Bienfang MASTERPIECE 550 User manual

Masterpiece®550 and 250

Mechanical Dry Mounting/Laminating Press

Operation and Service

OWNERS MANUAL

CONTENTS

•Fast Operation: Superior heating system quickly brings

the platen to uniform temperature ensuring 100%

bonding.

•Extended Temperature Range: Thermostat control

adjusts from 100º F to 300º F (38 º –150º C) to cover a

wide range of operating temperatures.

•Programmed Heating Cycles: Temperature and time may

be set by stored programs in control unit.

• TemperatureReadout: Platen temperatureis indicated

on LED display on top of unit.

•Cycle Time Readout: Remaining time in the cycle is

displayed.

•Oversize Capacity: Design allows processing of materials

larger than the press platen by sliding the work side-to-

side or out the front or back of the press.

•Extra-Wide Opening: Opens a full 9” (23cm) for 550

and 10” (25cm) for 250 to provide easy access to

platen surface.

•Easy Pressure Adjustment: Pressure adjusts and locks

in seconds to accept materials up to 1" (25mm) thick.

•Non-Stick Surface: Platen surface is specially coated to

help keep adhesives from sticking.

•Free-Floating Platen: Seats evenly on the work without

shifting to provide uniformpressureacross the entire

surface.

•Rugged Construction: Steel cantilevers increase

durability and allow maximum pressureon work

within the press. Metal top and base construction

adds ruggedness.

PRESS FEATURES AND SPECIFICATIONS

2

Press Features and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Important Safeguards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Identification of Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation and Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Program Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Procedures For Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Processing Oversize Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pressure Adjustment Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

SPECIFICATIONS

3

Please read the entire manual and fully understand

the proper operating procedures before proceeding

to use the press.

1. Place the heat press on a sturdy, flat, level table in a

clean work area. The press should be accessible from

three sides. The press should not be located in the

direct path of air conditioning vents or room-cooling

fans.

2. Correct pressure adjustment is essential to the safe

and proper operation of the press and should be

checked prior to every use.

3. Grasp the center of the handle firmly when opening

and closing the press. Keep body, head and hands

clear of all moving parts and away from the press

opening at all times.

4. Objects such as knives, tools, rulers, paper clips and

markers should be kept out of the press and away

from the press opening at all times.

5. Proper maintenance of the press is easy and essential.

The press platen and sponge pad should be kept clean

and free of adhesive residue, and all functions should

be checked periodically.

6. Turn the power switch off and keep in the closed (but

not locked) position when not in use. Do not leave the

press on overnight, and unplug the power cord while

cleaning or replacing parts.

Contact an authorized Bienfang®dealer or Bienfang

Technical Service (1-888-240-6021) in the event the

press needs service or parts not covered in this Owners

Manual.

IMPORTANT SAFEGUARDS

MASTERPIECE®550

Work Capacity:

One piece 26" x 34"

66cm x 86cm

Sections 50" (132cm)

by any length

Dimensions:

Width 39" (99cm)

Depth 37" (94cm)

Height 12" (30cm)

Open 26" (66cm)

Net Weight 210 lbs. (95 kg)

Power Consumption 1,400 watts

MASTERPIECE®250

Work Capacity:

One piece 18.5" x 23"

47cm x 58cm

Sections 36" (91cm)

by any length

Dimensions:

Width 27" (69cm)

Depth 25" (64cm)

Height 11" (28cm)

Open 20" (51cm)

Net Weight 72 lbs. (33 kg)

Power Consumption 1,350 watts

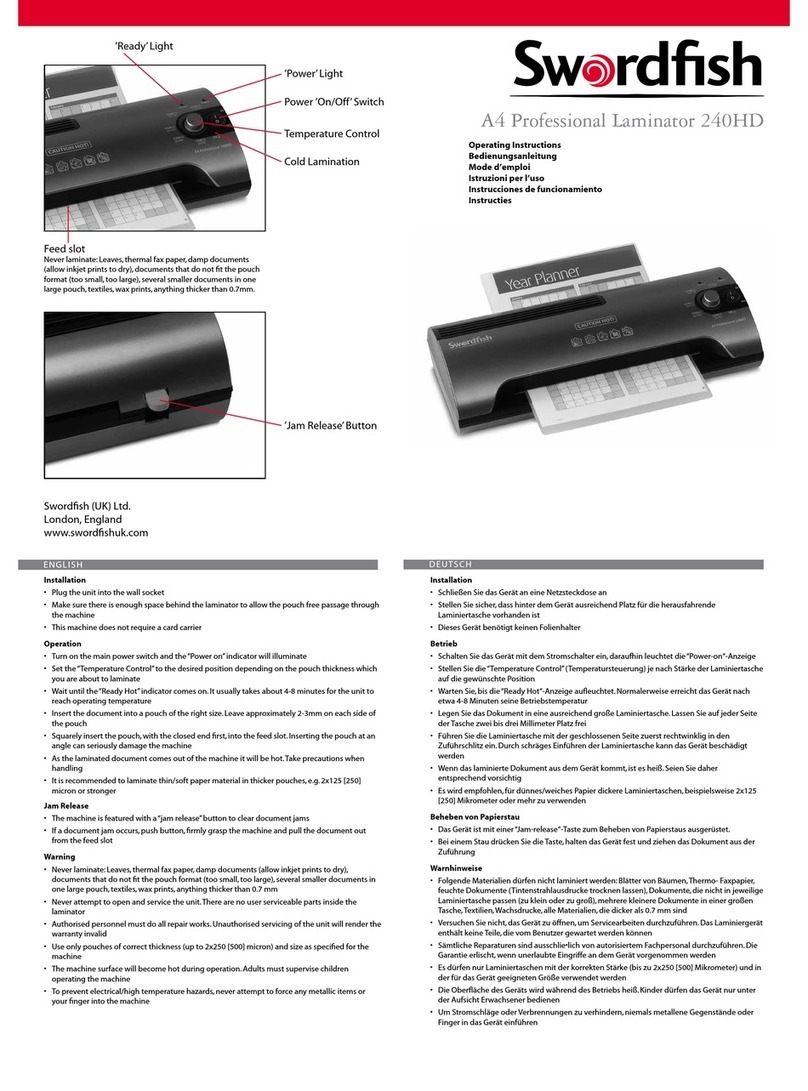

IDENTIFICATION OF CONTROLS

A. Power Switch: Turns main power on/off.

B. Temperature Display: Indicates set temperature

or press platen temperature.

C. Temperature Adjustment Button: Controls

platen temperature. Set at 100ºF (47.5ºC) with

the power switch on, the platen temperature

should rise to 100ºF (47.5ºC) and cycle within

+/- 5ºF of that setting.

D. Time Display: Indicates set time or remaining

cycle time.

E. Time Adjustment Buttons: Controls cycle time.

F. Program Button: Activates pre-set and user

set programs.

G. Reset/Clear Button: Clears the displays for

re-entry.

H. Start/Stop Button: Stops and/or starts the

current cycle.

I. Fº/Cº Button: Switches between Fahrenheit &

Celsius temperaturedisplay.

4

Pressure Adjusting Screw

Lever Arm

A E C HG F B

I

D

Digital Control Pad

Your press is fully assembled and factory adjusted for

immediate use. Install as follows:

1. Position the press squarely on a sturdy, flat, level table

inaclean work area. Make certain that all four feet are

resting on the surface. Access to the press from three

sides is recommended. Making the adjacent table tops

level with the sponge pad will facilitate handling oversize

substrates.

2. Locate and identify all function controls (pg. 4).

3. Turn power switch off and plug the power cord into an

outlet that is rated to supply the electrical current

required for the press. See the Temperature Control

Panel for specific information regarding the voltage

required for proper electrical supply.

1. With the press turned on, press the “PROG” key.

The program number will display in the “seconds”

position. The time and temperaturewill then appear

on the display for the chosen program.

2. Continue pressing the PROG key to go to the next

program setting. The first six programs are pre-set as

follows:

4. The press should be cleaned thoroughly before initial

use. Bienfang®UnStik™Adhesive Releasing Solvent or

Bienfang®Platen Cleaner is suggested to fully clean the

platen. Normal cleaning solutions can be used on the

painted metal components. Clean only when press is

cool and in a well-ventilated area.

The press is now ready for use. Check operation by closing

(but not locking) the press and turning the power switch on.

The power light should illuminate and the press should

begin to warm up.

Please read the entire manual and fully understand the

proper operating procedures before proceeding to use

the press.

Programs 7–10 are for user-specific programs. The time

and temperaturemay be input for these program numbers.

Once the time and temperature have been input to the

desired settings, press and hold the PROG key for 5

seconds to store the settings.

Once the desired program is reached, wait 5 seconds and

the actual temperaturewill be displayed. The temperature

will increase or decrease until the programmed temperature

is reached. Once the programmed temperature is reached,

press the START/STOP key.

INSTALLATION AND PREPARATION

PROGRAM MODE

5

Masterpiece®550 1,400 Watts

(Recommendation: Verify proper amperage before powering up)

Masterpiece®250 1,350 Watts

(Recommendation: Verify proper amperage before powering up)

Time TemperatureApplication

Program 1: 2 min. 200ºF 93ºC ColorMount®

Program 2: 2 min. 185ºF 85ºC Fusion®4000/

BufferMount®

Program 3: 3 min. 150ºF 60ºC SingleStep®Plus

Program 4: 2 min. 180ºF 82ºC SingleStep®

Program 5: 6 min. 215ºF 102ºC Finish Guard™UV

(posters)

Program 6: 8 min. 215ºF 102ºC Finish Guard™UV

(photos)

1. With the press in the closed (but not locked) position,

turn the power switch ON. The control pad will be

activated.

2. Normal operating temperatures of the press are

170-300°F (38-149°C). Refer to the specific instruc-

tions provided with supplies being used and set the press

temperature display to stabilize the press at the

Recommended Temperature setting.

NOTE: When mounting or laminating color photos or

delicate materials, a temperature slightly lower than the

Recommended Temperature may be used (no less than the

Minimum Temperature setting for the specific

adhesive or laminate). For heavier or thicker materials,

or for faster results, a temperature slightly higher than

the Recommended Temperature may be used (for best

results, use lower temperaturewith longer dwell time).

3. Press the “SET MINUTES” key to increase the

minutes to the desired setting. Press the “SET SEC-

ONDS” key to increase the seconds to the desired

setting. Press the “UP” arrow key to increase the

temperature to the desired setting. Once the desired set-

ting is reached, the actual temperature of the press will

be displayed within 5 seconds and will increase to the

desired setting.

4. The press will reach the selected operating temperature

and be ready for use in approximately 20-30 minutes.

The degree symbol in the temperature display will blink

rapidly until the operating temperature is reached…

enough time should be allowed for it to stop blinking

rapidly (slow blink to solid) before initial use to be

certain that the platen temperaturehas stabilized.

5. Pre-dry the artwork and substrate (if needed) and

assemble the materials to be processed. Refer to the

specific instructions for the supplies being used.

6. Check the pressure adjustment of the press by placing

the assembled materials inside and closing (but not

locking) the press. The lever arms should be at a 45°

angle. Adjust the pressure, if needed, then close and

lock the press.

7. Press the “START/STOP” key to start the cycle.

NOTE: Assure that the temperature in the display is

at the desired temperature.

NOTE: See following section on PressureAdjustment

Procedures for proper pressure adjusting directions.

8. Leave the assembly in the press long enough to heat the

materials to at least the Minimum Temperature indicated

on the instructions provided with the

adhesive or laminate being used (refer to the Time Chart

in the instructions with the adhesive or

laminate being used).

9. Open the press, remove the assembled materials and

cool them under a Bienfang®Weight to reduce bowing

and improve the bond strength.

PROCEDURES FOR USE

Lever Arm

Approx. 45º

Closed (not locked)

6

PROCESSING OVERSIZE MATERIALS

Materials substantially larger than the press platen can

often be processed in multiple sections using the

following precautions:

•Check that the pressure adjustment has been made to

accommodate the thickness of materials.

• In the case of impressionable substrates (i.e. foam board)

aRelease Boardor other buffer sheet slightly larger than

the press platen may be placed over the materials; this

helps prevent the possibility of platen lines appearing on

the materials.

•Materials extending out of the press should be supported so

that they do not bend or flex.

•When processing in sections, it is recommended to start

in the center of the work and then work out towards the

edges.

Pre-Drying Materials:

In humid, moist or damp conditions, certain porous materials

absorb water and need to be pre-dried; this removes the

excess moisture that would otherwise possibly interfere with

good bonding or affect the finished appearance of the results.

To pre-dry, place the materials inside a folder of smooth,

porous paper or between 2 pieces of Kraft paper, and process

for a shorttime.

Materials up to 1" (25mm) thick can be handled

if the following pressure adjustment procedures

are used:

1. Check the pressure adjustment of the press by placing

the assembled materials inside and closing (but not

locking) the press. The lever arms should be at a 45°

angle to the top of the table as shown, if not, proceed

to adjust the pressure.

2. Close and lock the press, leaving the materials to be

processed inside (or materials of equal thickness).

3. Loosen the knurled pressure locking nuts – (if the lock-

ing nuts do not loosen easily, open the press, insert an

extra thickness of materials, close and lock the press,

and then loosen the locking nuts. Remove the extra

materials beforeproceeding to adjust the pressure).

4. Return the press to the closed (but not locked) position.

5. Turn each pressure-adjust-

ing screw clockwise to

lower the lever arms and

decrease pressure, or

counter clockwise to raise

the lever arms and

increase the pressure.

Make sure that the screws are adjusted so each arm is

at the same 45° angle.

6. Return the press to the locked position and tighten each

locking nut finger tight.

Alternative Pressure Adjustment Method

Ashim can be made to simplify adjustment between two

different thicknesses of substrates that are commonly used

(example: 3/16" (5mm) foam board and 100 pt. card stock).

1. Set the pressure adjustment for the thicker of the

two substrates (3/16" (5mm) foam board), using the

preceding procedure.

2. Find a firmboardthat is equal to the difference in thick-

ness between the two substrates (approximately 1/8"

((3mm)) in this example). Cut this board(to be used as

ashim) the size of the pressure board beneath the

sponge pad in the press.

3. Slide the shim under the pressure board when processing

materials the thickness of the thinner board (100 pt.

card stock). Remove the shim when using the thicker of

the two substrates (the 3/16" ((5mm)) foam board).

PRESSURE ADJUSTMENT PROCEDURES

Lever Arm

Approx. 45º

Closed (not locked)

Decrease Increase

Closed and Locked

7

WIRING DIAGRAM

8

*Masterpiece 550 International only

REPLACEMENT PARTS

Masterpiece®550

Platen Kit TS6299018

Sponge Pad TS153260

Lever Arm – Right TS100170

Lever Arm – Left TS100171

Foot Kit TS6299021

Toggle Plate/Bolt Kit TS6299017

Crossbeam Bolt Kit TS6299025

Handle Kit TS6299028

Pressure Adj. Kit TS6299031

Screw Kit TS6299034

Control Assembly TS2304084

Output Module TS1408005

Sensor Assembly TS6208059

Heater Kit TS6299009

Electrical Kit TS6299040

Transformer TS2304083

Masterpiece®250

Platen Kit TS6299019

Sponge Pad TS143222

Lever Arm – Right TS100223-1

Lever Arm – Left TS100224-1

Foot Kit TS6299022

Crossbeam Bolt Kit TS6299026

Handle Kit TS6299029

Pressure Adj. Kit TS6299032

Screw Kit TS6299035

Output Module TS1408005 (210M-K)

Sensor Assembly TS6208059

Control Assembly TS2304084

Electrical Kit TS6299040

Transformer TS2304083

Heater Kit TS6299141

Toggle Plate/Bolt Kit TS6299024

The Bienfang®550 Mechanical Press has been

specifically engineered to require a minimum level

of maintenance. The following guidelines were

designed to keep the press in prime operating

condition throughout its lifetime.

1. Clean the platen regularly. Bienfang®UnStik™adhesive-

releasing solvent or Bienfang®Platen Cleaner should be

used to dissolve and remove difficult deposits as need-

ed. Do not use abrasive materials such as steel wool or

gritty cleaners.

2. Check the sponge pad periodically for cleanliness and

uniformresiliency.If the pad shows any areas of soft or

"dead" spots it should be replaced. Uniformpressure is

essential for quality results when mounting or laminat-

ing. Replace the sponge pad as necessary when soiled

or uneven.

3. Check the platen temperature periodically using

temperature indicator strips to verify calibration of the

thermostat and thermometer settings. Make sure the unit

is warmed up and has stabilized to the set temperature.

Torecalibrate or replace call an authorized Bienfang

dealer or Bienfang Technical Services.

4. Lubricate all pivot points twice a year with a Teflon®or

silicone dry lubricating spray. Oil or graphite lubricants

arenot recommended.

5. Inspect the power cordfor breaks and cuts. Make sure

thereareno severebends or crimps in the cord. The

cord should not be pinched between the table, press or

wall. If the cord needs to be replaced, please contact

Bienfang Technical Supportat 888-240-6021. This

should be done by the manufacturer only.

6. Check the overall press occasionally for levelness, loose

screws, or damaged components. Adjust, tighten or fix

as necessary.

Disclaimer

The information contained herein is based upon our research and

believed to be accurate, but the accuracy and completeness of our

recommendations is not guaranteed. The user shall determine the

suitability of the product for their intended use, before using the

product, and the user assumes all risk and liability whatsoever in

connection with the use of the product. Neither seller nor manu-

facturer shall be liable for any injury, loss or damage, direct or

consequential, arising out of the use of or inability to use the

product. The following is made in lieu of all warranties, express or

implied. Seller’s and manufacturer’s only obligation shall be to

repair, replace or credit such quantity of the product proved to be

defective.

PERIODIC MAINTENANCE

•Kits listed above contain the components and instructions necessary for normal replacement of the affected item. This precludes the

necessity of identifying and ordering individual parts and helps ensureall the necessaryparts are on hand.

• If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a similarly qualified person in order to

avoid a hazard.

9

TROUBLESHOOTING GUIDE

10

11

Elmer’s Products,Inc warrants to the original consumer purchaser that each new Bienfang®equipment product which

proves defective in materials or workmanship within the applicable warranty period will be repaired or, at our option,

replaced without charge upon its return, postpaid, as outlined below. The applicable warranty shall be one year from

date of purchase. “Original consumer purchaser” means the person who first purchased the product covered by this

warranty other than for purposes of resale.

Elmer’s liability for breach of any warranty express or implied shall be limited to the repair or replacement, at Elmer’s

option, of the defective item. Elmer’s shall not be liable for damages, including but not limited to incidental or conse-

quential damages, arising out of or in connection with the use or performance of any Bienfang product.

To get performance under this warranty, contact Bienfang Technical Support (1-888-240-6021) for assistance or to

obtain a Return Authorization. If it is to be returned, pack the product securely to prevent damage in transit, and

send the product, postpaid or freight prepaid, with a description of the defect or malfunction and proof of the date of

purchase to elmer’s, Attn: RA Number.Elmer’s is not responsible for damages from mishandling and abuse in transit,

in which case a claim should be filed with the carrier.

This warranty extends to and is enforceable only by the original consumer purchaser,and only for the period (during

applicable term) during which the product remains in the possession of the original consumer purchaser.

Bienfang Framing Products

2020 W Front St.

Statesville, NC 28677

Tel: 888-240-6021

LIMITED WARRANTY

www.elmers.com

www.forframersonly.com

©2005 Elmer’s Products Inc.

4836-05-rev

OM550

(5/05)

Bienfang Framing Products

ADivision of Elmer’s Products, Inc.

2020 W Front St.

Statesville, NC 28677

Cust. Service: 888-240-6021

Tech. Service: 888-240-6021

Tech. Fax: 704-871-8671

Hrs: 8:00 a.m.-5:00 p.m. (EST)

This manual suits for next models

1

Table of contents