Beverage-Air SM Series User manual

INSTALLATION AND OPERATING INSTRUCTIONS

for all Hydrocarbon

SM School Milk Cooler Models

3779 CHAMPION BLVD, WINSTON-SALEM, NC 27105

Phone: (888) 845-9800 | Fax: (800) 253-5168 | Web: beverage-air.com

809-186A 6/6/2020 SEE BACK COVER FOR

WARRANTY REGISTRATION

User Manual for SM School Milk Cooler Beverage-Air

Rev. 06/20Beverage-Air2

WELCOME

Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Important Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Product Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Clearance and Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Unpacking and Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Using The Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Sequence of Operations Refrigerator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cleaning and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Condenser Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Methods For Cleaning Stainless Steel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

For The Service Tech - R290 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

For The Service Tech - Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Limited Warranty (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Important Information

• PLEASE READ THESE INSTRUCTIONS CAREFULLY

BEFORE INSTALLING OR USING, IF RECOMMENDED

PROCEDURES ARE NOT FOLLOWED, WARRANTY

CLAIMS MAY BE DENIED.

• Your warranty registration information is located with

this manual. Please complete the card and submit it to

Beverage-Air within TEN days of installation. Failure

to properly register equipment may limit or void the

warranty.

• Beverage-Air reserves the right to change

specications and product design without

notice. Such revisions do not entitle the buyer to

corresponding changes, improvements, additions, or

replacements for previously purchased equipment.

Thank you for purchasing a Beverage-Air cabinet. This

series has passed our strict quality control inspection and

meets the high standards set by Beverage-Air! You have

made a quality investment that with proper maintenance

will give you many years of reliable service!

Please read the following installation and maintenance

instructions before installing or using your unit. If you

have any questions, Please call our Technical Service

Department at (800) 684-1195. 8:00 AM to 5:00 PM EST.

User Manual for SM School Milk Cooler Beverage-Air

Rev. 06/20 Beverage-Air 3

SAFETY

This appliance has been designed with your safety in mind. It has many features to keep you from being harmed. However,

safe operation and maintenance are your responsibilities.

Use: When using this unit, please:

• Move it carefully. If on casters be sure the casters

do NOT run over the power cord.

• Lock the casters when in use.

• Seek help. This machine is heavy! Be sure to move

with enough help to avoid tipping or dropping the

cabinet.

• Prevent children from playing in or on the cabinet.

Persons unable to use this product must be

prevented access.

• Follow all instructions. There are many safety

labels and directions on the unit. Heed them.

• Watch your ngers. There may be pinch points near

the door hinges.

Maintenance

Do NOT:

• Clean a frozen evaporator with a sharp object

• Clean a dirty condenser with a sharp object.

• Store gasoline, kerosene or any other ammable

material near the cabinet.

Do ALWAYS

• Use a Beverage-Air recommended technician certied

to repair R290 equipment.

• Use ONLY Beverage-Air factory service parts. Use of

non OEM parts can be dangerous because of the design

changes needed to safely use R290.

Observe the Caution and Warning notices. They are indicators of

important safety information. Keep this manual for future reference.

Important Information to Add

Record the model number, serial number and the date of installation here for future reference. The model and serial

numbers are on the unit's serial number dataplate, which is located on the left inside wall.

Model Number

Serial Number

Date of Installation

Purchased From

CAUTION

WARNING

CAUTION

CAUTION

User Manual for SM School Milk Cooler Beverage-Air

Rev. 06/20Beverage-Air4

IMPORTANT INFORMATION

This unit is intended to be used in a commercial application. That includes schools and cafeterias.

If installed in a residence some commercial service companies may not be able to service it on site.

The manufacturer has designed and produced this machine with the nest in materials. The manufacturer assumes no

liability for units that have been altered in any way. Alterations or part substitutions will void the warranty.

Limitations

The machine is designed for use indoors in a controlled

environment. It must be kept dry, not overheated or

subjected to excessive cold. May only be connected to

a dedicated electrical circuit. Extension cords are not

permitted.

Minimum Maximum

Voltage 104 127

Room Air Temp 60º F 100º F

Air Flow

Agency Approvals

These marks appear on the dataplate or serial tag, located

in the inside of the left wall. The dataplate also contains

the model and serial numbers as well as electrical

requirements.

User Manual for SM School Milk Cooler Beverage-Air

Rev. 06/20 Beverage-Air 5

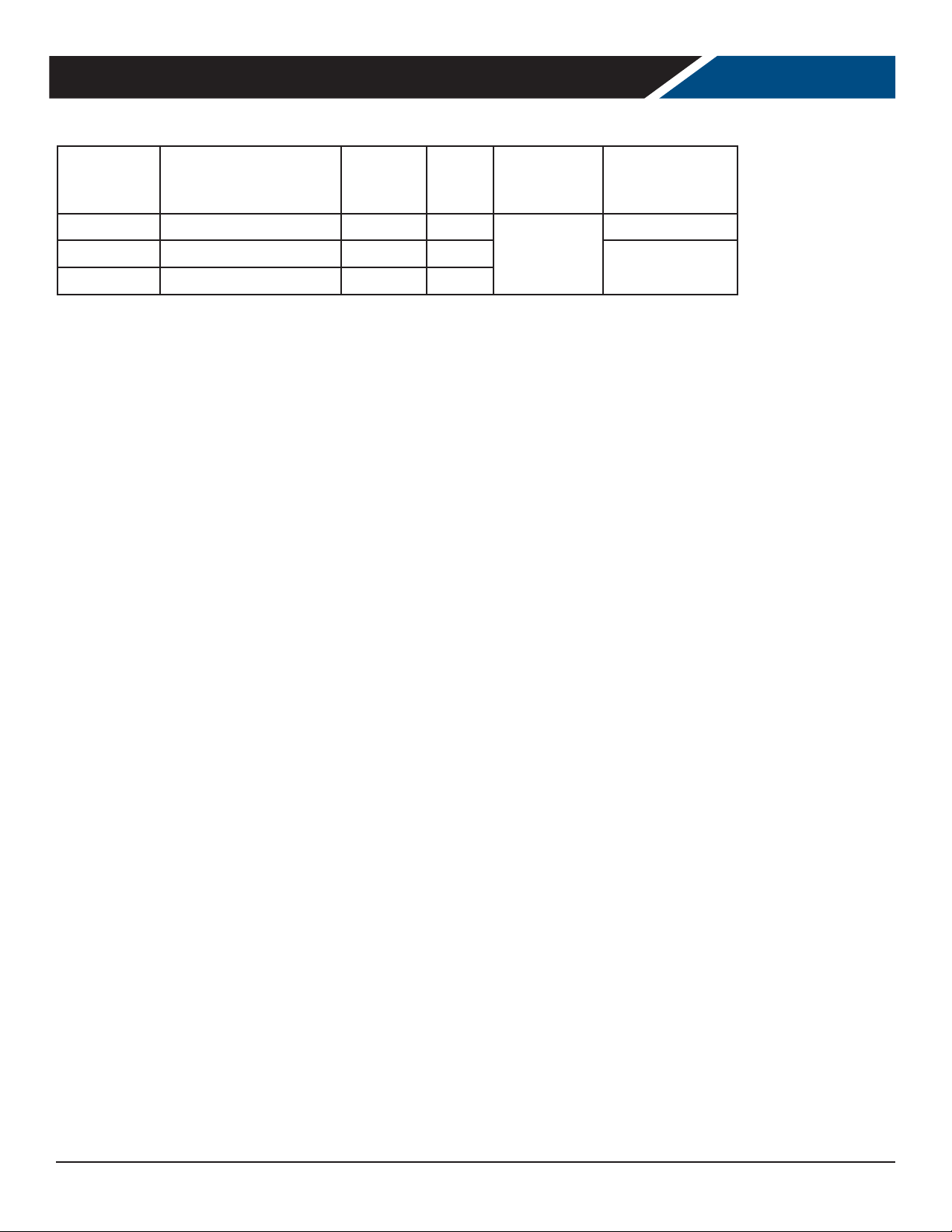

Model Cabinet Dimensions

w x d x h (Inches)

Glass

or Solid

Door

Full

Load

Amps

Power Cord

Plug (NEMA)

Refrigerant Type

/ Charge g /

Charge oz

SM34HC 34 x 30 5/8 x 41 1/8 Solid 2.2

5-15P

R-290 / 60 / 2.12

SM49HC 49 x 30 5/8 x 41 1/8 Solid 2.2 R-290 / 70 / 2.82

SM58HC 58 x 30 5/8 x 41 1/8 Solid 2.2

Height includes casters

PRODUCT INFORMATION

• All models will maintain product temperature between 35.5 and 40.5 degrees F. at the factory setting of 38.0F.

• All models are 115 volts, 60 Hz AC.

• ALWAYS REFERENCE YOUR EQUIPMENT DATA PLATE AMPS, REFRIGERANT AND REFRIGERANT CHARGE FOR THE

MOST UP TO DATE AND ACCURATE VALUES.

• There are no access valves on the refrigeration system.

This manual suits for next models

3

Table of contents

Other Beverage-Air Accessories manuals