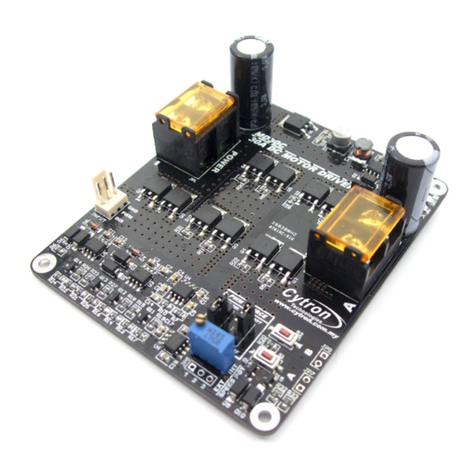

Bholanath BH-MSD-2A User manual

BH-

MSD

User’s Manual

For

MSD

-2A Micro Stepping Driver

Website:-www.bholanath.in

E-mail id:-support@bholanath.in

BHOLANATH PRECISION ENGINEERING PVT. LTD.

Page |

2

Product Number Code For Micro step drive

BH MSD 2A

2 Amp

MICRO STEP DRIVE

BHOLANATH

1:DC power input :12V~36VDC

2.Output current:0.25A-2A

3.Microstepping: 1, 2, 4, 8, 16, 32, 64, 128

4.Protect From:

Overvoltage, under voltage, over current , phase short circuit

5. imension: 96mmx60mmx24.5mm

6.Weight:180g.

7.Working environment: Temperature -15~80 C

Website:-www.bholanath.in

E-mail id:-support@bholanath.in

BHOLANATH PRECISION ENGINEERING PVT. LTD.

Page |

3

Table of Contents

1. Introduction, Features and Applications

...........................................................

4

Introduction

..............................................................................................

4

Features

....................................................................................................

4

Applications

..............................................................................................

4

2. Specifications

...............................................................................................

4

Electrical Specifications

.............................................................................

4

Model no:-BH-MSD-2A

.....................................................................

4

Drive prevention

........................................................................................

4

Operating Environment

..............................................................................

4

Elimination of Heat

....................................................................................

5

3. Pin Assignment and Description

......................................................................

5

Connector P1 Configurations

......................................................................

5

Connector P2 Configurations

......................................................................

5

External Limiting Resistance................................................................................

5

Full current And Half current ...............................................................................

5

Wiring Notes.........................................................................................................

6

Switch Choices .....................................................................................................

6

4.

Sequence Chart Of Control Signals

…………………………………………………….6

5.

Calculation of pulse frequency……………………………………………………...7

Frequency with Different RPM At 400 Micro Step............................................

7

Frequency with Different RPM At 800 Micro Step............................................

7

6. Connecting the Motor

....................................................................................

7

Connections to 4-lead Motors

......................................................................

7

Connections to 6-lead Motors

......................................................................

7

Half & Full Coil Configurations

..........................................................

8

Connections to 8-lead Motors

...............................................................

8

Series Connections

..............................................................................

8

Parallel Connections

...........................................................................

8

7. Power Supply Selection

.................................................................................

9

Regulated or Unregulated Power Supply

.......................................................

9

Multiple Drivers

........................................................................................

9

8. Troubleshooting

…………………………………………………………….

9

9. Dimensions

................................................................................................

11

10. Circuit connections Of BH MSD 4.5A With BH SDC-01,02

........................ .

12

11. Circuit connections of BH MSD 4.5A With Arduino & PLC

........................... .

13

12. Frequently Asked Questions

.......................................................................

13

13. Contact Us

................................................................................................

14

Website:-www.bholanath.in

E-mail id:-support@bholanath.in

BHOLANATH PRECISION ENGINEERING PVT. LTD.

Page |

4

1. Introduction, Features and Applications

Introduction

Micro stepping driver is particularly suitable for the applications desired with extremely low noise

and low temperature rise technology which significantly improve the performance of the stepper

motor that leads to low temperature rise, low vibration. With the adjustment technology (step/rev and

current) according to different motors, the driven motors automatically generate optimal parameters

for different motors, and achieve the best performance at higher speed. It is suitable for driving 2-

phase and 4-phase hybrid stepping motors.

Features

High performance, cost-effective

Suitable for 2-phase and 4-phase motors

Support PUL/DIR and CW/CCW modes

Short-voltage, over-voltage, over-current and short-circuit protection

Low temperature rise, smooth motion

Pulses Response Frequency Can Reach 200KHz

Applications

Suitable for a wide range of stepping motors, for NEMA size 17. It can be used in various kinds of

machines, such as X-Y tables. And a variety of automation equipments and instruments. It always

performs well when applied for equipment which requires for low-vibration, low-noise, high-

precision and high-velocity.

2. Specifications

Electrical Specifications

Model No:-BH-MSD-2A

Parameter

Min

Typical

Max

Unit

Input

Voltage(DC)

12

-

36 VDC

Input

Voltage(AC)

-

-

-

VAC

Output current

0.25

-

2

A

DRIVE PREVENTION :-

NOTE:-THE ABOVE VOLTAGE MAY DIFFER ACCORDING TO THE POWER SUPPLY IT IS RECOMMENDED

THEORITICALLY TO USE ABOVE VOLTAGE AS IT WILL PREVENT DRIVE FROM DAMAGE.

Operating Environment

Cooling Natural cooling or Forced cooling

Operating Environment Environment-Avoid dust, oil fog, corrosive gases

Temperature- -15℃

℃℃

℃-

--

-80℃

℃℃

℃

Humidity-Not Condensation, No Water Droplets

Operating Temperature- -10℃

℃℃

℃-

--

-45℃

℃℃

℃

Storage Temperature -20℃

℃℃

℃-

--

-65℃

℃℃

℃

Website:-www.bholanath.in

E-mail id:-support@bholanath.in

BHOLANATH PRECISION ENGINEERING PVT. LTD.

Page |

5

Elimination of Heat

Driver’s reliable working temperature should be <70

℃

℃℃

℃

, and motor working temperature

should be <80

℃

℃℃

℃

;

It is recommended to use automatic idle-current mode, namely current automatically reduce

to 60% when motor stops, so as to reduce driver heating and motor heating;

It is recommended to mount the driver vertically to maximize heat sink area. Use forced

cooling method to cool the system if necessary.

3. Pin Assignment and Description

The driver has two connectors namely P1 & P2, Connector P1 for control signals connection,

Connector P2 for power and motor connections.

The following tables are brief descriptions of the two

connectors

.

Connector P1 Configurations

Pin Function Details

PUL PULSE SIGNAL NEGATIVE

DIR DIRECTION SIGNAL NEGATIVE

EN ENABLE SIGNAL NEGATIVE

VCC SIGNAL VOLTAGE

Connector P2 Configurations

Pin Function Details

VDC+ DC POWER SUPPLY

GND GROUND

A+,A- MOTOR PHASE A

B+,B- MOTOR PHASE B

EXTERNAL CURRENT LIMITING RESISTANCE:

Signal current in both the“+” “-”ports,

can’t be too big and not too weak. It is necessary to connect current-limiting resistor in external, refer

to following table

VOLTAGE LIMITING RESISTANCE(R )

5 V R=0

12 V R=1KΩ

24 V R=2.2 KΩ

NOTE

: FULL CURRENT AND HALF CURRENT CHOICE: (PORT SW 4)

FULL CURRENT:-IF THE DRIVER IS IN FULL CURRENT MODE THIS WILL LEAD TO MOTOR HEAT AND IT WILL ALSO

DAMAGE THE DRIVER.

HALF CURRENT:-THE DRIVER SHOULD ALWAYS BE IN HALF CURRENT MODE AS THIS WILL REDUCE THE HEAT

OF MOTOR AND DRIVER.

Website:-www.bholanath.in

E-mail id:-support@bholanath.in

BHOLANATH PRECISION ENGINEERING PVT. LTD.

Page |

6

Wiring Notes

To prevent noise incurred in PUL/DIR signal, pulse/direction signal wires and motor wires

should not be tied up together. It is better to separate them by at least 10 cm, otherwise the

disturbing signals generated by motor will easily disturb pulse direction signals, causing

motor position error, system instability and other failures.

If a power supply serves several drivers, separately connecting the drivers is recommended

instead of daisy-chaining.

It is prohibited to pull and plug connector P2 while the driver is powered ON, because there is

high current flowing through motor coils (even when motor is at standstill). Pulling or

plugging connector P2 with power on will cause extremely high back-EMF voltage surge,

which may damage the driver.

Switch Choice:

1.Microstepping choice:

SW 5 ON OFF ON OFF ON OFF ON OFF

SW 6 ON ON OFF OFF ON ON OFF OFF

SW 7 ON ON ON ON OFF OFF OFF OFF

Micro

1 2 4 8 16 32 64 128

2.Current choice

:

::

:

SW 1 OFF ON OFF ON OFF ON OFF ON

SW 2 OFF OFF ON ON OFF OFF ON ON

SW 3 OFF OFF OFF OFF ON ON ON ON

Current

(A)

0.25 0.5 0.75 1 1.25 1.5 1.75 2

4.Sequence Chart of Control Signals

In order to avoid some fault operations and deviations, PUL, DIR and ENA should abide by

some rules, shown as following diagram

:

NOTE:

Enable signal is always high in this drive. Any external supply of 5 Vdc applied will disable

the Drive.

Page |

7

Remark:

a)

t1: ENA must be ahead of DIR by at least 5

connected). See “

Connector P1 Configurations

b)

t2: DIR must be ahead of PUL effective edge by 5

c)

t3: Pulse width not less than 1.5

d)

t4: Low level width not less than 1.5

5

.

CALCULATION OF PULSE FREQUENCY

If N

eed 60 RPM

Then Frequency

TABLE :-

(a Frequency With Different RPM A

RPM

60

120

FREQUENCY(Hz

400

800

TABLE :-(b Frequency

With Different RPM A

RPM

60

120

FREQUENCY(Hz

800

1600

6. Connecting the Motor

Connections to 4-

lead Motors

4 lead motors are the least flexible but easiest to wire. Speed and torque will depend on winding

inductance

.

Connections to 6-

lead Motors

Like 8 lead stepping motors, 6 lead motors have two configurations available for high speed or high

torque operation. The higher speed configuration, or half coil, is so described because it uses one half

of the motor’

s inductor windings. The higher torque configuration, or full coil, uses the full windings

of the phases.

Website:

E-mail id:-

support@bholanath.in

BHOLANATH PRECISION ENGINEERING PVT. LTD.

t1: ENA must be ahead of DIR by at least 5

µ

s. Usually, ENA+ and ENA

Connector P1 Configurations

”for more information.

t2: DIR must be ahead of PUL effective edge by 5

µ

s to ensure correct direction;

t3: Pulse width not less than 1.5

µs;

t4: Low level width not less than 1.5

µs.

CALCULATION OF PULSE FREQUENCY

:-

F = (RPM X MICRO STEP /60 Hz

eed 60 RPM

at 400 Micro Step (Half Step Setting)

Then Frequency

= (60X400) /60

= 400Hz

(a Frequency With Different RPM A

t 400 Micro Step

120

180

240

300

360

420

800

1200

1600

2000

2400

2800

With Different RPM A

t 800 Micro Step

If Need 60 RPM at 800 Micro step

Then Frequency = (60X800) /60

= 800Hz

120

180

240

300

360

420

1600

2400

3200

4000

4800

5600

lead Motors

4 lead motors are the least flexible but easiest to wire. Speed and torque will depend on winding

lead Motors

Like 8 lead stepping motors, 6 lead motors have two configurations available for high speed or high

torque operation. The higher speed configuration, or half coil, is so described because it uses one half

s inductor windings. The higher torque configuration, or full coil, uses the full windings

Website:

-www.bholanath.in

support@bholanath.in

BHOLANATH PRECISION ENGINEERING PVT. LTD.

s. Usually, ENA+ and ENA

- are NC (not

s to ensure correct direction;

F = (RPM X MICRO STEP /60 Hz

420

480

540

2800

3200

3600

420

480

540

5600

6400

7200

4 lead motors are the least flexible but easiest to wire. Speed and torque will depend on winding

Like 8 lead stepping motors, 6 lead motors have two configurations available for high speed or high

torque operation. The higher speed configuration, or half coil, is so described because it uses one half

s inductor windings. The higher torque configuration, or full coil, uses the full windings

Page |

8

Half Coil Configurations

As previously stated, the half coil configuration uses 50% of the motor phase windings. This gives

lower inductance, hence, lower torque output. Like the parallel connection of 8 lead motor, the torque

output will be more stable at higher speeds. This

6-

lead motor half coil (higher speed) connections

Full Coil Configurations

Lower speed

is desired. This configuration is also referred to as full chopper. In full coil mode, the

motors should be run at only 70% of thei

6-

lead motor full coil (higher torque) connections

NOTE:

THE ABOVE CONFIGURATIONS IS FOR CONNECTI

MICROSTEP DRIVE AS PER APPLICATION/

MICROSTEP DRIVE

.

Connections to 8-

lead Motors

8 lead motors offer a high degree of flexibility to the system designer in that they may be connected

in series or parallel, thus satisfying a wide range of applications.

Series Connections

A series motor configuration would typically be used in applications where a higher torque at lower

speeds is required. Because this configuration has the most inductance, the performance will start to

degrade at higher speeds. In series mode, the motors s

current to prevent overheating

.

Parallel Connections

An 8 lead motor in a parallel configuration offers a more stable, but lower torque at lower

because of the lower inductance, there will be higher torque at higher speeds

Website:

E-mail id:-

support@bholanath.in

BHOLANATH PRECISION ENGINEERING PVT. LTD.

As previously stated, the half coil configuration uses 50% of the motor phase windings. This gives

lower inductance, hence, lower torque output. Like the parallel connection of 8 lead motor, the torque

output will be more stable at higher speeds. This

conf

iguration is also referred to as half chopper.

lead motor half coil (higher speed) connections

is desired. This configuration is also referred to as full chopper. In full coil mode, the

motors should be run at only 70% of thei

r rated current to prevent overheating.

lead motor full coil (higher torque) connections

THE ABOVE CONFIGURATIONS IS FOR CONNECTI

NG IN A BIPOLAR

MICROSTEP DRIVE AS PER APPLICATION/

NON-

AVAILABILITY OF A

lead Motors

8 lead motors offer a high degree of flexibility to the system designer in that they may be connected

in series or parallel, thus satisfying a wide range of applications.

A series motor configuration would typically be used in applications where a higher torque at lower

speeds is required. Because this configuration has the most inductance, the performance will start to

degrade at higher speeds. In series mode, the motors s

hould also be run at only 70% of their rated

8-lead motor series connections

An 8 lead motor in a parallel configuration offers a more stable, but lower torque at lower

because of the lower inductance, there will be higher torque at higher speeds

.

FOR HALF COIL CONNECTION

CONNECT (A+)-

A Com & (B+)

A Com

-

(A

-

) & B Com

FOR

F

ULL

COIL CONNECTION

CONNECT (A+)-(A-

) & (B+)

LEAVE A Com & B Com

Website:

-www.bholanath.in

support@bholanath.in

BHOLANATH PRECISION ENGINEERING PVT. LTD.

As previously stated, the half coil configuration uses 50% of the motor phase windings. This gives

lower inductance, hence, lower torque output. Like the parallel connection of 8 lead motor, the torque

iguration is also referred to as half chopper.

is desired. This configuration is also referred to as full chopper. In full coil mode, the

NG IN A BIPOLAR

AVAILABILITY OF A

UNIPOLAR

8 lead motors offer a high degree of flexibility to the system designer in that they may be connected

A series motor configuration would typically be used in applications where a higher torque at lower

speeds is required. Because this configuration has the most inductance, the performance will start to

hould also be run at only 70% of their rated

An 8 lead motor in a parallel configuration offers a more stable, but lower torque at lower

speeds. But

FOR HALF COIL CONNECTION

A Com & (B+)

-B Com/

) & B Com

-

(B

-

)

COIL CONNECTION

) & (B+)

-(B-)/

LEAVE A Com & B Com

Page |

9

7. Power Supply Selection

Th

e Microstep Driver can match small size stepping motors (f

driving performances, it is important to select supply voltage and output current properly. Supply

voltage determines the high speed performance of the motor, while output current determines the

output torque of the driven motor (particula

higher motor speed to be achieved, at the price of more noise and heating. If the motion speed

requirement is low, it’

s better to use lower supply voltage to decrease noise, heating and improve

reliability.

Regulated or Unregulated Power Supply

Both regulated and unregulated power supplies can be used to supply the driver. However,

unregulated power supplies are preferred due to their ability to withstand current surge. If regulated

power supplies (such

as most switching supplies.) are indeed used, it is important to have large

current output rating to avoid problems like current clamp. On the other hand, if unregulated supply is

used, one may use a power supply of lower current rating than that of motor

motor current). The reason is that the driver draws current from the power supply capacitor of the

unregulated supply only during the ON duration, but not during the OFF duration. Therefore, the

average current withdrawn from power s

Multiple Drivers

It is recommended to have multiple drivers to share one power supply to reduce cost, if the supply has

enough capacity. To avoid cross interference,

the drivers. (Instead, please connect them to power supply separately).

8. Troubleshooting

1. The status on light’s indication

POWER: normal work light.

NOTE:

TO CHECK IF DRIVE IS OK/NOT OK, CONNECT ONLY

GROUND TO THE MICROSTEP DRIVE AND CHECK THE LED INDICATOR IF IT SHOWS

GREEN THEN DRIVE IS OK AND IF THE LED INDICATOR SHOWS RED THEN DRIVE IS

NOT OK.

THIS TEST SHOULD

CARRIED AND MOTOR IS NOT RUNNING

Website:

E-mail id:-

support@bholanath.in

BHOLANATH PRECISION ENGINEERING PVT. LTD.

8-lead motor parallel connections

e Microstep Driver can match small size stepping motors (f

o

r Nema size 17

driving performances, it is important to select supply voltage and output current properly. Supply

voltage determines the high speed performance of the motor, while output current determines the

output torque of the driven motor (particula

rly at lower speed). Higher supply voltage will allow

higher motor speed to be achieved, at the price of more noise and heating. If the motion speed

s better to use lower supply voltage to decrease noise, heating and improve

Regulated or Unregulated Power Supply

Both regulated and unregulated power supplies can be used to supply the driver. However,

unregulated power supplies are preferred due to their ability to withstand current surge. If regulated

as most switching supplies.) are indeed used, it is important to have large

current output rating to avoid problems like current clamp. On the other hand, if unregulated supply is

used, one may use a power supply of lower current rating than that of motor

(typically 50%

motor current). The reason is that the driver draws current from the power supply capacitor of the

unregulated supply only during the ON duration, but not during the OFF duration. Therefore, the

average current withdrawn from power s

upply is considerably less than motor current

It is recommended to have multiple drivers to share one power supply to reduce cost, if the supply has

enough capacity. To avoid cross interference,

DO NOT daisy-

chain the power supply input pins of

the drivers. (Instead, please connect them to power supply separately).

1. The status on light’s indication

TO CHECK IF DRIVE IS OK/NOT OK, CONNECT ONLY

SUPPLY (AC /DC) VOLTAGE AND

GROUND TO THE MICROSTEP DRIVE AND CHECK THE LED INDICATOR IF IT SHOWS

GREEN THEN DRIVE IS OK AND IF THE LED INDICATOR SHOWS RED THEN DRIVE IS

THIS TEST SHOULD

BE DONE WHEN THE BELOW TROUBLE SHOOTING

CARRIED AND MOTOR IS NOT RUNNING

Website:

-www.bholanath.in

support@bholanath.in

BHOLANATH PRECISION ENGINEERING PVT. LTD.

r Nema size 17

). To achieve good

driving performances, it is important to select supply voltage and output current properly. Supply

voltage determines the high speed performance of the motor, while output current determines the

rly at lower speed). Higher supply voltage will allow

higher motor speed to be achieved, at the price of more noise and heating. If the motion speed

s better to use lower supply voltage to decrease noise, heating and improve

Both regulated and unregulated power supplies can be used to supply the driver. However,

unregulated power supplies are preferred due to their ability to withstand current surge. If regulated

as most switching supplies.) are indeed used, it is important to have large

current output rating to avoid problems like current clamp. On the other hand, if unregulated supply is

(typically 50%

~

~~

~

70% of

motor current). The reason is that the driver draws current from the power supply capacitor of the

unregulated supply only during the ON duration, but not during the OFF duration. Therefore, the

upply is considerably less than motor current

It is recommended to have multiple drivers to share one power supply to reduce cost, if the supply has

chain the power supply input pins of

SUPPLY (AC /DC) VOLTAGE AND

GROUND TO THE MICROSTEP DRIVE AND CHECK THE LED INDICATOR IF IT SHOWS

GREEN THEN DRIVE IS OK AND IF THE LED INDICATOR SHOWS RED THEN DRIVE IS

BE DONE WHEN THE BELOW TROUBLE SHOOTING

IS

Website:-www.bholanath.in

E-mail id:-support@bholanath.in

BHOLANATH PRECISION ENGINEERING PVT. LTD.

Page |

10

2. Troubles

Problems

Possible cause

Solutions

No power supply Check the power supply

Motor is not

No control signal Check the control signal

rotating

The driver is disabled

Don’t connected the enable signal

or enable the driver

Supply voltage is too high or

Check the supply voltage

too low

ALM lights

Motor line short-circuit

Check motor lines eliminate the

short-circuit

Motor line wrong connect

Check the motor wiring

Motor or drive failure

Replace the motor or drive

Motor rotates in

Motor phases connected in

Reverse the phases line

the wrong

reverse

direction

Wrong I/p direction signal Change direction setting

Motor line break

Change the phases are connected

Inaccurate

The Micro steps set incorrectly.

Set the correct segments

The motor load is too heavy. Increasing the current

Position

Control signal is interfered Eliminate interference

Power supply voltage too low

Increasing the supply voltage

Motor Stalled

Accelerating time is too short.

Extend the acceleration time

Current setting is too small Increasing the current

Motor torque is too small

Replace the motor

Page |

11

Problems

Wrong connection for power

LED off turn

Low

Wrong connection of stepper

Motor

doesn’t

run,

motor

without holding torque

RESET signal is effective

Motor

doesn’t

run,

but

Without input pulse signal

maintains holding torque

Too small relative to current

setting

Motor’s holding torque is

Acceleration is too fast

too small

Motor stalls

Driver does not match with

The motor

9. Dimensions

Website:

E-mail id:-

support@bholanath.in

BHOLANATH PRECISION ENGINEERING PVT. LTD.

Possible cause

Solutions

Wrong connection for power

Check wiring of power

Low

-

voltages for power

Enlarge voltage of power

Wrong connection of stepper

Correct its wiring

motor

RESET signal is effective

when offline Make RESET

Ineffective

Without input pulse signal

Adjust PMW & signal level

Too small relative to current

Correct rated current setting

setting

Acceleration is too fast

Reduce the acceleration

Motor stalls

Rule out mechanical failure

Driver does not match with

Change a suitable driver

The motor

Website:

-www.bholanath.in

support@bholanath.in

BHOLANATH PRECISION ENGINEERING PVT. LTD.

Solutions

Check wiring of power

Enlarge voltage of power

Correct its wiring

when offline Make RESET

Adjust PMW & signal level

Correct rated current setting

Reduce the acceleration

Rule out mechanical failure

Change a suitable driver

Page |

12

10.

10. Circuit connections Of BH MSD 2A With BH

NOTE:-

ENABLE SHOULD BE KEPT OPEN (USE ONLY IF REQUIRED)

Website:

E-mail id:-

support@bholanath.in

BHOLANATH PRECISION ENGINEERING PVT. LTD.

10. Circuit connections Of BH MSD 2A With BH

-

SDC 01,SDC 02

ENABLE SHOULD BE KEPT OPEN (USE ONLY IF REQUIRED)

Website:

-www.bholanath.in

support@bholanath.in

BHOLANATH PRECISION ENGINEERING PVT. LTD.

SDC 01,SDC 02

ENABLE SHOULD BE KEPT OPEN (USE ONLY IF REQUIRED)

Page |

13

11. Circuit Connections Of BH MSD 2A With PLC & Arduino

11. Circuit connections Of Arduino

NOTE:

Enable signal is always high in this drive. Any external supply of 5 Vdc applied will disable

the Drive.

Website:

E-mail id:-

support@bholanath.in

BHOLANATH PRECISION ENGINEERING PVT. LTD.

11. Circuit Connections Of BH MSD 2A With PLC & Arduino

11. Circuit connections Of Arduino

Enable signal is always high in this drive. Any external supply of 5 Vdc applied will disable

Website:

-www.bholanath.in

support@bholanath.in

BHOLANATH PRECISION ENGINEERING PVT. LTD.

Enable signal is always high in this drive. Any external supply of 5 Vdc applied will disable

Page |

14

12.

Frequently Asked Questions

In the event

that your driver doesn

problem is electrical or mechanical in nature. The next step is to isolate the system

component that is causing the problem. As part of this process you may have to discon

the individual components that make up your system and verify that they operate

independently. It is important to document each step in the troubleshooting process. You may

need this documentation to refer back to at a later date, and these details wi

our Technical Support staff in determining the problem should you need assistance.

Many of the problems that affect motion control systems can be traced to electrical noise,

controller software errors, or mistake in wiring.

The content in

this manual has been carefully prepared and is believed to be accurate, but no

responsibility is assumed for inaccuracies

We manufacture 1.8⁰

HYBRID STEPPER MOTORS of size NEMA17, NEMA23, NEMA24, and

NEMA34 in square frame and Nema

are Linear Actuator Stepper Motors, Planetary Geared Stepper Motors, Stepper motors

with Brakes and Customized Stepper Motors.

Website:

E-mail id:-

support@bholanath.in

BHOLANATH PRECISION ENGINEERING PVT. LTD.

Frequently Asked Questions

that your driver doesn

’

t operate properly, the first step is to identify whether the

problem is electrical or mechanical in nature. The next step is to isolate the system

component that is causing the problem. As part of this process you may have to discon

the individual components that make up your system and verify that they operate

independently. It is important to document each step in the troubleshooting process. You may

need this documentation to refer back to at a later date, and these details wi

our Technical Support staff in determining the problem should you need assistance.

Many of the problems that affect motion control systems can be traced to electrical noise,

controller software errors, or mistake in wiring.

this manual has been carefully prepared and is believed to be accurate, but no

responsibility is assumed for inaccuracies

HYBRID STEPPER MOTORS of size NEMA17, NEMA23, NEMA24, and

NEMA34 in square frame and Nema

23 in Round frame and available in our product range

are Linear Actuator Stepper Motors, Planetary Geared Stepper Motors, Stepper motors

with Brakes and Customized Stepper Motors.

BHOLANATH STEP SERVO MOTOR & DRIVE

Website:

-www.bholanath.in

support@bholanath.in

BHOLANATH PRECISION ENGINEERING PVT. LTD.

t operate properly, the first step is to identify whether the

problem is electrical or mechanical in nature. The next step is to isolate the system

component that is causing the problem. As part of this process you may have to discon

nect

the individual components that make up your system and verify that they operate

independently. It is important to document each step in the troubleshooting process. You may

need this documentation to refer back to at a later date, and these details wi

ll greatly assist

our Technical Support staff in determining the problem should you need assistance.

Many of the problems that affect motion control systems can be traced to electrical noise,

this manual has been carefully prepared and is believed to be accurate, but no

HYBRID STEPPER MOTORS of size NEMA17, NEMA23, NEMA24, and

23 in Round frame and available in our product range

are Linear Actuator Stepper Motors, Planetary Geared Stepper Motors, Stepper motors

BHOLANATH STEP SERVO MOTOR & DRIVE

Table of contents

Other Bholanath DC Drive manuals

Popular DC Drive manuals by other brands

Phoenix Mecano

Phoenix Mecano DEWERT MEGAMAT 2 installation instructions

Hubbell

Hubbell GAI-TRONICS 13310 Series manual

GFA

GFA ELEKTROMAT SI 35.15-40,00 GA35/15GD installation instructions

Lenze

Lenze SM004S operating instructions

Infineon

Infineon TLD7002-16SHIELD user guide

GFA

GFA ELEKTROMAT FT 60.4-45,00 installation instructions

Toshiba

Toshiba ACE-tronics G9 ASD quick start guide

Siemens

Siemens Simovert Masterdrives Compact Plus Series operating instructions

SOMFY

SOMFY Oximo 40 io instructions

GFA

GFA ELEKTROMAT SI 500.10 FU-100,00 installation instructions

BMG

BMG CRUSADER ONE 72H-033 instruction manual

FnL

FnL SRD Series Quick installation guide