BGW 150 User manual

mcnciirrc

For more Hi-Fi manuals and set-up information

please /is it www.hifiengine.com

12300-1

13130 SOUTH YUKON AVENUE HAWTHORNE, CALIFORNIA 90250

PHONE (213) 973-8090 TELEX NO. 86-4494

OWNER'S MANUAL

MODEL 150

PROFESSIONAL POWER AMPLIFIER

TABLE OF CONTENTS

DESCRIPTION FORM NUMBER

Important 00601

Description 01530

Specifications 02150

Unpacking and Set-Up 02500

Rack Mounting Hints 02650

Stereo Input Connections 03002

Bridging Balanced Line Inputs 03011

Bridging Unbalanced Line Inputs 03021

Balanced Line Input 03031

Unbalanced Line Input 03041

Terminating Resistance Chart 03051

Stereo Output Connections 03501

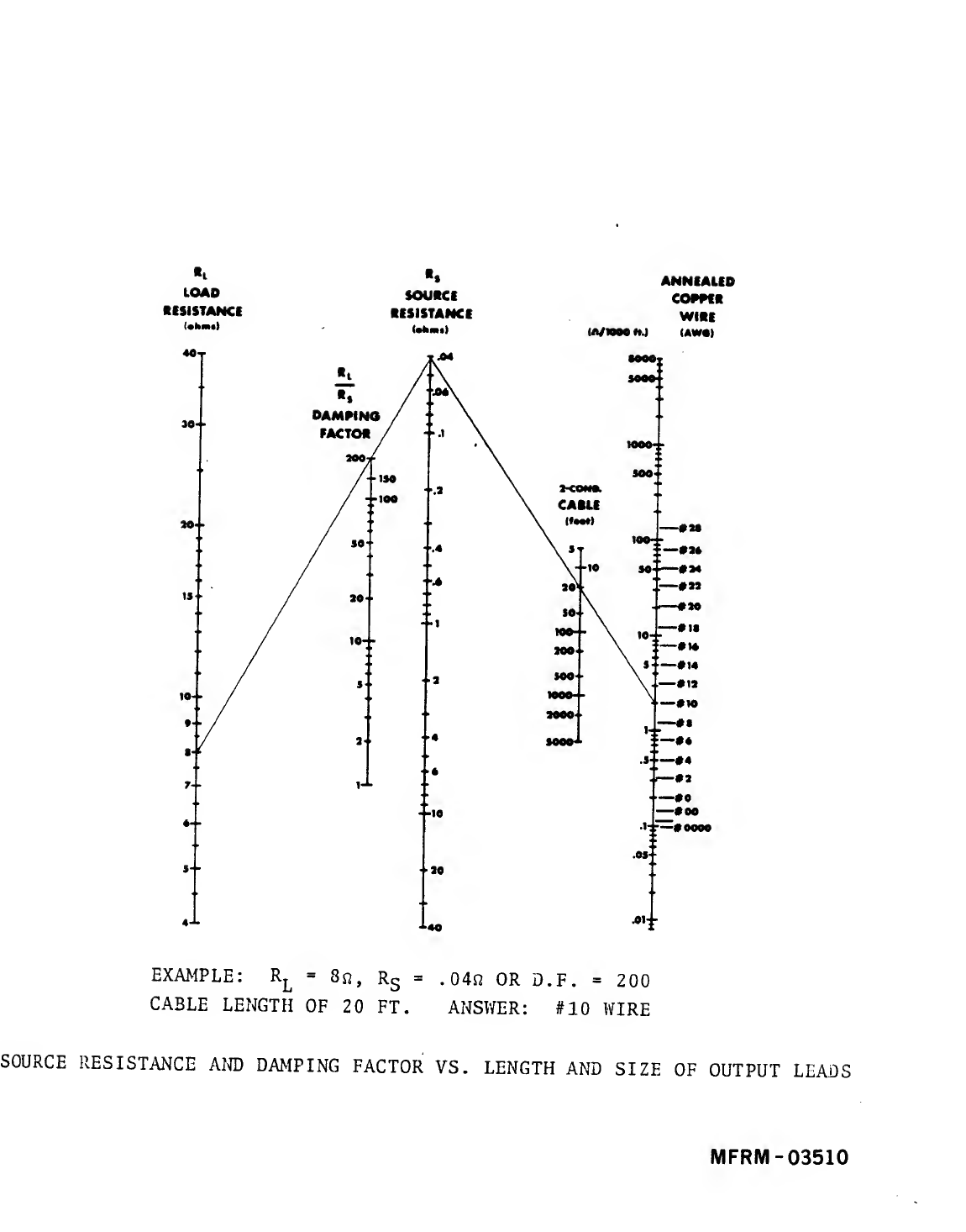

Damping Factor Nomagraph 03510

Speaker Fuse Nomagraph 03530

Mono Operation 03650

Power Mains Connection 04000

Operation 05200

Circuit Description 12310

Schematic Diagram, Amplifier Heatsink 12380

Schematic Diagram, Chassis 12370/71

12300-2

Schematic Diagram, AC wiring 12360/61

Block Diagram, Power Amplifier 12350

Parts List 12390

Warranty 17010

Service Authorization Form 17020

Warranty Registration Form 17030

00601

-IMPORTANT-

PLEASE READ THIS PAGE BEFORE OPERATING

YOUR

BGW POWER AMPLIFIER

Your new BGW amplifier is designed to provide years of trouble free performance.

Observing these few precautions will insure proper operation.

.All connections should be made to the power amplifier with the power OFF.

.Speaker fuses should be used to afford maximum speaker protection.

.Never connect the output of one channel to that of another.

.Connect the power cord to the proper vdltage mains as indicated on the rear of

the amplifier. Conversion to another voltage requires internal rewiring.

.Do not remove the amplifier's cover. Amplifiers may not be covered under

warranty if they are tampered with. There are NO adjustments within.

Potentially lethal voltages exist within the amplifier. Refer all service work to

an authorized BGW service station.

01530-1

DESCRIPTION

The BGW Model 150 is one of the most advanced solid state’, fully complementary,

bridgeable, stereo power amplifiers available.

Features of the Model 150 include precision step attenuator level controls, LED

metering, separate circuit and chassis grounds, XLR and K»" input connectors with

transformer sockets, and small size.

The front panel includes two vertical rows of four red LED's, one row for each

channel. The lower LED in each row is the IDLE indicator or pilot lamp. They will

be lit whenever the amplifier is turned on.

The top LED in each row is aclipping indicator and utilizes an exclusive BGW

circuit. Whenever either channel of the 150 is driven into clipping, acorresponding

indicator lights and remains lit for 0.20 seconds. These indicators, which actually

indicate loss of feedback, tell the operator that the amplifier is being overdriven

and can be invaluable to the engineer who must be sure that every component in his

system is producing aclean, distortion-free signal. An inadvertant short-circuited

output (with signal) will cause the LED to remain on until the short is removed.

The middle LED's are connected to acircuit employing integrated circuit to

provide an audio level indication of 0.5% and 50% of maximum power output. They

provide avaluable tool for total system evaluation in multiple amplifier

installations.

Both the circuit and chassis grounds are connected to separate barrier strip

terminals on the rear of the amplifier. They are connected together by a

removeable link. By removing the link, the circuit grounds of all active units

(amplifiers, preamplifiers, mixers, etc.) can be tied to earth ground at acommon

point. This aids in eliminating ground loops.

Either XLR-type of K» inch phone plugs may be used for input connections. If plug-

in transformers are used, the XLR-type connectors are connected. If not, jumpers

must be employed in the transformer sockets. See sections 03011, 03021, 03031,

and 03041 for details.

The size of the Model 150 is convenient for awide variety of applications.

However, please note the following precaution:

1) Do not use the front panel as the sole support for the amplifier.

Side rails or rack shelves should be employed (See section

02650).

The output stages of your amplifier use the most advanced type of transistors

available. These large geometric, complementary, power devices have large safe

operating areas and extended power bandwidth. Electrostatic and other highly

reactive speaker systems present no difficulties for the Model 150. The aluminum

heat sinks are located so the 150 power amplifiers can be stacked on top of each

other and air can be forced through both sides to cool the products.

01530-2

All of the semiconductors in the output area are in intimate contact with the heat

sink. The bias circuit is also mounted on this isotherm to provide rock steady bias

stability with temperature.

The voltage gain circuits are aiso mounted on the same circuit board. Atrue

operational amplifier integrated circuit acts as the front end.

The op-amp is aspecial unit featuring very low noise, high speed (10MHz). The op-

amp stage is followed by adiscrete complementary pair acting as an active current

source/sink and providing voltage gain. The current source is the ideal way to

drive the output stage, which is basically atriple Darlington voltage follower.

This sophisticated circuit design makes for an extremely accurate amplifier. The

accuracy of an amplifier is afunction of the ratio of the open loop gain to the

closed loop gain. In this case, the open loop gain is about 1,000,000. This

extremely accurate signal processing enables the amplifier to drive speakers at

very high levels while adding absolutely no coloration of its own. Even at milliwatt

levels, the output waveform exhibits no sign of crossover distortion.

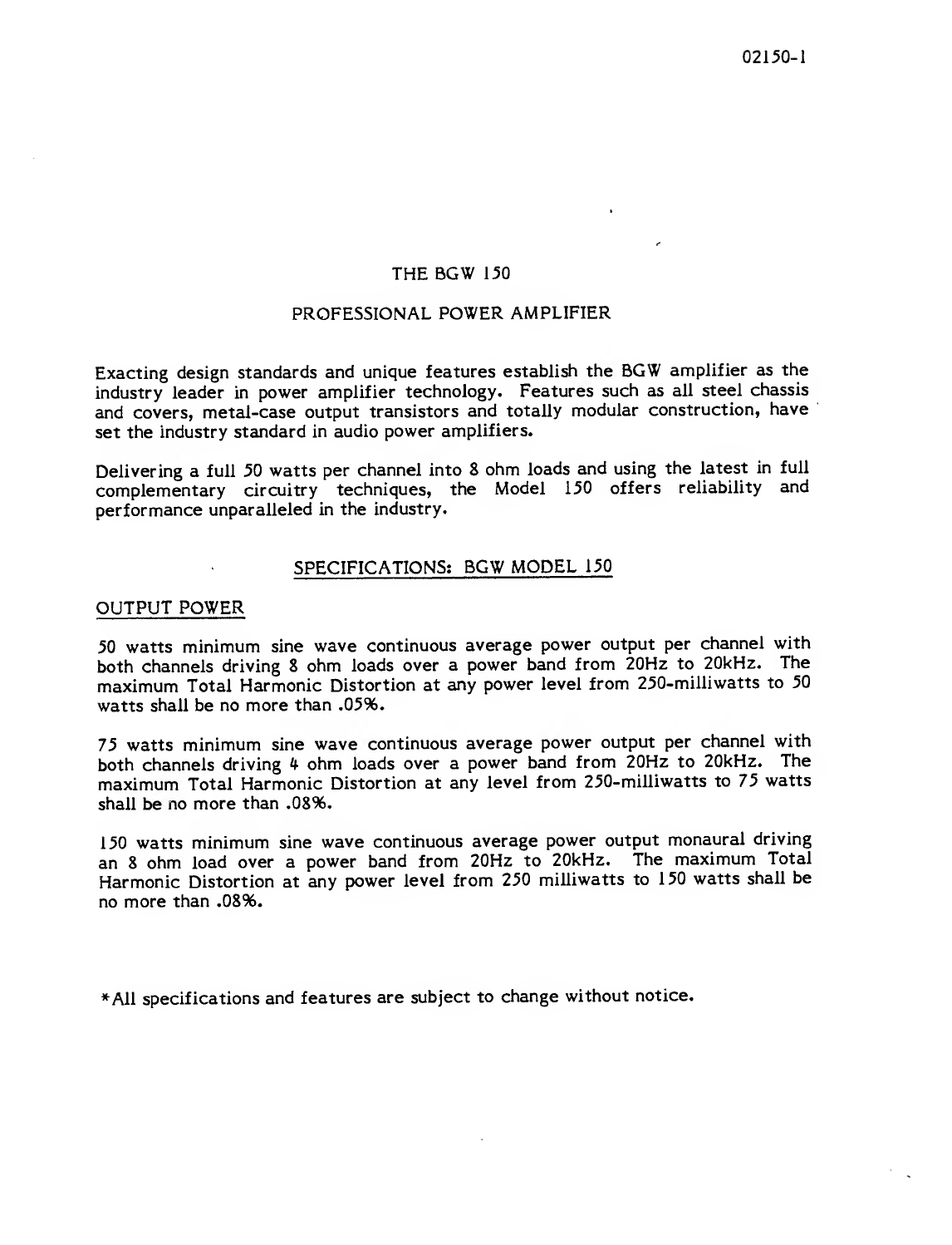

02150-1

THE BGW 150

PROFESSIONAL POWER AMPLIFIER

Exacting design standards and unique features establish the BGW amplifier as the

industry leader in power amplifier technology. Features such as all steel chassis

and covers, metal-case output transistors and totally modular construction, have

set the industry standard in audio power amplifiers.

Delivering afull 50 watts per channel into 8 ohm loads and using the latest in full

complementary circuitry techniques, the Model 150 offers reliability and

performance unparalleled in the industry.

SPECIFICATIONS: BGW MODEL 150

OUTPUT POWER

50 watts minimum sine wave continuous average power output per channel with

both channels driving 8ohm loads over apower band from 20Hz to 20kHz. The

maximum Total Harmonic Distortion at any power level from 250-milliwatts to 50

watts shall be no more than .05%.

75 watts minimum sine wave continuous average power output per channel with

both channels driving 4ohm loads over apower band from 20Hz to 20kHz. The

maximum Total Harmonic Distortion at any level from 250-milliwatts to 75 watts

shall be no more than .08%.

150 watts minimum sine wave continuous average power output monaural driving

an 8ohm load over apower band from 20Hz to 20kHz. The maximum Total

Harmonic Distortion at any power level from 250 milliwatts to 150 watts shall be

no more than .08%.

All specifications and features are subject to change without notice.

02150-2

SPECIFICATIONS

Inter modulation Distortion:

Small Signal Frequency

Response:

Less than 0.02% from 250 milliwatts to

rated power.

+0, 3dB, 1Hz to 100kHz,

+0, 0.25dB, 20Hz, to 20kHz.

Hum and Noise Level:

Input Sensitivity:

Better than 102dB below 50 watts

(unweighted, 20Hz to 20kHz).

1.0 volts for maximum power output.

Voltage gain 26dB (20 times).

Input Impedance: 15K ohms.

Damping Factor: Greater than 400 to 1. Referenced at 8

ohms at 1kHz.

Output Impedance: Designed for any load impedance equal

to or greater than 4ohms.

Power Requirements: 100, 120, 200, 220 or 240 volts 50-60Hz

350 watts.

Semiconductor Complement:

Dimensions:

Weight:

2Ultra-low noise Op Amp IC's, 2level

detector IC's, 2delay timer IC's, 26

transistors, 4zener diodes, 12 diodes, 8

LED's.

13/4" by 19" standard rack front panel.

Depth behind front panel IIK

2". (4.45cm

X48.26cm X29.21cm).

14 lbs. (6.37 kg) net, 18 lbs (8.18 kg)

shipping.

02500

UNPACKING AND SET-UP

Your BGW Power Amplifier is shipped in an advanced packing container.

SAVE THE CONTAINER

AND ALL PACKING MATERIAL!

The container should be saved in the event the unit is moved or shipped at some

future date. Replacement containers are available from BGW.

Inspect the unit for damage in transit immediately upon receipt. If damage is

found, notify the transportation company immediately. Only the consignee may

institute aclaim with the carrier for shipping damage. BGW will cooperate fully in

such event. Be sure to save the container as evidence of damage for the shipper to

inspect.

The amplifier's mounting position must be chosen carefully so that the air flow to

the sides of the unit is not restricted. Inadequate ventilation may cause the

protective heat sensors to shut the unit off. For rack mounting, the four rubber

feet on the bottom of the unit may be removed and no hardware will be loosened

inside the unit.

DO NOT PLUG THE AMPLIFIER IN YET!

All connections should be made before power is applied.

02650

RACK MOUNTING HINTS

KEEPING IT COOL

Apower amplifier draws energy from aprimary electrical service, usually a120

VAC outlet, to drive loudspeaker systems with an audio signal. Typically, only half

of the energy can be delivered to the loudspeakers; remaining energy is converted

into heat, and must be dissipated (ventilated) into the air.

Air circulating past heat-producing components, absorbs the heat and carries it

away. To accomplish this, low and medium power amplifiers rely on natural

convection currents, while most high power amplifiers use fans. If the air flow is

impeded, the resulting rise in heat may cause an amplifier to stop working or fail.

Circulating air currents must not be cut off when installing power amplifiers in

racks. Power amplifiers using convection cooling require spacing between

amplifiers to permit air flow between them. Power amplifiers using forced-air

cooling, on the other hand, can usually be stacked closer to each other and may not

need any blank panel spacing between amplifiers.

To improve natural convection currents within arack, achimney can be created by

closing the back of the rack and venting the rack at the bottom to let in fresh air,

and at the top to exhaust hot air. Vents should be large rectangular slots

approximately 19" wide by 4" high.

The rack cabinet will require some type of blower if alarge air-flow is required. It

is best to exhaust air from the top of the rack rather than to blow it in from the

bottom. There will be less dust and dirt in the rack this way, if the bottom vent is

sufficiently large.

INSTALLING THE UNITS

Use care when mounting equipment in arack. Place the heaviest units near the

bottom of the rack and fill in all unused rack spaces with blank panels. Equipment

cannot always be supported by front panels alone. This is especially true of

amplifiers whose depth is more than twice their height. Uniform support can be

insured by installing bottom or side rails.

When racks are to be transported or used in amobile installation, some means of

securing the rear of the equipment is required. Angle brackets either attached to

the bottom, side rails or rear panel are practical approaches.

03002-1

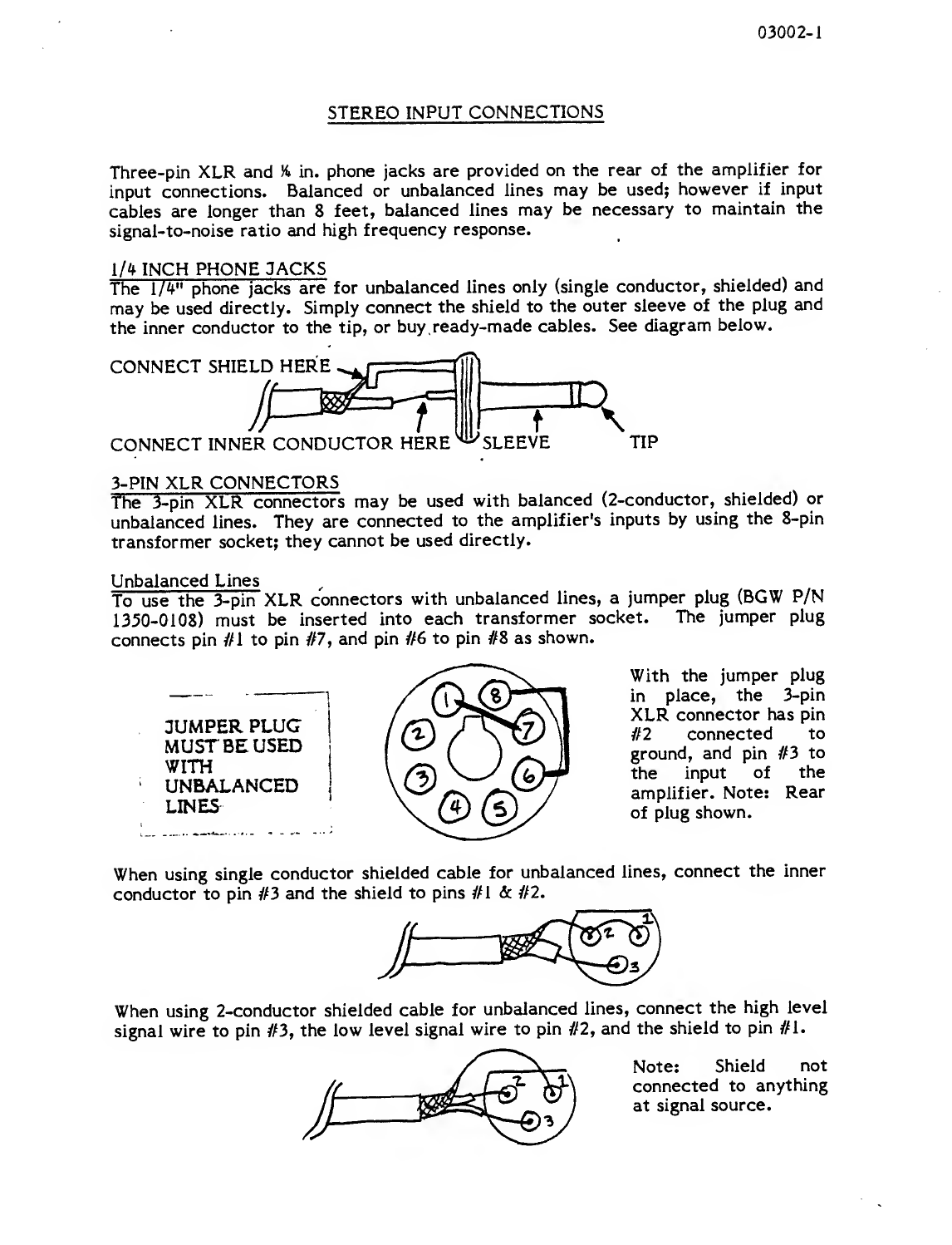

STEREO INPUT CONNECTIONS

Three-pin XLR and in. phone jacks are provided on the rear of the amplifier for

input connections. Balanced or unbalanced lines may be used; however if input

cables are longer than 8feet, balanced lines may be necessary to maintain the

signal-to-noise ratio and high frequency response.

1/4 INCH PHONE JACKS

The 1/4" phone jacks are for unbalanced lines only (single conductor, shielded) and

may be used directly. Simply connect the shield to the outer sleeve of the plug and

the inner conductor to the tip, or buy ready-made cables. See diagram below.

CONNECT SHIELD HERE ms

CONNECT INNER CONDUCTOR HERE ^SLEEVE

ID

f\TIP

3-PIN XLR CONNECTORS

The 3-pin XLR connectors may be used with balanced (2-conductor, shielded) or

unbalanced lines. They are connected to the amplifier's inputs by using the 8-pin

transformer socket; they cannot be used directly.

Unbalanced Lines

To use the 3-pin XLR connectors with unbalanced lines, ajumper plug (BGW P/N

1350-0108) must be inserted into each transformer socket. The jumper plug

connects pin //I to pin #7, and pin //6 to pin #8 as shown.

JUMPER PLUC

MUST BE USED

WITH

UNBALANCED

LINES

With the jumper plug

in place, the 3-pin

XLR connector has pin

#2 connected to

ground, and pin //3 to

the input of the

amplifier. Note: Rear

of plug shown.

When using single conductor shielded cable for unbalanced lines, connect the inner

conductor to pin #3 and the shield to pins #1 &// 2.

When using 2-conductor shielded cable for unbalanced lines, connect the high level

signal wire to pin //3, the low level signal wire to pin //2, and the shield to pin //l.

Note: Shield not

connected to anything

at signal source.

03002-2

To achieve atrue balanced input, it is necessary to use one transformer for each

input. These should be plugged into the octal sockets provided. Depending on the

specific application, one of several different transformers may be selected.

Forms are included in this manual to help guide you in your use and selection of

transformers. Use the index below to find the appropriate form to match your

needs.

CONNECTING ON SOURCE TO ONE AMPLIFIER

Using Balanced Lines; Refer to form #03031

Using Unbalanced Lines: Refer to form #03041

CONNECTING ONE SOURCE TO TWO OR MORE AMPLIFIERS OR DEVICES

Using Balanced Lines; Refer to form #030 1

1

Using Unbalanced Lines; Refer to form #03021

NOTE: Each amplifier input will be referred to as the "Load" in the above

mentioned forms. Only one channel will be shown.

Two conductor shielded cable should be used in abalanced line system. Connect

input cables as shown below.

Pin #1 Shield (Ground)

Pin #2 Signal (Minus)

Pin #3 Signal (Plus)

FOR MONO (BRIDGED) OPERATION

To operate the unit as amono amplifier, use the left channel input only. DO NOT

use the right channel input. Remember to place the stereo/mono switch in the

mono position.

BRIDGING BALANCED LINE INPUTS

Used only when two or more devices are driven from the same input line.

MAXIMUM NUMBER OF AMPLIFIER 25ea

Input transformers for above

A. Use 1:1 transformer 600 ohms to 600 ohms

B. Nth load must have aterminating resistor added to the secondary

of the Input transformer.

One alternative configuration is

C. 1:1 transformer 15K ohms to 15K ohms

D. Nth load must have aterminating resistor added to the primary

of the input transformer.

To find this resistance value see sheet TERMINATING RESISTANCE CHART,

MFRM 03051.

NOTE: Terminating resistance is required when source is atransformer. Sources

other than a transformer may not need atermination.

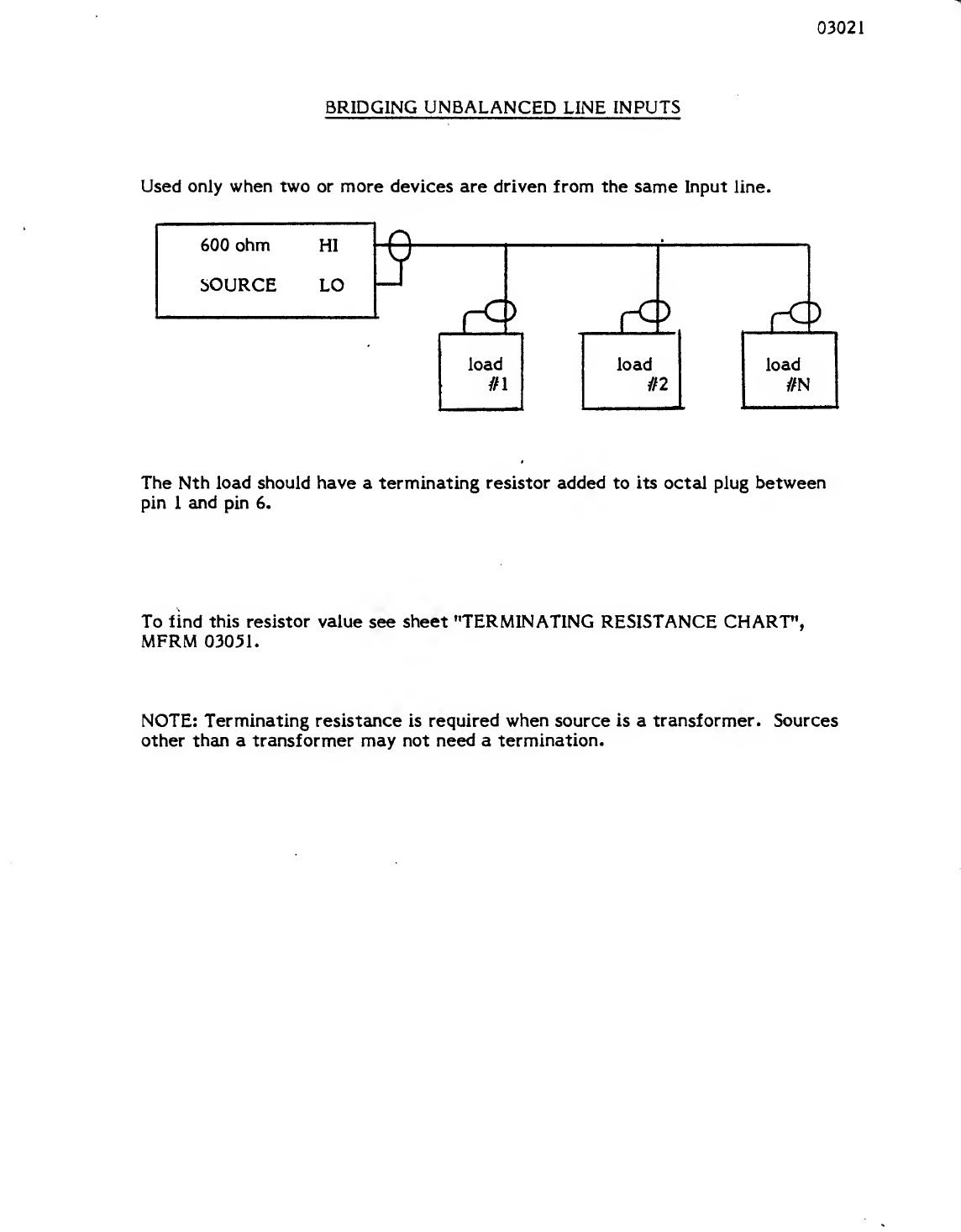

03021

BRIDGING UNBALANCED LINE INPUTS

Used only when two or more devices are driven from the same Input line.

The Nth load should have aterminating resistor added to its octal plug between

pin 1and pin 6.

To find this resistor value see sheet "TERMINATING RESISTANCE CHART",

MFRM 03051.

NOTE: Terminating resistance is required when source is atransformer. Sources

other than atransformer may not need atermination.

03031

BALANCED LINE INPUT:

Used only when one amplifier is driven from one source.

600 ohm

Source

A^

LOAD

X1L

Input transformer for above

A. Use 1:5 transformer 600 ohms to 15K ohms

NOTE: No 600 ohm TERMINATION IS REQUIRED

B. Alternate transformer

Use 1:1 transformer 600 ohms to 600 ohms

NOTE: 600 ohms termination is required on the secondary of the transformer

NOTE: Terminating resistance is required when source is atransformer: sources

other than atransformer may not need atermination.

600 ohm termination, when required, can be accomplished by soldering the resistor

across pins 1and 6of the transformer as shown below

or by installing the resistor in a1/4" phone plug and inserting it into the unused

unbalanced input jack.

03041

UNBALANCED LINE INPUT

Used only when one amplifier is driven from one source

600 ohm

Source

A600 ohm terminating resistor must be added to its octal plug.

Between pin 1and pin 6

NOTE: Terminating resistance is required when source is atransformer. Sources

other than atransformer may not need atermination.

03051

TERMINATING RESISTANCE CHART

How to find terminating resistance for balanced or unbalanced 600 ohm

lines, driving more than one amplifier.

STEP AInput Impedance of Amplifiers Total Load Impedance

Number of Amplifiers “of Amplifiers

STEP BTotal Impedance of Amplifiers -600 K(Impedance Factor)

STEP C

™~60(5 “

(i+l)x 600 ohms =Load Resistor Required

EXAMPLE:

Input Impedance of Amplifiers =15,000 ohms

Number of Amplifiers =4

A1M92. -3750 ohms

B3750-600 e

Too =5-25

Cx600 =1.19 x600 =714.29 ohms

Closest value is 715 ohms 1% metal film resistor.

*Note ail amplifiers must have the same input impedance. If not, use

formula below:

30k and 7.5k

1

X+

+

X

Zi Zj Zu

EXAMPLE:

Total Load Impedance

Four (4) Amplifiers with input impedance of 15k, 30k,

1

lfffc 50K. 50(C 7.SK

=3750 ohms

03501-1

STEREO OUTPUT CONNECTIONS

Two sets of five-way binding posts, on the rear panel, serve as output connectors,

with one black and one red binding post for each channel. Left channel leads go to

the binding posts marked LEFT; right channel, to those marked RIGHT.

Output leads are best connected, to the amplifier, with standard banana plugs;

however, the five-way action of the binding posts permits the use of tinned wires

or spade lugs.

Make certain that the speakers are properly phased. Connect the black or minus (-)

terminal on the speaker cabinet to the appropriate black binding post on the

amplifier. Connect the red or plus (+) terminal to the red binding post. Check to

see that the stereo-mono switch on the rear of the amplifier is in the stereo

position.

SPEAKER PROTECTION

All speakers can be damaged by having too much power applied to them. Fuse

protection is an effective and inexpensive way of preventing this from occurring.

If your speaker system does not contain a fuse or acircuit breaker, afuse should be

placed in series with each speaker and the wire going to the red terminal on the

rear of the amplifier.

Maximum protection can be obtained with fast-acting fuses. Use the value

recommended by the manufacturer. If no value is specified, use the chart provided

to select the correct value (MFRM-03530).

To use the chart, take astraightedge, such as aruler, and line up the speaker's

impedance with its peak music power rating. The proper fuse value can then be

read from the center column. Choose afuse that is closest to, and below, the

value indicated.

WIRE SIZE AND DAMPING FACTOR

The high damping factor of BGW amplifiers results in avery clean bass response.

Excessively long, and small diameter speaker wires can lower the damping factor

and distort the lower frequencies. Adamping factor of at least 50 should be

maintained to insure good audio quality.

The relationship between wire length and diameter, and damping factor can be

calculated using the chart (MFRM-03510) on the following page. Proceed as

follows:

1. Using astraight-edge, line up the gauge of the speaker wire with its length.

Mark off the resulting source resistance where this line crosses the center

column.

2. Line up the source resistance, determined in step #1, with the

manufacturer's impedance* of the speaker system. The damping factor can

now be read.

03501-2

The impedance of aspeaker system can be approximated by measuring the resistance

across the speaker terminals, with the amplifier disconnected. Multiplying this

result by 1.33, gives you the approximate impedance.

Note: This method cannot be used with electrostatic speakers.

«l

LOAD

RESISTANCE

(•tents)

*» ANNEAUD

SOURCI COSSCR

RESISTANCE WIRE

{A/1000 HJ (AWOt

EXAMPLE: \=8«, Rs=.04s? OR D.F. =200

CABLE LENGTH OF 20 FT. ANSWER: #10 WIRE

SOURCE RESISTANCE AND DAMPING FACTOR VS. LENGTH AND SIZE OF OUTPUT LEADS

MFRM -03510

Other manuals for 150

2

Table of contents

Other BGW Amplifier manuals