9

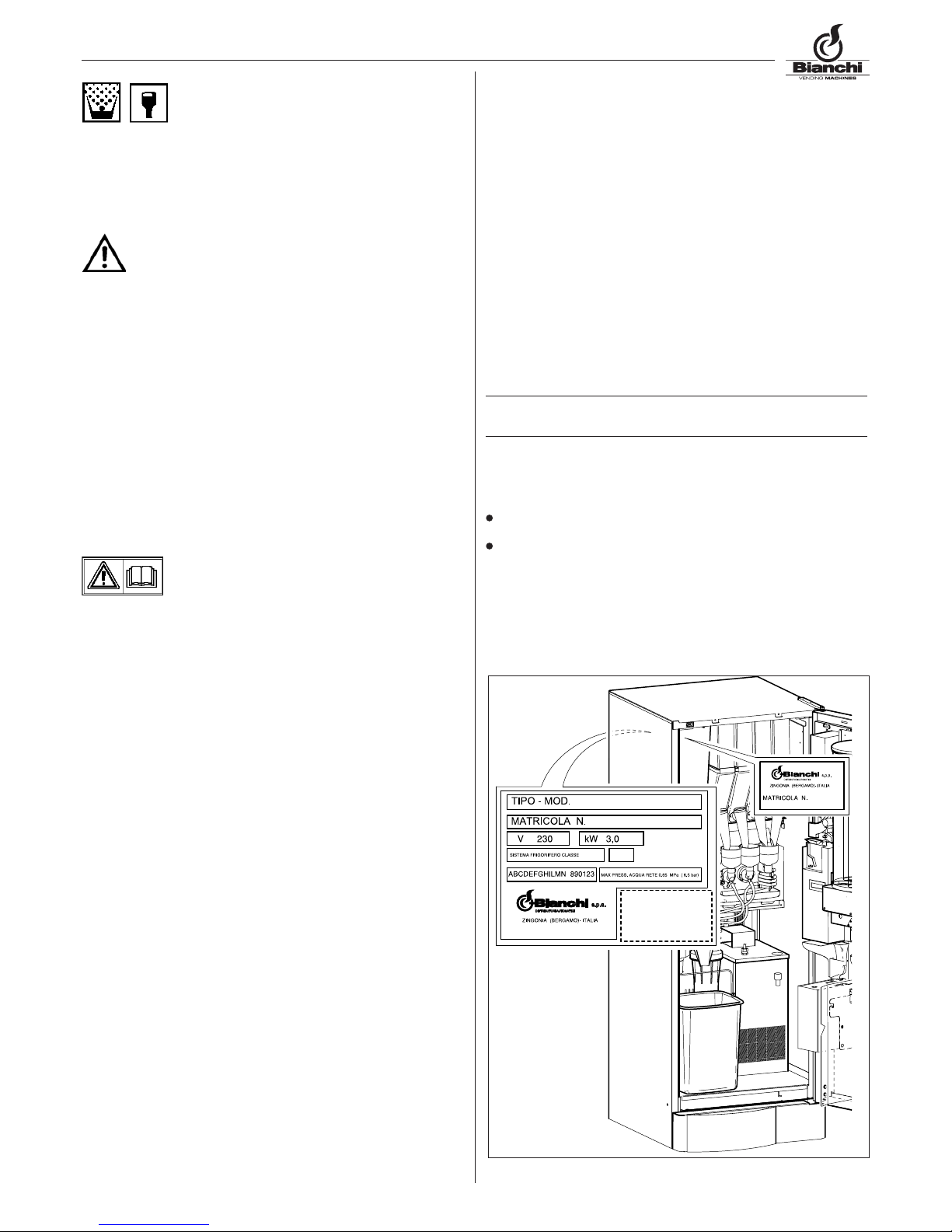

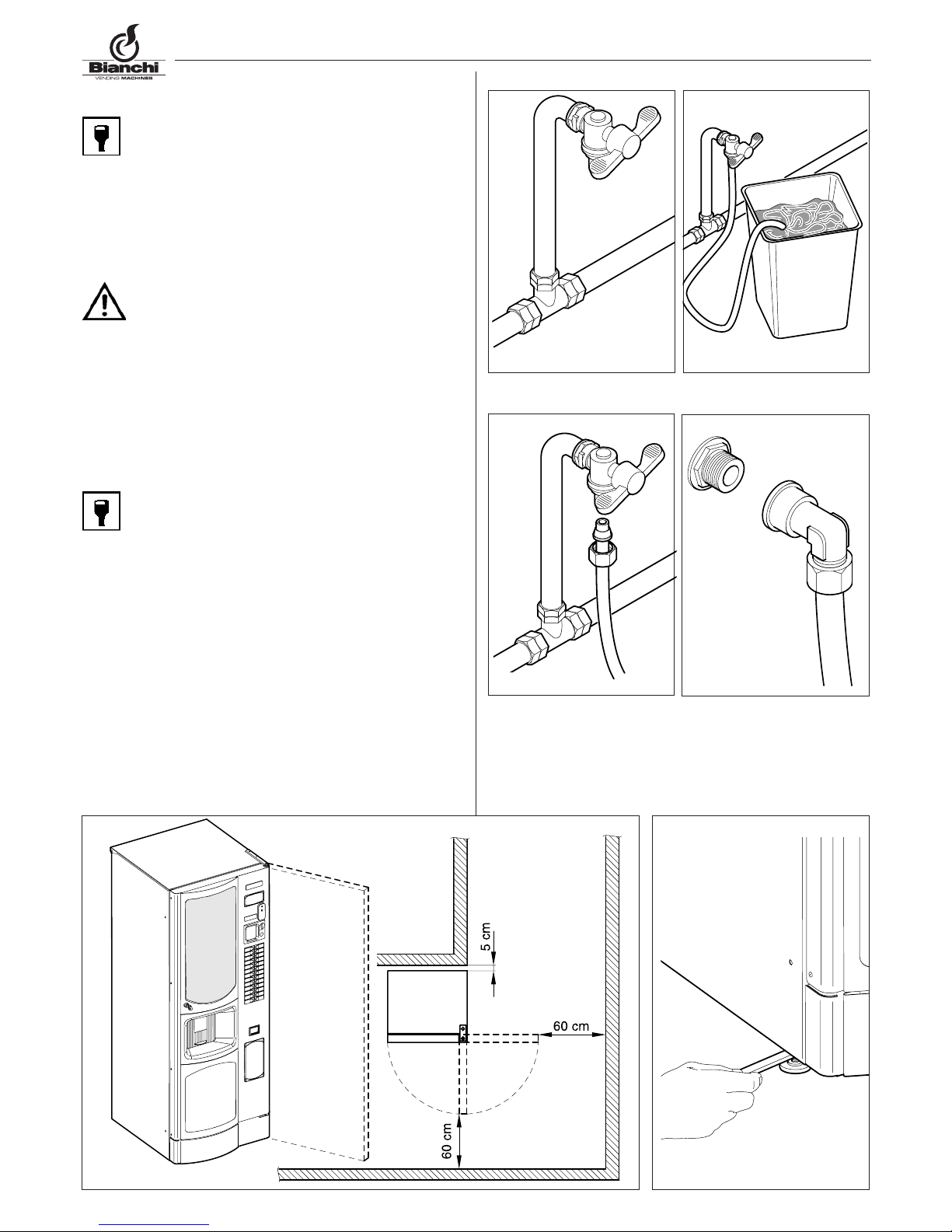

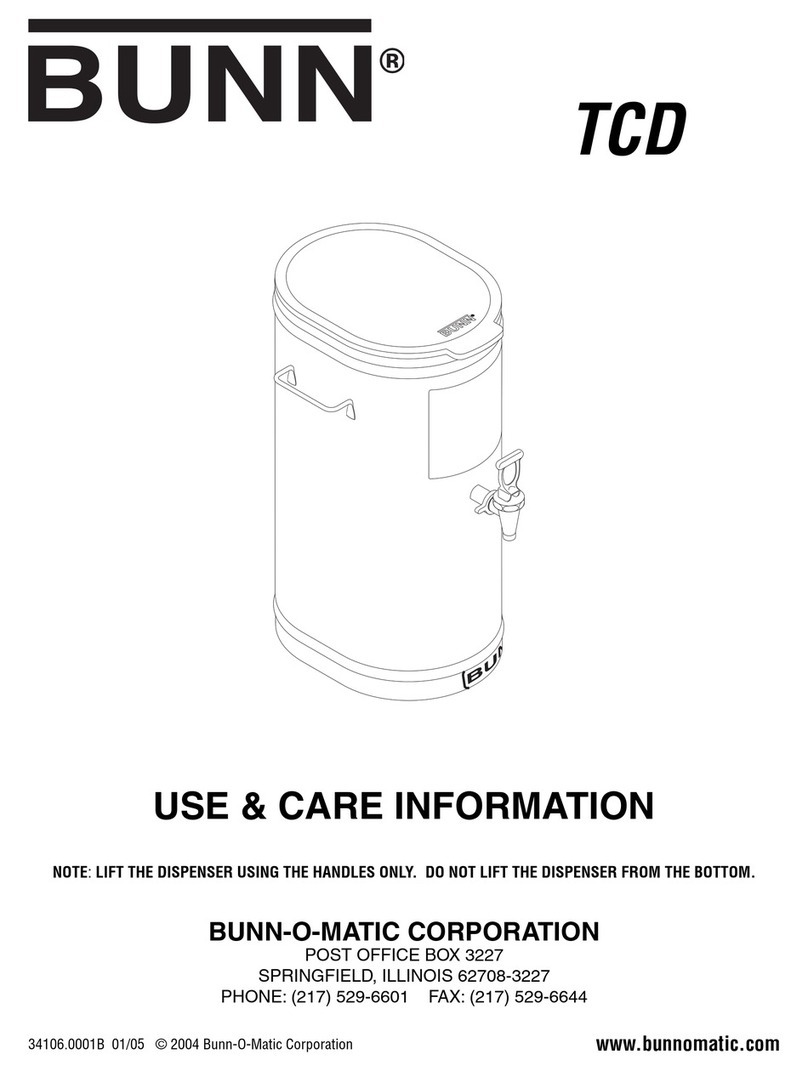

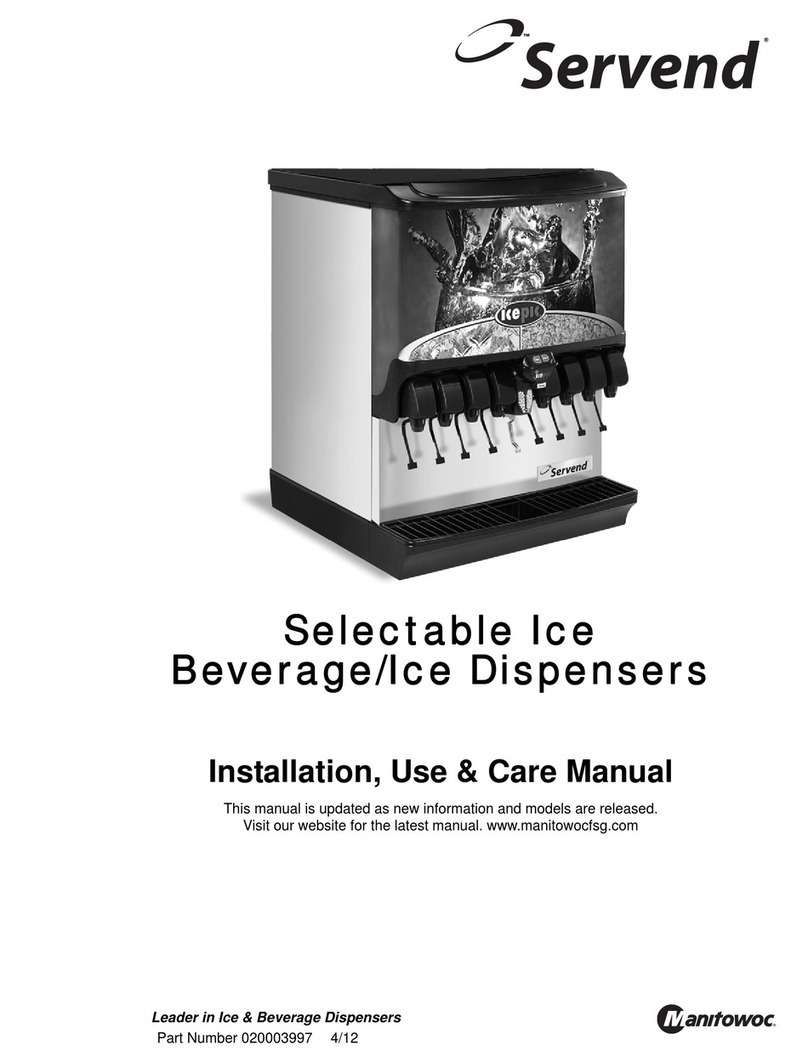

FIG.1.1

PREMISE

I Important notices for operator

This automatic distributor has been designed and constructed in

full accordance with current safety regulations and is therefore safe

for those who follow the ordinary filling and cleaning instructions

as indicated in this manual.

The user must not under any circumstances remove the

guards that require a tool for removal.

Some maintenance operations (to be done solely by specialized

technicians and indicated in this manual with a special symbol)

require that specific safety protections of the machine must be

switched off .

In accordance with the current safety regulations, certain opera-

tions are the exclusive responsibility of the installation technician,

and the ordinary maintenance technician may have access to

specific operations on with specific authorization.

The acquaintance and absolute respect, from a technical point of

view, of the safety instructions and of the danger notices contained

in this manual, are fundamental for the execution, in conditions

of minimum risk, for the installation, use and maintenance of

this machine.

II General Instructions

Knowledge of the information and instructions

contained in the present manual is essential for

a correct use of the automatic vending machine

on the part of the user .

– Interventions by the user on the automatic vending machine

are allowed only if they are of his competence and if he has

been duly trained.

The installation technician must be fully acquainted with all

the mechanisms necessary for the correct operation of the

machine.

– It is the buyer’s responsibility to ascertain that the users have

been trained and are informed and regulations indicated in the

technical documentation supplied.

Despite the full observance of the safety regulations by the

constructor, those who operate on the automatic dispensers

must be fully aware of the potential risks involved in operations

on the machine.

– This manual is an integral part of the equipment and as such

must always remain inside of the same, so as to allow further

consultations on the part of the various operators, until the

dismantlement and/or scrapping of the machine.

– In case of loss or damage of the present manual it is possible

receive a new copy making application to the manufacturer,

with prior indication of the data registered on machines’ serial

number.

– The functional reliability and optimization of machine’s ser-

vices are guaranteed only if original parts are used.

– Modifications to the machine not previously agreed on with

the construction company and undertaken by the installation

technician and/or manager, are considered to be under his

entire responsibility.

All the operations necessary to maintain the machine’s effi-

ciency, before and during it’s use are at the users charge.

– Any manipulations or modifications made to the machine that

are not previously authorized by the manufacturer, relieve

the latter from any responsibility for damages deriving from,

and will automatically result in the cancellation of the machine

guarantee terms.

– This manual reflects the status at the moment of the emission

of the automatic vending machine on the market; possible

modifications, upgrading, adaptments that are done the ma-

chine and that are subsequently commercialized do not oblige

BIANCHI VENDING Spa neither to intervene on the machine

previously supplied, nor, neither to update the relative technical

documentation supplied together with the machine.

– It is however BIANCHI VENDING‘s faculty, when deemed

opportune and for valid motives, to adjourn the manuals already

present on the market, sending to their customers adjournment

sheets that must be kept in the original manual.

Possible technical problems that could occur are easily resolvable

consulting this manual ; For further information, contact the di-

stributor from whom the machine has been purchased, or contact

Bianchi Vending’s Technical Service at the following numbers:

When calling it is advisable to be able to give the following infor-

mation:

The data registered on the serial number label (Fig.1.1)

version of program contained in the microprocessor (Adhesive

label on the component installed on board).

035 4196711 - fax 02 70048332