic foundation without expansion

joints. The permissible tolerance in the evenness of the surface is +/- 7.5 mm.

Mounting holes for straddling dowels with a diameter of 21 mm and a depth of

150 mm must be possible. When using compound anchors, mounting holes with

a diameter of 32 mm and a depth of 250 mm must be possible. The quality of

concrete must be at least BN 1045 according to DIN 25

Lighting

Arrange for sufficient lighting around the machine. Avoid glaring light, strobo-

scopic effects, reflections, flashing or other harmful influences.

Power supply

Electrical energy

Designation Data

Rated voltage for the system 3/N/PE AC 460 V 60 Hz

Rated voltage for the control DC 24 V

Rated voltage for the emergency stop circuit DC 24 V

Rated voltage for emergency stop contactors AC 115 V

Rated voltage for motor contactors DC 24 V

Rated voltage for valves DC 24 V

Permissible voltage fluctuation ± 10 %

For a safe and trouble-free operation, a stable power supply has to be provided.

Technical data BEUMER stretch hood® S

18 BA-6090103-EN

19.08.09

Pneumatic energy

Designation Data

Compressed-air connection required 6 bar

Permissible input pressure max. 10 bar

Compressed-air connection R 3/8 "

Air volume required per package 180 NL

In order to achieve a safe and trouble-free operation, a stable compressed-air

supply system has to be provided. The compressed air used should be filtered

and dried; it should be oil-free and have an input pressure of 6 bar.

• Solid particles:

class 4; max. permissible particle size 40 my.

• Water content:

class 4; dew point +10 °C = 9.356 g/m³ water content.

• Oil content:

class 4; max. permissible content 5 mg/m³.

Pneumatic cylinders are provided with a basic lubrication in the workshop.

Therefore, the cylinders can be used with either oiled compressed air (0.5 to 5

drops of oil / 1000 litres of air) or oil-free compressed air.

Once used with oiled compressed air, the cylinders should always be used with

oiled compressed air (oil content > 10 mg/m³, about 5 drops of oil / 1000 litres o

f

air). Oiled compressed air eliminates the basic lubrication.

Material/items transported

Designation Data

Product medical products

Product packing cardboard boxes

Items transported palletised load units

Weight max. 2,000 kg

Temperature max. 80 °C

Pallets

The pallets must correspond to the dimensions indicated in the installation draw-

ing. The tolerances for length, width and height may amount to ± 3 mm.

All boards of the lower and upper side must be in place and in perfect condition.

Any edges, nails etc. protruding must be removed beforehand. Only then the

pallets can be transported properly.

BEUMER stretch hood® S Technical data

BA-6090103-EN

19.08.09 19

Film specification

The film used must correspond to the film specification. Only then a perfect func-

tioning of the system can be ensured.

The following changes require that a film roll is ordered first as sample for a

functional test:

• Change of film manufacturer or supplier

• Change of film dimensions

• Change of film thickness

If the test has been successful, larger quantities of film can be ordered.

The current film specification is indicated on the specification sheet included in

the annex.

Performance data

Designation Data

BEUMER stretch hood®6090103.50 - 130

Packaging capacity 40 packages/h

Maximum package length 1,219 mm

Maximum package width 1,016 mm

Maximum package height 2,750 mm

Height of platform 4,500 mm

Max. weight of full pallet 2,000 kg

Installed power approx. 6.7 kW

Field of application, ambient temperature +5 °C to +40 °C

Noise emission < 70 dB(A)

Pallet transport system 6090103.10 - 40

6090103.160 - 190

Height of transport system 700 mm

Maximum bearing capacity per roller conveyor 2,000 kg

Conveying speed, transport system 0.23 m/s

Installed power approx. 5.6 kW

Field of application, ambient temperature +5 °C to +40 °C

Noise emission < 75 dB(A)

Table of contents