BGW 250 User manual

..

' .

OWNERS

MANUAL

MODEL

250

STEREO

POWER

AMPLIFIER

S

ER

I

AL

~JUMBER

rJ

4/1'='

BGW

SYSTEMS

P.O.

BOX

3742

BEVERLY

HILLS, CALIF.

90212

..

H1PORTArJT

--PLEASE

READ

THIS

PAGE

BEFORE

OPERATING

YOUR

BGW

POWER

AMPLIFIER

YOUR

NEW

RGW

POWER

AMPLIFIER

IS

DESIGNED

TO

PROVIDE

YEARS

OF

TROUBLE

FREE

PERFORt"1ANCE.

OnSERV

I

NG

THESE

Fnl

PRECAUT

IONS

WILL

INSURE

PROPER

OPERATION.

ilEVER

CONNECT

THE

OUTPUT

OF

OtlE

CHAWJEL

\'IHI

THAT

OF

M!OTHER.

l'

lEVER

CONNECT

A

DIRECT

SHORT

FROM

THE

OUTPUT

OF

ANY

CHANNEL

TO

GROUND.

ONLY

CONNECT

THE

POWER

COgD

I8

THf

PROPE~

MAINS

(NORMALLY

THIS

WILL

BE

lO~-12

VOkTS

AC

~O-6UHZ).

SEE

SECTI

ON

~t_

FOR

CONVERS

ION

TO

L4u

VOLT

OPERAT

I

ON.

ONLY

MAKE

CONNECTIONS

TO

THE

POWER

AMPLIFIER

~IITH

THE

POWER

OFF.

Do

NOT

REMOVE

FACTORY

SEAL.

AMPLIFIERS

~IILL

NOT

BE

COVERED

UNDER

WARRANTY

IF

SEAL

IS

BROKEN.

THERE

ARE

.tlQ.

ADJUSTMENTS

~/ITHIN.

'. .

TABLE

OF

1.

DESCRIPTION

2.

SPECIFICATIONS

3.

WARRANTY

4.

FACTORY

SERVICE

5.

INSTALLATION

A.

UNPACKING

B.

MOUNTING

C.

OUTPUT

CONNECTIONS

D.

INPUT

CONNECTIONS

E.

nC

MAINS

&

CONVERSION

6.

OPERATION

7.

SCHEMATIC

DIAGRAM

8.

PARTS

LST

9.

WARRANTY

REGISTRATION

FORM

10.

SERVICE

AUTHORIZATION

FORM

..

.

CONTENTS

TO

240

VOLTS

I .

J .

" .

I-DESCRIPTION:

The

BGW

250

is

the

most

advanced

dual

solid

state

power

amplifier

available.

The

basic

design

criteria

used

are

those

which

are

applied

to

present

day

computers

and

related

equipment.

Unique

design

features

incorporated

in

the

250 make

it

virtually

"FAIL

SAFE"

and

free

from

accidental

damage

caused

by

human

error

in

audio

service.

A

fast

acting

SCR

(silicon

controlled

rectifier)

crow

bar

is

employed

as

a

safe

guard

for

your

speakers.

The

sophisti-

cated

sensing

circuitry

for

the

crow

bar

constantly

samples

the

individual

outputs

of

each

channel.

The

outputs

of

each

channel

are

integrated

and

passed

through

an

absolute

value

detector.

The

output

of

the

detector

is

connected

to

a

compar-

ator

which

is

activated

by

the

presence

of

a

large

DC

component.

If

such

a

voltage

is

present

the

comparator

in

turn

triggers

a

fast

discharge

pulse

circuit

which

fires

the

SCR

crow

bar.

The

crow

bar

is

essentially

a

direct

short

placed

across

the

two

power

supplies-

If

activated

this

causes

abnormally

high

current

to

flow

in

the

primary

circuit

and

within

a

fraction

of

a

second

the

ultra

fast

acting

circuit

breaker

disconnects

the

power.

The

crow

bar

circuit

quickly

discharges

all

energy

stored

in

the

power

supply

internally,

not

into

the

speaker;

thus

protecting

the

load.

The

packaging

inside

your

250

is

unlike

ordinary

power

amplifiers.

Each

channel

assembly

is

on

its

own

separate

module,

which

simply

plugs

in

or

out

for

quick

and

easy

service.

Each

of

these

units

is

constructed

on

a

tremendous

aluminum

extrusion.

The

total

radiating

surface

area

of

each

heat

sink

is

330

square

inches.

The

heat

sinks

have

mating

circuit

boards

which

carry

the

passive

components.

Each

unit's

wiring

is

identical

with

the

next

as

the

circuits

are

photo

etched.

The

heat

sinks

plug

in

with

an

8

pin

connector.

The

output

stage

of

your

250

uses

the

most

powerful

type

of

transistors

available.

The

large

geometry

single

diffused

devices

have

the

largest

safe

operating

area

of

any

type

of

transistor

available.

All

the

semiconductors

in

the

output

stage

are

in

intimate

contact

with

the

heat

sink.

The

dynamic

bias

circuit

is

also

mounted

on

this

isotherm

providing

rock

steady

bias

stability

with

temperature.

The

voltage

gain

circuits

are

also

mounted

on

the

same

circuit

card.

A

true

operational

amplifier

integrated

circuit,

hermetically

sealed

in

a

metal

can,

acts

as

the

front

end.

The op

amp

(as

they

are

called)

is

a

special

unit

featuring

high

speed

(15MHz)

and

high

slew

rate

(50

volts/microsecond)

yet

still

having

very

low

noise

due

to

its

darlington

input

stage

and

careful

design.

The op

amp

stage

is

followed

by a

discrete

complementary

pair

acting

as

an

active

current

source/sink

and

providing

additional

voltage

gain.

The

current

source

is

the

ideal

way

to

drive

the

output

stage

which

is

basically

a

voltage

follower.

This

sophisticated

circuit

design

makes

for

an

extremely

accurate

amplifier.

The

open

loop

gain

is

higher

than

found

in

the

competitors'

products.

The

accuracy

of

an

amplifier

is

a

function

of

the

difference

between

the

open

loop

gain

and

the

closed

loop

gain.

In

this

case

the

closed

loop

gain

is

26

db

(a

voltage

gain

of

only

20)

while

the

open

loop

gain

is

about

1,000,000.

The

accuracy

of

the

250

is

so

great

that

conventional

audio

test

equipment

is

unable

to

provide

meaningful

measurements.

Harmonic

distortion

Measurements

are

simply

the

residual

level

of

the

distortion

analyzer.

This

extremely

accurate

signal

processing

enables

the

250

to

drive

speakers

at

very

high

levels

while

adding

absolutely

no

coloration

of

its

own.

EVen

at

milliwatt

levels

the

output

waveform

exhibits

no

sign

of

crossover

distortion.

The

dynamic

range

capability

of

a

typical

250

is

almost

115

db.

.

..

'

f'

2-

SPECIFICATIONS

TIle

following

specifications

are

guarranteed

mInImum

perfor-

mance

levels,

not

typical

or

best

cnse

numbers

measured

under

ideal

conditions.

All

test

procedures

used

are

according

to

the

most

conservative

techniques

in

use

today.

POWEK

OUTPUT:

8S-watts

average

continuous

power

per

channel

at

8-ohms.

FRf,QIJENCY

R[SPONSE:

+0-0.25

dB

201lz

to

20KHz

+0-3

dB

211z

to

65

Kllz

HARMONIC

DISTORTION:

Less

than

0.1%

at

85

watts

per

cnannel

or

less

into

8 ohms.

1M

DISTORTION:

(00

&

7khz

4:1):

Less

than

.l~

at

85

watts

per

channel

or

less

into

8

ohms.

tfUM

&

NOISE

(20-20

kHz):

105

dB

below

HS

watts

into

8

oj~s

INPUT

SENSITIVITY:

I

volt

+2%

for

20

volts

out

(SO

watts,

8 ohms)

voltage-gain

of

26

db

(20xL

1.5

volts

required

for

full

outpuL

INPUT

H!PEDANCE:

47,000

ohms

DAMPING

FACTOR:

Greater

than

500

at

low

frequencies

(8 ohms )

OUTPUT

LOAD

H1PEDANCE:

Designed

for

any

load

impedance

greater

than

2 ohms.

Haximum

output

po'veT

occllrs

rtt

2

()l'r~.

RISE

TIMBrIO-90t):

5

micro5cconds-

inuicat.ing

a

bandwidth

of

(IS

KlIz.

POWER

BAND:

10

Hz

to

20 kHz.

POWER

REQU

I

REr-IENT

:

105-120

volts

50-60Hz

at

5 amps maximum

or

210-240

volts

at

2.5

amps maximum.

TURN

ON:

Anti

surge

turn

on,

no

switching

transients

or

thump

wil

l

appear

at

output.

OUTPUT

PROTECTION:

Each

channel

is

p~otected

against

shorts,

open

circuit

opcration,

mismatched

loads,

etc.

LOAD

PROTECTION:

Exclusive

SCR

crow

bar

protccts

speakers

against

malfunction.

OVERALL

PROTECTION:

Power

line

is

protected

with

fast

acting

computer

type

,

circuit

breaker.

No

fuses

of

any

kind

are

used.

Two

thermal

switches

(one

per

channel)

protect

against

over

temperature

operation.

Controlled

power

bandwidth

and

slew

rate

protect

tweeters

and

amplifier

against

excessive

high

frequency

operation.

Input

overload

protection

is

afforded

op amps

by

series

limiting

resistance.

POt\,ER

SUPPLY:

A

large

power

transformer

with

twin

primary

windings

is

used.

Computer

grade

electrolytic

capacitors

storing

over

22

joules

of

energy,

and

a 25

amp

bridge

rectifier

are

employed.

Two

Zener

regulated

supplies

power

each

operational

amplifier

front

end.

POWER

REQUIREHENTS:

Unit

requires

either

10S-129V

AC

or

210-240V

SO-60Hz

power.

A 5

amp

circuit

breaker

is

supplied

for

units

Hired

for

120V

operation

or

a

2.5

amp

breaker

for

240V

operation.

HEAT

SINKING:

Each

channel

has

its

own

removable

heat

sink.

Each

extrusion

has

330

square

inches

of

surface

nrea.

·.

CHASSIS:

A

heavy

steel

chassis

forms

a

protective

cage

for

unmatched

mechanical

strength.

A

3/16"

aluminum

rack

mount

panel

is

supplied.

All

modules

are

bolted

to

the

chassis.

The

power

supply

is

mounted

close

to

the

front

panel

to

allow

rack

mounting

without

the

use

of

guide

rails

or

supports.

CONNECTORS:

Output-

standard

3/4"

spacing,

5 way

binding

posts

for

outputs

(color

coded

for

easy

identification).

Input-

1/4"

phone

jack

AC

line-

three

wire

grounded

male

connector

on 5

ft.

min.

cable.

MODULES:

3

plug

in

modules

contain

95%

of

the

circuitry.

Modules

consist

of

2

heat

sink

channel

assemblies

and

1

crow

bar

trigger

circuit

board.

CIRCUIT

BOARDS:

Flame

retardant

glass

epoxy

boards

per

mil

spec.

DIMENSIONS:

Panel

19"

Wx

5~

H x 11

3/4"

D-

brushed

satin

aluminum.

Notching

is

standard

Western

Electric.

WEIGHT:

27

pounds

net

35

pounds

packaged

shipping

container;

unique

double

boxed

system

using

8

toro

pads

(trade

mark

of

Hardigg

Corp.)

between

inner

and

outer

cartons

for

shock

protection

in

transit.

~~RAANTY

BGW

Systems

warrants

all

power

amplifiers

for

a

period

of

three

years

from

date

of

manufacture.

This

warranty

covers

both

defects

in

workmanship

and

materials.

If

malfunction

occurs,

the

product

will

be

repaired

or

replaced

(

at

our

option)

without

charge

for

materials

or

labor;

if

returned

prepaid

to

BGW

Systems.

The

warranty

does

not

cover

equipment

damaged

due

to

negligence,

misuse,

shipping

damage

or

accident,

or

if

the

serial

number

has

been

defaced,

altered

or

removed.

Purthermore,

units

altered,

modified

or

improperly

serviced,

in

any

way,

will

not

be

repaired

under

terms

of

the

warranty.

5-

INSTALLATION

a.

UNPACKING:

Your

BGW

power

amp

is

shipped

in

an

advanced

double

boxed

container

using

8

energy

absorbtion

"Toro

Pads"

between

the

inner

and

outer

boxes.

The

container

should

be

saved

in

event

the

unit

is

moved

or

shipped

at

some

future

date.

Replacement

containers

are

available

from

BGW

Systems

for

$10.00

freight

included.

Damage;

Inspect

the

unit

for

damage

in

transit

immediately

upon

receipt.

If

damage

is

found,

notify

the

transportation

company

immediately.

Only

the

consignee

may

institute

a

claim

with

the

carrier

for

shipping

damage.

BGW

will

cooperate

fully

in

such

event.

Be

sure

to

save

the

container

as

evidence

of

damage

for

the

shippers

inspection.

b.

MOUNTING:

The

BGW

power

amp

is

supplied

with

a

heavy

standard

19"

rack

panel.

The

unit

may

be

bolted

into

a

rack

by

the

front

panel

alone.

Regardless

of

how

the

unit

is

mounted,

provIsIons

for

unrestricted

air

flow

must

be

provided.

Good

ventilation

practice

will

provide

for

air

flow

above

and

below

the

unit.

Inadequate

ventilation

may

cause

the

protective

thermal

switches

to

shut

the

unit

off.

Normal

installation-

all

connections

should

be

made

before

power

is

applied!

c.

OUTPUT

CONNECTIONS:

Adequate

size

wire

must

be

used

between

the

amplifier

and

the

speakers

to

preserve

damping

factor.

WIRE

SIZE

(damping

factor

=50)

Wire

length

up

to

Impedance

4 8 16 ohms

10'

#16 #18 #20

25'

#10 #14

1#16

SO'

#8 # 12 #14

Observe

polarity

markings

when

connecting

speakers.

Speaker

fusing

is

recommended

to

prevent

overpowering

and

damaging

speakers.

If

fuses

are

not

included

in

the

speaker

system

they

must

be

connected

in

series

with

the

lead

to

the

red

binding

post

on

the

rear

of

the

amplifier.

Consult

speaker

instructions

for

recommended

fuse

size

and

type.

4-

FACTORY

SERVICE:

Should

service

be

required

please

fill

out

the

Service

Authorization

form

and

mail

it

to

BGW

Systems.

All

units

must

be

shipped

prepaid

in

the

factory

supplied

shipping

container,

to

prevent

damage

in

transit.

Units

will

be

returned

freight

collect.

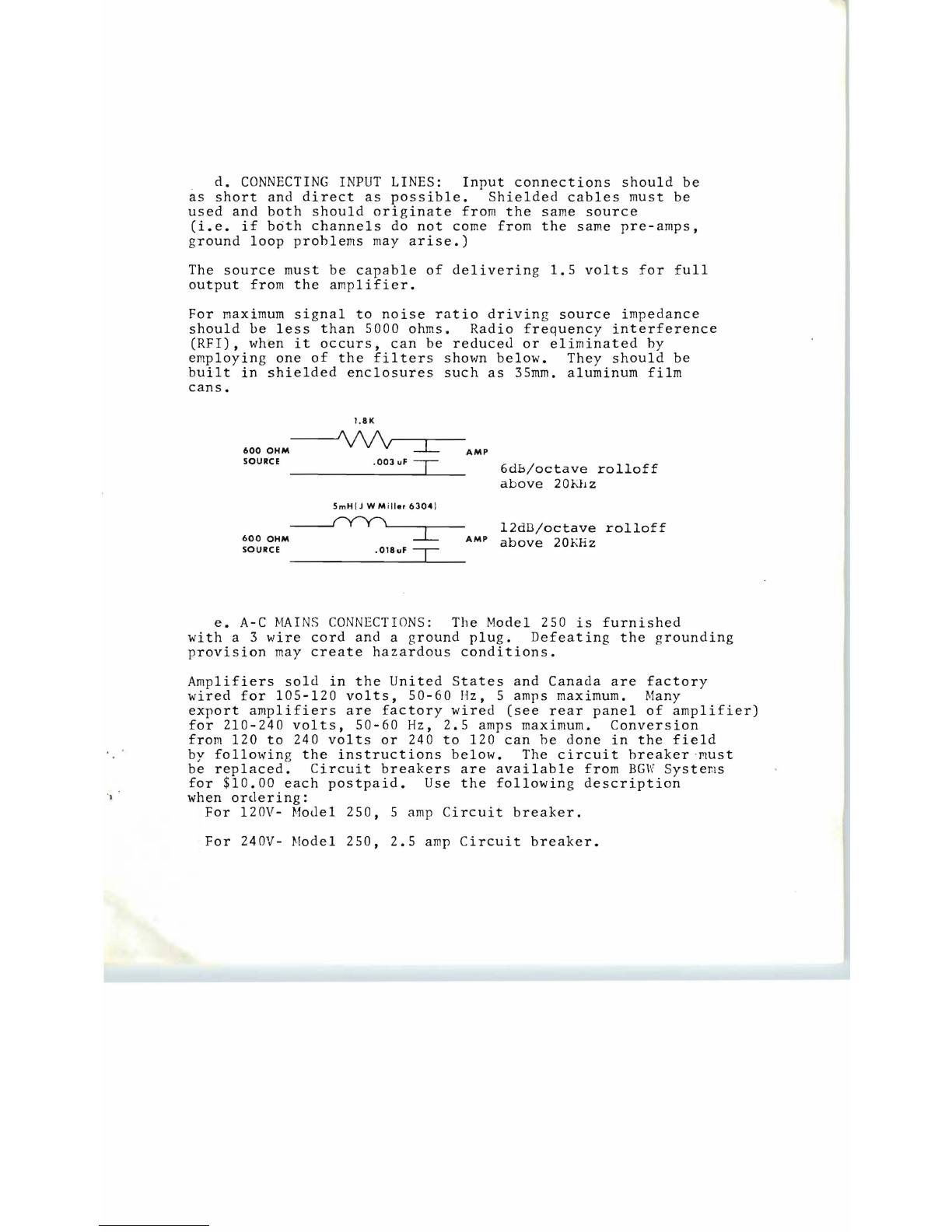

d.

CONNECTING

INPUT

LINES:

Input

connections

should

be

as

short

and

direct

as

possible.

Shielded

cables

must

be

used

and

both

should

originate

from

the

same

source

(i.e.

if

both

channels

do

not

come

from

the

same

pre-amps,

ground

loop

problems

may

arise.)

The

source

must

be

capable

of

delivering

1.5

volts

for

full

output

from

the

amplifier.

For

maximum

signal

to

noise

ratio

driving

source

impedance

should

be

less

than

5000 ohms.

Radio

frequency

interference

(RFI),

when

it

occurs,

can

be

reduceu

or

eliminated

by

employing

one

of

the

filters

shown

below.

They

should

be

built

in

shielded

enclosures

such

as

3Smm.

aluminum

film

cans.

1.8K

600

OHM----'''v\/'v

I

T

AMP

SOURCE

.003

uF

6db/octave

rolloff

above

20l\.bz

5mH(J

W

Miller

6304)

----~~-~~---

12dB/octave

rolloff

600

OHM

--L-

AMP

above

20l\.!iz

SOURCE

.018uF

T

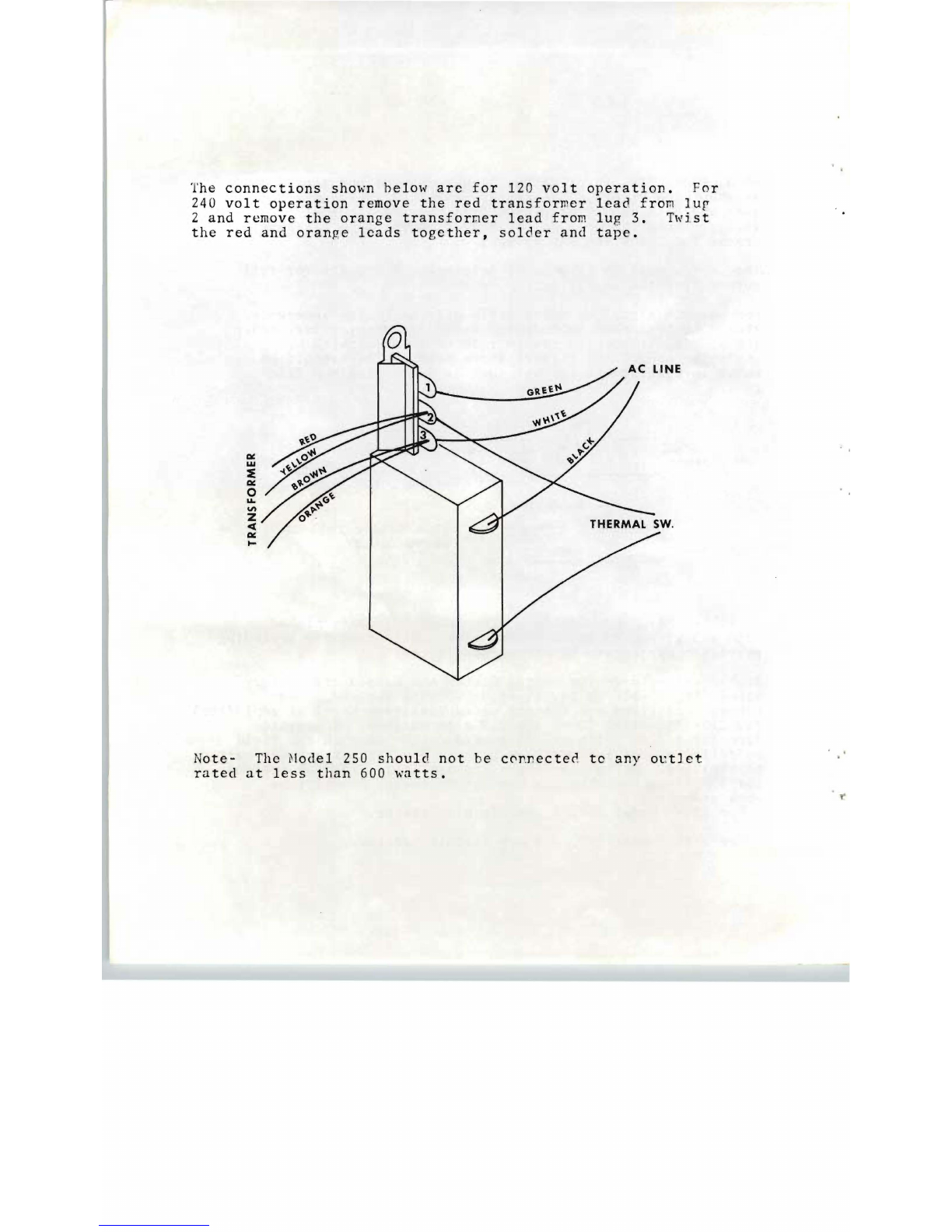

e.

A-C

MAINS

CONNECTIONS:

The Model 250

is

furnished

with

a 3

wire

cord

and

a

ground

plug.

Defeating

the

grounding

provision

may

create

hazardous

conditions.

Amplifiers

sold

in

the

United

States

and

Canada

are

factory

wired

for

105-120

volts,

50-60

Hz,S

amps maximum. Many

export

amplifiers

are

factory

wired

(see

rear

panel

of

amplifier)

for

210-240

volts,

50-60

Hz,

2.5

amps maximum.

Conversion

from

120

to

240

volts

or

240

to

120

can

he

done

in

the

field

by

following

the

instructions

below.

The

circuit

hreakerrnust

be

replaced.

Circuit

breakers

are

available

from

BGW

Systems

for

$10.00

each

postpaid.

Use

the

following

description

., when

ordering:

For

120V- Moue1

250,

5

amp

Circuit

breaker.

For

240V- Model

250,

2.5

amp

Circuit

breaker.

Ihe

connections

shown

below

arc

for

120

volt

operation.

For

240

volt

operation

remove

the

red

transformer

lead

from

lup

2

and

remove

the

orange

transforner

lead

from

lug

3.

Twist

the

red

and

orange

leads

together,

solder

and

tape.

Note-

The

Hodel

250

shoulc

1

not

be

c(,J".necte~

tc

any

ot:t]

et

rated

at

less

than

600

watts.

6-

OPERATION

TURN

ON:

The Model 250

is

free

from

thumps

or

transients

during

turn

on.

Often,

turn-on

transients

originate

in

the

pre-amp

or

tuner.

This

is

especially

true

of

tube-type

units.

If

this

situation

arises,

turn

the

amplifier

on

after

the

other

units

have

had

sufficient

time

to

stabilize.

PROTECTION:

Three

protection

circuits

are

employed

in

the

Model

250.

1.

The

fast

acting

magnetic

circuit

breaker

shuts

the

unit

down

whenever

the

unit

draws

excessive

current.

2.

The

exclusive

DGW

SCR

crow

bar

circuit

instantaneously

discharges

the

power

supply

capacitors

and

triggers

the

circuit

breaker

if

any

conditions

exist

which

could

potentially

damage

the

speakers.

3.

Thermal

switches

mounted

on

each

heat

sink

protect

the

amplifier

from

thermal

failure.

The

amplifier

will

shut

off

if

the

heat

sink

temperature

rises

ahove

70

degrees

C (1580 F)

and

will

turn

on

again

when

the

temperature

drops.

Activation

of

the

thermal

switches

usually

means

that

insufficient

air

circulation

is

being

allowed.

Shown

wired

for 120V

R42

10K

C25

0.1

-so

CHANNEL 1

J2@LL-_-'

J3~~

______________

_

o

+50

NOTE :

I.,illllnc.

in

ohnu.

topocitan,.

in

microfarad.

un'e"

CHANNel

2

<both

module.

identical)

J5

(S)

J6 o

Cll

1000pf

mark.d.

BGW

MODEL

250

Msa

1-74

PRINTED

1:"01

u.s

A

8-

PARTS

LIST

CAPACITORS

Cl

10uF,

25V

electrolytic

.65

C2

50uF,

l2V

electrolytic

.65

C3

47pF,

NPO

ceramic

.20

*C4,C5

0.047uF,

25V

ceramic

.40

*C6,C7 20pF

ceramic

.20

*C8

47pF,

NPO

ceramic

.20

*C9,ClO

10uF,

50v

electrolytic

.65

*Cll,C12

1000pF

dipped

mica

.40

*C13,C14

O.luF,

100V

mylar

.40

*C15

0.68uF,

100V

mylar

.85

*C16

O.luF,

100V

mylar

.40

C17,C18

0.01,

400V

paper

.40

C19,C20

9000uF,

50Velectrolytic

9.50

C2l

lOuF,

50V

electrolytic

.65

C22

O.OluF,

100V

mylar

.40

C23

l40pF

dipped

mica

.30

*C24,C25

O.luF,

lOOV

mylar

.40

*C26 240pF

dipped

mica

.35

DIODES

*Dl,D2 lN4745A l6V

zener

diode

2.87

*D3,D4 lN4003

or

lN4004

.69

*D5

lN4752

33V

zener

2.87

*D6-D9,DlO IN4003

or

IN4004

.69

INTEr,RATED

CIRCUITS

*ICI

LM3l8H

(National

Semiconductor)

6.95

CONNECTORS

*Jl

8-pin

socket

(octal

type)

.80

J2,J

5 Red

5-way

binding

post

1.

20

J3,J6

Black

5-way

binding

post

1.

20

J4,J7

Open

circuit

insulated

phone

jack

1.

00

*

These

parts

in

~ach

HS250,

double

for

total

parts

in

each

250.

JNDUCTORS

*L1

O.Suli

output

inductor

MISCELLANEOUS

~!l

3-wire

line

cord

and

plug

H2

25

amp,

200P.I.V.

bridge

rectifier

PLUGS

P1,P2

8-pin

plug

(octal

type)

TRANSISTORS,

ETC.

*Q1

40410

(RCA)

*02 40409

(RCA)

*03 2N2219A

*Q4

2N3S83

*05 2NS954

*Q6-Q11 40636

(RCA)

*Q12

2N5401

Q13

2N4442

Q14

2N4871

or

MUlO

(Motorola)

Q1S

MPS

3394

(Motorola)

RESISTORS

*R1

1 megohm,

5%,

~

watt

carbon

film

*R2

47.000

ohms,

st,

~

watt

carbon

film

*R3

2,500

ohms,

1%,

~

watt

carbon

film

*R4

47,000

ohms,

1%,

~

watt

carbon

film

*RS-R7

1,000

ohms,

5%,

~

watt

carbon

film

*R8,R9

1,500

ohms,

st,

~

watt

carbon

film

*R10

1,000

ohms,

St,

~

watt

carbon

film

*R11

47,000

ohms,

5%,

~

watt

carbon

film

*R12

4,700

ohms,

5%,

~watt

carbon

film

*R13 100 ohms,

Sl

',

~

watt

carbon

film

*R14 680 ohms,

5%,

~

watt

*R1S,R16

15,000

ohms,

5%,

~

watt

*R17 680 ohms,

5%,

~

watt

*

These

parts

in

each

IIS250,

double

for

total

parts

1.

25

2.25

6.95

1.

00

1.

80

1.

80

.78

2.25

2.85

3.00

1.

26

3.00

1.14

.45

.20

.20

.60

.60

.20

.20

.20

.20

.20

.20

.20

.20

.20

in

each

250.

*R18,R19

68

ohms,

5%,

~

watt

.20

*R20

1,500

ohms,

5%,

~

watt

.20

*R2l

500

ohm

potentiometer

1.

00

*R22

1,000

ohms,

5%,

~

watt

(may

vary)

.20

*R23-R25

10

ohms,

5%, 1

watt

.40

*R26-R3l

0.18

ohms,

2

watts,

wirewound

.40

*R32

100,000

ohms,

5%,

~

watt

.20

*R33

330,000

ohms,

5%,

~

watt

.20

*R34

100,000

ohms,

5%,

~

watt

.20

*R35

2.7

ohms,

10%,

1

watt

.40

*R36

30

ohms,

5

watts,

wirewound

.95

R37 2

ohms,

50

watts,

wirewound

1.

00

R38

33,000,

1

watt

.40

R39

10,000

ohms,

5%,

~

watt

.20

R40

33

ohms,

5%,

~

watt

.20

R4l,R42

10,000

ohms,

5%,

~

watt

.20

SWITCHES

Sl

5

amp,

l20V

or

2.5

amp,

240V

circuit

breaker

10.00

S2,S3

Normally

closed

thermal

switch

2.50

TRANSFORMERS

Tl

Power

transformer

52.50

SUB

ASSEMBLIES

*HS250C

Complete

single

channel

amplifier

heat

sink

167.00

*CB250

Crowbar

trigger

module

12.50

f\1ECHANICAL

COHPONENTS

HS-250

1

heat

sink

extrusion

15.90

1

printed

circuit

board

7.90

1

TO-5

mounting

clip

.85

8

mica

insulators

.20

16

nylon

shoulder

washers

.10

16

6-32

x

5/8

RH

plated

steel

Phillips

machine

screw

16

6-32

x

~

plated

steel

hex

nut

16

#6

internal

tooth

lock

washer

2

4-40

x

~

RH

plated

steel

Phillips

machine

screw

2

4-40

x

5/16

flat

head

Phillips

6

#4

internal

tooth

lock

washer

heat

sink

compound

MECHANICAL

COMPONENTS

CHASSIS

4

4

8

4

6

4

2

8

8

8

7

6

2

8

8

7

6

1

6

5

1

1

1

1

1

1

4

PACKAGING

1

1

10-32

x 1

FH

Phillips

10-32

x

~

FII

Phillips

10-32

x

3/4

Hex

socket

cap

screws

10-32

x

~

pan

head

Phillips

8-32

x

~

pan

head

Phillips

6-32

x

3/4

pan

head

Phillips

6-32

x

~

pan

head

Phillips

#6

sheet

metal

screws

10-32

chrome

plated

cap

nuts

10-32

hex

nuts

8-32

hex

nuts

6-32

hex

nuts

#6 x

~

spacers

#10

split

lockwashers

#10

flat

washers

#8

split

lockwashers

#6

external

tooth

lockwashers

Heyco SP-4

strain

relief

flat

blade

lugs

round

lugs

ground

strap

(back

panel)

ground

strap

(capacitors)

3-lug

terminal

strip

steel

chassis

aluminum

cover

aluminum

rack

panel

feet

set

of

cartons

10.00

I-exterior

carton

I-interior

carton

8-Toro-Pads

owners

manual

,.

-----------------------------------------

lO-SERVICE

AUTIlORIZATIDtJ

FORM

Please

complete

this

form

as

completely

as

possible

and

return

to

BGW

Systems

before

returning

unit.

NN1E--------------------------------------------

ADDRESS

UNIT

--f"j.,...O

....

n

.....

ErL--

SERIAL

NUMBER

1.

Describe

symptoms:

2.

Which

channel(s)

exhibits

the

problem?

3.

What

other

equipment

was

involved?

Manufacturer

Hodel

No.

Preamp

Speakers

4.

Under

what

conditions

does

the

problem

occur

(check

those

that

apply.)

a.

all

the

time

b.

after

a

while

c.

at

high

volume

levels

d.

at

high

temperatures

e.

other

(explain)

S.

How

often

did

the

problem

occur?

6.

What

did

you

do

to

isolate

the

problems

to

the

power

amp.

7.

Further

comments:

*It

is

more

expediant

to

call

your

dealer

or

our

factory

explaining

the

nature

of

your

problem.

In

many

instances

the

problem

can

be

solved

without

returning

the

unit

to

the

factory.

WARNING:

the

unit

must

be

returned

in

an

original

factory

container,

if

you

do

not

have

one,

we

will

proviJe

a

replacement

for

$10.00.

Table of contents

Other BGW Amplifier manuals