BFI Automation CFC 2000 Parts list manual

technology for your future

Automation

BFI

COMPACT FLAME CONTROLLER

CFC 2000

TECHNICAL DESCRIPTION

EDITION: TB CFC2000-JMM REV.1

Important:

This data sheet is intended for authorized service personnel and engineers

of combustion engineering who have sufficient experience with the installa-

tion and the use of flame monitoring devices. We gladly help you if you still

have no experience with flame monitoring devices of BFI Automation.

Please contact BFI Automation if you have questions or if you require any

support. Read this technical description carefully it contains all technical

references!

BFI – Automation Dipl.-Ing. K.-H. Mindermann GmbH, Eggerscheidter Str. 57, D-40883 Ratingen

Phone. +49 (0) 2102 96 82 – 0, Fax +49 (0) 2102 9682 – 42

E-Mail: [email protected]

technology for your future

Automation

BFI

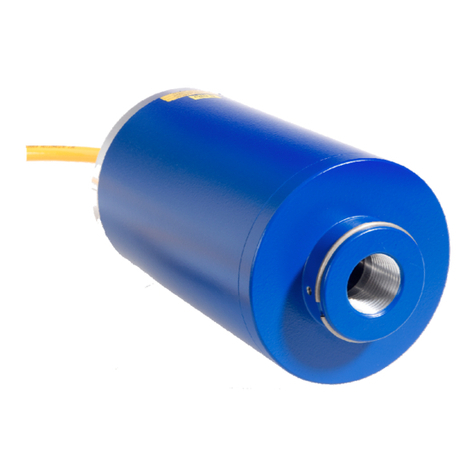

Compact Flame Controller

CFC 2000

UV, UV1, IR, IR1, IR2

- Flame scanner with integrated flame amplifier and flame relay.

- TÜV approved, DIN-DVGW, DIN-CERTCO certified

- For intermitted, continuous operation and 72-hours operation

- Type UV, UV1 : For natural Gas-, Oil- and dual fuel operation

- Type IR (VIS-IR): For monitoring of oil flames on diffusion burners

- Type IR1 (IR): For monitoring of natural gas flame in duct burners

- Type IR2 (IR): in preparation

- Dual channel flame monitoring and evaluation system.

- Adjustable sensitivity for both channels separate by software.

- Analogue output 0(4) – 20mA Intensity

- Possible flame evaluation by software

- Status indication of flame relay, and intensity indication by LED

- No additional wiring to separate flame scanners.

- Class of protection IP 65.

!

WARNING

WARNING: IMPROPER INSTALLATION OF THESE PRODUCTS

MAY BE HAZARDOUS TO LIFE AND PROPERTY

Function

For the flame radiation analysis, a well approved

integral procedure in the respective spectrum is

carried out with the compact flame controller.

After a pre-amplification, the unwanted CW light

component is withdrawn from the output signal of

the wear-resistant detector. The subsequent

sensitiveness attitude allows an attenuation of

the signal for adaptation to the combustion proc-

ess. The post-connected band pass filter caused,

that only the typical modulation of the flame ra-

diation of the primary combustion zone is valued

and so extraneous light signals by neighbour

burners can be distinguished from the own fla-

me.

Further functional groups include signal condi-

tioning and other for the so-called dynamic

monitoring channel which checks the fail safe

function of the device continuously.

A component or component defect leads to an

immediate disconnection of the flame relay,

which one is available as a floating change-over

contact for use with the burner management sys-

tem.

The switching condition is announced addition-

ally by a yellow LED on the reverse side of the

device behind the Perspex pane.

For the optimal adjustment of the compact flame

controller the flame strength can be read off di-

rectly on the device by means of a pulsating

green LED. For the visualization or remote indi-

cation, a current output is available at 0 or 4-20

mA.

The safety switched-off time which depends on

the combustibles to be checked is set ex-works

to a second. Longer switched-off times are op-

tionally available upon request.

technology for your future

Automation

BFI

!

WARNING

WARNING: The functioning of the compact flame controller depends

both on the burner configuration and from the air flow as well as the

spectral pattern of the flames (wavelength). We will advise you gladly

in this regard on request.

Selection of the current output 0 or 4 to 20mA

The switch over of the current output of the

compact flame controller CFC 2000 will be car- ried out by the special software which is avail-

able from BFI Automation.

Selection of the right modulation filter

For furnaces with very high power density, it

can become necessary to activate another

modulation filter besides.

The compact flame controller should not be ad-

justed to maximum signal level "Flame ON" but

as with the flame scanners also, to the highest

"Flame ON" / "Flame OFF" relation. Through

the numerous adjusting options of the compact

flame controller the system itself could be eas-

ily adjusted to all boiler geometries and any

combustible throughput for getting an optimal

availability.

The adjustment of the modulation filter occurs

via DIP switches which are arranged on the

main board (red 4-part switches). A change of

adjustment to the DIP switches should only oc-

cur if an adjustment of the compact flame con-

troller is no more possible with the aid of soft-

ware.

Mounting

For guarantee of an optimal flame safeguard

control, the correct and oscillation poor posi-

tioning of the sight tube to the flame is an es-

sential assumption. For the selective burner

control, the mounting has to occur in such a

way that the primary combustion zone will be

in all load ranges at the viewing angle of the

device. The prolongation of the viewpoint axis

must not cut the first half of other flames.

Length and diameter of the viewpoint tube have

a direct influence on the valuable flame radia-

tion since the viewing angle of the compact

flame controller CFC 2000 is defined. The maxi-

mum length of the used sight tube should not

exceed the maximum length 'L' on a given dia-

meter 'd' that no influence on the field of view

will occur.

d 1" 1,5" 2"

L 0,5m 0,8m 1,1m

However the sight tube should always be kept

as short as possible. A diameter of 2"is rec-

ommended. The correct direction is repre-

sented in the subsequent drawing. The optical

alignment system BFI 235 (part-no: P106) can

be supplied by BFI ex stock.

The compact flame controller CFC 2000 is

supplied completely with a quick release

flange. This flange assures possible assembly

and dismantling of the device on site which

could be done as quickly as possible. The

flange has a purge air connection which spe-

cial construction prevents the lens of contami-

nation or damaging by dust polluted air.

The optimal alignment system consists of heat

insulator, stop valve and ball flange.

This mechanical periphery can be supplied

upon request.

technology for your future

Automation

BFI

!

CAUTION

CAUTION: All alignments and or adjustments must always be applied

if new repair parts were installed, the flame scanner was moved or

the flame picture was modified (e.g. through additional combustibles,

new torches, changes to the torches / air registers), as well as all ini-

tial installations.

heating

insulator

optical

adjustment

ball flange sight tube

mounting flange

flame scanner

adjustment angle

30° max

how to adjust in the right way

right wrong

░

30° ░

30°

primary air

fuel

flame root combustion area

changing of frequency and amplitude in

relationship to the distance of the flame root

technology for your future

Automation

BFI

Installation

The pin assignment of the connector is shown in

the wiring diagram.

The output signal 0(4)-20mA for flame intensity is

not separated by the supply voltage, so the sig-

nal refers to the operating voltage measures. If

this should lead to problems, a corresponding

isolating transformer can be provided upon re-

quest. The burden of 250 ohms should always

not be exceeded.

The device is immediately ready for operation af-

ter switch-on of the supply voltage.

Wiring Diagram

Pin/Terminal Description colour code

BFI special cable KW6

1 Flame relay: Root white

2 Flame relay: Contact flame ON brown

3 Flame relay: Contact flame OFF pink

4 power supply: +24 V DC green

5 power supply: 0V (GND) yellow

6 current output 0(4)-20 mA grey

7 switch over canal 1 / canal 2 – 24V DC red

8 failure indication output +24V DC blue

!

CAUTION

CAUTION: In order to guarantee a proper operation the compact

flame controller must be tested several times at all conditions. The

burner has to be started and stopped several times (the flame relay

must always interrupt reliably with no flame on). Carry out these tests

while different neighbour burners are started and stopped as well as

on different boiler loads. This is a vital assumption for a proper and

reliable operation.

sensitivity switch over time I / II 7

red 7

failure indication output 8

blue 8

power supply +24V DC

flame relay "flame ON"

flame relay "root"

flame relay "flame OFF"

outer braided shield

current output 0/4 - 20mA

4

2

1

3

4

2

6

green

brown

white

pink

grey CFC

2000

6

power supply 0V (GND) 5

yellow 5

1

3

BFI-special cable KW5

technology for your future

Automation

BFI

Standard Housing

Flame Proof Housing

Flame proof protection class: EEx d IIC T 6

for PTB 87/1095

Accessories

Power supply 230/115V AC

Ball flange 1” with 2” flange plate

Heating insulator 1“

3-way-ball-valve 1“

5bar pressure barrier 1“

Optical adjustment device

G1

223

Ø120

63

sensitivity

setting-

LED green = intensity

LED yellow = "flame ON"

Automation

technology for your future

BFI

BFIBFI

BFI

Type

Ser.-No.:

24Vdc

Germany

8.xx

G1/2

108

190

G 1

235

purge air

Automation

technology for yo ur future

BFI

BFIBFI

BFI

USC

R

Type

Ser.-No.: 24Vdc

Germany

technology for your future

Automation

BFI

Technical Data Sheet

Spectral Sensitivity

UV 270 to 420 nm

UV1 190 to 500 nm

IR 300 to 1050 nm

IR1 1050 to 2700 nm

Viewing angle 3°

Power supply 24 V DC +/-15%

Current consumption ca. 300 mA

Ambient temperature range -20°C...+70°C

Current output 0(4)...20 mA (Ra < 250 Ohm)

Current window possible adjustment by software

Failure output 24 V DC, short circuit protected

Sensitivity switch over Selection of the sensitivity switch over 24 V DC

Flame relay 1 change over contact, floating

VDE 0110, class A

max. 48 V switching voltage

max. 1 A switching current

max. 30 W switching power

Switching thresholds programmable by software

Safety switch off time factory adjusted to 1s

Sight tube connection 1" inside screw ISO 228

Purge air connection 1/2" inside screw ISO 228

Value of purge air 10 Nm3/h

Electrical connection

Standard dust proof Harting connector

Flame proof housing 3m special cable

Dimension

Standard with flange 235 x 108 mm (Length x Diameter)

Flame proof housing 223 x 120 mm (Length x Diameter)

Class of protection IP 65, NEMA 4

Weight

Standard 1,0 kg

Flame proof housing 3,5 kg

Full electronically self-check function for the guarantee of the faultless function of the device after VDE

0116, EN 230, EN 298, it correspond the guidelines TRD 411 to 414 and filled the additional require-

ments of TRD 604 for the 72- hours operation. DIN DVGW and DIN-CERTCO approved, CE conform.

Other manuals for CFC 2000

1

Table of contents

Other BFI Automation Controllers manuals

BFI Automation

BFI Automation CFC 2000 User manual

BFI Automation

BFI Automation CFC 2000L User manual

BFI Automation

BFI Automation CFC 4000L User manual

BFI Automation

BFI Automation CFC 200 User manual

BFI Automation

BFI Automation CFC 100 User manual

BFI Automation

BFI Automation CFC 3000L User manual

BFI Automation

BFI Automation CFC 200 Parts list manual

BFI Automation

BFI Automation CFC 1000L User manual