3

1.Designated Use

2.Prerequisites

The drive system is …

for the motorized adjustment of movable

in an environment where or gases or vapours

(e.g. anaesthetics) are likely to occur.

The installation steps descriped in these instructions must be performed by a

or .

This being the case, you should never carry out this work by unless you

are a or

you should this work to a

.

Conformity in accordance with EC Directives

The drive system is supplied ex factory as a in accordance with

the EC "Machinery" Directive. In other words, you may not put the drive system into

operation until you have met the objectives of the

MEGAMAT 2designedfor installing in end products

inflammableexplosive

suitable

qualifiedtrained person

yourself

suitable trained person

entrust suitablequalified, skilled or trained person

only

machine not ready for use

safety

furniture parts

.

The drive system is ...

"Machinery” Directive and issued a

corresponding !

The drive system with DEWERT controls meets the safety objectives of the EC Directives

concerning and

The drive is if you install it into a medical device, manufacture in

with the EC Directive for "Medical Products" or other regulations it is the

responsibility of the . For this purpose, DEWERT has

additionally applied, fully or partially, a number of standards from the medical products

sector, in order to facilitate use in medical products (see page 19, Additional Information).

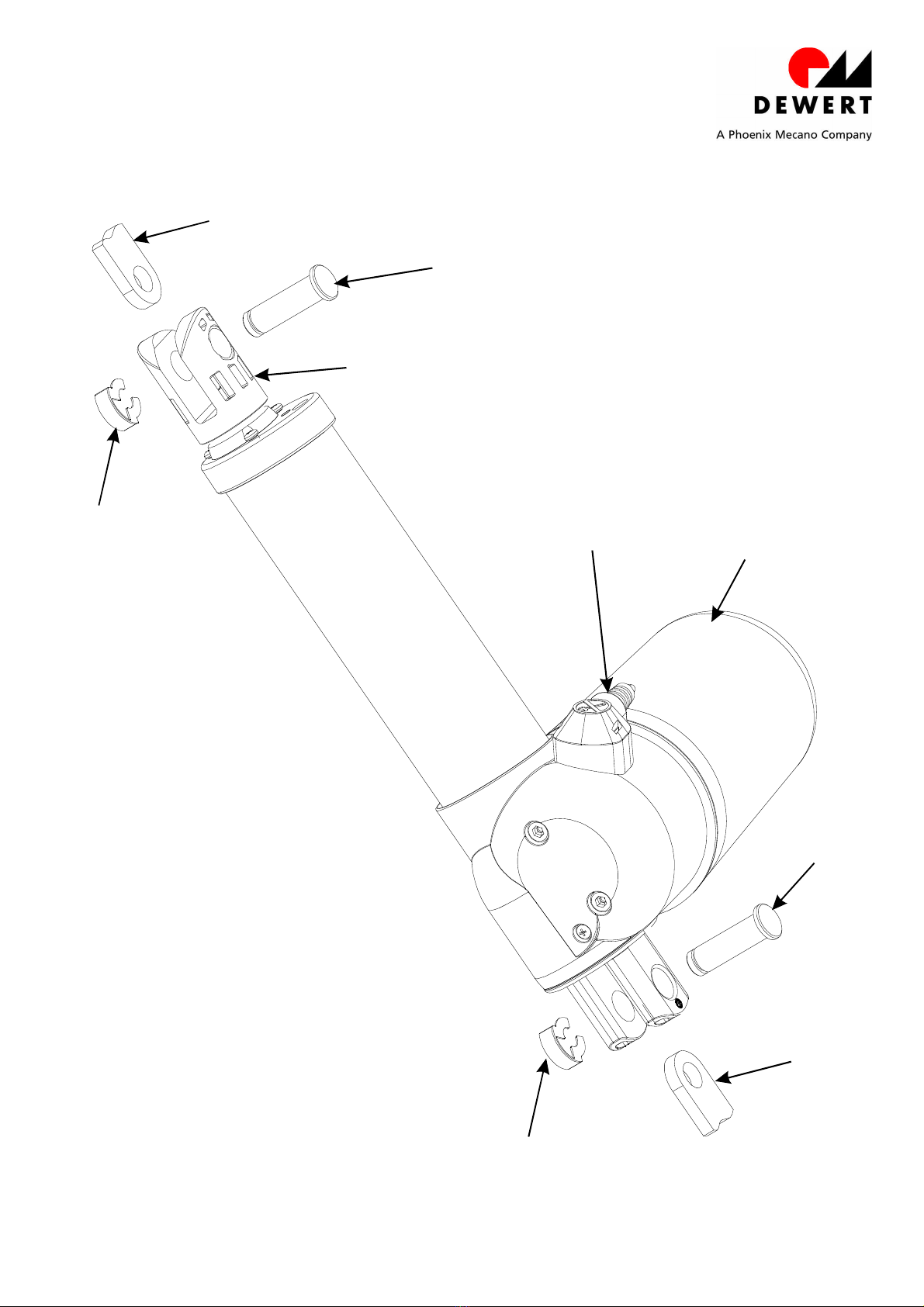

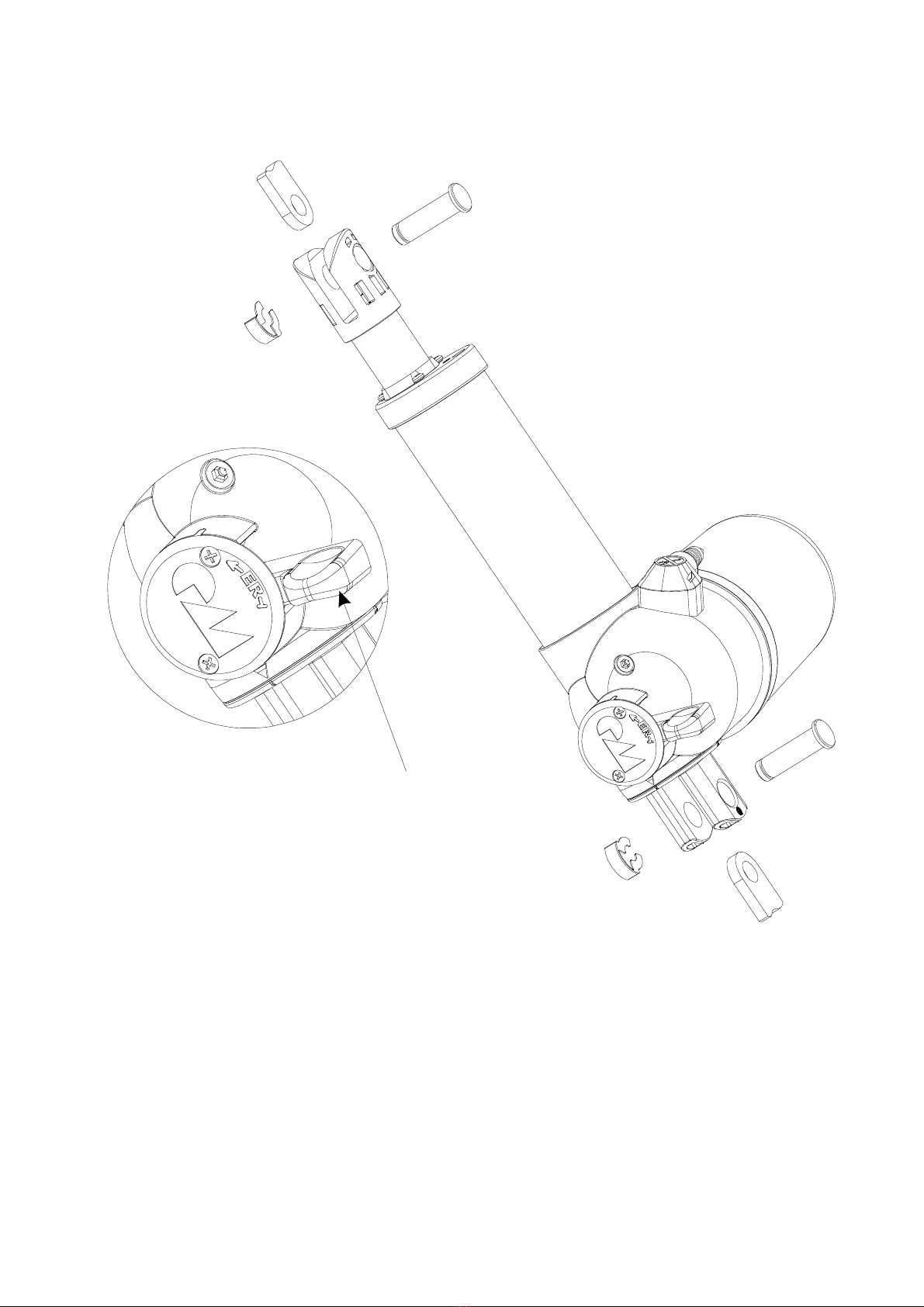

using suitable fittings/

mountings or mechanics

MEGAMAT 2not intended for use

Declaration of Conformity

"Low Voltage" "Electromagnetic Compatibility (EMC)".

not a medical product

conformity

manufacturer of the end product

3.Getting to Know the System

The drive system is intended for the German market and complies with the

Law applicable in Germany in implementation of relevant EC Directives.

With regard to other variation options contact your after-sales service or take a look at the

current catalogue. We will be happy to assist you with any special requests you may have.

MEGAMAT 2

in a damp environment, i.e. outdoor,

by small children or fragile persons,

in the immediate vicinity of young children.

11/2008

ID-Nr. 48148