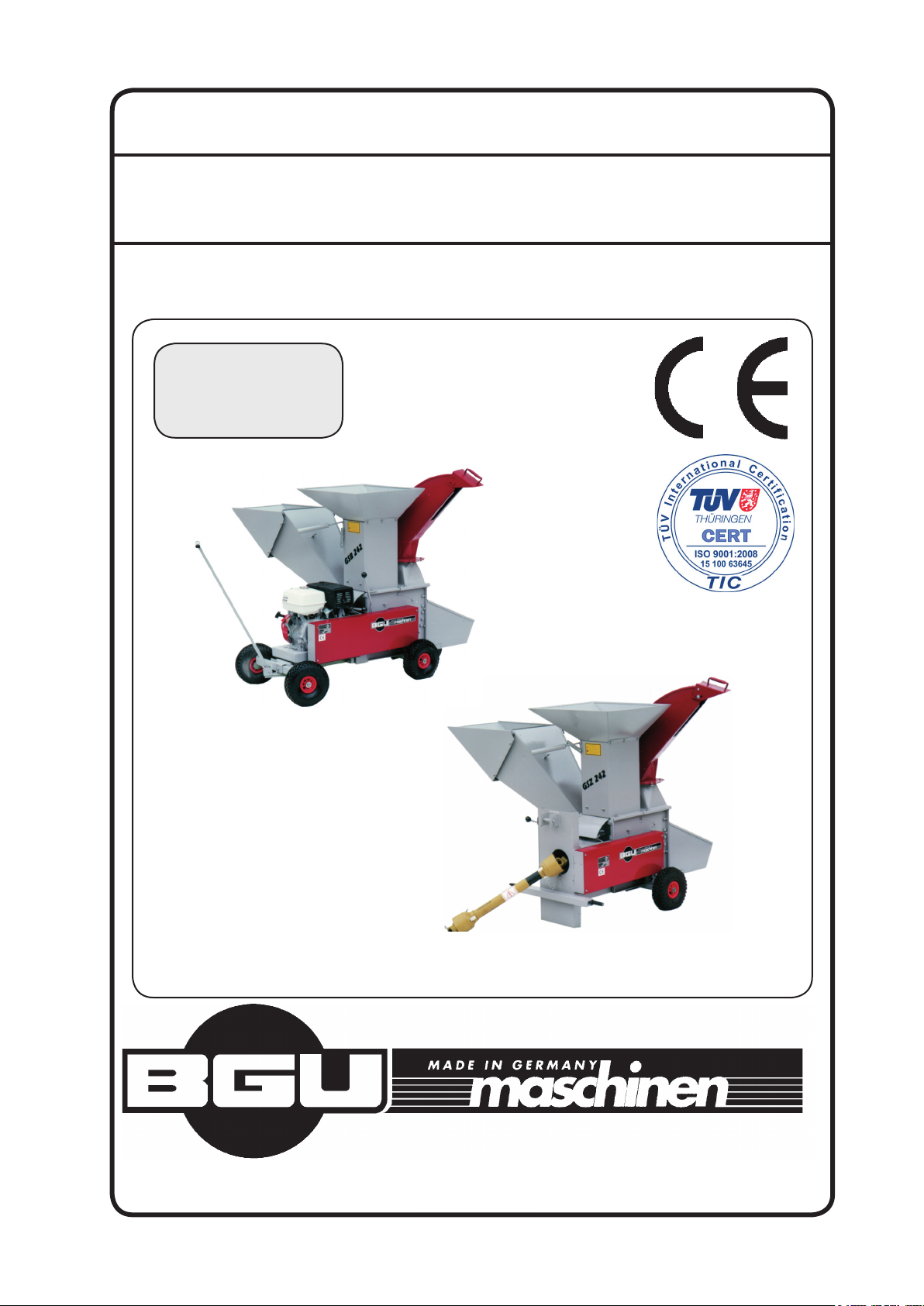

BGU GSE 242 User manual

- 1 -

Carefully read these instructions

before starting and using your shredder!

Operator's Manual

- Set-up & installation

- Use

- Maintenance

- Accessories

Garden shredder

GSE/GSB/GSZ 242

Südharzer Maschinenbau GmbH

99734 Nordhausen, Helmestraße 94

Service Tel. 0 36 31 / 62 97 104 • Fax 0 36 31 / 62 97 111

Internet: www.bgu-maschinen.de

e-mail: [email protected]

- 2 -

Südharzer Maschinenbau GmbH

Nordhausen

Helmestraße 94

99734 Nordhausen

Tel. 0 36 31/62 9 7-0 Fax 0 36 31/62 97 111

CE – Statement of Compliance

In accordance with the EC Machine Directive No. 42/2006 and EMV (Low Voltage) Directive 108/2004

We hereby declare that the equipment described in this manual responds in full to the actual version brought on the

market. We, the manufacturer further declare that this equipment was duly designed and manufactured in accord-

ance with the actual European Safety and Health Standards settled by the relevant EEC directives as well as the lat-

est electromagnetic standards issued by the European Council of 3.5.89 and later enforced by all member states.

This statement of compliance does not apply to customer modifications of the equipment without manufactur-

er’s written approval. The manufacturer shall not be responsible for such modified equipment and machines.

Machine type: Garden shredder

Model: GSE 242, GSB 242, GSZ 242

Production number: See model label

Applicable European Standards: EC Machine Directive 42/2006

EC Low Voltage Directive (93/68 EWG) 95/2006

EC-EMV (ElectroMagnetic Compatibility) Directive 108/2004

Other Standards:

To assure full compliance with law requirements, due consideration

was equally taken for the following harmonized rules:

EN 292, EN 294, EN 60204-1

EN 50081-2/07.93; EN 50082-2/03.95

EN55014-1:2006; EN 55014-2:1997+A1;

DIN EN 61000-3-2:2006; DIN EN 61000-3-3

Applicable national rules

and technical specifications: International Standards draft “manual, portable

garden machines” - TC 144/WG 6 Draft no. 4/94

Person responsible of the technical documents: René Pareis (Director)

Nordhausen, 21.12.2016

................................... ............................................................

Date René Pareis, Director

Official customer language: English (Customer copy)

- 3 -

List of content

Page

1. Information ................................................................................................................. 4

2. Safety signs and decals ............................................................................................. 5

3. General safety rules ................................................................................................... 7

3.1 Mandatory application field ........................................................................................ 7

4. About your garden shredder ...................................................................................... 8

4.1 Electric operated versions .......................................................................................... 8

4.2 Gasoline operated versions ....................................................................................... 8

4.3 PTO versions .............................................................................................................. 8

4.4 Optional tools ............................................................................................................. 8

5. Operation ................................................................................................................... 9

5.1 Downward side discharge .......................................................................................... 9

5.2 Upper ejection pipe .................................................................................................... 9

5.3 General operating tips ................................................................................................ 9

5.4 Additional instructions for PTO models ...................................................................... 10

5.5 Additional instructions for gasoline models GSB 242................................................. 10

6. Stretching the V-belt ................................................................................................... 11

7. Repairs and maintenance .......................................................................................... 12

7.1 Replacing the hammers ............................................................................................ 12

8. Safety tips .................................................................................................................. 12

8.1 Disposal precautions .................................................................................................. 12

9. Transportation ............................................................................................................ 13

10. Technical data ........................................................................................................... 14

10.1 Noise emissions ......................................................................................................... 14

10.2 Electric wiring diagram .............................................................................................. 14

11. Other areas of possible risk ....................................................................................... 15

12. Warranty ..................................................................................................................... 15

13. Spare parts list ........................................................................................................... 16

- 4 -

1. Introduction

Dear customer, thank you very much for your trust and preference in choosing our equipment and joining

the number of our best customers in the world. We are confident that our equipment will be up to all your

expectations and assure you a long lasting quality and performance.

1.1 Delivery and transport claims

Upon delivery of the machine please check for visual machine dama-ges such as damaged packing or

scratched buckled parts. If so, make a remark on all copies of the delivery bill before signing for acceptance.

Also have the truck driver sign al copies of the delivery bill.

Also have the truck driver sign al copies of the delivery bill.Should your shipper or the truck driver refuse

to accept your claim, fully reject delivery and make sure to inform us (the manufacturer) immediately. No

claims shall be taken into account by the shipper or by the insurance company, if a reservation note is not

made on the delivery bill.

All transport damages must be noti.ed within latest 2 days from delivery. Therefore delivery must be collected

and inspected within this term. Later claims shall be disregarded. In case of assumed but not visually clear

transport damages make sure to mark the following sentence on the delivery bill: „Reserved delivery due to

assumed transportation damages“. Insurance and shipping companies act with extreme caution in case of

transport damages and sometimes refuse to accept responsibility.

Please make sure to provide clear and exhaustive evidence (photos) of the claimed damages. Thank you

in advance for your help and attention to this matter.

- 5 -

1. Safety decal "Wear ear plugs and goggles"

Loud noise can cause impairment or loss of hearing, wear a suitable protective

device such as ear plugs or goggles.

2. Safety decal “WARNING! Always wear safety gloves”

Wearing safety gloves is advisable and particularly for continuous operation of

the machine.

3. Safety decal “WARNING! Always wear safety shoes”

Wearing safety shoes is advisable and particularly for continuous operation of

the machine.

.

4. Warning label „Read before use"

Never operate the machine without reading or understanding the operator’s

manual.

5. Warning label „Read before use"

Never operate the machine without reading or understanding the operator’s

manual.

6. Operation safety label "Do not reach inside hopper"

Do not reach inside the hopper or the discharge chute with your hands.

VERY DANGEROUS!

7. Operation safety label

Before setting-up, servicing, maintaining and cleaning the machine, dis-

engage all power and stop the engine.

2. Safety signs and decals

PH-6504, 6538 Auswurf geöffnet, geschlossen

Achtung! Gefahr für die Hände!

Drehrichtung beachten (nur PH-6504)

Vor Erstinbetriebnahme Seitentrichter....

8. Operation safety label

Read, understand, and follow all instructions in this manual and on the

splitter before starting!

9. Warning label “ATTENTION! Direction arrow!“

This arrow shows the revolution sense of the motor. PLEASE CHECK motor

rotation at first start.

10. Operation safety label

Effectively assemble and firmly secure the infeed hopper and the discharge

chute on the machine before setup. Make sure that both the infeed hopper and

the discharge chute are duly set in working position before first use.

11. Product identification label

PH-6504, 6538 Auswurf geöffnet, geschlossen

Achtung! Gefahr für die Hände!

Drehrichtung beachten (nur PH-6504)

Vor Erstinbetriebnahme Seitentrichter....

- 6 -

12. Identification label „BGU-Maschinen“ Logo

13. Warning label

KEEP BYSTANDERS AWAY "5 meter dangerous aera!„

14. V-belt maintenance label

Set vbelt tension "slacken off - stretch"

15. Machine safety label „CAUTION burning parts“ - GSB 242

16. Warning lable (GSZ 242 only) „540 RPM“

This label shows the maximum admissible number of PTO shaft revolutions.

Achtung!

5 Meter

Gefahrenbereich

Vorsicht!

Heiße Teile

- 7 -

Damaged or buckled blades (very likely to break during operation) should not be used.

Always wear work gloves to protect your hands while replacing worn blades/hammers.

Strictly ask a skilled licensed electrician for any intervention on the electric system.

Operate the shredder in dry conditions. Using an electrical appliance in wet conditions, such as rain

or snow, or near a pool or sprinkler system could result in damage to the on/off motor switch or to the

electric motor itself.

Do not try to defeat or override any safety features. Never operate the machine without its protection

safeties. Strictly use original spare parts of the manufacturer.

3.1 Mandatory application field

Strictly use this equipment for shredding pruning material and reducing tree branches, small logs and

bark, bush, stalks, and garden waste to fine particle size. All other applications are forbidden and

considered as “misuse”. Make sure that no foreign matter (nails, screws, stones or alike) in or on

wooden material gets trapped in the machine.

This machine is not suitable for chipping stones, metals and glass, plastic ropes/lines and other similar

workshop material. Grass and vignards waste should be stored for at least one week before shredding.

Strictly perform installation, set-up, maintenance, cleaning and transpor-

tation with the motor switched off and the tool/moving parts of the machi-

ne firmly secured against accidental operation.

NEVER leave the machine unattended with the running motor.

Before leaving the operator‘s station for any reason, stop the machine motor or the tractor engine,

disconnect power (or PTO drive), make sure to remove the ignition key of the tractor and secure the

machine against accidental operation.

Never allow anyone to stand in the dangerous area of the machine while in operation.

REMEMBER: the operator is responsible for safety of all nearby thirds on site. Never direct the discharge

of material towards bystanders.

Due and proper illumination of the working site must be provided at all times.

To ensure stability during operation make sure to choose a flat, dry floor free from any tall grass, brush or

other interferences.

Always wear suitable hearing (ear plugs or muffs) while operating the machine.

Operators must wear steel toe safety shoes, tear-resistant gloves, safety glasses and snug-fitting work

cloths.

3. General safety rules

- 8 -

4. About your garden shredder

Our garden shredders are designed for mulching and production of small size compost out of various waste

and debris. THEY SHOULD NOT BE USED FOR PRODUCTION OF WOOD CHIPS.

Waste material fed through the upper square hopper is handled by a special rotor with 34 steel hammers

performing grinding of the material so that quicker decay will occur during mulching.

All BGU shredders are equipped with a very practical, adjustable ejection pipe saving users with laborious

compost piling or shovelling into a tank.

All models are available in the following 3 versions depending on type of power:

4.1 Electric version "GSE 242"

The GSE model 242 is powered by means of an electric motor. A 32A protection is required on domestic

power supply (5 poles, CEE socket) of the GSE model 242.

The shredder is fit with a standard special socket-switch combination integrated with overload and under

voltage protection.

When you first run your shredder, check rotation side upon connection of your power cable. The motor

should rotate in the direction shown by the arrow-label on the motor casing. Should the motor turn in the

opposite way, provide immediate adjustment by switching the phases inside the power cable by means of

a small screwdriver.

The ideal extension should have a 1,5mm² section and should not be longer than 50m. With longer extensions

there could be a risk of voltage drops. In that case make sure to use the next section size up (2,5mm²).

4.2 Gasoline engine version "GSB 242"

BGU shredder 242 is equipped with a 13 PS (9,6kW) gasoline Honda engine. Before installation make sure

to ready instructions of the engine manufacturer carefully through. (available on each gasoline shredder)

4.3 PTO versions "GSZ 242"

BGU shredders GSZ 242 are powered with a cardan shaft from the tractor PTO. The number of admissible

revolutions of the PTO shaft should not exceed max. 540 U/min. Quicker revolution may lead to shredder

damages or earlier wear. If you wish to run your shredder on front PTO shaft, ask your dealer for help.

4.4 Optional tools

BGU shredders may be equipped with a further accessory for grinding polystyrene: a specially perforated

grain screen with 6, 8 or 10mm (2.3” , 3.1 or 3.9”) holes located between the upper exhaust pipe and the

main shredder body. To assemble the screen, release screws on the upper ejection pipe, locate the screen

on the opening and reassemble the pipe in place making sure that all screws are tight back in place. It is

also possible to assemble on the ejection pipe a special mount for fixation of transpiring collection sacks.

Polystyrene is reduced down to a very fine grain size and may be then used in flower nurseries (for aeration

of the earth around flowers) or as a common damming agent. This accessory makes it possible to use

your shredder for an easy and economical disposal of polystyrene which can be then well used for other

applications.

- 9 -

5. Operation

Become familiar with the shredder by reading the owner’s manual before operation.

Set your shredder on an even, safe stable and non-slip foundation.

Do not allow any bystander in the dangerous area of the machine. Avoid directing the discharge chute to any

nearby area accessible by staff or other persons. Anyone who operates the shredder must receive proper

instructions on its safe operation and must read the owner’s manual.

REMEMBER: the operator is responsible for safety of all nearby thirds on site. Never direct the discharge

of material towards bystanders. Strictly provide access to the nearby area to authorized, trained persons

who are familiar with the machine and its use.

Use the upper infeed hopper to shred branches (no hard wood) up to 3 cm (1.8”). Larger material should

be fed through the lateral infeed chute.

All BGU garden shredders are equipped with a lateral crushing rotor with infeed chute.

The combination of a lateral crushing rotor and an upper hopper allow continuous handling of thick branches

up to respectively 12 cm and 10 cm Ø best mixed with garden and chicken waste at the same time.

5.1 Downward side discharge

The downward side discharge is equipped with a number of removable square rods. To activate downward

side discharge simply remove the upper rod and let the discharge chute flap down. Before activating the lower

side discharge, the special shutter plate (supplied separately with each shredder) must be duly assembled

underneath the upper ejection pipe. To assemble the shutter plate first release the fixation screws, remove

the small close elbow and replace it with the shutter plate so to fully close the upper ejection pipe.

By removing and inserting the square rods one by one you can change the mulching size of the material

that can be then shredded down to a bigger or smaller particle size at wish. The average particle size of

the shredded material is obtained by removing every other square rod. For next size up material additional

square rods may be removed at wish.

5.2 Upper ejection pipe

If you are to discharge through the upper ejection pipe of your shredder, make sure to remove the shutter

plate and clear the way through the pipe. So first remove the shutter plate and replace it with the small close

elbow. Then flap the side chute up and insert the upper square rod to secure it in place.

The position of the upper ejection pipe can be adjusted to direct the material discharge at wish. To do so first

release (without removing them) all 4 fixation screws between the transition piece and the upper ejection

pipe. Then turn the ejection pipe to the desired direction and tighten the screws again.

5.3 General operating tips

Make sure that your debris are not too wet as this may lead to possible choking of the ejection

pipe.

Do not forget to check regularly on the ejection side in order to promptly clear possible choking or

if required – switch the shredder off.

To clear hopper choking release the deflection flap below the infeed hopper and exercise hand pressure in

the direction of the upper hopper.

Make sure to switch the motor off and wait till the rotor has come to a complete stop before trying

to clear eventual pipe plugging!

- 10 -

5.4 Additional instructions for PTO models (GSZ 242)

BGU PTO-model GSZ 242 is specially suitable and recommended for users who are processing the

shred material directly on site.

Installation of this model is performed by attaching the

three-point hitch available on the shredder with the tractor

one by means of the special safety pins. A PTO must be

mounted between tractor and shredder to provide for power

take off.

When performing attachment of three point hitch make sure

to comply with channels overlapping instructions!

For increased safety make sure that a minimum wrapping

of 1/3 of the total useful channel length is achieved.

Strictly use a driveline of an approved type. The drive

shaft is known as the implement input driveline (IID). The

entire IID shaft is a wrapping point hazard if it is completely

unshielded.

Always connect and secure the driveline in

compliance with shaft manufacturer instructions.

Manufacturer installed guards and master-shield must be

replaced when removed for maintenance. These guards

are designed to protect the operator and equipment.

Never use a PTO driveline without safety shield or

with a damaged guard and make sure that the shield

is of the correct size and length for the drive shaft!

Before uncoupling the processor, make sure to stop the tractor engine in order to avoid damaging

the tractor power drive.

The PTO-version GSZ242 is a ground-driven 3-point hitch implement. Lower the machine to the “field”

position when you are ready to use it.

5.5 Additional instructions for gasoline models GSB 242

BGU PTO-model GSB 242 is specially suitable and recommended for users who are processing the

shred material directly on site and do not own a tractor.

Before starting the gasoline engine set the belt tensioner crank on "slacken off".

To start the rotor release the belt tensioner crank and slowly shift it to the right on the "Stretch-Position"

until the maximum number of rotor revolutions is reached.

At the end of your work day make sure to set the belt tensioner crank back on "slacken off".

Wrapping of the driveshaft channels

- 11 -

6. Stretching of the v-belt

Perform ordinary tension check-up of the vbelt located under the lateral protection casing. To remove the

casing release all fixation screws and then access the belt and check whether duly stretched. If not, adjust

belt tension or entirely replace the belt if required. An excessively slacken off belt will cause slipping and

earlier belt wear.

To adjust vbelt tension on GSE models 242 release all fixation screws on the motor, push the motor ahead

and tighten screws again.

On GSB models GSB242 it is also possible to adjust the vbelt tension by ways of the special crank lever

available on the lateral protection casing.

Alternatively you can adjust the vbelt tension by using the adjustment screw located on the angular gearbox

bracket.

- 12 -

7. Repairs and maintenance

At work end make sure to check presence of eventual shred rests in the machine and clean them.

When operating PTO shredders GSZ 242 make sure that the PTO arrangement is duly shielded before

starting.

Before performing any maintenance/repair work on the machine, make sure that the machine is fully

disconnected (unplug the machine or switch the tractor off).

Should your electric shredder fail to start when first switching the engine on, check up the switch fuse. If

fuse and switch are OK but shredder keeps failing to start, so consult your electrician for complete check

up and repair of the electric system

Do not self grind the lateral cutting blade. For this operation help of a skilled mechanic is required.

7.1 Rotor hammers replacement

The steel hammer on the rotor can be used twice.

Slightly rounded hammer profile will immediately lead to a poor shredding quality. For this reason hammers

must be regularly grounded.

To regrind perform hammers removal as below:

1. Lift the lateral cover (Service-Cover) on top of the driving pulley after releasing of 2 hex nuts,

2. Remove the upper cover on the ejection opening,

3. Manually turn the drum till the hammer shaft becomes visible through the opening,

4. Release the countersunk head screw on the hammer shaft and pull the screw fully out,

5. Remove the hammer shaft from one side,

6. Pull hammers and spacers off the shaft and fit them back having care to invert their side around.

Take good care of the spacers, nuts and screws while dismounting the hammers.

IMPORTANT: assemble the hammers and bushings back on the chipper in the order as they were

taken out

7. After inverting the hammer side around, secure the hammer shaft using the same countersunk head

screws,

8. Keep turning the rotor to the next hammer and repeat the same procedure as before for all hammers,

9. When all hammers side has been inverted, reassemble the upper cover and secure the two nuts,

10. Secure the upper cover, the upper ejection pipe and the ejection chute

Make sure all screws are duly secured and tightened.

ATTENTION: when both hammer sides are worn out REPLACE THE HAMMER completely. DO

NOT REUSE DULLED HAMMERS.

When pulling the hopper off for unwrapping or rotor maintenance reasons make sure that power is fully

disconnected from the shredder.

DO NOT LET THE SHREDDER RUN WITHOUT HOPPER ON.

For repair/maintenance of the gasoline engine follow separate instructions given by the engine manufacturer

and enclosed to these instructions.

8. Safety tips

Maintenance, installation, repair and cleaning works as well as shredder transportation may be

strictly performed when the unit is switched off and the rotor is still.

- 13 -

Make sure to comply at all times with relevant instructions for use, installation, maintenance and repair.

Failure to comply with the manufacturer’s instructions may lead to severe danger and damages both for the

operator and surrounding properties.

The shredder may be only used, maintained or repaired by skilled operators who have previously gained

familiar with the machine and relevant instructions.

Also make sure to comply with all applicable national safety standards other technical health and road

regulations as required by the country of use.

Do not let young people below 18 operate any shredder or chipper and make sure that the working area is

always clean and well illuminated in order to assure safest operation.

• When working always wear protection gloves, glasses and over-the-head hearing protectors

• Do not ever leave the shredder unattended!

• Comply with applicable electrical connections rules

• Before installation, make sure that all sockets and connections are duly insulated and provide for

replacement of eventual damaged cables and sockets

• Immediately replace damaged lines, wires and plugs

• Never handle the shred material in the machine with bare hands: always use a suitable leaves

tamper!

• When starting an electric model make sure to check the engine rotation is correct and unplug

power before performing repair or maintenance works on the machine

• Do not shred with wore blades on the machine

• Remember that machine users are responsible for thirds safety and health at all times

• When leaving work for some time make sure to switch off the machine (unplug electric power, pull

off the cardan shaft or switch the motor off)

• On GSZ model 242 make sure to provide due shaft shielding

• Do not feed in stones, glass, metal pieces, plastic cords or sheets or other equivalent material

• Install and use the shredder only in safe and due location

• Never reach inside the hopper or any ejection chute while the shredder is working

• Strictly use mechanical tools (i.e. wood stocks) to turn and release jammed or skewed branched/

sticks inside the hopper or discharge chute. Never reach with your hands inside the hopper or

discharge chute when the machine is running.

• Never attempt to remove a jammed piece of wood or material before disconnecting/unplugging

the machine from the power and before the cutting tools (blades and hammers)

have come to a complete stop.

8.1 Disposal precautions

Electric parts and components are polluting and dangerous for the environment, therefore they should

be separately disposed of. In case of fire do not extinguish with water, use preferably chemical agents

(powders).

9. Transportation

When on the highway, make sure that the shredder does not cover any of the tractor illumination/signal lights

(back drive lights, stops or turn indicators). If so provide for an additional electric arrangement when transporting

on public roads. The same applies for all other machines infringing the tractor light beam by respectively 1

meter rear and 40cm laterally (in which latter case a clearance light is also required in front). .

CAREFUL! Dangerous area !

Standing in this area is very dangerous and

forbidden! –

WARNING!

Standing in this area is forbidden! 30o

- 14 -

10. Technical data

GSE 242 GSZ 242 GSB 242

Shredding rotor diameter [mm] 440 440 440

Rotor width [mm] 240 240 240

Number of rotor rev. [RPM] 2400 2400 2400

Number of hammers [pieces] 34 34 34

Motor power P1 [kW] 9 - -

Motor power P2 [kW] 7,5 - -

Honda gasoline engine [kW] - - 9,6

PTO shredder power [kW] - 12 -

Shredder length w/ handle [mm] 1650 1900 1900

Shredder width [mm] 1700 1170 1700

Shredder height [mm] 1610 1980 1610

Shredder weight [kg] 260 175 275

Max. PTO shaft rev. [RPM] - 540 -

10.1 Noise emissions

Noise emissions were measured in accordance with the European directives for the measurement of noise

emissions on the workplace. The measurement was performed by external authorized certification bodies

in compliance to the applicable Standards based on applicable rules for agricultural and forestry equipment.

The detected noise levels were:

Measurement on the machine front edge at 1600 mm height and 1000mm away from the deflector door.

Measured values: Idle 94 dB(A)

Max load 104 dB(A)

The test was carried out while shredding hardwood (alder Ø 80mm lateral infeed and peeled alder through

the infeed hopper).

When working with BGU shredder, use of ears protectors is MANDATORY.

10.2 Electric wiring diagram

Works on the shredder electric system should be strictly performed by skilled electricians!

- 15 -

Wiring diagram GSE 242

11. Other areas of possible risk

1. Mechanical dangers

All moving parts (for instance: rotor, hammer, vbelt) are duly protected by fixed guards or covers which can

be only removed with use of special tools in order to avoid any accidental injury.

WARNING: possible severe injuries or damages may occur if you run the machine without special fixed

guards on. The same applies to the use of the machine without safety protections (for instance hopper)

2. Electrical dangers

All shredder parts working under voltage are duly proofed and insulated by means of special cover and fixed

protections which can be only removed with use of special tools.

WARNING: should you use special tools to remove electric protections and covers, possible severe injuries

due to electric shocks may occur.

3. Burning

All engine and hydraulic parts susceptible of high temperature are already covered and isolated by the

manufacturer.

WARNING: do not try to bypass such protections. This may cause severe burns and injuries.

12. Warranty

All shredders are covered with 6 months warranty. Customers should promptly notify eventual material

or production claims on their detection. While asking for warranty service, customer should show copy of

their purchase invoice or receipt. The warranty does not cover for faults due to natural wear, temperature

or weather agents as well as misuse faulty installation or improper lubrication. No warranty will be given

on parts damaged by improper handling. The manufacturer is further not responsible for warranty service

on machines used for other applications as mentioned in this manual, or modified by the customer or other

thirds, or overloaded.

No warranty applies to consumable parts (for instance: steel hammers and other fittings) and to adjustment/

calibration works.

Please call our service office for any warranty claim or service requirement.

- 16 -

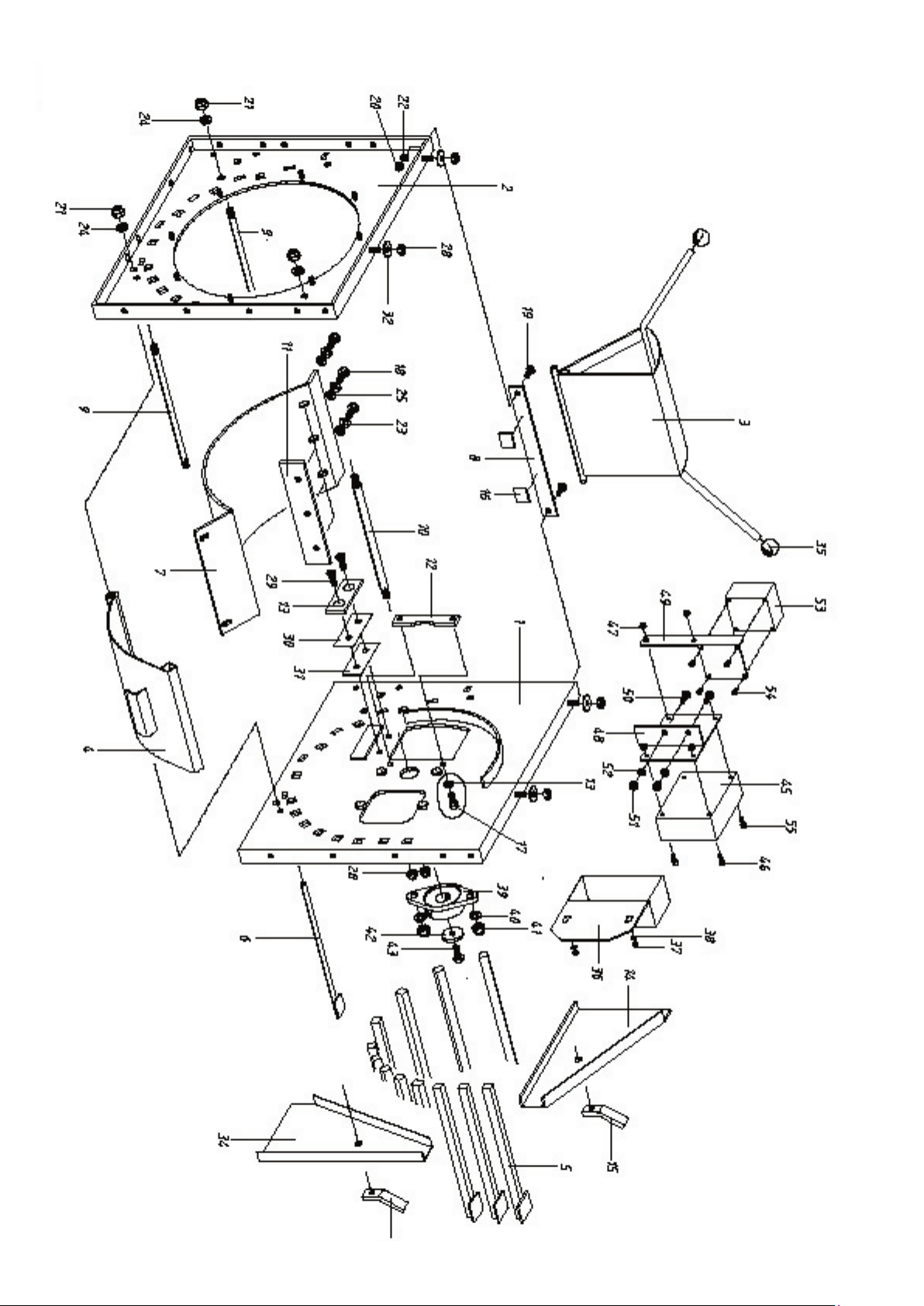

Shredder Frame GSE/GSB/GSZ 242

Pos. Description Nr. DIN Size

Electric version GSE 242

45 Star/Delta switch 50781

46 Socket head screw 51340 DIN 912 M 6x16

47 Self-locking hex screw 51606 DIN 985 M 6

48 Bracket for electric switch 12352

49 Emergency stop plate 12358

50 Hex screw 51444 DIN 933 M 8x20

51 Self-locking hex screw 51607 DIN 985 M 8

52 Lockwasher 51706 DIN 127 B 8

53 Emergency Box 50858 018572

Pos. Description Nr. DIN Size

Main frame

GSE/GSB/GSZ 242

1 Side plate, left 12275

2 Side plate, right 12084

3 Flap plate 12276 GSE 242

3 Flap plate 14229 GSB 242

3 Flap plate 14231 GSZ 242

4 Ejection steel baffle 12277

5 Hammer stop 12278

6 Stay-rod for lower chute 12279

7 Lower feedthrough plate 12280

8 Flap plate stop 12281

9 Tie rod 12282

10 Spacer rod 12283

11 Counter hammers 12284

12 Counter hammer, vertical 12094

13 Counter hammer, horizontal 12286

14 Hammer stops casing 12096

15 Sealing cap 12097

16 Foam rubber 12098

17 Socket head screw 52857 DIN 912 M 10x16

18 Hex screw 52622 DIN 933 M 10x18

19 Hex screw 51446 DIN 933 M 8x25

20 Self-locking hex screw 51607 DIN 985 M 8

21 Self-locking hex screw 51609 DIN 985 M 12

22 Lockwasher 51706 DIN 127 B 8

23 Lockwasher 51707 DIN 127 B 10

24 Lockwasher 51708 DIN 127 B 12

25 Washer 51649 DIN 125 10,5

28 Self-locking hex screw 51608 DIN 985 M 10

29 Socket head screw

w. hex recess. 51512 DIN 7991 M 10x30

30 Spacer plate 1 12099

31 Spacer plate 2 12100

32 Shim 51698 DIN 9021 10,5

33 Spacer shim 51636 12x24x1

34 Hammer stops casing 12101

35 Ball knob 50995 DIN 319 D=40 M12

Shredder Frame GSE/GSB/GSZ 242

- 17 -

Shredder Frame GSE/GSB/GSZ 242

- 18 -

Pos. Description Nr. DIN Size

Rotor, weldment

GSE/GSB/GSZ 242

1 Rotor 12303

2 Hammer shaft 12304

3 Mounting cover 12418

4 Side blades 12305

5 Hammer spacer shim 12130

6 Hammer 12131

7 Pulley 12306 GSE 242

7 Small vbelt pulley 12426 GSB 242

7 Belt pulley 12306 GSZ 242

8 Flange bearing (machined) 12078

9 Hex screw 51461 DIN 933 M 10x20

10 Washer 12133

11 Socket head screw with

hex recess 51512 DIN 7991 M 10x30

12 Self-locking hex nut 51608 DIN 985 M 10

13 Lockwasher 51708 DIN 127 B 12

14 Self-locking hex nut 51609 DIN 985 M 12

15 Slotted socket head

cap screw 51533 DIN 963 AM 8x25

16 Self-locking hex nut 51607 DIN 985 M 8

17 Feather key 51721 DIN 6885 A 8x7x28

18 Lockwasher 51706 DIN 127 B 8

19 Lockwasher 51707 DIN 127 B 10

20 Sealing plate 12145 GSE 242

20 Sealing plate 12419 GSB/GSZ

21 Hex screw 51444 DIN 933 M 8x20

22 Washer 51648 DIN 125 8,4

Rotor, weldment GSE/GSB/GSZ 242

- 19 -

Rotor, weldment GSE/GSB/GSZ 242

- 20 -

Motor bracket / Electric Power Drive /

belt casing

Pos. Description Nr. DIN Size

Motor bracket, weldment

GSE 242

1 Motor bracket 12260 GSE 242

2 Pressure screw 12149

3 Hex screw 51446 DIN 933 M 8x25

4 Self-locking hex nut 51607 DIN 985 M 8

5 Washer 51648 DIN 125 8,4

6 Hex nut 51595 DIN 934 M 12

7 Lockwasher 51706 DIN 127 B 8

Electric power drive

GSE 242

10 Motor 50740

11 Motor mount 12177

12 Lockwasher 51706 DIN 127 B 8

13 Self-locking hex nut 51607 DIN 985 M 8

14 Washer 51648 DIN 125 8,4

20 Washer 12133

21 Complete belt sheave 12268

22 Spacer bushing 12269

23 V-belt 51133 DIN 2215 13x1525 li

24 Hex screw 51461 DIN 933 M 10x20

25 Feather key 51727 DIN 6885 A 10x8x30

Belt casing, weldment

GSE 242

30 Motor casing 12184

31 Cover for power drive 12370

32 Spacer sleeve 12371

33 Front plate 12372

34 Hex screw 51444 DIN 933 M 8x20

35 Hex screw 51429 DIN 933 M 6x16

36 Self-locking hex nut 51607 DIN 985 M 8

37 Galvanized blind rivet nut 51777 M6 L=16

Motor bracket / Electric Power Drive / belt casing

This manual suits for next models

2

Table of contents

Other BGU Paper Shredder manuals

Popular Paper Shredder manuals by other brands

IDEAL

IDEAL 4107 operating instructions

UNITED OFFICE

UNITED OFFICE 100159 operating instructions

Formax

Formax FD 8400HS Operator's manual

STERWINS

STERWINS ESH1-40.3 Legal and Safety Instructions

Fellowes

Fellowes Powershred XC-6 manual

Champion Power Equipment

Champion Power Equipment 100472 Operator's manual