BICOLD WBA Series User manual

1

USER INSTRUCTIONS

Air-cooled Water chillers WBA and

Heat Pump WHA

GENERAL TABLE OF CONTENTS

1.

CE model plate

Page

2

2. Safety notes

Page

2

1.

Symbols on the unit

Page 3

2.

User Manual

Page

4

BICOLD Srl - Arzergrande (PD) - ITALY

WBA CHILLER ________ USER MANUAL Release 110613

2

Safety notices for use of the unit

Read this Manual carefully before using the unit!

Keep the manual safe and ready for consultation for all future requirements!

ALWAYS PROVIDE CUT-OUTS SO THAT THE POWER FEEDING LINE OF THE

UNIT CAN BE DISCONNECTED FROM THE ELECTRICAL MAINS SUPPLY, EVEN IN THE

PRESENCE OF A UNIT ON/OFF CONTROL TRANSMITTED FROM THE CUSTOMER’S

REMOTE STATION.

ALWAYS DISCONNECT THE ELECTRICAL POWER SUPPLY BEFORE CARRYING

OUT MAINTENANCE!

For details, refer to the unit’s wiring diagrams.

(1) Keep the unit in a VERTICAL POSITION during loading and unloading procedures and

check that installation surface is perfectly HORIZONTAL with a spirit level;

(2) Install the unit in a place that allows proper ventilation of the condensers! Do not install

the unit indoors or in a poorly ventilated place!

(3) Do not inspect the unit electrical panel with wet or moist hands (risk of electric shock);

(4) When the unit is running do not place objects on the top (object may fall with resulting

damage to the unit and injury to operators);

(5) Maintenance must be performed ONLY by skilled personnel. When the covers of the

electrical panels or external condenser/fans compartment are opened by a maintenance

technician, other maintenance personnel or other persons in the area must be notified of

the potential hazard my means of specific warning notices!

(6) Do not use tools or objects to touch the fan impeller blades (risk of injury to persons or

damage to property or the unit).

(7) THE UNIT IS NOT SUITABLE FOR USE IN EXPLOSIVE ATMOSPHERES!

(8) The chillers are designed and approved for operation in industrial and residential

environments. For more information, consult the BICOLD Srl Engineering Department.

(9) BICOLD Srl provides one year of warranty from the date of shipment and the warranty

will be held valid only if no repairs or modifications of the unit have been carried out by

personnel not authorised by BICOLD Srl. To avoid problems, possible accidents, or injury

to persons, consult our technical personnel for authorisations for possible alterations or

refittings, repairs, removal of components or disassembly of the entire unit.

10) THE UNIT CONTAINS FLUORINATED GASES (R410A) THE GREENHOUSE

EFFECT OF WHICH IS REGULATED BY THE PROVISIONS OF THE KYOTO PROTOCOL!

(

REGULATION

842/2006/EC)

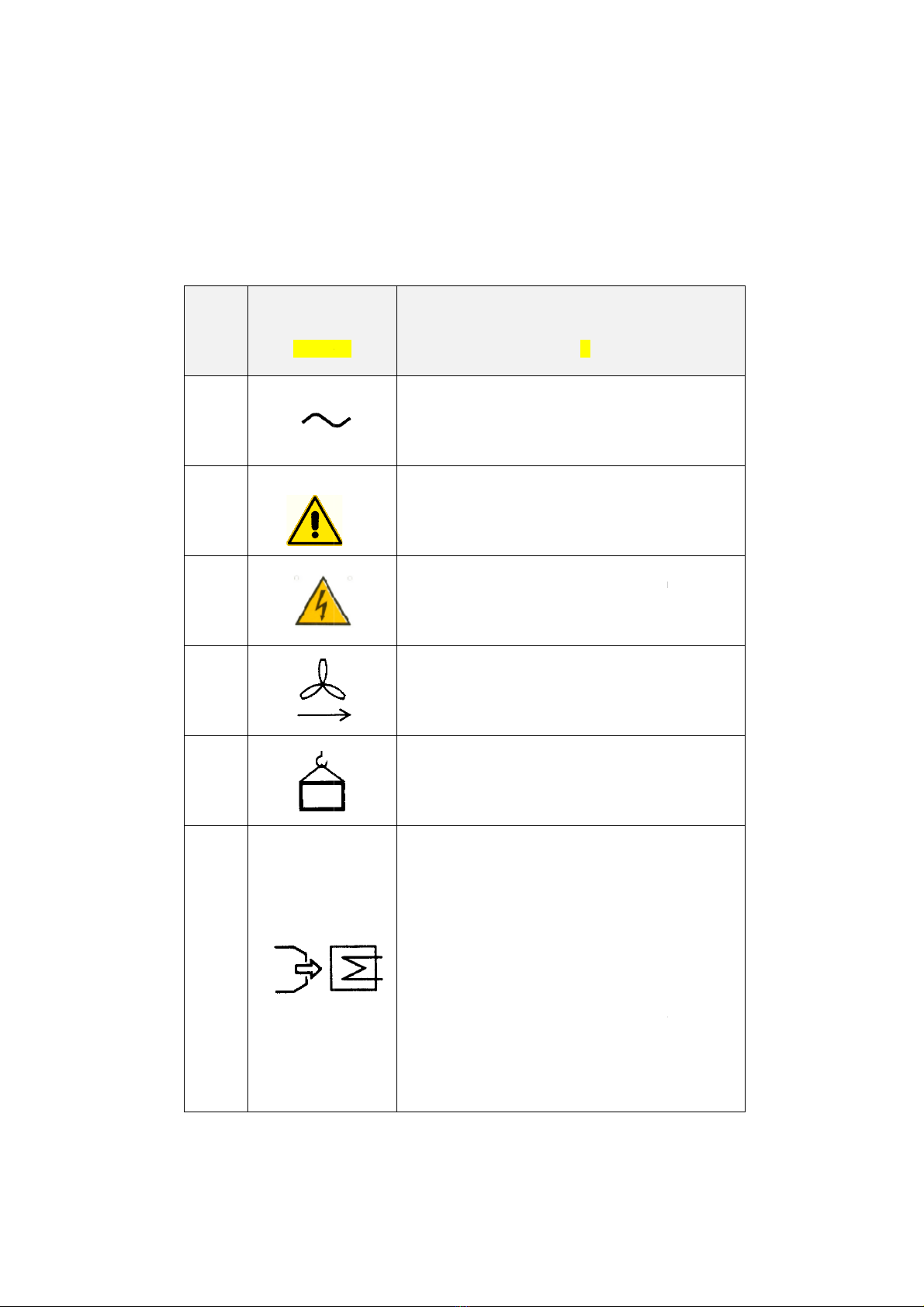

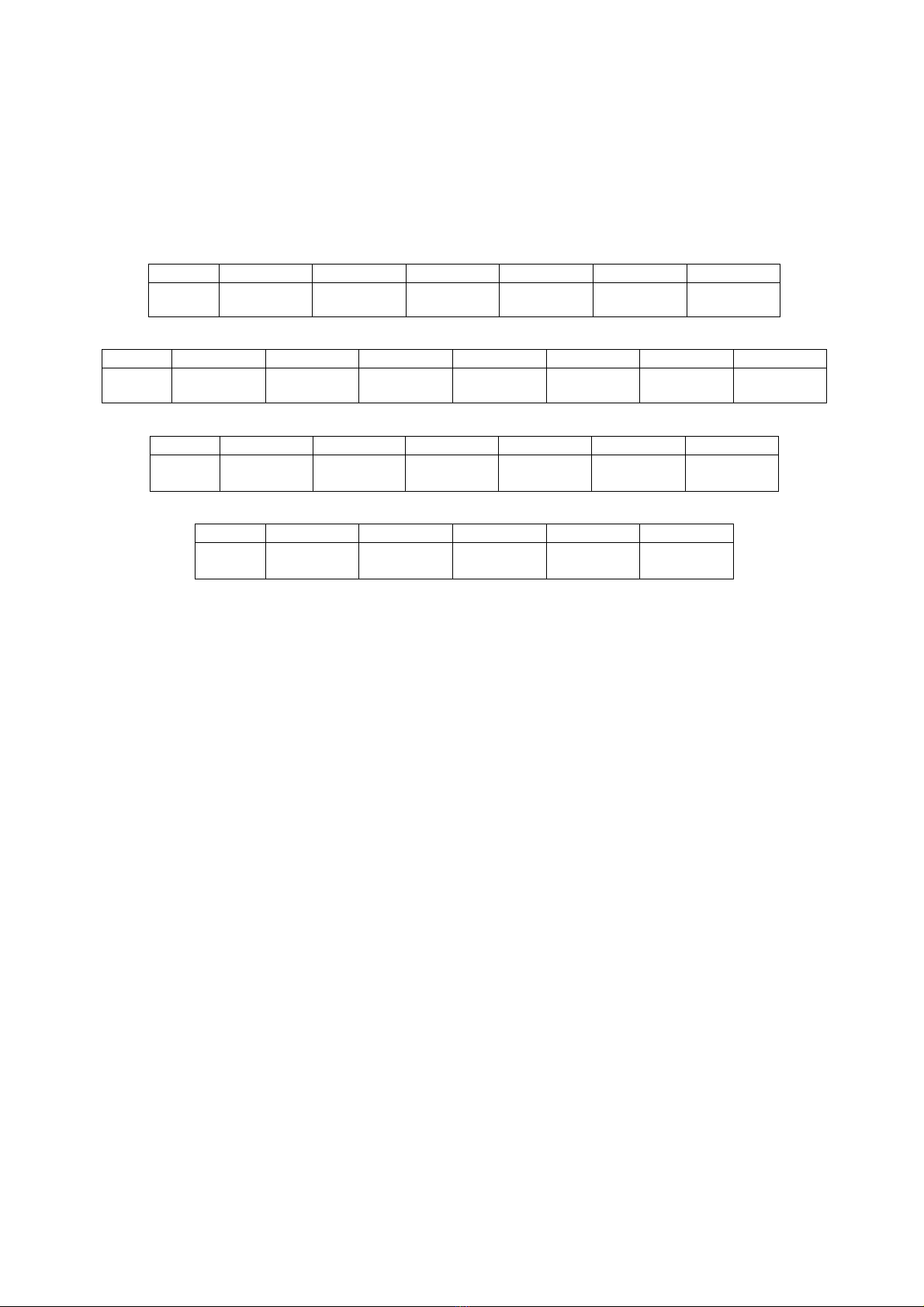

3.

SY

#

GRAFIC

SYMBO

SYMBO

SÍ

MBOL

DESSI

1

2

3

4

5

6

3

SYMBOLS ON THE UNIT

BODY

ICA

BOL

BOL

OLO

SIN

FUNZIONE

FUNCTION

FUNKTION

FUNCIÓN

FONCTION

Ingresso cavo elettrico

Electric cable inlet

Eingang Stromkabel

Entrada cable eléctrico

Entrée câble électrique

PERICOLO, PRESTARE ATTE

NZI

DANGER, PAY ATTENTION!

GEFAHR, VORSICHT!

¡PELIGRO, PRESTAR ATENCIÓ

DANGER, FAIRE ATTENTION

Pericolo ALTA TENSIONE sui compo

HIGH VOLTAGE on componen

Gefahr HOCHSPANNUNG an den Ba

¡Peligro ALTA TENSIÓN en los compo

Danger HAUTE TENSION sur les com

Senso di rotazione

Rotation direction

Drehrichtung

Sentido de rotación

Sens de rotation

Sollevamento (impiego dei golfa

Hoisting point (use eyebolts)

Heben (Hebeösen verwenden

Elevación (uso de l

os cáncamo

Levage (emploi des anneaux)

«

Pulire la batteria di raffreddamento so

macchina ferma con aria compressa

atm»

«

Clean the cooling coil using compre

pressurized max 6 atm and carry o

op

eration when the machine is not ru

«

Kühlbatterie monatlich reinigen. Bei s

Maschine mit Druckluft mit max. 6

ausblasen»

«Limpiar mensualmente la

baterí

enfriamiento. Soplar con la máquina pa

aire comprimido como má

x a 6 a

«

Nettoyer tous les mois la batteri

refroidissement.

Souffler quand la machine est arrêtée

comprimé à 6 atm max»

ZIONE!

N!

IÓN!

N !

onenenti!

nts!

Bauteilen!

ponente

s!

mposants !

lfari)

s)

en)

os)

x)

soffiando a

a a max 6

ressed air

out the

running

»

i stehender

. 6 atm

ría de

parada con

atm

»

rie de

e avec air

4

IMPORTANT WARNINGS

The indication IMPORTANT WARNINGS is used to focus attention on actions or

hazards that could damage the unit or its equipment

ENVIRONMENTAL PROTECTION

The indication Environmental Protection supplies instructions for use of the machine.

4. USER INSTRUCTION MANUAL

CONTENTS OF THE MANUAL

1. Introduction to the BICOLD WBA range ....................................................... 05

1-1 Description of BICOLD WBA units ...................................................... 05

1-2 Identification of the units ..................................................................... 07

1-3 Operating conditions and limits .......................................................... 08

1-4 Unit performance ................................................................................ 09

2. Installation requirements ............................................................................. 11

2-1 Lifting and transport ............................................................................ 11

2-2 Installation and positioning.................................................................. 13

2-3 Installation of electrical parts .............................................................. 15

3. Commissioning and running the chiller ........................................................ 17

3-1 Commissioning and operation notes.................................................. 17

3-2 Description of the electrical panel and controller ............................... 17

3-3 Operative settings of the controller .................................................... 24

3-4 Troubleshooting ................................................................................. 32

4. Maintenance ................................................................................................ 33

4-1 Periodic cleaning of the unit ............................................................... 33

4-2 Scroll compressor damage and replacement..................................... 34

4-3 Procedures in the event of prolonged inactivity of installed units........ 36

5. Warranty ..................................................................................................... 37

6. Scrapping / disposal of the unit at the end of its working life ....................... 37

Appendix I ……….. R410A technical data sheet (GB)

5

1. Introduction to the BICOLD WBA range

1.1 Description of the units

The WBA series constitutes a range of air-cooled water chillers designed to meet the

requirements of low and medium capacity air conditioning plants, operating with R410A, a

non-flammable and non-toxic high efficiency refrigerant for optimal energy saving in operation

of the unit.

The entire range is composed of 21 models characterised by the use of scroll compressors

connected in tandem for each circuit, with the exception of the first two sizes of the unit, which

are equipped with just one scroll compressor, by one or two separate refrigerant circuits, and

plate evaporators in brazed AISI stainless steel.

The fans installed are of the axial low-noise type.

The basic version is equipped with exclusively the plate evaporator. The equipment can

consist of a pump, pump with storage tank, dual pump, or dual pump with storage tank.

The pump and storage tank assembly is designated “hydronic unit”.

Control of the chillers is provided by an electronic microprocessor controller.

The refrigerant and hydraulic circuits comply with the PED directive.

Compressors

The compressors are of the hermetic scroll type with orbital scrolls. The rotating scroll is driven

by a two-pole motor cooled by the refrigerant on the suction line. All the compressors are

complete with a crankcase heater to prevent mixing of oil with the refrigerant during stoppages,

electronic thermal protection (if part of the equipment) and thermal overload protection.

All models in the WBA range feature a high pressure unloading function. When a high

condensing temperature is reached (as established by a pressure switch) due to abnormally

high ambient temperature, one compressor stops on each circuit. This results in oversizing of

the condensing coil surface area and dropping of the condensing temperature. Output in these

conditions is slightly higher than 50% of total output but it becomes unnecessary to stop the

unit so that cooling can continue throughout the critical period.

The compressors are filled with polyester oil, which is suitable for use in conjunction with

R410A.

Water-refrigerant plate evaporator

The evaporators are composed of AISI 316 stainless steel brazed plate exchangers. The

exchangers are clad externally with an anticondensation mat made of closed cell expanded

foam.

The exchanger is protected by a series of temperature probes installed on the refrigerant

discharge having an anti-freeze function, and by a pressure switch monitoring the pressure

differential between refrigerant suction and discharge sides.

Air-cooled condenser

The air-cooled condenser is composed of a finned core coil made with copper tubes and

high-efficiency corrugated aluminium fins adequately spaced in such a way as to ensure

optimal heat exchange efficiency. The copper tubes are of sufficient diameter and wall

thickness to withstand the highest R410A resign pressures.

6

7

Options:

•Metal mesh filters protecting the condensing coils.

Axial Fans

Axial fans with IP 54 protection rating, external rotor, with moulded blades made of

fibreglass-reinforced plastic with a die cast aluminium core.

The fans are accommodated in dynamically profiled external ports complete with a safety

mesh protecting the exterior side.

Electrical cabinet for power and control circuits

Electrical power and control cabinet, made in compliance with EN 60204-1/IEC 204-1 (Safety

of Machinery), complete with:

- control circuit transformer;

- main door-lock circuit breaker;

- thermal-magnetic cut-outs or fuses protecting compressors, fans and pumps

- contractors controlling compressors, fans and pumps;

- terminals for common alarms block;

- terminals for remote On/Off input;

- control circuit terminal boards;

- exterior quality electrical cabinet with single door and weather seals;

- electronic controller;

- control circuit numbered cables;

- 400/3/50Hz power supply; 230 Vac and 24 Vac control circuits for the electronic controller.

Options:

•phase sequence monitoring;

•electrical cabinet fan;

•electrical cabinet anticondensation heater;

•remote keypad kit.

Microprocessor controller

All WBA series units are equipped with a microprocessor controller capable of managing the

following functions:

-water temperature control in the traditional method with a probe on the system return line

(especially suitable for applications in which an inertia storage tank is installed);

-fans ON-OFF control;

-freeze protection;

-automatic compressors start sequence rotation;

-compressor time intervals;

-alarms signalling and reset;

-presentation on the display of the programmed set-points and the values read by the probes.

8

1.2

Identification of the units in the range

BICOLD WBA WATER CHILLERS

WBA 2 220 VDS MH

1 2 3 4 5 6

1 - MODEL

WB – Water chiller units with hermetic scroll

compressors and plate evaporators.

WH – Heat pump version

2 - CONDENSATION

A = AIR-cooling with axial fans (suitable for

outdoor installation);

3 – NUMBER of REFRIGERANT CIRCUITS

1 = one circuit

2 = two circuits

4 - SIZE

Numerical value denoting the cooping capacity in

kW in nominal conditions (water 12/7 °C and

ambient 35 °C)

5 - VERSION

STD = standard

6 – LAYOUT

SE = Unit with one evaporator. Including

differential pressure switch to protect the

evaporator.

MP = Unit with evaporator and one centrifugal

pump. Including a differential pressure switch

to protect the evaporator.

DP = Unit with evaporator and two centrifugal

pumps. Differential pressure switch to protect

the evaporator included.

MH = Unit with hydronic module; the layout

includes a centrifugal pump, storage tank,

water pressure relief valve and differential

pressure switch to protect the evaporator.

MHD = Unit with hydronic module; the layout

includes two centrifugal pumps, storage

tank, water pressure relief valve and

differential pressure switch to protect the

evaporator.

MC = Condensing unit; unit without

evaporator or expansion valve; supplied

without refrigerant charge.

.

9

1.3

Operating conditions and limits

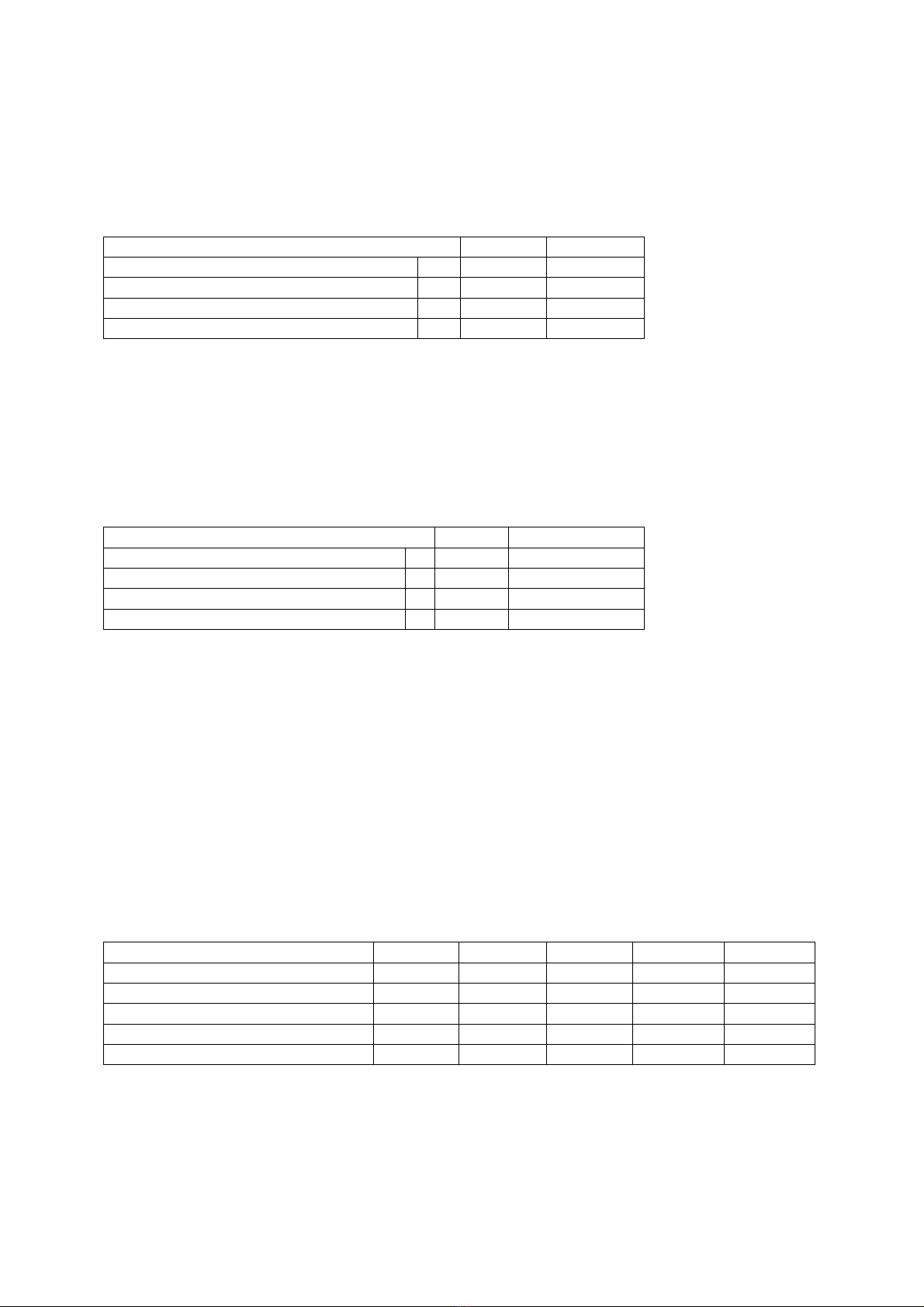

Operating limits in Cooling Mode.

MIN MAX

Water inlet temperature °C 9 17

Water outlet temperature °C 5 13

Temperature gradient °C 4 8

Ambient air temperature °C 5 / -15 (*)

(**)

(*) First value refers to standard unit. Second value refers to unit with fans electronic control,

antifreeze heater on pump and storage tank (when present).

(**) Value depends on size of chiller and operating conditions.

Operating limits in Heating Mode.

MIN MAX

Water inlet temperature °C

25 45

Water outlet temperature °C

30

50 (***) / 40 (****)

Temperature gradient °C

4 8

Ambient air temperature °C

-5 20

(***) Max hot water outlet temperature with minimum ambient air temperature of +5 °C

(****) Max hot water outlet temperature with minimum ambient air temperature of -5 °C

In the presence of a risk of freezing of the fluid medium in the hydraulic circuit antifreeze

mixtures are required; the following are guideline values of the freezing point for mixtures of

water and ethylene glycol, withy glycol percentages expressed in weight. To avoid pump

damage in the event of glycol percentages above 25%, consult the BICOLD Srl sales

department.

The use of this type of mixture causes slight alterations in some of the thermodynamic

parameters of the chillers. The new values can be established by multiplying the value of the

required parameter in nominal operating conditions by the appropriate coefficients shown in

the following table:

% GLYCOL by weight

10

20

30

40

50

Freezing temperature (°C) -3.7 -8.7 -15.3 -23.5 -35 .6

Cooling capacity correction factor

0.99 0.98 0.97 0.96 0.93

Absorbed power correction factor

0.99 0.98 0.98 0.97 0.95

Mixture flow rate correction factor

1.02 1.05 1.07 1.11 1.13

Pressure drops correction factor 1.083 1.165 1.248 1.33 1.413

10

WARNING! WITHOUT GLYCOL IN THE SYSTEM:

IMPORTANT!

If the unit is not used in the winter the water in the circuit may freeze

IMPORTANT!

The use of mixtures of water with glycol affects performance characteristics of the unit

1-4 Unit performance

1.4.1 Cooling duty and electrical power consumption values

Performance values of the models in the WBA range of chillers are shown below referred to

water inlet/outlet temperature of 12/7 °C and ambie nt temperature of 35 °C.

Models

WBA

-

1020

WBA

-

1026

WBA

-

1030

WBA

-

1034

WBA

-

1039

WBA

-

1045

Cooling

DUTY kW 19,7 26,1 30,2 33,2 39,3 43,3

Power

CONS. kW 6,4 8,8 9,6 10,7 12,8 15,4

Models

WBA

-

1053

WBA

-

1059

WBA

-

1066

WBA

-

1075

WBA

-

1090

WBA

-

1098

WBA

-

1110

Cooling

DUTY kW 52.7 58.3 66.1 75 89.1 97.4 110.0

Power

CONS. kW 16.5 19.4 21.6 26.5 28.7 33.5 37.8

Models

WBA

-

1126

WBA

-

1145

WBA

-

1158

WBA

-

2180

WBA

-

2195

WBA

-

2220

Cooling

DUTY kW 125.7 144.2 157.6 178.2 194.9 224.0

Power

CONS. kW 40.8 46.5 54.5 57.4 67.0 75.7

Models

WBA

-

2250

WBA

-

2290

WBA

-

2315

WBA

-

2376

WBA

-

2412

Cooling

DUTY kW 249.3 288.4 315.2 375.5 412.0

Power

CONS. kW 82.3 92.2 109.0 116.0 135.2

11

1.4.2 Sound pressure level

The following table gives the noise data in Sound Pressure Lp(A) at 10 metres from the

condensing coil and 1 metre height above ground in free field conditions (direction factor Q=2).

The Sound Pressure level refers to the machine std layout with the compressors compartment

insulated with sound absorbing matting.

Models

WBA

-

10

20

WBA

-

10

26

WBA

-

10

30

WBA

-

10

34

WBA

-

10

39

WBA

-

10

45

Lp(A)

10 m

47 48 48 48 49 49

Models

WBA

-

1053

WBA

-

1059

WBA

-

1066

WBA

-

1075

WBA

-

1090

WBA

-

1098

WBA

-

1110

Lp(A)

10 m

47 48 49 49 52 54 56

Models

WBA

-

1126

WBA

-

1

145

WBA

-

1158

WBA

-

2180

WBA

-

2195

WBA

-

2220

Lp(A)

10 m 57 57 57 55 57 59

Models

WBA

-

2250

WBA

-

2290

WBA

-

2315

WBA

-

2376

WBA

-

2412

Lp(A)

10 m 60 60 60 63 63

12

2 – INSTALLATION REQUIREMENTS

2.1 Lifting and transport

13

Before lifting the unit refer to the following WEIGHTS table, wherein values are calculated

without the hydronic unit:

Models

WBA

-

1020

WBA

-

10

26

WBA

-

10

30

WBA

-

10

34

WBA

-

10

39

WBA

-

10

45

Weight

kg 350 365 380 460 480 560

Models

WBA

-

1053

WBA

-

1059

WBA

-

1066

WBA

-

1075

WBA

-

1090

WBA

-

1098

WBA

-

1110

Weight

kg 620 635 665 680 870 950 1020

Models

WBA

-

1126

WBA

-

1145

WBA

-

1158

WBA

-

2180

WBA

-

2195

WBA

-

2200

Weight

kg 1100 1160 1180 1495 1665 1760

Models

WBA

-

2250

WBA

-

2290

WBA

-

2315

WBA

-

2376

WBA

-

2412

Weight

kg 2050 2100 2210 2630 2680

Models

WHA

-

1020

W

H

A

-

10

2

6

W

H

A

-

10

30

W

H

A

-

10

34

W

H

A

-

10

39

W

H

A

-

10

45

Weight

kg 380 400 415 500 530 620

Models

WHA

-

1053

WHA

-

1059

WHA

-

1066

WHA

-

1075

WHA

-

1090

WHA

-

1098

WHA

-

1110

Weight

kg 670 685 720 740 940 1030 1100

Models

WHA

-

1126

WHA

-

1145

WHA

-

1158

WHA

-

2180

WHA

-

2195

WHA

-

2200

Weight

kg 1190 1255 1280 1620 1800 1930

Models

WHA

-

2250

WHA

-

2290

WHA

-

2315

Weight

kg 2260 2310 2450

14

DANGER!

The unit must be handled with care to avoid damage to the external structure

and the internal mechanical end electrical components. Also make sure that

there are no obstacles or persons along the route, to avoid the risk of collision,

crushing or overturning of the lifting and handling vehicle.

The unit can be handled and/or lifted exclusively using the specific lifting attachments

incorporated in the frame.

Lifting of the unit is possible by means of textile webbing inserted in the channels in the

base frame, or by means of the forks of a suitable lift truck.

Once the unit has been installed remove the protective film from the panelling and the

shrink wrap plastic.

ENVIRONMENTAL PROTECTION

Dispose of the packing materials in compliance with national legislation and

local bylaws in your country.

DANGER!

Keep packaging materials out of reach of children.

2-2 Installation and positioning

(1) The chiller must be installed in a site with good air quality without a corrosive or

inflammable or exceptionally dusty atmosphere.

THE UNIT IS NOT SUITABLE FOR USE IN EXPLOSIVE

ATMOSPHERES!

(2) The chiller must be installed in a site in which ventilation is sufficient and the heat

release by the unit can be easily dispersed to the exterior. Considering that the chiller

disperses heat to the exterior when it is running, if the place of installation is confined or

lacks sufficient fresh air, the room temperature will rise progressively and the hot air, which

will recirculate over the condenser, will cause rapid degradation of the performance to the

point at which the unit shuts down due to high pressure.

IMPORTANT !

The unit must be sited taking account of the minimum

recommended clearances, taking account of the position of the

condensing coils and accessibility of the hydraulic and electrical

connections.

An installation without the recommended clearances will cause poor operation of the unit

with an increase in power consumption and a reduction in cooling capacity due to an

increase in the condensing pressure.

15

The area above the unit must be completely free of obstacles in such a way as to

guarantee unimpeded air flow from the condensing fans.

If the unit is surrounded by walls, the minimum clearances shown are still valid as long as

at least the two adjoining walls closest to the unit are no higher than the total height of the

unit.

Greater spaces than the spaces indicated must be provided to allow handling of any

components to be replaced.

WBA MODELS

10

20

/10

45

1053/1075

1090/1110

1126/1158

2180/2220

Installation

clearances

L1 mm

1000 1000 1000

1000

1000

L2 mm

1000 1000 1200 1200 1200

L3 mm

800

800

800

800

800

L4 mm

1000

1000

1000

1000

1000

WBA MODELS

2250/2315

2376/2412

Installation

clearances

L1 mm

1000 1000

L2 mm

1200 1200

L3 mm

800 800

L4 mm

1200 1200

(3) To ensure a sufficient air flow the condenser fins must NEVER be obstructed or

excessively fouled;

(4) Free air circulation around the electrical cabinet must be guaranteed.

(5) It is mandatory to install an 0.5 / 0.8 mm mesh filter on the chiller water inlet

16

2-3 Installation of electrical parts

WBA chillers are completely wired in the factory. The only cable required is the connection

to the electrical mains supply, the connection of the flow switch (optional) and the remote

On/Off switch (ON-OFF jumpered by default). All operations described above must be

carried out by qualified personnel in compliance with statutory legislation. For all electrical

work refer to the wiring diagrams.

General warning or precautions to be strictly observed. Serious hazard.

Electric shock hazard

THE UNIT ELECTRICAL HOOK-UP MUST BE CARRIED OUT BY A LICENSED

ELECTRICIAN WITH THE NECESSARY PROFESSIONAL SKILLS AND IN

COMPLIANCE WITH STATUTORY REGULATIONS IN THE COUNTRY OF

INSTALLATION !

IMPORTANT ! FOR INSTALLATION REFER TO THE UNIT WIRING DIAGRAMS

SUPPLIED ON BOARD THE UNIT TOGETHER WITH THIS MANUAL, AND TO THE

DATA ON THE CE RATING PLATE

(1)

The unit must be connected to the power supply only when the installation work

(mechanical, hydraulic and electrical) has been completed.

(2)

The electronic control board is located in the chiller electrical cabinet.

Only qualified technicians must open the unit to perform work on it. To hook up the

WBA unit to the mains electrical panel, for power feeding and for the signals

input/output, always refer to the wiring diagram.

(3)

Comply with the connection specifications for the phase and protective earth

conductors. There must be a specific protection against short circuits and ground

faults upline from the power feeding line, capable of disconnecting the plant from

all other users.

(4)

Install suitable protection on the WBA unit power feeding line in compliance with

the regulations in force in the country in which the unit is installed.

17

(5)

For the electrical connections use cables that comply with the statutory electrical

regulations in force in the country of installation

(6)

After installation, check that the mains power values are within a tolerance of ±10%

of the nominal machine input voltage (unless otherwise specified on the electrical

wiring diagram) with a maximum phase-to-phase imbalance of 3%. If these

parameters are not present, contact your local electricity company.

(7)

No external thermostat can be used to connect/disconnect the unit’s power

feeding line, or malfunctions and poor performance of the unit will result.

(8)

Keep the power lines separate from the signal cables; signal cables must be

shielded and connected to a voltage-free PE point at just one end of the shield.

(9)

It is mandatory to make an efficient protective earth connection. The manufacture

cannot be held liable for any damage caused by the omitted or inefficient

connection of the unit to the earth system.

18

3. Commissioning and running the chiller

3-1 Commissioning and operation notes

Before starting up the unit check that the water circuit pipes have been

correctly connected to the evaporator and that the electrical panels and condenser

compartment doors are properly closed. At this point the chiller can be started.

Pay attention to moving parts if the panels or covers

are raised or have been removed from the unit!

Access to the unit is permitted only to qualified technical personnel.

3-2 Description of the electrical panel and controller

The electrical panel is located inside the unit at the top of the technical compartment that

houses the various refrigerant circuit components.

To gain access to the electrical panel open the front panel of the unit after setting the door

lock breaker switch to 0 (OFF).

OPERATION AND ADJUSTMENT

The electrical cabinet is equipped with a main disconnect switch with door-lock device.

Feeding of the 230Vac auxiliary circuits and the 24Vac control circuits is obtained internally

from the three-phase power input. Adjustments can be carried out by means of a compact

electronic controlled, of the size of a normal thermostat, which provides complete

management of the chiller.

Unit regulation and switching-on of the external high and low prevalence

pumps.

The water temperature probe which controls the thermoregulation of the machine, is

positioned on the pipe that connects the water tank to the evaporator inlet.

The microprocessor switches on or off the compressor according to the temperature set.

The inner circulatory pump is always switched on. This pump makes the water flow circulate

between the tank and the evaporator.

The 2 external pumps for the users pumping, are regulated by a 3-positions selector according

to the following logic:

“Man” position: the pump is switched on

“0” position: the pump is switched off

“Auto” position: the pump is switched on by an external contact (at customer’s charge) as

quoted on the electrical scheme.

19

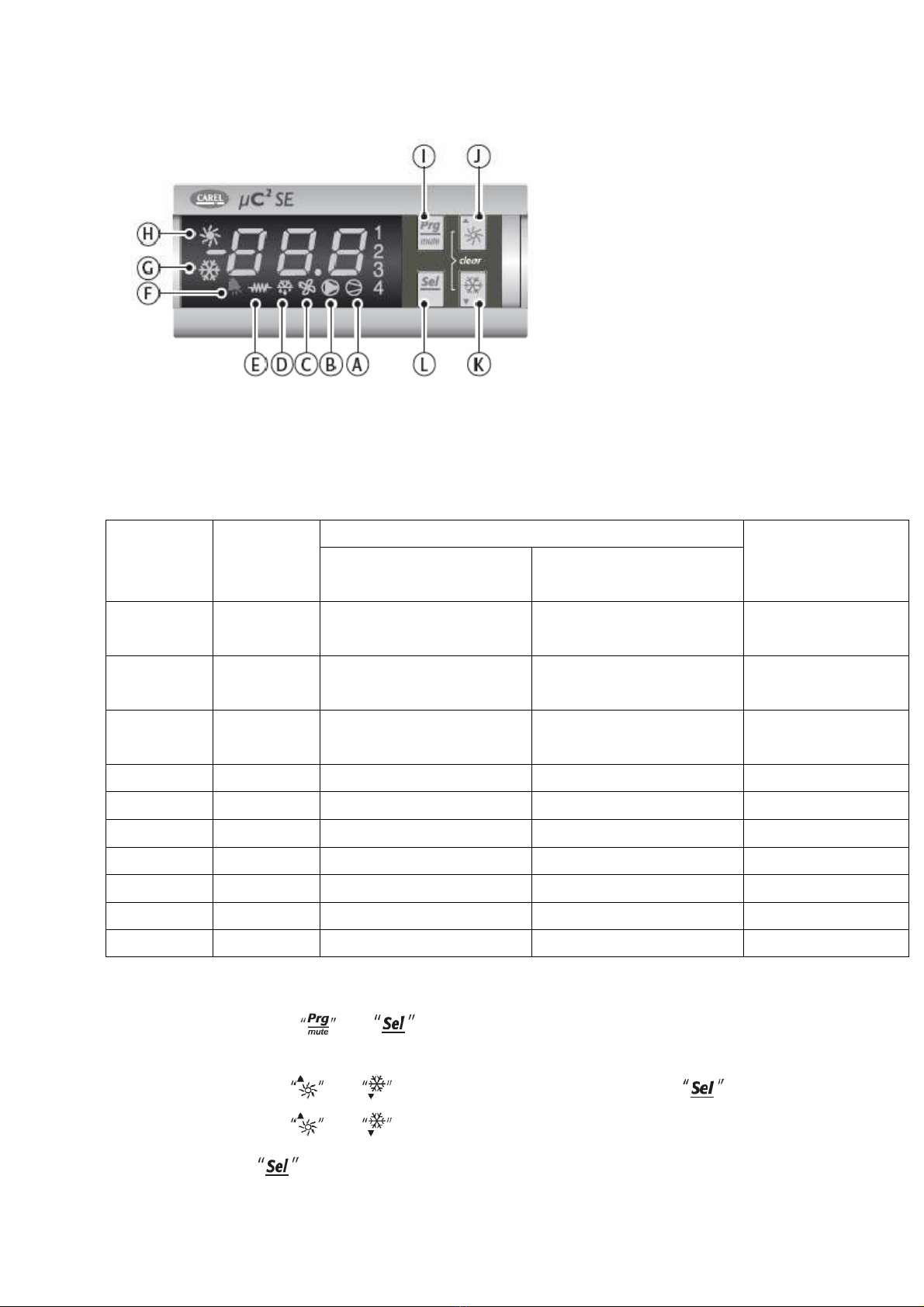

1. USER INTERFACE

SYMBOL COLOUR MEANING REFERENCE

REFRIGERANT

CIRCUIT

WITH LED

ON WITH LED

FLASHING

1;2 amber Compressor 1 and/or 2

running Start request 1

3;4 amber Compressor 3 and/or 4

running Start request 2

A amber At least one compressor

running 1/2

B amber Pump running Start request 1/2

C amber Condenser fan running 1/2

D amber Defrost on Defrost request 1/2

E amber Crankcase heater on 1/2

F red Active alarm 1/2

G amber Heat pump mode Heat pump mode request 1/2

H amber Chiller mode Chiller mode request 1/2

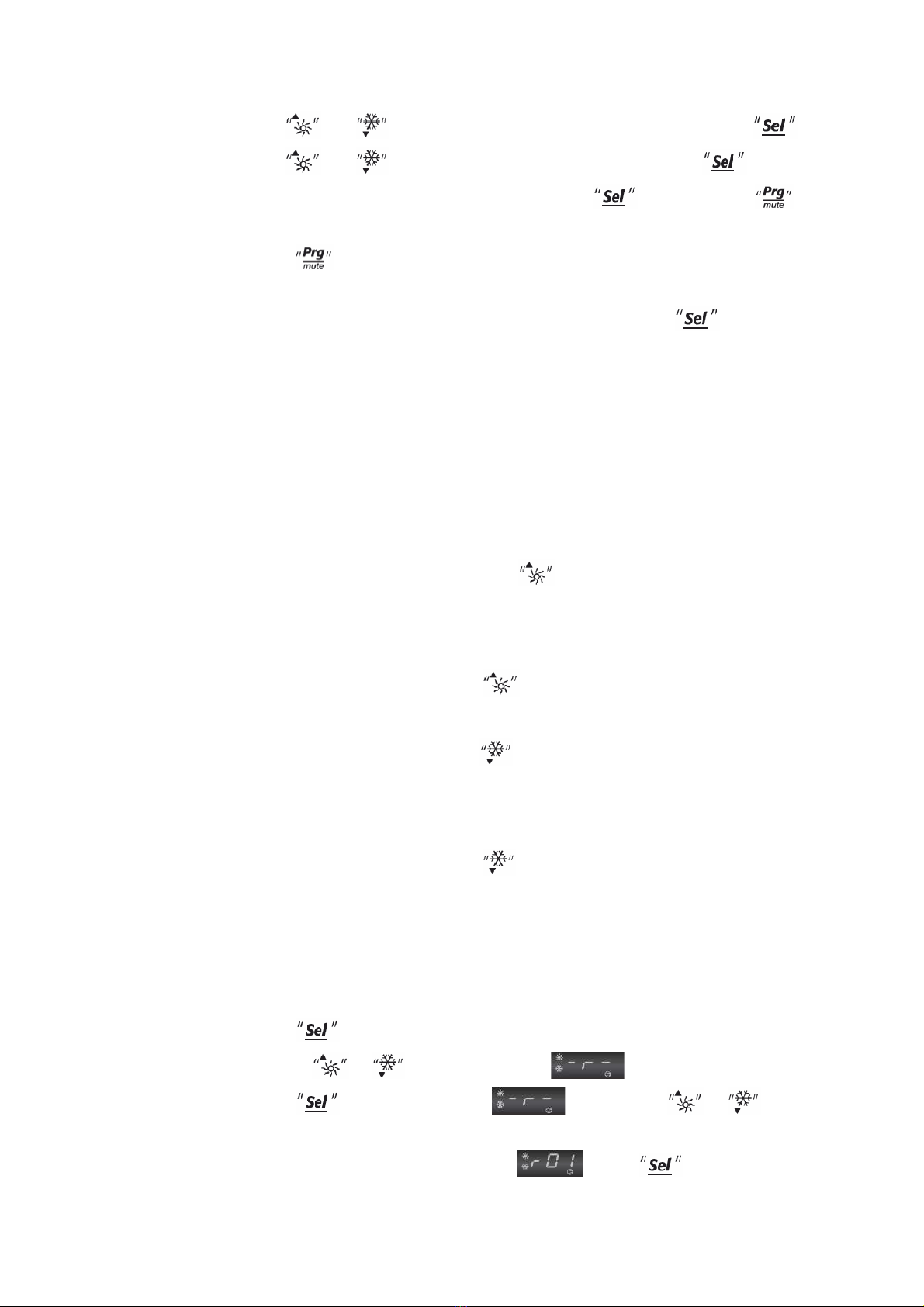

1. PARAMETERS PROGRAMMING AND SAVING PROCEDURE

Press and for 5 s;

The hot and cold symbol and the value “00” will appear;

Use and to set the password and confirm with ;

Use and to select the parameters menu

and confirm with

;

20

Use and to select the parameters group and confirm with ;

Use and to select the parameter and confirm with ;

Once the parameter has been edited press to confirm or to

cancel your changes;

Press to restore the previous menu;

NOTES:

Parameters edited without confirmation by pressing will simply

revert to the previous value;

If no keys are pressed for 60 s, the controller will quit the parameters

editing menu due to time-out and the changes that have been made will

be cancelled.

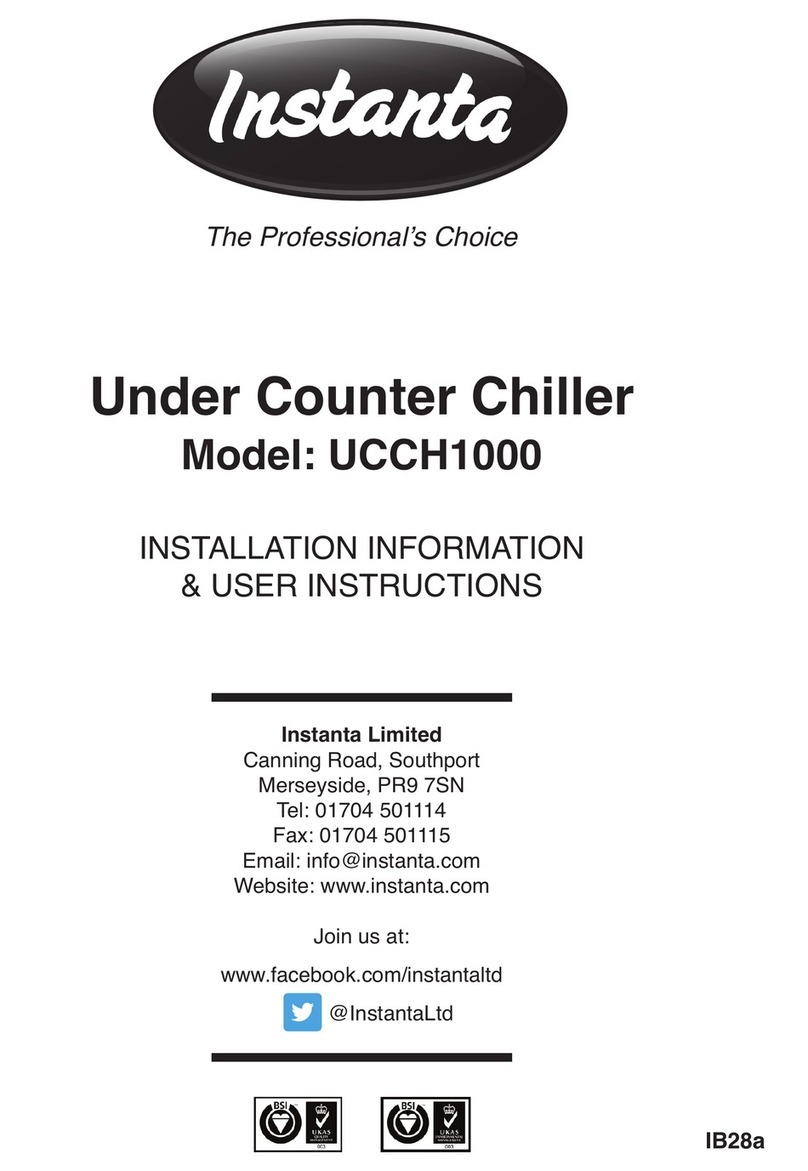

1. SWITCHING THE UNIT ON AND OFF

Turn the main power switch to 1(ON).

CHILLER OPERATION

To start the unit hold down the key for 5 seconds. The pump

operating mode LEDs will light.

Depending on the return temperature from the installation one or both

compressors may be started.

To stop the unit hold down the key for 5 seconds.

HEAT PUMP OPERATION

To start the unit hold down the key for 5 seconds. The pump operating

mode LEDs will light.

Depending on the return temperature from the installation one or both

compressors may be started.

To stop the unit hold down the key for 5 seconds.

2. PROGRAMMING THE SET-POINT

CHILLER MODE OPERATION

The factory setting in cooling mode is 9.5°C.

To change the set point, proceed as follows:

Press for 5 sec to access the main parameters window.

Use the or key to scroll to the submenu.

Press to access submenu and use the or key to

scroll through the parameters accessible from said menu.

To change the Set-point, parameter , press

This manual suits for next models

47

Table of contents

Popular Chiller manuals by other brands

York

York YCAS Series Installation operation & maintenance

Carrier

Carrier OPEN-DRIVE CENTRIFUGAL LIQUID CHILLERS 17CB Start-up instructions

York

York YCAS0250 Wiring diagram

Instanta

Instanta UCCH1000 INSTALLATION INFORMATION & USER INSTRUCTIONS

Daikin

Daikin MicroTech II Installation and maintenance manual

York

York YVAA Installation operation & maintenance

Carrier

Carrier AquaEdge 23XRV installation instructions

LG

LG RCWFL Series installation manual

Kaysun

Kaysun KEM-30 DRS4 Service manual

CLIVET

CLIVET WSH-EE Series Installation and use manual

Robur

Robur GA ACF Installation, use and maintenance manual

Trane

Trane Koolman R410A Installation, operation and maintenance