BEXT PJ 250 User manual

1

PJ 250

FM Power Amplifier

87.5 - 108 MHz Range

TECHNICAL

MANUAL

2

INDEX

PRELIMINARY INSTRUCTIONS AND WARRANTY INFORMATION........................................... 2-3

INSTALLATION ....................................................................................................................................... 4

MECHANICAL / ELECTRICAL .............................................................................................................. 4

OPERATION ........................................................................................................................................... 4-5

TECHNICAL SPECIFICATIONS ............................................................................................................. 6

FRONT AND REAR PANEL CONTROLS .............................................................................................. 7

FIGURE 1 FRONT PANEL ....................................................................................................................... 8

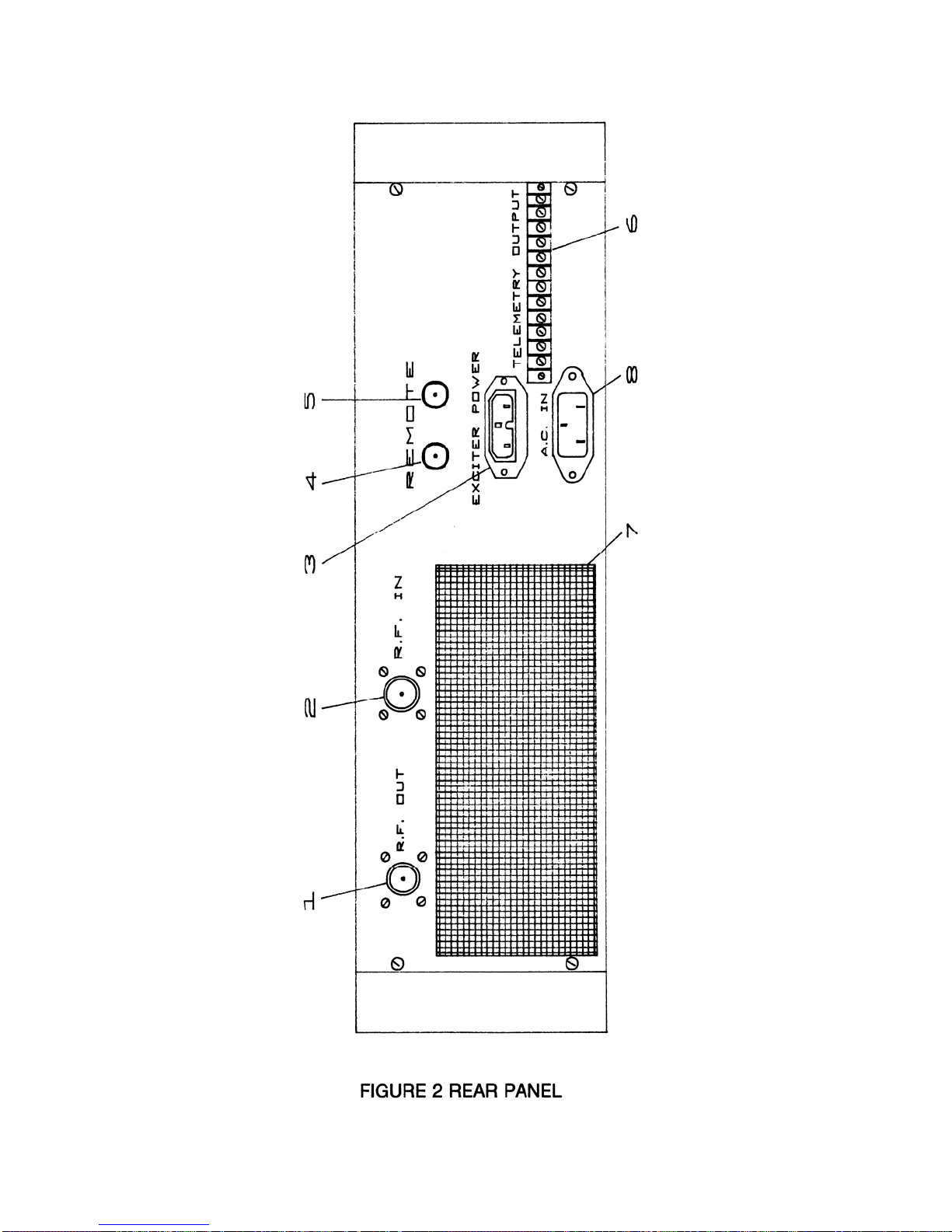

FIGURE 2 REAR PANEL .......................................................................................................................... 9

GENERAL AND ELECTRICAL DESCRIPTION ............................................................................. 10-11

RECOMMENDED TEST EQUIPMENT ................................................................................................. 11

MAINTENANCE AND ADJUSTMENTS ......................................................................................... 11-14

SETUP 1 ................................................................................................................................................... 15

SETUP 2 ................................................................................................................................................... 16

FIGURE 3 AMPLIFIER BLOCK DIAGRAM ......................................................................................... 17

FIGURE 4 AC POWER CONNECTIONS ............................................................................................... 18

FIGURE 5 SCHEMATIC, UNREGULATED POWER ........................................................................... 19

FIGURE 6 SCHEMATIC, REGULATED POWER ................................................................................ 20

FIGURE 7 SCHEMATIC DRIVER AMPLIFIER (PJ250 L/D ONLY) .................................................. 22

FIGURE 7a IPA RF AMPLIFIER (PJ250 L/D ONLY) ........................................................................... 23

FIGURE 8 SCHEMATIC, POWER AMPLIFIER ................................................................................... 25

FIGURE 9 SCHEMATIC, ALARMS CARD .......................................................................................... 27

FIGURE 10. COMPONENTS ARRANGEMENT, ALARMS CARD .................................................... 28

FIGURE 11. SCHEMATIC, LOW PASS FILTER .................................................................................. 31

FIGURE 12. SCHEMATIC, VSWR BRIDGE ......................................................................................... 33

FIGURE 13. SCHEMATIC, TELEMETRY CARD ................................................................................ 34

FIGURE 14. COMPONENTS ARRANGEMENT, TELEMETRY CARD ............................................. 35

FIGURE 15. WIRING DIAGRAM, TELEMETRY INTERCONNECT ................................................. 36

PARTS LIST POWER SUPPLY .............................................................................................................. 21

PARTS LIST RF DRIVER BOARD (PJ250 L/D ONLY) ....................................................................... 24

PARTS LIST RF POWER AMPLIFIER .................................................................................................. 26

PARTS LIST LOW PASS FILTER .......................................................................................................... 32

PARTS LIST DIRECTIONAL COUPLER .............................................................................................. 32

PARTS LIST ALARMS PROTECTION CARD ................................................................................ 29-30

PARTS LIST TELEMETRY CARD ........................................................................................................ 37

3

PRELIMINARY INSTRUCTIONS AND

WARRANTY INFORMATION

1. Please observe all safety precautions when handling this unit. This equipment contains

dangerous currents and voltages.

2. This manual is written as a general guide for those having previous knowledge and

experience with this kind of equipment. It is not intended to contain a complete statement

of all safety precautions which should be observed by personnel in using this or other

electronic equipment.

3. BEXT Inc. does not assume responsibility for injury or damage resulting from improper

procedures or practices of untrained/unqualified personnel in the handling of this unit.

4. Please observe all local codes and fire protection standards in the operation of this unit.

5. CAUTION: Always disconnect power before opening covers or removing any part of this

unit. Use appropriate grounding procedures to short out capacitors and high voltage

points before servicing.

6. Any damage to the goods must be reported to the carrier in writing on the shipment

receipt. Any discrepancy/damage discovered subsequent to delivery shall be reported to

BEXT Inc. within five days of receipt.

7. BEXT Inc. extends to the original end-user purchaser all original manufacturer’s

warranties which are transferable and all claims are to be made directly to BEXT Inc. per

indicated procedures.

8. All manufacturer’s warranties will be supported by BEXT Inc. to ensure precise and

speedy service where possible.

9. BEXT Inc. shall not be liable for damages of any nature arising out of or in connection

with the product or its use thereof.

10. BEXT’s warranty shall not include:

10.1 Reshipment of the unit to BEXT for repair purposes.

10.2 Any unauthorized repairs/modifications.

10.3 Incidental/consequential damages as a result of any defect.

10.4 Nominal non-incidental defects.

10.5 Reshipment costs or insurance of the unit or replacement units/parts.

11. Warranty shall commence on the invoice date and for the period of the manufacturer’s

warranty.

4

12. To claim your rights under this warranty:

12.1 Contact the dealer or distributor from whom this product was purchased. Describe

the problem and ask if they have an easy solution. Dealers and distributors are

supplied with information on problems which may occur and usually can repair

the unit more quickly than going directly to the factory. It is also often true that

errors in installation or use will be discovered by your dealer.

12.2 If your dealer cannot help, contact BEXT Inc. at (619) 239-8462 and explain the

problem. If it is determined that the unit needs to be returned to the factory,

BEXT will provide a return authorization number with instructions.

12.3 When you receive the return authorization, you can return the unit. Pack the unit

carefully for shipment. Preferably, use the original packing materials and assume

that the shipping carton will be dropped several times during the transportation

process. We recommend the use of UPS or similar freight services and would

discourage the use of the postal system. The customer assumes the risk of loss,

(i.e. BEXT Inc., is not responsible for damage or loss) until the package is

received by BEXT, so we advise taking out insurance for the full replacement

value of the unit. Ship the unit PREPAID to the address specified by BEXT’s

service manager on the return authorization. DO NOT RETURN UNITS

WITHOUT A RETURN AUTHORIZATION, AS THEY WILL NOT BE

ACCEPTED.

12.4 Be sure to enclose a written descriptive statement of the problem experienced and

a copy of your original invoice establishing the starting date of the warranty.

13. BEXT Inc. reserves the right to modify the design and specifications of the equipment in

this manual without notice.

14. Replacement and warranty parts may be ordered from the address below. Be sure to

include equipment model and serial number and part description and part number.

BEXTInc.

1045 Tenth Avenue

San Diego, CA 92101 USA

(619) 239-8462 • FAX (619) 239-8474

24-Hour Pager: (619) 529-4711

http://www.bext.com

5

INSTALLATION

INSTALLATION

A. Read the BEXT warning, shipping and warranty information at the front of the manual.

B. Handle the unit as carefully as possible.

C. Unpack the amplifier and, before any other operation, check that the amplifier isn't damaged and

that all controls on the front and rear panel are in good condition.

D. Save the original packing materials.

MECHANICAL / ELECTRICAL

A. Operate the unit with adequate ventilation in a relatively cool environment.

B. Check that the A.C. supply is adequate for the expected power consumption and that the line

voltage matches the taps in the unit with minimal line voltage variation. If the line voltage

fluctuates frequently and extensively, a voltage regulator is recommended. A surge/transient

suppression system is also highly recommended.

C. Never operate the unit without a dummy load or properly matched antenna load.

D. If you are going to operate solid state equipment as a final amplifier in a very crowded

transmitting site, it is suggested that a fundamental frequency/cavity bandpass filter be inserted in

the line between the equipment and the antenna. The BEXT staff can assist you.

OPERATION

A. Open the cover and check the voltage setting on the transformer. The transformer offers several

taps for different voltages. If it is found necessary to move the taps, move only the A.C. primary

taps. Do not move the fan wires which are connected to the same terminal block.

B. Turn the "power adjust" of the exciter to zero and turn the power switches to the "off" position of

both the amplifier and the exciter. Set the exciter to the desired frequency of operation.

C. Connect the RF output of the exciter to the input of the amplifier. The input of the amplifier uses

a type "N" connector. Use good quality cable to prevent RF leakage. Connect the RF output of

the amplifier to a suitable dummy load or antenna.

D. Connect the exciter A.C. cord to the plug provided on the rear of the amplifier. This will provide

protection by shutting down the exciter when an alarm condition is detected by the amplifier.

Connect the amplifier A.C. cord to the A.C. supply.

E. Turn the amplifier power on. The power indicator should come on and the fans should begin

running. CAUTION: Do not apply RF drive unless the fans are running properly. If the unit does

not come on the user should check the following:

1. Check the A.C. line fuses.

2. Check the A.C. line connections.

3. Check the internal transformer taps and the fan/blower itself.

F. Turn on the exciter. The power indicator light should come on and a lock indication should come

on. The exciter blower should also be running. Check all power supply voltages on the amplifier

and exciter to ensure they are correct before proceeding. The amplifier voltage should be

approximately 28 volts. Exciter voltages will be marked on the front panel of the exciter and will

vary with the type of exciter.

G. Set the power meter switch to the forward power position on both the exciter and the amplifier.

Slowly advance the power on the exciter until RF power output is observed on both meters.

Check now for VSWR. If the standing wave reading appears normal (less than 1.5:1) then

proceed to raise the power. The voltage on the amplifier should remain steady at approximately

6

28 volts. The exciter PA voltage will change with drive level. Efficiency of the amplifier will be

approximately 60%.

H. Maximum VSWR should never exceed 2:1. Should the amplifier see a VSWR higher than this it

will trip the alarm board and shut down both the amplifier and the exciter.

I. Alarm conditions which will shut down the amplifier are: VSWR of greater than 2:1; excessive

power output(higher than the rating); high temperature. Should the amplifier sense any of the

above conditions it will shut down and automatically attempt to restart after 90 seconds and will

attempt 4 times to restart. The unit will then shut down for 15 minutes; and again go through the

4 restart attempts. After four of these cycles the unit will go into a permanent shutdown. The

power must be recycled to reset the alarm circuits. The operator should always look at the front

panel to determine which alarm shut the unit down. This will aid in locating conditions which are

causing the problem should one exist.

J. Telemetry is provided on the rear panel to monitor the voltage, current, power, and reflected

power of the amplifier. Terminals are also provided to enable putting the amplifier in standby via

a momentary contact closure. A momentary contact closure will also reactivate the amplifier. A

second input is provided which will place the amplifier and exciter in standby. Two "BNC"

connectors labeled "REMOTE" are provided on the rear of the amplifier and another on the rear

of the exciter. Connect the exciter remote BNC to the either of the amplifier remote BNC

connectors. By placing a ground on the center pin of the second BNC connector the RF drive will

be shut down to the amplifier. This can be accomplished by placing a ground on the exciter

remote connection only.

K. High VSWR conditions may be caused by icing of the antenna during winter storms. Leaking

transmission lines may have moisture or damage may occur to the antenna itself. Do not attempt

to reset the alarm levels to circumvent an external problem. This will cause damage to the

expensive RF output transistors and void the warranty. The user should also provide effective

lightening protection such as sorted quarter wave stubs on the transmission line. Power line

protection is also recommended as lightening hits many time come in on the power or telephone

lines. The telemetry lines should also be protected if connected to the telephone lines or lines

exiting the building. A good grounding system will help ensure many years of reliable operation

from your solid state equipment.

7

TABLE A

TECHNICAL SPECIFICATIONS

A.C. Supply 100-130 V or 198-250 V

50-60 Hz

Cooling Forced Ventilation

Frequency Range from 87.5 to 108 MHz or

from 66 to 75 MHz

Power Output Max 300 W, typ. 250 W (Note: Limit power to

250W to maintain a good level of reliability.

RF Drive Power approximately 25 W for

P out=250 W

RF Input Impedance 50 ohm

RF Output Impedance 50 ohm

I/O Connector Standard "N" Connector

Harmonic and Spurious Signal Suppression meets or exceeds FCC and CCIR regulations

Power Consumption 800 w

TABLE B

DIMENSIONAL AND ENVIRONMENTAL SPECIFICATIONS

Cabinet Dimension 122mm(4.8")H x 420mm(16.54")W

350mm(13.78")D

Panel Size 483mm(19")W x 132mm(5.2")H

Operating Temperature -10°C to 45°C

Humidity 90% Max, Non Condensing

Weight 19 Kg

The protection acts for excessive SWR, over-temperature and overdrive. It indicates the problem with

warning lights and disables the pilot exciter.

8

FRONT AND REAR PANEL CONTROLS

A. FRONT PANEL

1. Fuse 6.3 amps 220 Vac or 15 amps 120Vac

2. On/Off A.C. power switch

3. A.C. Blown Fuse Indicator

4. A.C. Power Indicator

5. Multimeter

6. Multimeter Switch

7. D.C. Fuse 20 amps

8. D.C. Blown Fuse Indicator

9. Temperature Alarm Indicator Lamp

10. Excessive Drive Alarm

11. VSWR Alarm Indicator

12. Remote Disable Indicator

B. REAR PANEL

1. RF output connector Type "N"

2. RF input connector Type "N"

3. Accessory AC plug for exciter (max 3 amps)

4. Remote protection connector Type "BNC", ground to activate

5. Remote protection connector Type "BNC". ground to activate

6. Telemetry Connections

7. Air Duct

8. A.C. Line Input

9

10

11

PJ250 GENERAL DESCRIPTION

EXTERNAL DESCRIPTION

The PJ250 is housed in a 3U 19" rack, on the front panel the alarm indicators are placed in a central

position, the mains switch and the meter for the forward and reflected power. On the rear panel the RF

INPUT and RF OUTPUT connectors are located, together with the interlock connectors, one of BNC type

and one VDE female, the main voltage input.

ELECTRICAL DESCRIPTION

The PJ250 is a power amplifier working on the 87.5-108 MHz band with an output power in excess of

250W and a drive level of about 25W. This amplifier uses a RF module composed of four amplification

stages (MRF 317), with power supplies fixed with the RF module on cooling ribs to obtain a high

dissipation. A built in low pass filter suppresses the harmonic contents below the FCC and CCIR

requirements. A protection system protects the amplifier against thermal problems, excessive input drive

power and excessive SWR inside the amplifier or along the feeder. This system provides an automatic

reset to initial conditions when the problem ceases.

METERS AND INDICATORS

The forward and reflected power of the amplifier are read by the analog multimeter (11.Fig.1) and

selected by the selector (12.Fig.l) on the front panel. Various led indicators indicate the alarm conditions

caused by thermal problems (3.Fig.l), excessive input drive power (4.Fig.l) and excessive SWR (5.Fig.l).

A green indicator confirms the amplifier is operational (10.Fig.1).

PROTECTION CIRCUITS

The protection circuits put the amplifier in stand-by in the case of a fault condition. After 90 seconds the

protection reactivates the amplifier if the fault has disappeared. If not, this process is repeated 4 times, at

the end of which the amplifier stays disabled for 15 min; after 15 min, if the trouble persists, the

protection performs another four cycles and then disables the amplifier indefinitely. If during these cycles

the anomaly disappears and the amplifier works regularly for more than 15 min, the counting system is

reset and the original conditions established.

NOTE: the intervals described are nominal.

ELECTRICAL DESCRIPTION

INTRODUCTION

This section describes the overall working theory of the PJ250. For ease of description the amplifier is

subdivided into subassemblies that will be discussed in detail below. The block diagram is illustrated in

Fig.5.

POWER SUPPLY

The power supply comprises of a P.C. board fitted to the cooling fins and is accessible from the lower

part of the amplifier, unscrewing the fixing bolts of the cooling fins as shown in Fig.4. A mains

transformer has a selectable input for voltages between 110 and 240 V and two outputs:

"A": 31 V, "B": 18 V.

The output "A" drives the RF modules. Output "B" supplies the ALARMS CARD; inside this circuit a

rectifying and stabilization circuit provides the +15 V needed by the electronics.

ALARMS CARD

12

This module is composed of a board shielded by a metal box mounted on the left side near the rear panel,

as shown in Fig.3. on this board, the electronics detect any system anomaly such as excessive SWR,

internal or antenna, over-temperature or overdrive, This module will also, whenever possible, reset the

system to its original conditions, after a fault has occurred.

RF POWER AMPLIFIER

The module is placed in the upper right side of the amplifier. This module is totally shielded and placed

on a heat sink (see Fig.3). This circuit delivers 300W with 25-30W of drive and is supplied by a dedicated

power supply. The quiescent parameters of each module are:

Vdc=28V Ia=15A Pout=250 W

The active devices employed are BJT NPN MOTOROLA (MRF317).

LOW PASS FILTER

This filter is fitted in a metallic box mounted on the heat sink on the right position as shown in Fig.3.

Thanks to this low pass filter the harmonic suppression is greater than 75 dBm.

DIRECTIONAL COUPLER

This circuit is placed on the upper right side of the amplifier and fitted on the rear panel as shown in

Fig.3. This module makes the measurement of the forward and reflected power.

RECOMMENDED TEST EQUIPMENT

INSTRUMENT TYPE SUGGESTED MODEL CRITICAL SPECIFICATIONS

Non Inductive Bird 50 ohm P > 250 W

Dummy Load

Spectrum Analyzer Advantest 10KHz-3.5GHz

MOD. R4131D

FM Monitoring R/S

Demodulator MOD. F.A.M.

Digital Multimeter MOD. Metrix

Calibrated in-line Bird MOD. 43 50 ohm

Wattmeter with Sample

Exciter BEXT Frequency 87.5-108MHz

MOD TEX 30 Pout from 2W to 30W

Dummy Load 25 ohm P 500W

MAINTENANCE

INTRODUCTION

The following section provides general maintenance information and electrical adjustment procedures for

the PJ250 Amplifier. Maintenance is divided into categories dependent upon the complexity of the

procedure and the test equipment required to complete the maintenance.

13

WARNING! WARNING! WARNING!

When the amplifier is operated with the top cover removed, hazardous voltages are accessible on the A.C.

line voltage selector and heavy currents are accessible on the exposed terminals of the power supply filter

capacitor and power transistors mounted on the RF amplifier heat sink assembly. Use the insulated tuning

tool provided for any adjustment and do not touch any component within the amplifier when power is

applied. Ensure all primary power is disconnected from the amplifier before attempting equipment

maintenance.

FIRST LEVEL MAINTENANCE

ORDINARY MAINTENANCE

The only regular maintenance needed by the PJ250, is the periodic replacement of the blowers, and the

cleaning of dust filters and any dust accumulated inside the amplifier. The time between overhauling of

the blowers depends upon several environmental factors, temperature, humidity, dust pollution etc.,

Blowers should be checked every 6 months and replaced if noisy. They should be replaced any way after

18 months of service.

SECOND LEVEL MAINTENANCE

CARDS REPLACEMENT

This section contains useful information for card replacement.

WARNING! TO RE-INSTALL CARDS SIMPLY FOLLOW THE REVERSE PROCEDURE.

POWER SUPPLY REPLACEMENT

1) open the top and bottom covers.

2) Remove the four screws (three external and one internal) of the Power Supply section placed

under the RF section.

3) From the bottom of the amplifier, open the power supply section taking care not to break the

wires connected to the card.

4) Disconnect the four fasteners placed on the power supply, and unsolder the other wire.

5) Extract the power supply section.

ALARMS CARD REPLACEMENT

1) Open the top cover.

2) Remove the screws fixing the card on the left side of the amplifier.

3) Take note of the position of wires placed on the rear of the metal box.

4) Unsolder the wires placed on the rear of the metal box.

5) Extract the Alarms card.

DIRECTIONAL COUPLER REPLACEMENT

1) Open the top cover.

2) Remove the fixing screws of the "N" type output connector (1.Fig.2).

3) Unsolder the output cable (RG 303 type) of the low-pass filter placed on the RF section.

4) Take note of the position of the four wires going out of the directional coupler and unsolder them.

5) Extract the Directional Coupler.

TRANSFORMER REPLACEMENT

1) Open the top and bottom covers.

2) Remove the central fixing bolt of the transformer.

14

3) Take note of the position of the transformer’s wires connected to the terminal block placed on the

metal support of the transformer (U.S. version), while for the standard version the wires of the

fuse and of the switch should be unsoldered.

4) Disconnect these wires from the terminal block (only for the U.S. version).

5) Unsolder the two wires connecting the transformer with the Alarms card.

6) Disconnect the fastener of the transformer placed on the diode bridge fixed on the central chassis

of the amplifier.

7) Extract the transformer.

FAN REPLACEMENT

1) Open the top and bottom covers.

2) Remove the four screws of the front panel.

3) Slide the front panel slowly.

4) Remove the fixing screws of the fan to the two rails.

5) Break the straps of the fan’s wires.

6) Disconnect the fasteners connected to the top of the fan (some units may not be fitted with

fasteners; in this case desolder the wires).

7) Extract the fan.

INTERNAL ADJUSTMENTS

POWER SUPPLY ADJUSTMENT

No adjustments are needed after this board has been changed.

DIRECTIONAL COUPLER BALANCING (PWR MEASURE)

1) Place the DIR/REF selector (12.Fig.1) to the REF position.

2) Connect (1.Fig.2) a non inductive dummy load 50 ohm / 250W to RF output with a through

wattmeter (e.g. BIRD mod.43) in series as shown in SETUP 1.

3) Set the exciter power to obtain 250W on the through external wattmeter.

4) Now, adjust variable capacitor C2 placed on the directional coupler to obtain the minimum value

on the meter, very near to zero.

FORWARD AND REFLECTED POWER ADJUSTMENT

1) Perform SETUP 1, and increase the amplifier’s output power to 250W (on the external

wattmeter).

2) Place the DIR/REF selector (12.Fig.1) to the DIR position.

3) Adjust trimmer R9 placed on the directional coupler so that the same reading is obtained on the

PJ250 meter.

4) Switch off the amplifier.

5) Connect a dummy load 25 ohm 500W (2 dummy loads 50 ohm 250W in parallel) with a through

wattmeter (e.g.. BIRD mod.43) in series, set for the reading of reflected power (SETUP 2).

6) Adjust the drive power to minimum and switch on the amplifier again.

7) Adjust the output power of the exciter to obtain a reading of 25W of reflected power on the

external wattmeter.

8) Adjust trimmer R6 placed on the directional coupler to obtain the same reading on the PJ250

meter.

ALARMS CARD ADJUSTMENT

There are three trimmers on the Alarms card that are necessary to adjust the alarm thresholds: over-

temperature - (R4); VSWR - (R7); and overdrive - (R21).

15

CALIBRATION OF OVER-TEMPERATURE ALARM THRESHOLD

1) Short-circuit the thermal switch placed on the RF section’s heat sink.

2) Adjust the trimmer, R4, placed on the Alarms card until the over-temperature protection is

activated, and the TEMP led lights up (3.Fig.1).

3) Remove the short-circuit on the thermal switch and verify that the TEMP led goes out.

4) Repeat this procedure again to verify the correct trimmer R4 adjustment.

CALIBRATION OF VSWR

1) Connect a dummy load, 25 ohm 500W (two dummy loads 50 ohm 250W in parallel) with a by-

pass wattmeter in series (e.g., BIRD mod.43) set for reflected power reading (SETUP 2).

2) Adjust the output power of the exciter to obtain a reading of 25W of reflected power on the

external wattmeter and the PJ250 meter.

3) Adjust the trimmer, R7, placed on the Alarms card until the R.O.S. protection is activated, and the

SWR led lights up (5.Fig.l).

4) Decrease the output power of the exciter and wait for the SWR led to go out (automatic

protection cycle).

5) Increase the output power of the exciter again over the R.0.S. threshold of 25W, and verify once

again, that the SWR led lights up (5.Fig.1).

CALIBRATION OF OVER-DRIVE ALARM THRESHOLD

1) Adjust the driver power to minimum and switch on the amplifier.

2) Place the DIR/REF selector (12.Fig,l) to the REF position.

3) Connect (1.Fig.2) a non inductive dummy load 50 ohm 250W to the RF output with a through

wattmeter (e.g., BIRD mod.43) in series as shown in the SETUP 1.

4) Set the exciter power to obtain 250W on the through external wattmeter and on the PJ250 meter.

5) Increase the output power of the exciter again until a reading of 270W on the PJ250 meter is

obtained.

6) Adjust the trimmer, R21, placed on the Alarms card until the over-drive protection is activated,

and the INPUT led lights up (4.Fig.1) with immediate shutdown of the amplifier.

7) Decrease the drive power of the exciter and wait for the INPUT led to go out.

8) Increase the drive power of the exciter again over the overdrive threshold of 270W, and verify,

that the INPUT led lights up (4.Fig.1).

RF SECTION ADJUSTMENT

No adjustment is required inside the RF section because it's a factory adjusted module; if calibration is

necessary, please send the module to your local distributor.

LOW-PASS FILTER ADJUSTMENT

No adjustment is required inside the Low-Pass Filter module because it's a factory adjusted module; if

calibration is necessary, please send the module to your local distributor.

16

SETUP 1

17

SETUP 2

18

19

20

FIGURE 5 SCHEMATIC, UNREGULATED POWER

Table of contents

Popular Amplifier manuals by other brands

Whelen Engineering Company

Whelen Engineering Company 01-0886999-00 installation guide

Larson Davis

Larson Davis PRM2103 Reference manual

Rockford Fosgate

Rockford Fosgate T I000-4ad Installation & operation manual

HELIX

HELIX DARK BLUE instruction manual

EarthQuake

EarthQuake Cinenova 7300 user manual

Jabra

Jabra MPA-II user guide