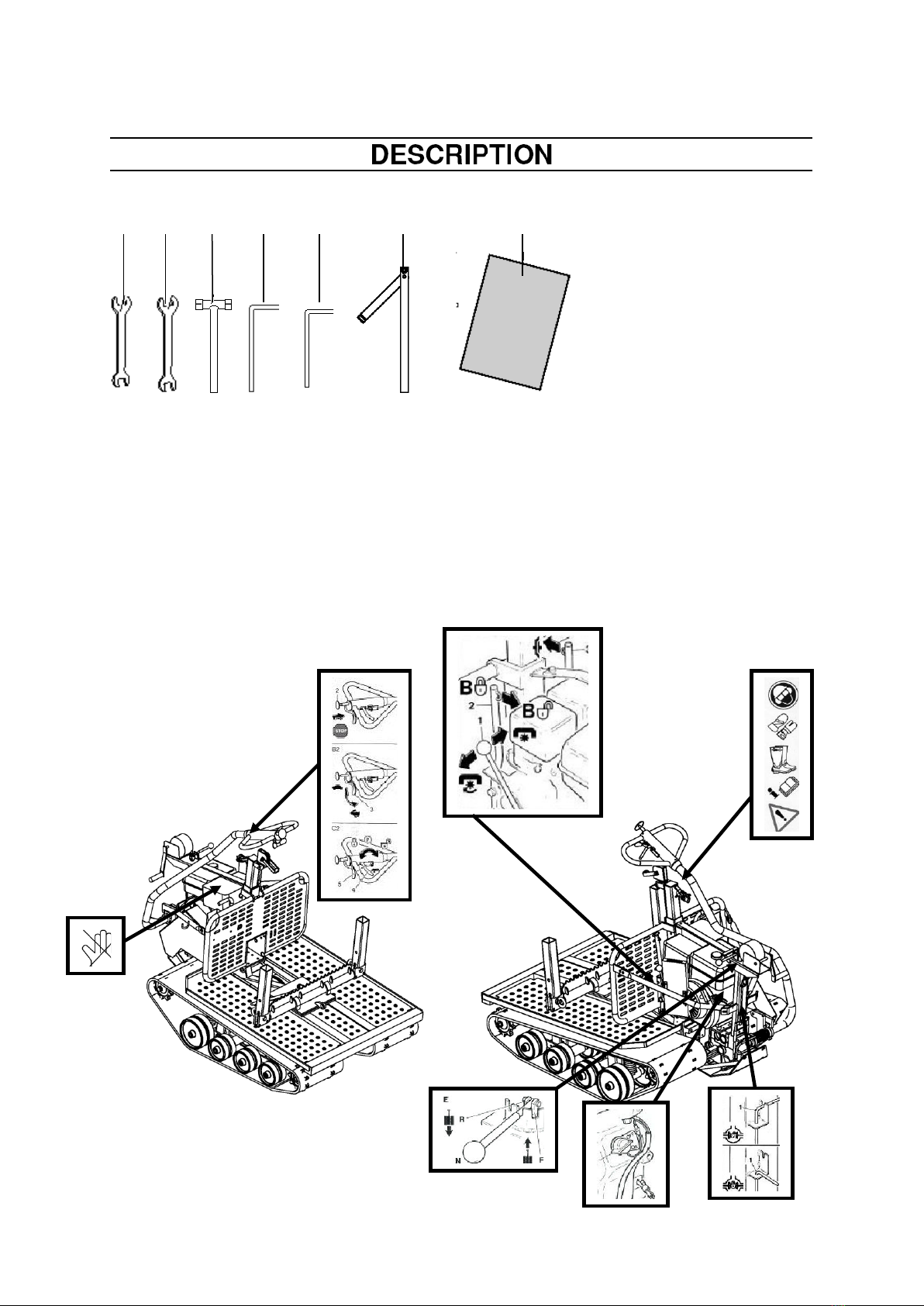

Iron Horse (FIG. 2)

The Iron Horse consists of the following parts:

Note! Some parts are optional and are not

included as standard.

• Chassis with mounts for the drive unit, log bunk,

bogie and caterpillar track.

• Load anti-slip guard.

• Load anti-slip guard with integrated power winch.

• Manual winch.

The drive unit consists of the following parts:

• Engine with muffler and fuel tank

• Variator.

• Gearbox with mounts for the steering arm and

drive axles.

• Dog clutch

• Steering brake.

The steering arm consists of the following parts:

• Handlebars with controls

• Adjustable spring for weight balance

• Steering yoke

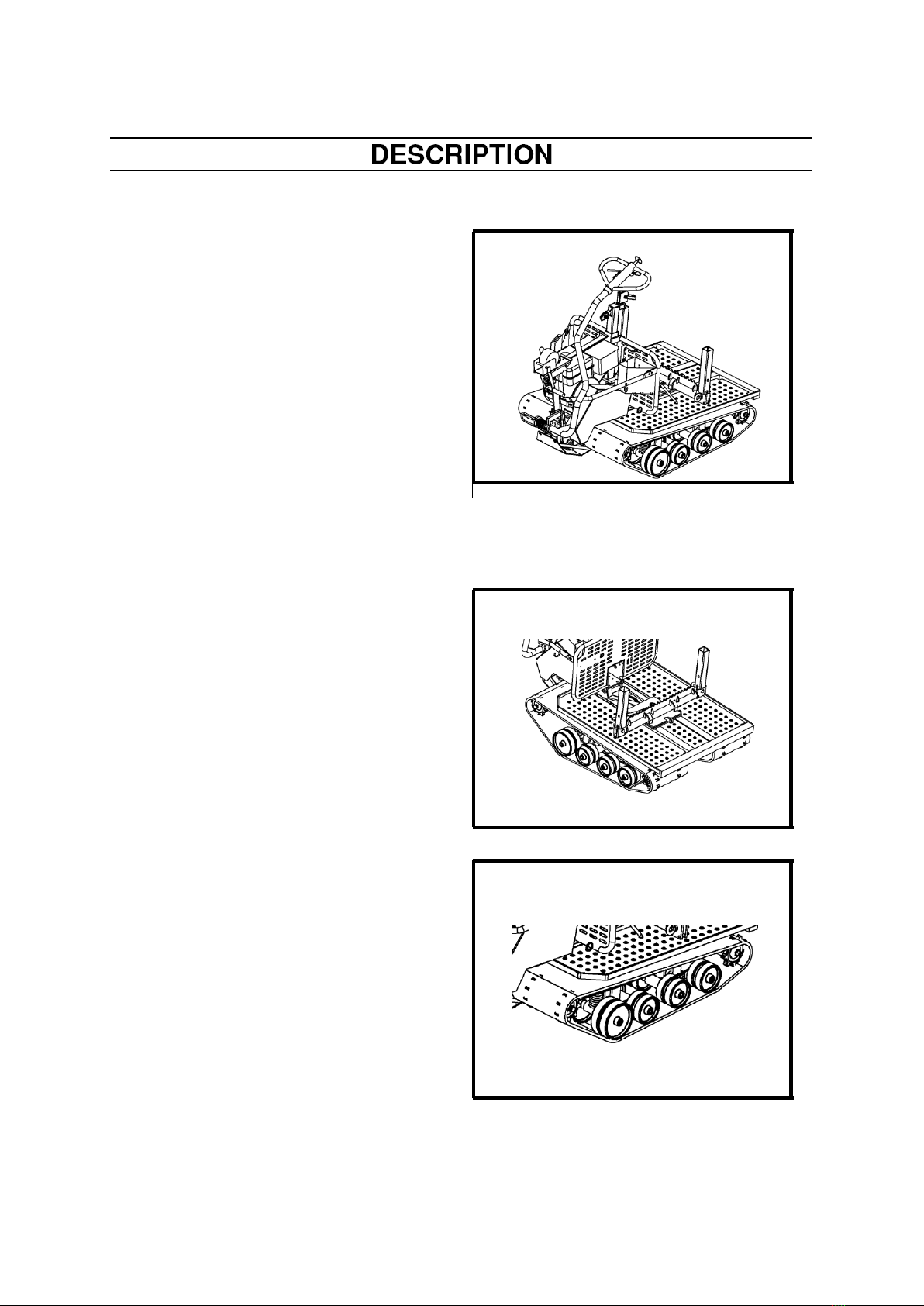

Chassis (FIG. 3) and (FIG. 4)

The chassis is made up of welded square tube

with mounts for the gearbox, load anti-slip guard,

drive axles and bogies. The chassis is also fitted

with perforated sheet metal plates that protect the

tracks. The plates can also serve as a basic

platform to transport loads. The chassis is

equipped with a swing plate to attach the log bunk

and other accessories. The chassis also houses

strong mounts for the machine's bogie and bogie

wheels. The Flex model also has an accessory

mount that is adjustable lengthwise for increased

application possibilities.

Wheel bogie and caterpillar track

(FIG. 3) and (FIG. 4)

The wheel bogie consists of the bogie cradles,

which is supported by bearings on the chassis.

The bogie is available with two types of wheels.

1. Nylon wheels with double wheels on all

axles.

2. Nylon wheels with double wheels on all

axles, supported on bearings and sealed.

The caterpillar track is manufactured of natural

rubber, which is extremely hardwearing and

reinforced with Kevlar and nylon cord. The tracks

are available in two versions.

1. With tooth gaps, which are reinforced by

metal clips and cast epoxy rods.

2. For particularly demanding conditions,

there is a version with internal drive with

interior rubber heels.