BI 399 User manual

Air-Jacketed Large Capacity

Flo-Thru CO2Incubators

Model No.

399

399-1

399GWH

057-641-00 • 6/8/05

Safety Information ........................................................................................................................................................3

Alert Signals ..........................................................................................................................................................3

Specifications ..............................................................................................................................................................4

Electrical Requirements ........................................................................................................................................4

Temperature Range ..............................................................................................................................................4

Temperature Control..............................................................................................................................................4

Uniformity in Chamber ..........................................................................................................................................4

Gas Flow Rates ....................................................................................................................................................4

Volume ..................................................................................................................................................................4

Humidity ................................................................................................................................................................4

Dimensions ............................................................................................................................................................4

Shelves ..................................................................................................................................................................4

Net Weight ............................................................................................................................................................4

Options ..................................................................................................................................................................4

Unit’s Environmental Operating Conditions ..........................................................................................................5

Unpacking and Installation ..........................................................................................................................................6

Shipping Carton ....................................................................................................................................................6

Location ................................................................................................................................................................6

Electrical Power ....................................................................................................................................................6

Shelf Positioning ..................................................................................................................................................6

Adjustable Screw Guards for Protecting Back of Unit ..........................................................................................7

Hooking Up Water ................................................................................................................................................7

Connecting Condensate Drain to the Incubator ....................................................................................................7

Air/CO2 Hook-Ups ................................................................................................................................................8

CO2 Connection: Standard and Siphon Type CO2 Gas Cylinders ......................................................................9

Operation....................................................................................................................................................................10

Auto Tune ............................................................................................................................................................12

For Best Results ..................................................................................................................................................12

Auto-Tuning Procedure........................................................................................................................................12

Temperature Calibration ......................................................................................................................................13

Setting the Hi-Limit Thermostat ..........................................................................................................................14

Loading the Incubator..........................................................................................................................................14

Air/Gas Ratio ......................................................................................................................................................15

Humidity Adjustment............................................................................................................................................16

CO2 Sampling/Measurement ..............................................................................................................................16

Air and CO2 (or Nitrogen) ..................................................................................................................................16

Humidification ......................................................................................................................................................17

Humidifying without the Optional Humidifier ................................................................................................17

Humidifying with the Optional Humidifier......................................................................................................17

About the Kind of Water to Use ....................................................................................................................18

Demineralizer Cartridge................................................................................................................................19

Operation of Humidification System ............................................................................................................20

Periodic Cleaning and Inspecting of Humidifier............................................................................................20

Humidity Controller ......................................................................................................................................22

Auto Tune ....................................................................................................................................................23

Offset Humidity Calibration ..........................................................................................................................23

Operating Suggestions ................................................................................................................................24

Hints on Using Fyrite ..........................................................................................................................................25

Taking a Fyrite Reading...................................................................................................................................... 26

Kwik Inject Automatic CO2 Recovery System ....................................................................................................29

Built-In Compressed Air Supply ..........................................................................................................................29

Maintenance ..............................................................................................................................................................30

Replacing Temperature and/or Humidity Controller ............................................................................................30

CO2 and Air Bubbler............................................................................................................................................30

Adjusting Automatic CO2 Recovery System ......................................................................................................31

Replacement Parts ....................................................................................................................................................33

Ordering Procedures ..................................................................................................................................................34

Decontamination Statement ......................................................................................................................................35

Two Year Limited Warranty ........................................................................................................................................36

Table of Contents

The Barnstead|Lab-Line Large-Capacity, 34 cu. ft. (963

liter), Flo-Thru CO2 Incubator has been specially

designed for laboratories that handle a high volume

of work. The unit has been factory tested and needs only

to be placed in a suitable location and connected to the

required electrical supply and air and CO2 (or nitrogen)

sources at a pressure of 15 psi. A blower fan assists in

maintaining uniformity of the CO2 concentration in the

chamber, as well as, minimizing any temperature gradi-

ents.

All controls are contained in the control panel. The micro-

processor- based controller maintains temperature from

slightly above ambient to 60ºC. The hydraulic hi-limit

thermostat controls temperature a few degrees above the

user established set point in the event the main controller

fails. This provides an added measure of protection to

the chamber.

The KWIK-INJECT™ system provides quicker recovery

and a more stable chamber environment. CO2 is inject-

ed into the chamber to compensate for losses incurred

during door openings. A timer on the control governs

injection time from 3 to 60 seconds.

6 perforated stainless steel shelves provide a total area of

36 sq. ft. (3 sq. m) with a load capacity of 100 lbs. (45 kg)

per shelf when the load is evenly distributed, 65 lbs. (29

kg) per shelf when the load is concentrated.

Humidification may be obtained simply by placing a pan

of deionized or distilled water on one of the shelves. A

humidifier and controller are available as factory-installed

options and require a demineralized water source. The

humidifier is controlled from the front panel and allows

regulation of the relative humidity from approximately

20% above ambient to 98% RH. A panel meter gives a

direct reading of relative humidity.

The exterior of the incubator is made from cold rolled

steel with a durable powder coated finish. The interior

and door are made of stainless steel. Inside the door and

between the double walls is 3-inch thick glass wool insu-

lation that helps hold heat loss to a minimum and pro-

motes temperature uniformity in the chamber.

Model 399GWH has an optional humidifier with controller.

Safety Information

Warning

Warnings alert you to a possibility of

personal injury.

Caution

Cautions alert you to a possibility of

damage to the equipment.

Note

Notes alert you to pertinent facts and

conditions.

Hot Surface

Hot surfaces alert you to a possibility of

personal injury if you come in contact

with a surface during use or for a period

of time after use.

Alert Signals

3

4

Electrical Requirements

399, 399GWH: 120 Volts, 50/60 Hz, 1400 Watts, 11.7 Amps

399-1: 230/240 Volts, 50/60 Hz, 1400 Watts, 5.8 Amps

Temperature Range

Ambient +5°C to 60°C

Temperature Control

±0.5°C

Uniformity in Chamber

±0.5°C

Gas Flow Rates

Air: 1.0 to 14.0 liters/minute

CO2: 0.1 to 1.2 liters/minute

Volume

34 cu. ft. (963 liters)

Humidity

Range: ambient to 98% RH

Accuracy: ±3% RH

Dimensions

Exterior: 42”W x 35”D x 91”H (107cm x 89cm x 231cm)

Chamber: 36”W x 25”D x 65”H (91cm x 64cm x 165cm)

Specifications

Shelves

6 perforated, stainless steel

Net Weight

980 lbs. (445 kg)

Options

H: Humidity Control

L: Left Hand Door

P: Built-in compressed air supply

GW: Glass Window 12” x 48” (30 x 122 cm)

Unit’s Environmental Operating Conditions

Pollution Degree: 2

Installation Category: II

Altitude: 2000 meters MSL (Mean Sea Level)

Humidity: 80% maximum, non-condensing

Electrical Supply: 120VAC or 240VAC

Voltage Tolerance: ±10% of normal rated line

Temperature: 15°C to 40°C

Product Usage: This product is intended for use indoors only

5

SPECIFICATIONS

6

Shipping Carton

The shipping carton should be inspected upon delivery.

When received, carefully examine for any shipping dam-

age before unpacking. If damage is discovered, the deliv-

ering carrier should both specify and sign for the damage

on your copy of the delivery receipt.

Open the carton carefully making certain that all parts are

accounted for before packaging materials are discarded.

After unpacking, if damage is found promptly report it to

the carrier and request a damage inspection promptly.

IMPORTANT: Failure to request an inspection of damage

within a few days after receipt of shipment absolves the

carrier from any liability for damage. You must call for a

damage inspection promptly.

Location

Select a location for the incubator that is free of drafts

and extraneous vibrations. The unit should be level.

Electrical Power

Turn all controls to the off position. Connect the power

cord of the incubator to an outlet providing the power

characteristics specified on the unit's nameplate or in this

manual.

Shelf Positioning

The 6 perforated stainless steel shelves are adjustable on

1/2" (12 mm) centers. Place the shelf support clips

where desired and then set shelves in place. Shelves

and support clips can be ordered to provide additional

shelf space.

Unpacking and Installation

Warning

Do not use in the presence of flam-

mable or combustible materials or

explosive gases. Do not use in the

presence of pressurized or sealed

containers. Fire or explosion may

result, causing death or severe

injury.

Warning

Do not heat any substance above a

temperature that will cause it to emit

toxic fumes. Death or severe injury

may result.

Warning

Use only an inert gas such as car-

bon dioxide in the incubator. Do not

under any circumstance inject oxy-

gen or other explosive gas or mix-

ture into unit. Failure to observe

these precautions can result in

explosion and/or fire and serious

injury or death to personnel and

property damage.

7

Adjustable Screw Guards for

Protecting Back of Unit

Exercise care in placing the back of the unit against a wall

to avoid damage to CO2 tubing and related attachments.

To protect against this, 2 adjustable screw guards on the

back are used to establish a buffer zone for the CO2 tubing.

If unit is shipped upright, guards are in place; if shipped flat,

guards are furnished loose and must be inserted.

Hooking Up Water

Connect supply water line to the 1/4” NPT fitting located on

the inlet side of the D. I. cartridge. The recommended

water pressure setting on the regulator gauge should be

adjusted to read between 10 and 15 psi.

Connecting Condensate Drain to

the Incubator

1/2” drain lines are located in back of the incubator.

UNPACKING AND INSTALLATION

8

Turn all flow meters on the incubator fully clockwise (closed).

Connect air and CO2 supply lines to their respective fittings on

the back of the unit. Use 1/4" (6 mm) ID tubing, flexible metal

hose, etc., (meeting local codes), with filters to ensure that the

air and CO2 are free of contaminants, for gas lines.

Set the supply regulators at 15 psi. Check all of the connec-

tions for leaks.

UNPACKING AND INSTALLATION

Air/CO2 Hook-Ups

Turn the power switch to OFF and insert the plug into the outlet.

To Air Fitting

To CO2 Fitting

100% Air 100% CO2

1/4" Hose Barb

Connections

Set pressure at 15 psi.

Pressure regulators and gauges must be

installed on each tank. Check local gas suppli-

er for proper regulators.

If air pump is used instead of tank, air must be

filtered to remove water, oil and dirt.

Warning

High concentrations of carbon diox-

ide produce metabolic abnormalities,

disturbances of the central nervous

system and cardiac instability.

Unconsciousness may occur at con-

centrations above 10%.

Note

It is our recommendation that this

unit run 24 hours empty before intro-

ducing media to be incubated. This

will facilitate ease of servicing if

required as well as nullify the need

to decontaminate the chamber in the

event a problem occurs.

This unit cannot be accepted for

servicing or credit by Barnstead

International unless accompanied by

a completed Certification of

Decontamination form, included at

the end of this manual.

Standard Type (Correct) Siphon Type (Incorrect)

1

2

3

12

3

4

5

6

7

8

1. Compressed Gas Association #320

connector.

2. Gas head space.

3. Liquid CO2 filled to 68% equal weight

of water that cylinder would hold at

60ºF.

1. Warning tag indicating that cylinder is siphoning type.

2* Aluminum ring.

3* Gold band.

4* Stamp or marking on cylinder: "Siphon" or "Eductor

Tube".

5* Valve should be of special type for service.

6* Withdrawal tube draws up the liquid CO2.

7* Gas head-space.

8* Liquid CO2 filled to 68% equal weight of water that

cylinder will hold at 60ºF.

*Note: Some gas suppliers will have no markings to indicate

an “Educator Tube” or “Siphon” type cylinder. Be sure to order

DRY, LAB-GRADE CO2.

Be sure to obtain a dual-stage regulator from the gas supplier

for the CO2 tank that is to be installed according to local

codes. Connect 1/4" ID (6.35 mm) flexible tubing to the regu-

lator. Connect the other end of the tubing to the unit's CO2

inlet (located on the back top panel). Insert tubing over hose

barb and fasten with an appropriate clamp to assure a proper

connection. Adjust the regulator for the pressure recommend-

ed on the previous pages when CO2 is to be injected into

chamber. For optimum results, do not exceed or reduce this

pressure.

CO2 Connection: Standard and Siphon Type CO2 Gas Cylinders

9

UNPACKING AND INSTALLATION

10

Operation

Amicroprocessor-based automatic tuning controller with a

platinum RTD temperature sensor provides a display of

either chamber or set point temperatures. The micro-

processor used in the unit automatically tunes PID

parameters to fit the characteristics of individual thermal

systems.

Auto-tune is a user-initiated function. It provides a tune-at-

temperature function that means the controller runs the

auto-tune program when the incubator is at set point.

Program parameters are retained in the nonvolatile mem-

ory in the event that there is power failure or interruption.

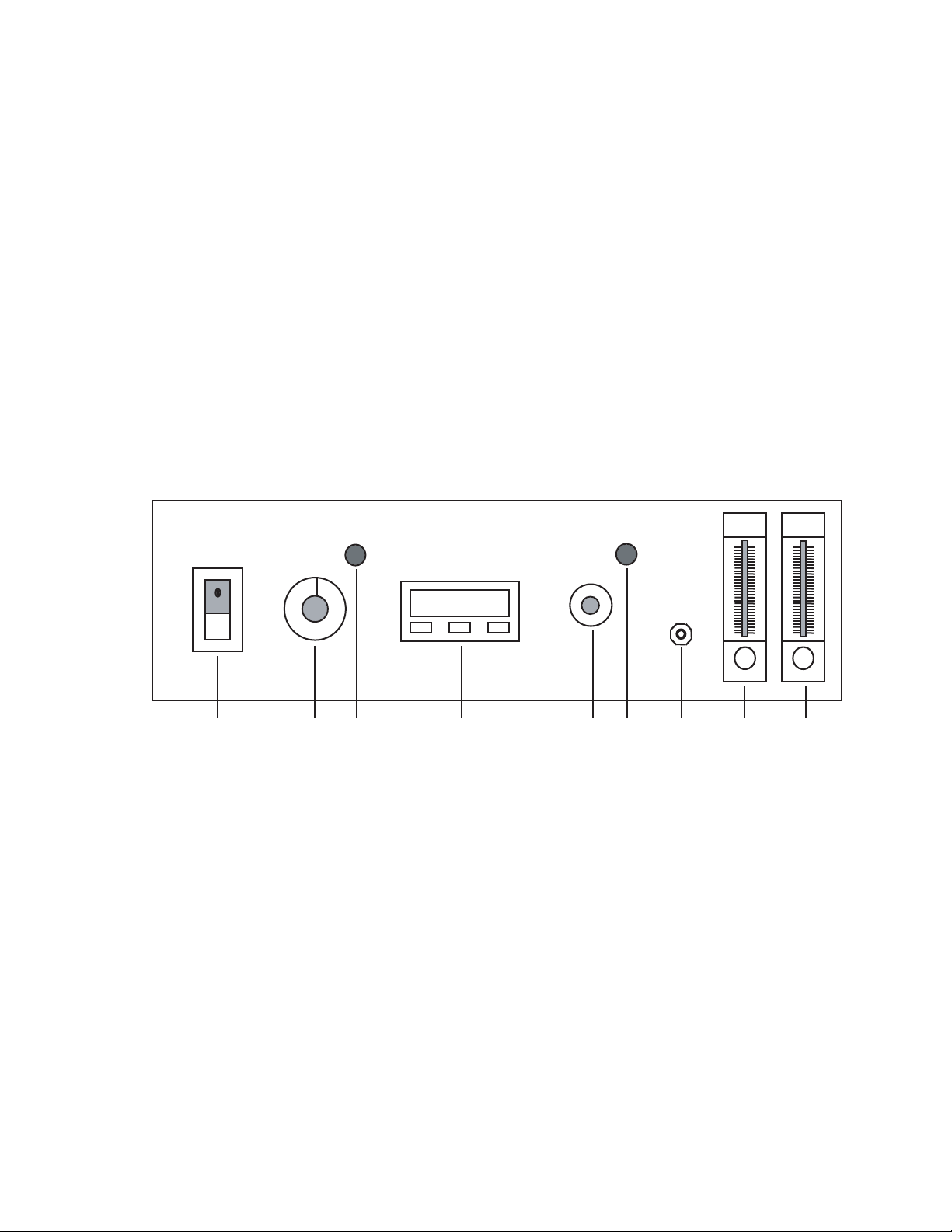

1 2 3 4 5 6 7 8 9

1. Power Switch

2. Hi-Limit Thermostat

3. Hi-Limit Thermostat Status Lamp

4. Temperature Controller

5. Kwik-Inject Control Dial

6. Kwik-Inject Status Lamp

7. Sample Access Port

8. Air Flow Meter

9. CO2 Flow Meter

1. CONTROLLER SELF-TEST: When the incubator is

powered up, the controller will display 8888 along with

three decimal points and the heat ON indicator lamp will

light. The display will then blank out for 2 seconds before

showing the chamber temperature.

2. HEAT ON INDICATOR:The heat ON indicator lamp is

lit when the chamber heater is receiving power. The lamp

will normally flash when the chamber temperature is at

set point.

3. SET POINT ADJUSTMENTS:The temperature con-

troller normally displays the chamber temperature. To

view or change the temperature set point proceed as fol-

lows:

A. Press and hold the star key and use either the

up or down arrow key to adjust the set point to

the desired temperature. Release the star key.

B. Allow at least 1 hour for the chamber tempera-

ture to stabilize.

11

OPERATION

Chamber or Setpoint Temperature

Heat Indicator

37.0

✱▼▲

Press Controller

✱View setpoint

✱▼ Decrease setpoint

✱▲ Increase setpoint

12

Auto Tune

The auto-tune program automatically adjusts the con-

troller parameters to achieve optimal temperature control.

It is not necessary to run the auto-tune program when

setting up the incubator. However, if the temperature

appears to be unstable, the auto-tune program can be run

using the procedure shown below:

For Best Results

• Set the usual set point temperature and use nor-

mal load conditions.

• Allow the incubator to stabilize at set point for at

least 1 hour.

Auto-Tuning Procedure

1. Enter the program mode by pressing and hold-

ing BOTH the up and down arrow keys for 3

seconds.

2. Release BOTH arrow keys when tunE is dis-

played.

3. The controller display should now be alternating

between tunE and oFF.

4. Press and hold the “STAR” (✱) key. Press and

release the up arrow key until At.SP is dis-

played. Release the “STAR” (✱) key.

5. After one minute has elapsed, the controller dis-

play will begin to alternate between showing the

chamber temperature, tunE and At.SP.

6. Allow the program to run until the display again

shows only the chamber temperature.

FEATURES

13

Temperature Calibration

1. Place a calibrated thermometer inside the cham-

ber on the corner shelf. Close both doors.

2. Press and hold the “STAR” (✱) key and using

the up or down arrow key, adjust the set point to

the desired temperature.

3. Allow the unit to run for at least 1 hour.

4. The controller display should now be indicating

the set point temperature. Make note of the ther-

mometer reading.

5. Press and hold both arrow keys until the con-

troller display indicates tunE. Release the arrow

keys. Press and release the down arrow key,

the display should now indicate LEUL. Press

and hold the “STAR” (✱) key and using the up

arrow key adjust the display to read 3. Release

the “STAR” (✱) key. Press and release the up

arrow key until the display indicates Zero. The

display should now alternate between Zero and

a numerical value.

6. Using the examples shown below and the ther-

mocouple value obtained in step above, enter

the correct Zero value into the controller using

the up or down arrow keys. If there is already a

Zero value present then add the new value to

the one already present.

7. When the correct Zero value has been entered,

press and hold the two arrow keys together until

the display again indicates the chamber temper-

ature. If the procedure was done correctly, the

controller display should now agree with the

thermometer reading to within ±0.5ºC.

OPERATION

Thermometer = 60°C

Controller Reading = 65°C

Subtract = -5°C

Enter Zero value of -5°C

Thermometer = 70°C

Controller Reading = 65°C

Subtract = +5°C

Enter Zero value of +5°C

8. Allow the unit to run for at least 1 hour.

9. Re-check the thermometer reading, the con-

troller display and the thermometer should agree

to within ±0.5ºC. If not, repeat steps 4 and 5

above.

Setting the Hi-Limit Thermostat

• Rotate the Hi-Limit thermostat (2) fully clock-

wise.

• Allow sufficient time for the unit to reach and

stabilize at the set point temperature plus an

additional hour or two for unit to cycle at the

temperature—4 hours for 37ºC is typical.

• After this time has elapsed, rotate the Hi-Limit

thermostat counterclockwise while watching the

red lamp (3). When the lamp is lit, you have

adjusted the Hi-Limit set point to be equal to the

operating set point. NOTE: Do not leave Hi-Limit

at this setting.

• Now rotate the Hi-Limit thermostat clockwise 30

degrees of rotation past the point where the

lamp goes out. This distance should be similar

to the distance from the twelve o’clock to the

one o’clock positions. This establishes a buffer

of a few degrees between the operating set

point and the HI-LIMIT temperature set point

and allows PID control to function normally.

NOTE: Under normal operating conditions, the

Hi-Limit LED should never come on. If it does,

readjust slightly clockwise.

Loading the Incubator

Load the chamber, spacing the items as far apart as pos-

sible (for maximum air circulation).

14

OPERATION

Warning

Do not operate the unit, if any of the

temperature controls become inop-

erative. A hazardous condition will

develop which can result in injury or

death and property damage.

Air/Gas Ratio

Set the flow meters to obtain the required air and CO2

flow—using the lowest possible CO2 flow rate will help to

conserve gas.

Use one of the following formulas to find the desired air-

to-gas ratio:

R = % CO2 in the chamber atmosphere

A=Air flow in liters/minute

C = CO2 flow in liters/minute

Equation 1 (to be used if air and CO2 flow rates are

known):

R = C x 100

A+C

Equation 2 (to be used if air flow rate and % CO2 are

known):

C = RA liters/min.

100-R

Equation 3 (to be used if CO2 flow rate and % CO2 are

known):

A= 100C-RC liters/min.

R

Example 1: If a CO2 percentage of 15% is desired at a

flow rate of 0.4 liters/min. of CO2, use Equation 3.

A= 100(0.4) - 15 (0.4) = 40-6

15 15

= 2.26 liters/min. of air

Example 2: If flow rates are set 0.1 liters/min. of CO2

and 3 liters/min. of air, use Equation 1 to find percentage

of CO2.

B = 0.1 x 100 = 3.2% CO2 in chamber

3.0 + 0.1 atmosphere

15

OPERATION

Humidity Adjustment

Placing a pan with water on the chamber floor can raise

chamber humidity. For minimum humidity, chamber should be

dry.

CO2 Sampling/Measurement

Insert sample probe into the sample access port making sure

that a tight seal is attained. Obtain a sample of CO2 suffi-

ciently large to meet the requirements of the analytical appa-

ratus or procedure being used. Perform CO2 analysis.

Air and CO2 (or Nitrogen)

The incubator is designed to be used with air and CO2 or

nitrogen only. Do not use any other gases. Each of the two

gas circuits has its own flow control. Air and CO2 flow

meters should be turned fully clockwise (shown below). Make

connections at the top of the unit at the air and CO2 inlets.

16

OPERATION

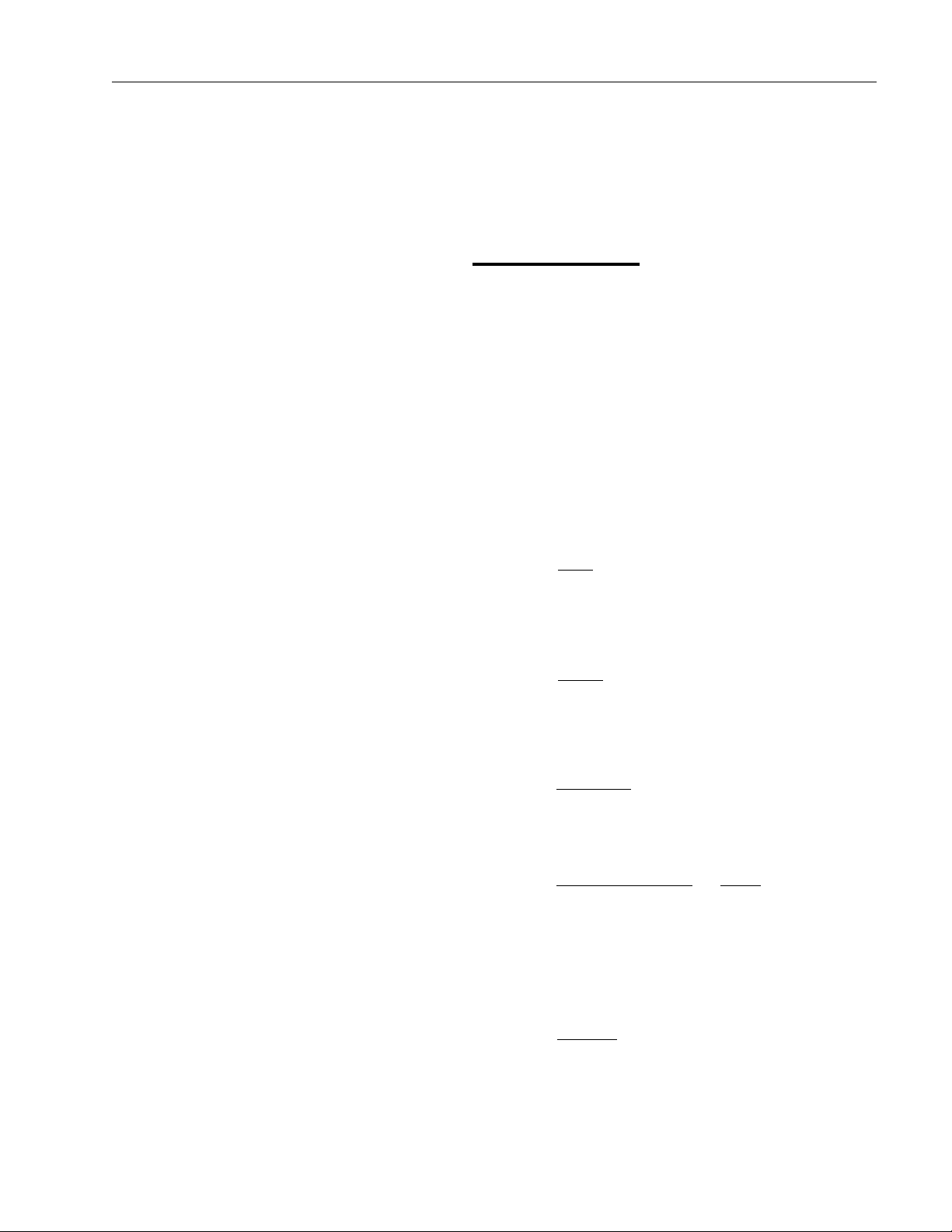

Control Panel Flow Meters

Rear/Top of Unit, Air and CO2 Inlets

Caution

Gas and air supplies must be

equipped with pressure-reducing

valves that are set at 15 psi. The

incubator is designed for a continu-

ous flow of gas, not for chamber

pressure.

Warning

High concentrations of carbon diox-

ide produce metabolic abnormali-

ties, disturbances of the central

nervous system and cardiac insta-

bility. Unconsciousness may occur

at concentrations above 10%.

Humidification

If the incubator is not to be humidified, keep the drain

valve (located on the bottom/rear outer panel) closed.

Humidifying without the Optional

Humidifier

Place a pan of distilled or deionized water on one of the

shelves to provide humidification. Run a hose from the

drainpipe at the bottom/center rear of the unit to a floor

drain or a pan. The drain petcock should be open.

Alternatively, moisture can be sponged up from the bot-

tom of the unit.

Humidifying with the Optional Humidifier

1. Humidity is produced by a humidifier located on

the roof of the unit.

2. The water inlet and outlet are on the rear panel

of the incubator (see figure at left).

3. Only demineralized or deionized water should

be used.

4. On the left side of the incubator is a rack for a

deionizer cartridge that can be connected as

shown in the deionizer diagram. Be sure to

connect a drain hose to the unit's drain pipe and

open the drain petcock.

17

OPERATION

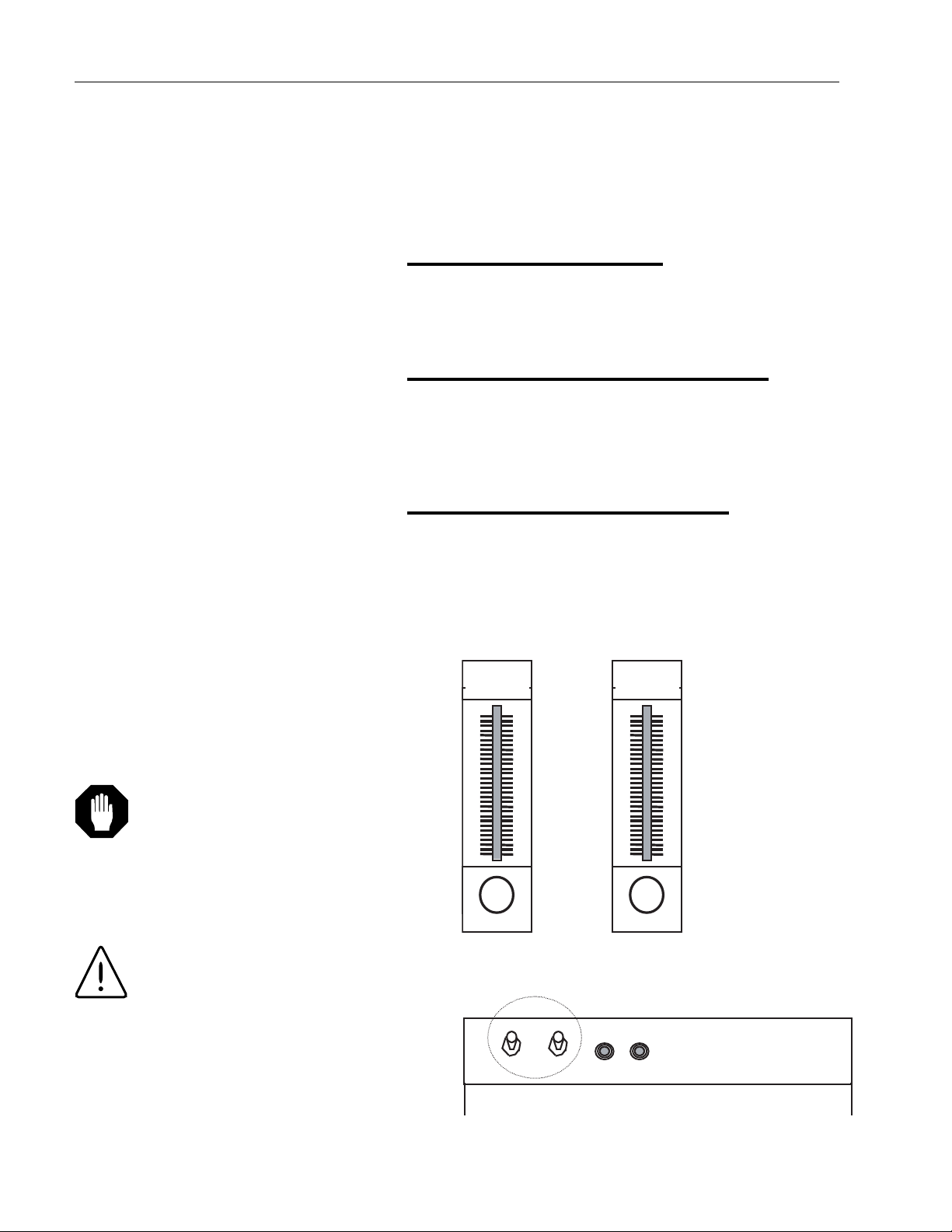

Incubator Drain Pipe

Hose

Petcock for Drain

Rear/Top of Unit, Water Inlet/Outlet

About the Kind of Water to Use

Distilled or deionized water MUST BE USED for humidifi-

er(s). ELECTRICAL RESISTIVITY OF THE DISTILLED

OR DEIONIZED WATER MUST BE BETWEEN 500 K

OHMS AND I MEG OHMS as measured between oppo-

site faces of a centimeter cube of an aqueous solution as

per ASTMD 1125-82. Distilled water, if available, will give

the best results and the longest life expectancy for the

equipment. All DI and/or city water final connects shall be

by others. Due to the great variations in water hardness

and chemical makeup from one geographical area to

another, demineralizer cartridges may not, in all cases, be

adequate to prevent damage to the internal wetted parts

of the humidifier(s).

Purchasers are responsible for determining, through

water analysis and recommendations by a qualified water

treatment company, if further treatment is required, either

before, after, or in place of using a demineralizer car-

tridge. If further water treatment is necessary or advis-

able, the user is obligated to supply and install all equip-

ment that might be required for this purpose.

18

OPERATION

Caution

Distilled water shall be provided by

others at a minimum rate of 18 gal-

lons per day and a minimum pres-

sure of 20 psig with an electrical

resistivity between 500 K ohms

and I meg ohms.

Note

Barnstead International expressly

disclaims liability for damage to

humidifier(s) and for loss sustained

by the user as a result of humidifier

failure, if such damage is the result

of improper treatment of water used

for humidification.

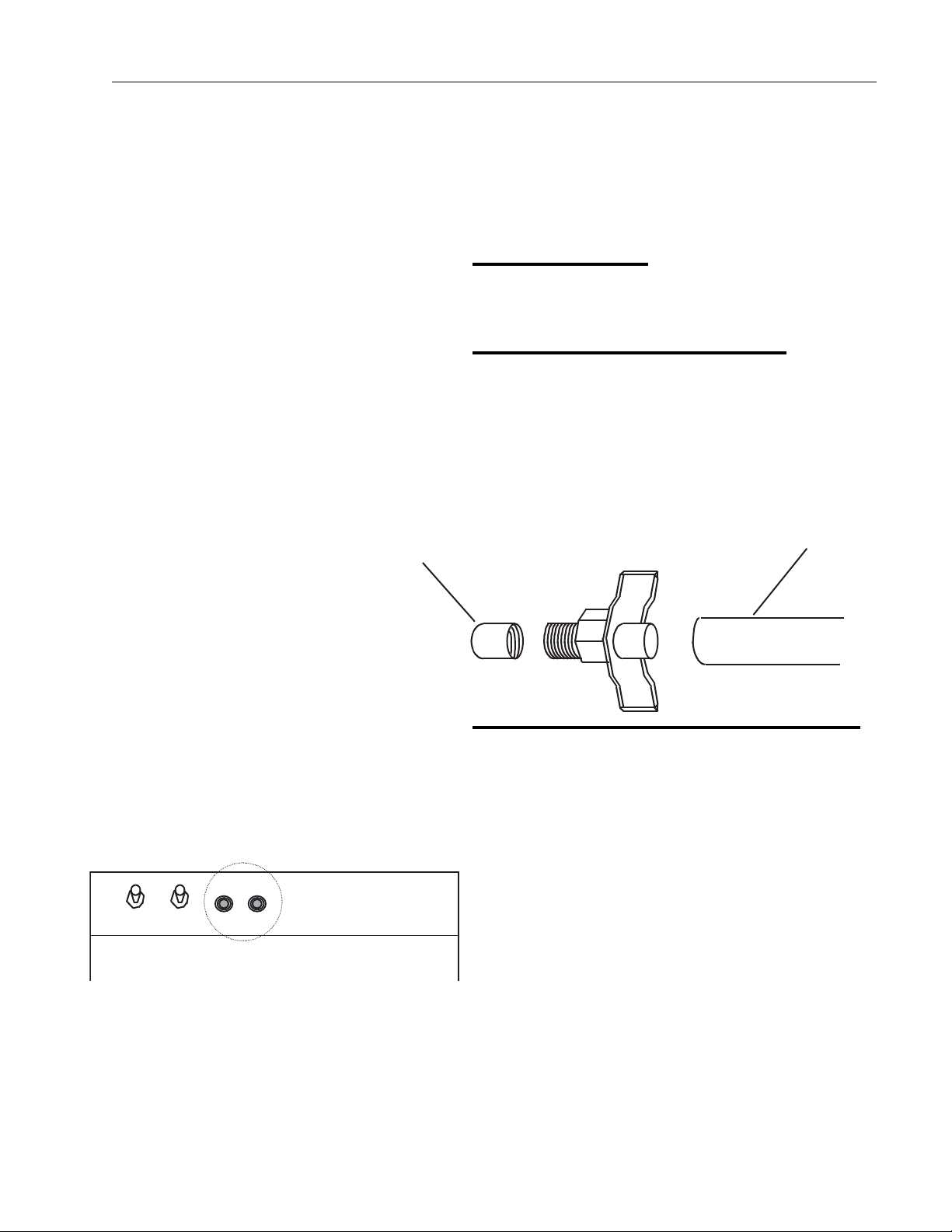

Demineralizer Cartridge

19

123

4

5

6

7

8

9

10

11

1. Water Outlet – To Chamber

2. D. I. Cartridge, #585-036-00

3. D. I. Cartridge Housing, #019-153-01

4. Regulator Bracket, #593-798-00

5. 1/4” NPT water inlet fitting, supplied by user

6. Plastic Regulator, #950-147-01

7. PSI Gauge, #950-147-02, Set for 10 to 15 psi

8. Connector, #730-414-01, Regulator Outlet

9. Tubing, #720-113-00

10. Quick Disconnect, #731-093-00

11. 90° Fitting, #730-501-01

OPERATION

Operation of Humidification System

1. Water pressure is not to exceed 20 pounds per

square inch. The recommended water pressure

setting is 10 to 15 psi.

2. Water temperature should be regulated to 77°F

(25°C) for optimal cartridge usage.

3. Do not store in an area where temperature will

be below 33ºF or above 100ºF.

4. When mounting cartridge in bracket, tighten nut

moderately tight and turn on water. If leak

occurs, tighten nut until leak is stopped.

5. To obtain optimum performance from the dem-

ineralizer cartridge, it is important to check the

color change that the resin undergoes. When

the color of the resin in the cartridge has

changed from brown to tan, the cartridge should

be replaced. Preferably, cartridge replacement

should be done before the entire cylinder has

changed color.

Periodic Cleaning and Inspecting of

Humidifier

1. Disconnect power source from unit. Turn off

water supply.

2. Remove dome from unit after first removing the

dome strap. The dome rests on the chromed

motor pan. It lifts out and away from the duct

and the unit. Tube seal is on the dome dis-

charge exhaust and will be carried with the

dome.

3. Lift out the atomizing unit—this rests freely on

the reservoir and lifts out easily.

4. Clean the atomizing unit. DO NOT SUBMERSE

IN WATER. First, remove the cylindrical

screen—twist slightly out of the LOCK position

and remove. Next, remove the impeller cap

from the pump tube by tapping lightly against

20

Caution

FAILURE TO CHANGE THE DEM-

INERALIZER CARTRIDGE AS

REQUIRED CAN RESULT IN DAM-

AGE TO THE HUMIDIFIER AND

AFFECT IT’S PERFORMANCE, EFFI-

CIENCY AND VOID THE MANUFAC-

TURER’S WARRANTY.

OPERATION

This manual suits for next models

2

Table of contents