BIFFI ELBS-20 User manual

Installation, Operation and Maintenance Manual

MAN712 Rev. 9

June 2021

Bif ELBS-20

Electronic Line Break System 20

Copyright © Biffi. The information in this document is subject to change without notice. Updated data sheets can be obtained from our website www.biffi.it or from your nearest Biffi Center:

Biffi Italia s.r.l. - Strada Biffi 165, 29017 Fiorenzuola d'Arda (PC) – Italy PH: +39 0523 944 411 – biffi_italia@biffi.it

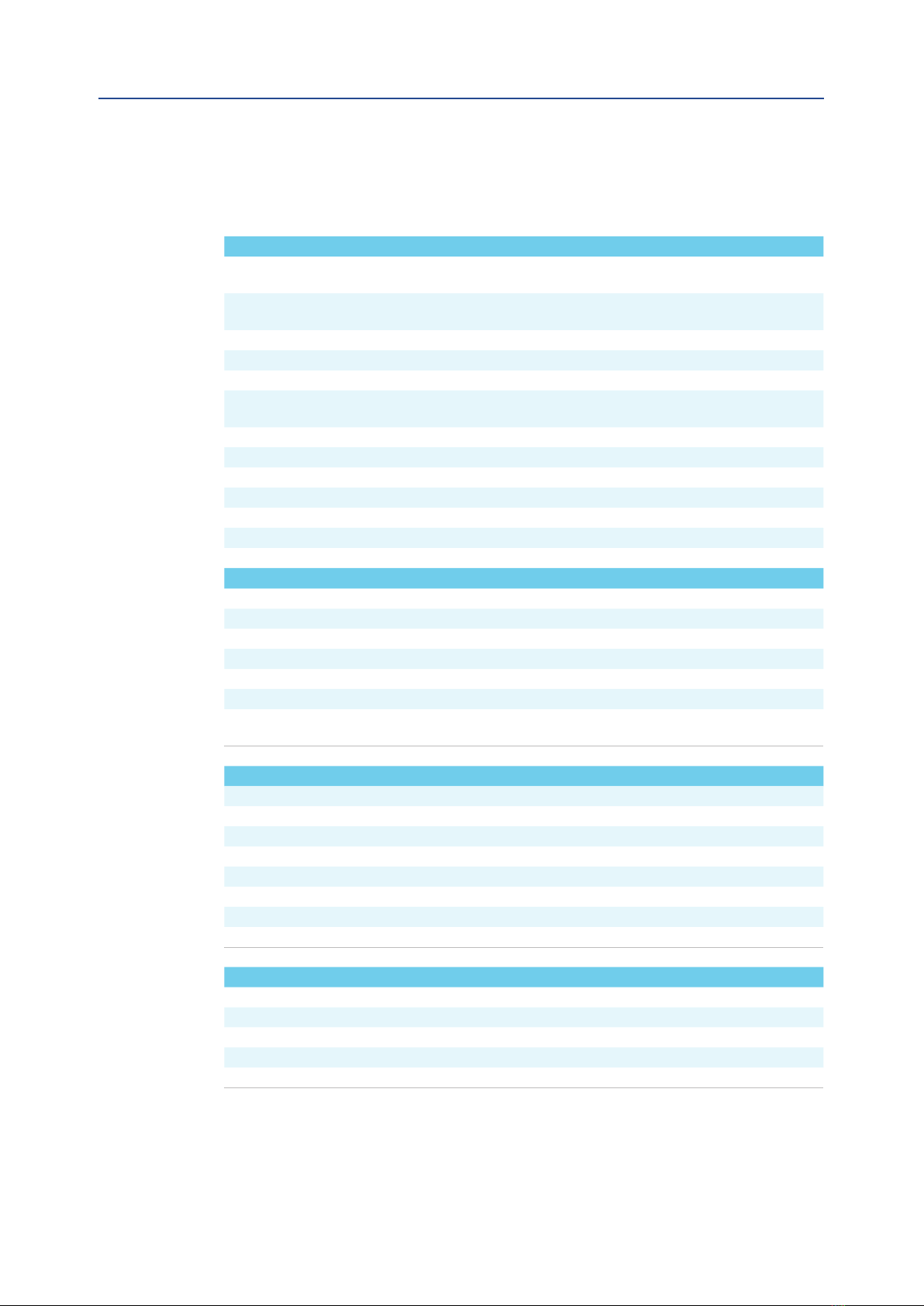

Revision Details

June 2021

Installation, Operation and Maintenance Manual

MAN712 Rev. 9

Revision Details

Revision Details

Rev. Date Description Prepared Checked Approved

9 June 2021 General update (Migration to new template)

8 September 2020 Eighth Issue Piacenti Doglio

7 July 2016 Seventh Issue Battaglia Vigliano

6 October 2015 Sixth Issue Battaglia Vigliano

5 December 2014 Fifth Issue Battaglia Vigliano

4 August 2013 Fourth Issue Battaglia Vigliano

3 July 2013 Third Issue Battaglia Vigliano

2 May 2013 Second Issue Battaglia Vigliano

1 April 2013 Second Issue Battaglia Vigliano

0 February 2013 First Issue Battaglia Vigliano

i

Installation, Operation and Maintenance Manual

MAN712 Rev. 9

Table of Contents

June 2021

Table of Contents

Table of Contents

Section 1: Reference Document

Reference Document...............................................................................................1

Section 2: General Safety Instructions

2.1 Manufacturer................................................................................................ 2

2.2 Intended Use................................................................................................. 2

2.3 Terms and Conditions ................................................................................... 3

2.4 Manufacturer’s Liability................................................................................. 3

2.5 Applicable Standards and Regulations........................................................... 3

Section 3: Storage

Storage....................................................................................................................4

Section 4: Device Description

4.1 Identication of the Main Parts...................................................................... 7

4.2 Electronic Cards ........................................................................................... 8

4.2.1 Electronic Cards - Pinout .................................................................... 8

4.2.2 Electronic Card – Details (Jumpers, Fuses,

Push-Buttons, Batteries).............................................................................. 10

4.3 Technical Specications .............................................................................. 13

4.4 Overall Dimensions (EJB51 Cabinet) ............................................................ 16

4.5 Options....................................................................................................... 16

Section 5: Working Principle and

Detailed Description

5.1 Working Principle........................................................................................ 17

5.1.1 Table of Operating Modes................................................................. 22

5.1.2 Details of the Valve Control Operating Mode.................................... 23

5.1.3 Examples of Pressure Drop Rate Control ........................................... 25

5.2 Detailed Description ................................................................................... 26

5.2.1 Conguration-Managing Interfaces.................................................. 26

5.2.2 Power Supply (External – Battery Pack)............................................. 28

5.2.3 Analog Output (Pressure or Position Retransmission) ....................... 31

5.2.4 Digital Input ..................................................................................... 31

5.2.5 Digital Output .................................................................................. 31

5.2.6 Analog Input - Pressure Transducer................................................... 32

5.2.7 Analog Input - Position Sensor.......................................................... 32

5.2.8 SOV Control Outputs........................................................................ 32

5.2.9 MODBUS RTU................................................................................... 35

Section 6: Conguration Parameters

6.1 Precision of the Analog Inputs..................................................................... 51

6.2 Table of Digital Outputs Functions .............................................................. 52

6.3 Table of Digital Inputs Functions.................................................................. 53

6.4 Tables of the Alarms and Warnings.............................................................. 54

ii

Table of Contents

June 2021

Installation, Operation and Maintenance Manual

MAN712 Rev. 9

Table of Contents

Section 7: Local Operator Interface

7.1 Info Bar ....................................................................................................... 57

7.2 Normal Mode Menu .................................................................................... 58

7.3 Login Menu ................................................................................................. 59

7.4 View Mode and Setup Mode Menus ............................................................ 60

7.4.1 View Graph of the Setup/View Mode Menus..................................... 60

7.4.2 Push-buttons Functionality .............................................................. 67

Section 8: Modbus RTU Interface

8.1 Modbus Standard References ...................................................................... 68

8.2 Modbus Communication Features............................................................... 68

8.3 Modbus Wirings.......................................................................................... 69

8.3.1 Modbus RS485 Transmission Mode .................................................. 69

8.4 Modbus Function Description ..................................................................... 71

8.4.1 Function Code 03 (0x03) Read Holding Registers ............................. 72

8.4.2 Function Code 06 (0x06) Write Single Register................................. 73

8.4.3 Function Code 16 (0x10) Write Multiple Registers ............................ 74

8.4.4 Function Code 72 (0x48) Read Event Data ........................................ 75

8.4.5 Function Code 101 (0x65) Read Alarms and Warnings Logs.............. 77

8.4.6 Exception Codes............................................................................... 79

8.5 Holding Registers Map ................................................................................ 80

Section 9: Typical Connections

9.1 Signals Description...................................................................................... 89

9.2 Typical Connections Example...................................................................... 93

9.2.1 Example 1 – Typical Connection ....................................................... 93

9.2.2 Example 2 – Typical Connection ....................................................... 95

Section 10: Installation – Start-Up

10.1 Installation in Ambient with Explosive Dusts................................................ 98

10.2 Checks to be Performed Before Installation................................................. 98

10.3 Battery Pack First Connection ..................................................................... 98

10.4 Cables and Electrical Connections............................................................... 99

10.4.1 Cables Connection ........................................................................... 99

10.4.2 Cables Requirements – EMC Protection.......................................... 100

10.4.3 Wires Dimensions .......................................................................... 101

10.4.4 Unused entries ............................................................................... 101

10.5 Start-up Procedure.................................................................................... 101

10.6 Position Limits Calibration (Optional)........................................................ 103

iii

Installation, Operation and Maintenance Manual

MAN712 Rev. 9

Table of Contents

June 2021

Table of Contents

Section 11: Restore Valve Control

Restore Valve Control...........................................................................................104

Section 12: Battery Maintenance and First Installation

Battery Maintenance and First Installation..........................................................105

Section 13: Parts List

13.1 General Assembly ..................................................................................... 114

13.2 General Assembly ..................................................................................... 115

Section 14: Decommissioning

Decommissioning................................................................................................116

Section 15: Troubleshooting

Troubleshooting...................................................................................................117

Section 16: Ordering Table

Ordering Table......................................................................................................119

Installation, Operation and Maintenance Manual

MAN712 Rev. 9

Notes

June 2021

This page is intentionally left blank

Installation, Operation and Maintenance Manual

MAN712 Rev. 9 June 2021

Reference Document 1

Section 1: Reference Document

Section 1: Reference Document

[1]: MDE226 - “ELBS-20 Bif Assistant User Manual”.

June 2021

Installation, Operation and Maintenance Manual

MAN712 Rev. 9

General Safety Instructions2

Section 2: General Safety Instructions

Section 2: General Safety Instructions

2.1 Manufacturer

Manufacturer with respect to Machinery Directive 2006/42/EC is Bif Italia, as specied on

the machinery label.

2.2 Intended Use

The ELBS-20 electronic device covered in this Installation, Operation and Maintenance

Manual is designed to monitor the pipeline integrity. The ELBS-20 continuously measures

the pressure in the line, it can store the pipeline data (pressure trend) and in case of failure

it can send a command to the actuator to stroke the line valve to the fail-safe position.

Bif Italia will not be liable for any possible damage or physical injury resulting from use

in other than the designated applications or by lack of care during installation, operation,

adjustment and maintenance of the machine. Such risks lie entirely with the user.

Depending on the specic working conditions, additional precautions may be requested.

Considering that Bif Italia has no direct control over particular applications, operation or

maintenance conditions, it is the operator’s responsibility to comply with all applicable

safety rules. Please inform Bif Italia urgently if you face unsafe situations not described

in this IOM. It is the sole responsibility of the operator to ensure that the local health and

safety regulations are adhered to.

! WARNING

It is assumed that the installation, setting, commissioning, maintenance and repair works

are carried out by qualied personnel and checked by responsible specialists.

! WARNING

Any repair work other than the operations outlines in this IOM will be strictly reserved to

qualied Bif Italia personnel or to personnel directly authorised by the company itself.

ELBS-20 devices are designed in accordance with the applicable International Rules and

Specications, but the following Regulations must be observed in any case:

• The general and safety regulations.

• The plant specic regulations and requirements.

• The proper use of personal and protective devices (glasses, clothing, gloves, etc.).

• The proper use of tools, lifting and transport equipment.

! WARNING

The electronic parts of the ELBS-20 and all the options can be damaged by a discharge

of static electricity. Before you start, touch a grounded metal surface to discharge any

static electricity.

Installation, Operation and Maintenance Manual

MAN712 Rev. 9 June 2021

General Safety Instructions 3

Section 2: General Safety Instructions

2.3 Terms and Conditions

Bif Italia guarantees each single product to be free from defects and to conform to current

goods specications. The warranty period is one year from the date of installation by the

rst user, or eighteen months from the date of shipment to the rst user, whichever occurs

rst. No warranty is given for products which have been subject to improper storage,

improper installation, misuse, or corrosion, or which have been modied or repaired by

unauthorised personnel. Repair work due to improper use will be charged at standard rates.

2.4 Manufacturer’s Liability

Bif Italia declines all liability in the event of:

• Use of the device in contravention of local safety at work legislation.

• Incorrect installation, disregard or incorrect application of the instructions

provided on the device nameplate and in this manual.

• Modications without Bif’s authorisation.

• Work done on the unit by unqualied or unsuitable persons.

2.5 Applicable Standards and Regulations

EN ISO 12100-1: Safety of machinery - Basic concepts, general

principles for design.

Part 1-Basic terminology, methodology.

EN ISO 12100-1: Safety of machinery - Basic concepts, general

principles for design.

Part 2-Technical principles and specication.

EN 60204/1: Electrical equipment of industrial machines.

Part 1- General requirements.

2006/42/EC: Machinery directive.

2004/108/EC: EMC Directive

94/9/EC: ATEX Directive

2006/95/EC: Low Voltage Directive

IEC 60068-2-6, IEC 60068-2-57: Vibration Test

June 2021

Installation, Operation and Maintenance Manual

MAN712 Rev. 9

Storage4

Section 3: Storage

Section 3: Storage

NOTICE

Not performing the following procedures will invalidate the product guarantee.

All the ELBS-20s leave the factory in perfect condition. When mounted together with

the actuator they are guaranteed by the actuator test certicate; in other cases, they are

guaranteed by an individual certicate. In order to maintain these characteristics until the

ELBS-20 is installed on site, proper attention must be observed for preservation during the

storage period.

The standard plastic plugs used to protect the cable entries during the transport are not

waterproof; they just prevent the entry of undesired objects during transport: during the

storage it is recommended to replace them with waterproof version.

In any case storage is recommended in close ambient without excessive humidity.

If the battery cells are included, the storage temperature must meet the battery cell

specications (storage).

Installation, Operation and Maintenance Manual

MAN712 Rev. 9 June 2021

Device Description

Section 4: Device Description

5

Section 4: Device Description

General Description

The Line Break Detection System type ELBS-20 is an electronic equipment, developed by

Bif, for monitoring the pipeline integrity. The ELBS-20 measures, with a settable time

interval, the pressure in the line, it can store the pipeline data (pressure trend) and in case

of failure it can send a command to the actuator to stroke the line valve to the fail-safe

position (Safety Action).

The ELBS-20 was especially engineered for “ON FIELD” service; it means capability of

working in the severest ambient conditions, as wide operating temperature range,

vibrations, explosive atmosphere, etc.

Conguration-Managing Interfaces

The ELBS-20 is provided with a powerful local operator interface, made of one 128x64

graphical OLED display and 3 push-buttons that allow entering the conguration data and

visualizing the values of variables or the status of the device.

Moreover an RS232, an RS485 and a Bluetooth serial communication ports are provided

for the connection with the “Bif Assistant” software tool (see [1] for details), to carry out

parameter conguration, or variables visualization or to download the recorded event data

for further analysis of pipeline behavior.

Power Supply

The ELBS-20 accepts two different sources of power supplies:

• External Power Supply from 19.2 V DC to 57.6 V DC (24 V DC -20% to 48 V DC

to +20%).

• Battery Pack power supply: 7.2 V DC (lithium batteries).

The two power supplies can be applied one or both per time.

When both the power supplies are present, the Battery Pack works as back-up of the

External Power Supply.

The ELBS-20 monitors the status of the External Power Supply and the status of the Battery

Pack Power Supply.

Battery Packs

The Battery Pack Card of the ELBS-20 provides two independent battery packs

(Default and Auxiliary) with dedicated protection circuit (diodes and fuses).

Each battery pack is composed by four Li-SOCl2 size D cells (parallel of two cells in series).

Analog Inputs (Pressure and Position Sensors)

The ELBS-20 is provided with two (Pressure and Position) congurable

(0 - 20 mA or 4 - 20 mA) analog inputs (AI). The ELBS-20 supplies a 14.5 V DC voltage to

the sensors.

Digital Inputs (Opto-isolated)

The ELBS-20 is provided with three congurable opto-isolated Digital Inputs (DI).

June 2021

Installation, Operation and Maintenance Manual

MAN712 Rev. 9

Device Description

Section 4: Device Description

6

Analog Output

The ELBS-20 is provided with a congurable 4 - 20 mA analog output (AO).

The AO can be used for the retransmission of the Pressure or Position measured by the AIs.

The AO can accept an external 24 V DC power supply or internally generates the 24 V DC,

necessary for the 4 - 20 mA signal.

Digital Outputs (Relay contacts).

The ELBS-20 is provided with 7 Digital Outputs (DO):

• 6x SPST latching relays contacts

• 1x SPDT single side stable relay contacts

Modbus RTU

The ELBS-20 is provided with a MODBUS RTU (RS485) bus interface.

SOV Control Outputs

The ELBS-20 is provided with the following outputs dedicated to the Solenoid

Valve Control:

• 2x 24 V DC - 100 mA isolated outputs (SVC)

• 2x SPDT single side stable relays contacts (RL)

The SOV Control Outputs are used for managing one or more external SOVs in order to

send a command to the actuator to stroke the line valve to the fail-safe position

(Safety Action).

The SOV Control Outputs can be used also to drive a contactor of an electrical actuator

(no SOVs required) to stroke the line valve to the fail-safe position.

The ELBS-20 provides also the possibility to use DO1 and DO2 as SOVs Control Outputs.

Integrity Check of the Safety Action Electrical Circuit

The ELBS-20 allows monitoring the status of the Safety Action Electrical Circuits

(dedicated SOV Control Output + Coil + Wiring Connection).

Auto-diagnostic

The ELBS-20 monitors the status of the power supply sources, of the internal voltages and

of the Analog Inputs circuits.

Installation, Operation and Maintenance Manual

MAN712 Rev. 9 June 2021

Device Description

Section 4: Device Description

7

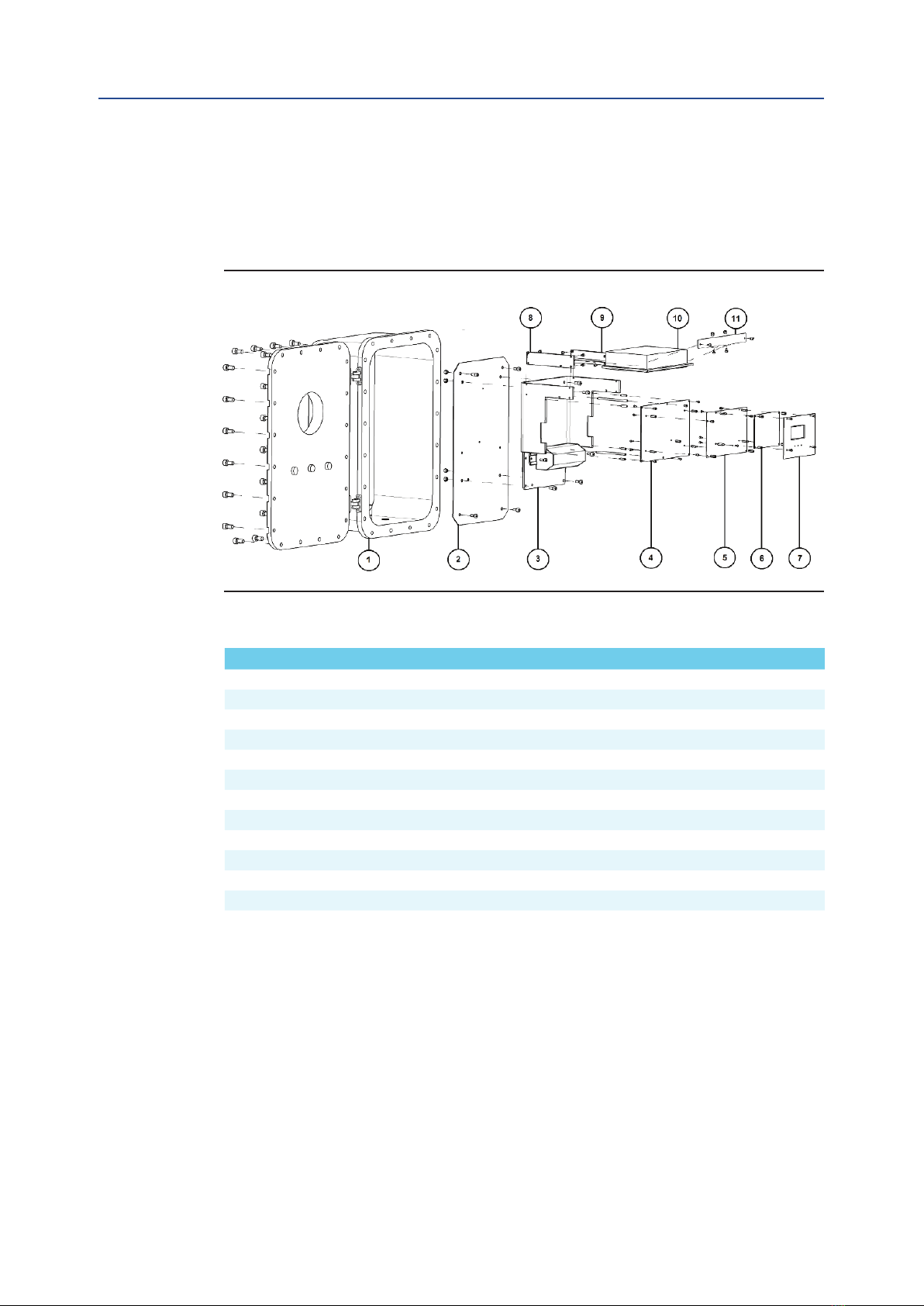

4.1 Identication of the Main Parts

In this section only the main parts of the ELBS-20 are shown. Refer to Section 13 for a full

list of the ELBS-20 parts.

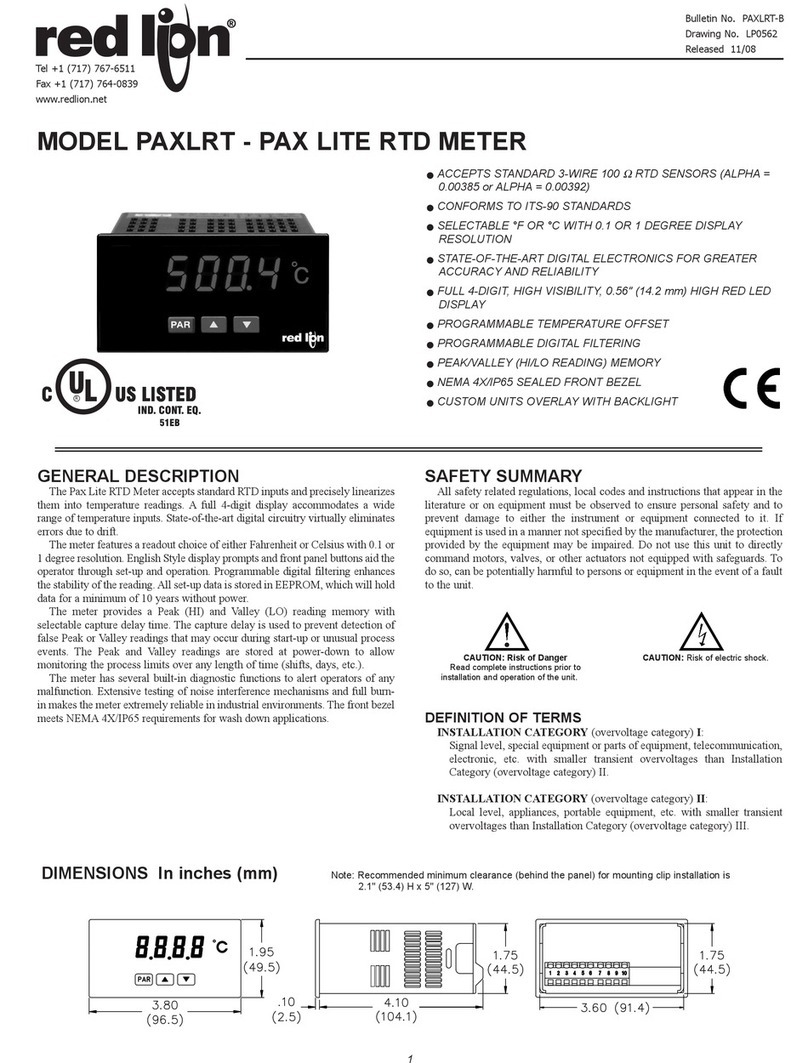

Figure 1

Table 1.

Pos. Description Qty

1 CABINET MOD. EJB51 (*) 1

2 EJB51 INTERNAL PLATE (*) 1

3 ELBS-20 CARDS BRACKET 1

4 PROCESS CARD 1

5 INTERFACES CARD 1

6 DISPLAY/BLUETOOTH CARD 1

7 DISPLAY/BLUETOOTH CARD MASK 1

8 BATTERY PACK LEFT BRACKET 1

9 BATTERY PACK RIGHT BRACKET 1

10 BATTERY PACK CARD (opt.) 1

10.1 BATTERY CELLS (opt.) 4 or 8

11 BATTERY PACK FRONTAL EXTRACTOR 1

NOTE:

(*) The EJB51 cabinet is normally provided when the following ordering options are selected:

Cabinet Material = A and Cabinet Electrical Certication = B (see Section 16 for details).

June 2021

Installation, Operation and Maintenance Manual

MAN712 Rev. 9

Device Description

Section 4: Device Description

8

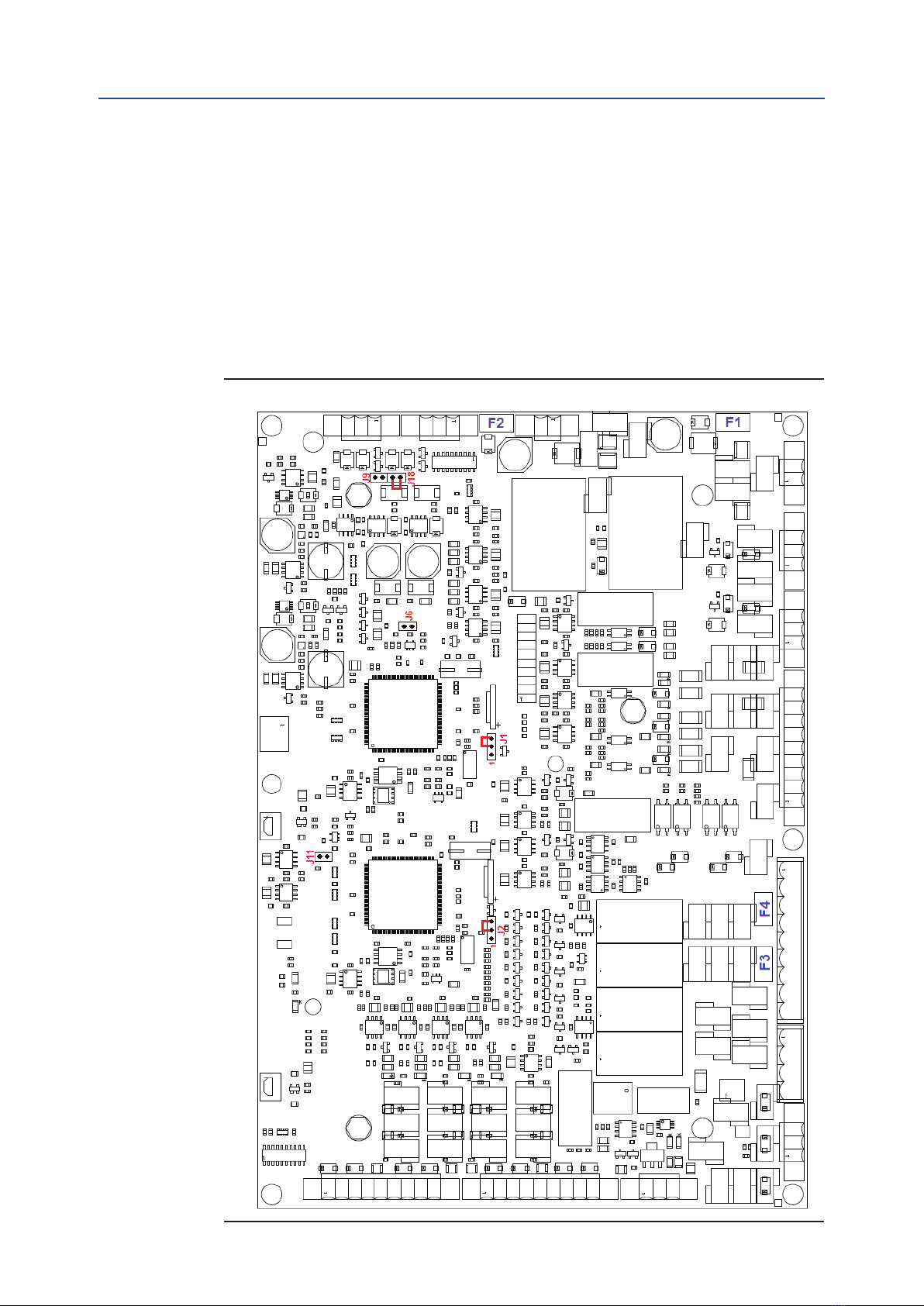

4.2 Electronic Cards

4.2.1 Electronic Cards - Pinout

The gure below shows the 292ELBS100 block that is composed by the following

electronic cards:

• 492LBDS100: DISPLAY/BLUETOOTH CARD

• 492LBIN100: INTERFACES CARD

• 492LBPR100: PROCESS CARD

Figure 2

Installation, Operation and Maintenance Manual

MAN712 Rev. 9 June 2021

Device Description

Section 4: Device Description

9

The gure below shows the 492LBBP100 – BATTERY PACK CARD.

Figure 3

Battery Pack

Default

7.2 V DC

EARTH CABLE

(optional)

Battery Pack

Auxiliary

7.2 V DC

492LBBP100 - BATTERY PACK CARD

June 2021

Installation, Operation and Maintenance Manual

MAN712 Rev. 9

Device Description

Section 4: Device Description

10

4.2.2 Electronic Card – Details (Jumpers, Fuses,

Push-Buttons, Batteries)

The gure below shows the Jumper Settings and the Fuses position of the Process Card.

The Jumpers of the Process Card (Figure below) must be set as follows:

• J18: close

• J9, J11: open

• J1, J2: 2-3 close

Figure 4 Process Card

Installation, Operation and Maintenance Manual

MAN712 Rev. 9 June 2021

Device Description

Section 4: Device Description

11

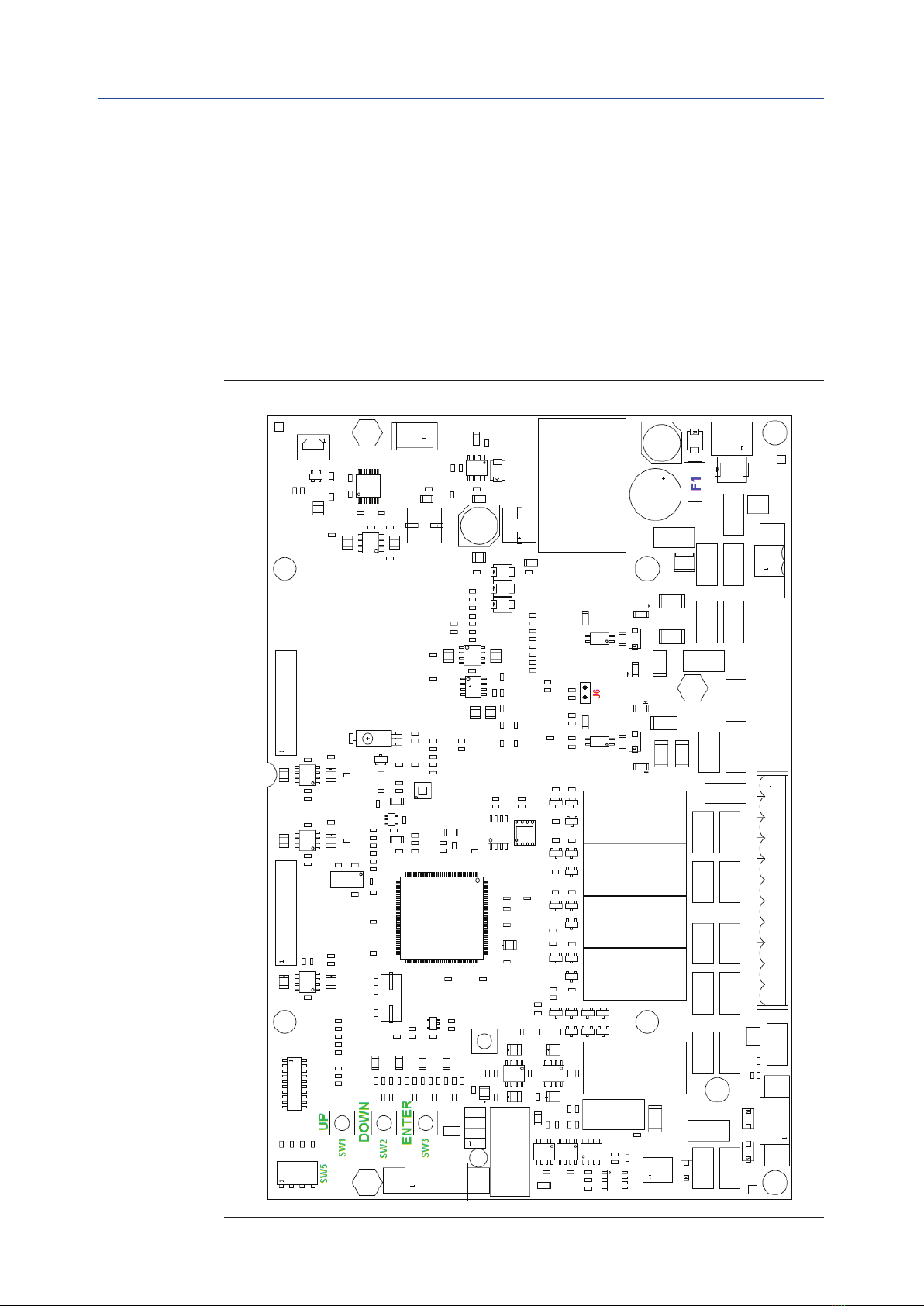

The gure below shows the Jumper Settings, the Fuse position and the Emergency

Push-buttons of the Interfaces Card.

The Jumpers of the Interfaces Card (Figure below) must be set as follows:

• J6: open

The Emergency push-buttons are:

• SW1 – UP

• SW2 – DOWN

• SW3 – ENTER

Figure 5 Interfaces Card

June 2021

Installation, Operation and Maintenance Manual

MAN712 Rev. 9

Device Description

Section 4: Device Description

12

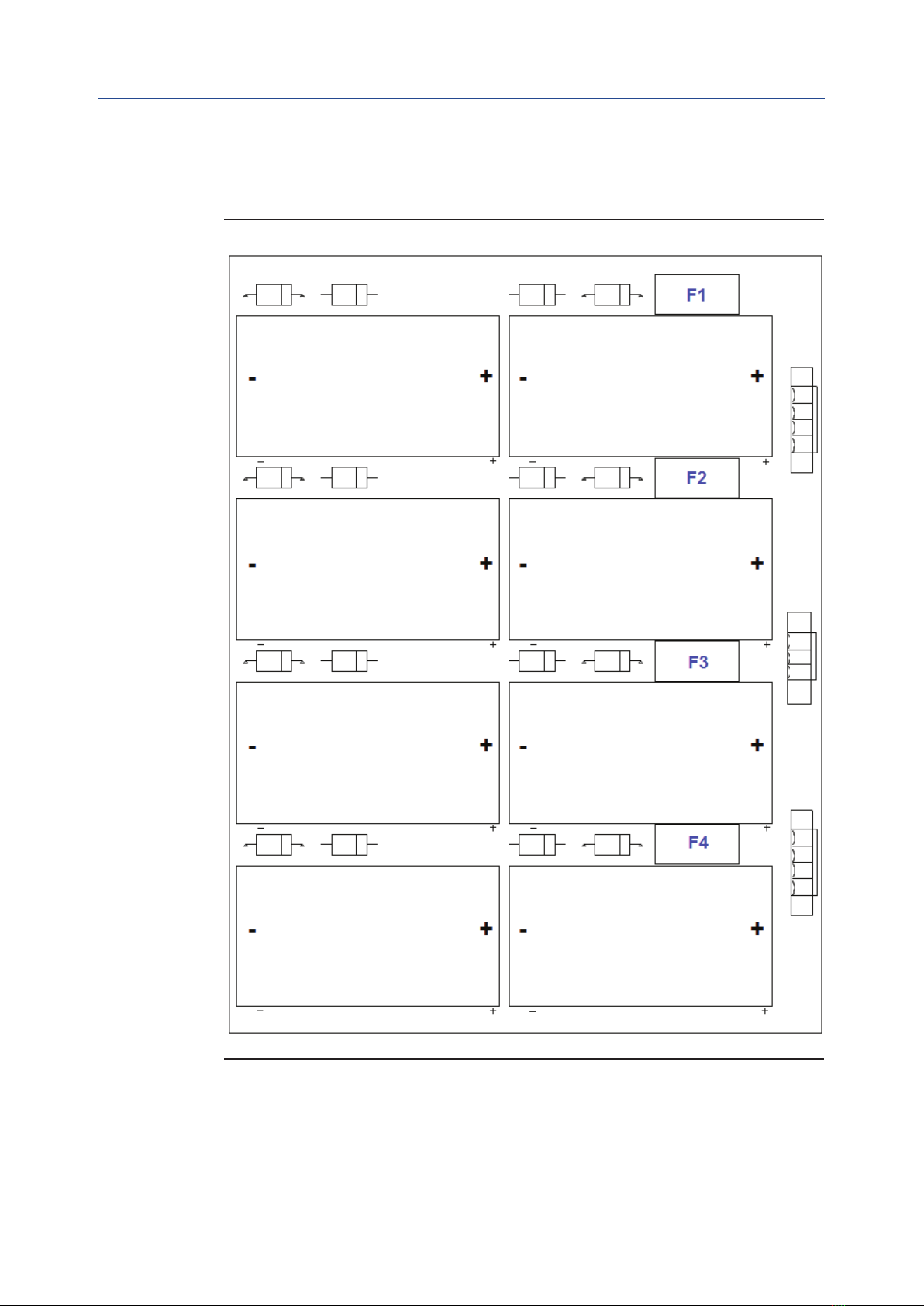

The gure below shows the Fuses position and the Battery Packs polarity of the Battery

Pack Card.

Figure 6 Battery Pack Card

BP1

BATTERY PACK DEFAULT

BP2

BATTERY PACK DEFAULT

BP3

BATTERY PACK DEFAULT

BP4

BATTERY PACK DEFAULT

BP5

BATTERY PACK AUXILIARY

BP6

BATTERY PACK AUXILIARY

BP5

BATTERY PACK AUXILIARY

BP6

BATTERY PACK AUXILIARY

Installation, Operation and Maintenance Manual

MAN712 Rev. 9 June 2021

Device Description

Section 4: Device Description

13

4.3 Technical Specications

Table 2.

External Power Supply

Supply Voltage Range 19.2 V DC - 57.6 V DC

(24 V DC -20% - 48 V DC +20%)

Std Current Consumption without sampling and

display ON (Sleep Mode or during Safety Action) (1) 70 mA - 24 V DC, 40 mA - 48 V DC

Std Current Consumption during sampling (2) 135 mA - 24 V DC, 65 mA - 48 V DC

Additional RL1 Current Consumption 20 mA - 24 V DC, 10 mA - 48 V DC

Additional RL2 Current Consumption 20 mA - 24 V DC, 10 mA - 48 V DC

Additional SVC2 Current Consumption

(100 mA Output) 200 mA - 24 V DC, 100 mA - 48 V DC

Additional AO Current Consumption (3) 60 mA - 24 V DC, 30 mA - 48 V DC

Additional MODBUS Current Consumption 20 mA - 24 V DC, 10 mA - 48 V DC

Additional RS485 Current Consumption 20 mA - 24 V DC, 10 mA - 48 V DC

Additional Bluetooth Current Consumption 20 mA - 24 V DC, 10 mA - 48 V DC

Maximum Current Consumption (4) 570 mA - 24 V DC, 290 mA - 48 V DC

Galvanic Insulation from Logic Yes

Battery Pack Power Supply

Battery Pack Nominal Supply Voltage 7.2 V DC

Single Cell Nominal Voltage 3.6 V DC

Single Cell Nominal Capacity 13.0 Ah or higher

Single Cell raccomended continuos current 1800 mA or higher

Single Cell raccomended operating temperature from -55 °C to +85 °C or wider

Battery cell type Li-SOCl2

Interval of Battery Pack replacement (5) max. 1 year (without Auxiliary Battery Pack)

max. 2 years (with Auxiliary Battery Pack)

Analog Input (Pressure and Position Sensors)

Pressure Range 10 – 1000 bar

Sensor Signal Output 4 - 20 mA or 0 - 20 mA (2 or 3 wires)

Supply Voltage (to each sensor) 14.3 – 14.8 V DC (6)

Supply Current (to each sensor) up to 25 mA

Internal Resistor (AI1 – Pressure Sensor) 119 ohm

Internal Resistor (AI2 – position Sensor) 102 ohm

Sensor Set-up Time max. 10 ms

Galvanic Insulation from Logic Yes

Digital Inputs

Allowed Voltage (”C” and “24/48” contacts) 19.2 - 57.6 V AC/V DC (24 -20% - 48 +20%)

Current Consumption (”C” and “24/48” contacts) min. 2.0 mA - max.11 mA

Allowed Voltage (“C” and “110” contacts) 99 – 132 V AC/V DC (110 -10% - 120 +10%)

Current Consumption (“C” and “110” contacts) min. 2.3 mA – max. 3.3 mA

Galvanic Insulation from Logic Yes

June 2021

Installation, Operation and Maintenance Manual

MAN712 Rev. 9

Device Description

Section 4: Device Description

14

Digital Outputs (SPST and DPST Relay Contacts)

Maximum allowed Voltage up to 120 V AC ± 10% and up to

110 V DC ± 10%

Maximum switching power

(resistive load)

up to 1 A – 120 V AC

up to 1 A – 30 V DC

up to 1 A – 48 V DC

up to 0.15 – 110 V DC

Galvanic Insulation from Logic Yes

Analog Output

Feedback Signal Pressure or Position

Output Current Range 4 - 20 mA

Maximum Load (cable+resistor) 300 ohm

Internal Power Supply Voltage 24 V DC

External Power Supply Voltage 21.6 - 26.4 V DC – max 25 mA

Galvanic Insulation from Logic Yes

SOV Control Outputs (RL1 and RL2)

Maximum allowed Voltage up to 120 V AC ± 10% and up to

110 V DC ± 10%

Maximum switching power

up to 1 A – 120 V AC

up to 1 A – 30 V DC

up to 1 A – 48 V DC

up to 0.15 – 110 V DC

Galvanic Insulation from Logic Yes

SOV Control Outputs (SVC1 and SVC2)

Output Voltage 22.5 – 24.2 V DC

Maximum Output Current 100 mA

Galvanic Insulation from Logic Yes

MODBUS RTU

Transmission Technology RS485

Baud rate (congurable) 600, 1200, 2400, 4800, 9600, 19200, 38400 bps

Parity Bit (congurable) Even, Odd, None

Stop Bit (according to Parity Bit) 1, 2

Galvanic Insulation from Logic Yes

RS485 (Conguration Port)

Baud rate 19200 bps

Parity Bit Even

Stop Bit 1

Hardware ow control Off

Galvanic Insulation from Logic Yes

Distance (cable length) (7) Max. 1000 meters

Table of contents