IKALOGIC SP259 Series User manual

SP259 series datasheet and user manual

SP259 and SP259i 9 channels, 250 MSPS logic analyzer with industrial

inputs option

www.ikalogic.com | support@ikalogic.com

August 31, 2023

SP259 Series User Manual SP259 / SP259i

Contents

SP259 Series overview 4

Embeddedmemory ....................................... 4

Evolution from older SP209 series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Typicalapplications ....................................... 5

Producthighlights ........................................ 6

Warning 7

SP259 system architecture 8

Main characteristics 10

Operatingconditions....................................... 10

Timingandmeasurements.................................... 10

Logicinputsspecifications.................................... 10

Powerrequirements ....................................... 10

SP259(i) Interfaces 11

Industrial ports (SP259i version only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Principle of operation 12

Embeddedmemoryvsstreaming ................................ 12

Versatiletriggersystem...................................... 12

Flexitrig®timingperformances.................................. 13

External trigger OUT specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

External trigger IN specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Industrial port (SP259i only) 14

RS485receiverspecifications .................................. 15

RS232receiverspecifications .................................. 15

CANreceiverspecifications.................................... 15

LINreceiverspecifications .................................... 16

What’s in the box 17

Unpacking and first usage 17

StatusLEDsbehavior....................................... 17

SowareQuickStartguide.................................... 17

Capturingyourfirstsignal .................................... 18

(c) Ikalogic SAS 2023 2/26

SP259 Series User Manual SP259 / SP259i

Mechanical data 18

ModelSP259i ........................................... 19

ModelSP259 ........................................... 20

Probes............................................... 21

Soware technical requirements 22

Ordering information and customer support 22

Accessories and maintenance 22

Certifications and regulations 22

Safety information 24

Symbolsdefinitions ....................................... 24

Importantsafetynotes...................................... 24

Limited warranty & limitation of liability 25

Document Revisions 26

(c) Ikalogic SAS 2023 3/26

SP259 Series User Manual SP259 / SP259i

SP259 Series overview

SP259 series logic analyzers and protocol decoders oer in depth analysis of logic signals and protocols

with 250MHz (4ns) timing resolution. 9-channel operation allows 8-bit parallel data to be captured

along with a clock or strobe signal. SP259 series logic analyzers connect to a computer via a USB3

interface to configure the device and to visualize captured data.

SP259 Series is composed of two devices, SP259 and SP259i. Both oer 9 logic inputs, but

SP259i integrates industrial receivers for CAN, LIN, RS232 and RS485 buses.1

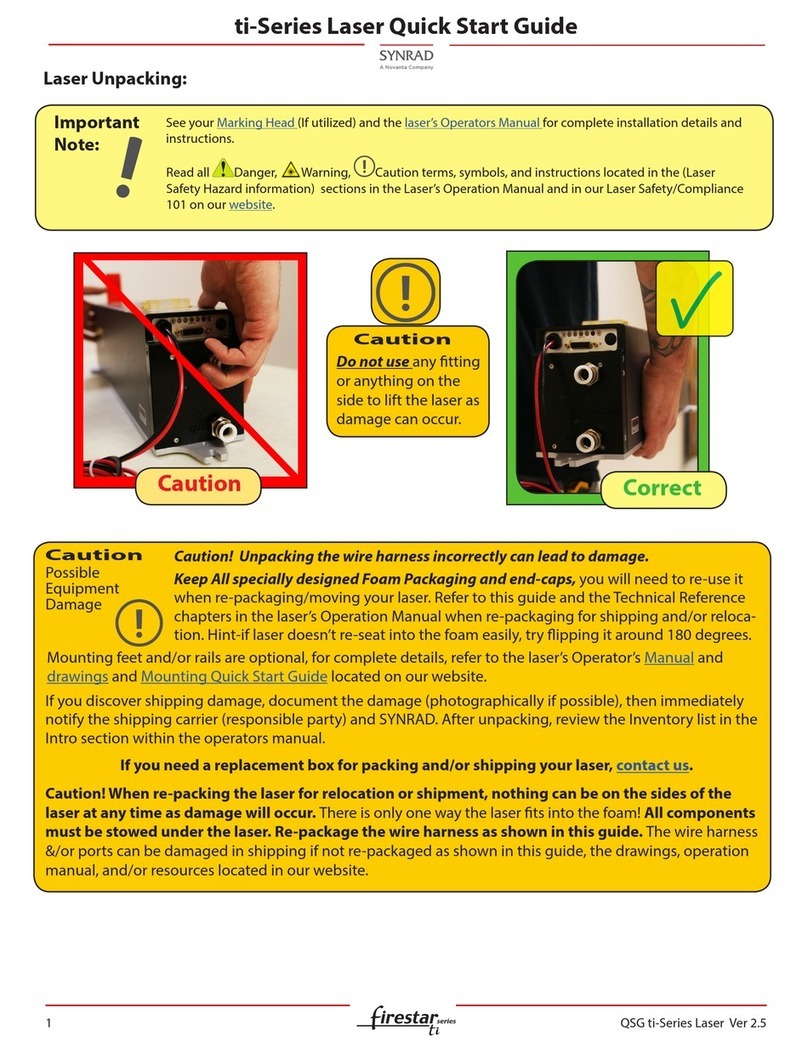

Figure 1: SP259 Logic Analyzer

Figure 2: SP259i logic analyzer (industrial version)

Embedded memory

SP259 series logic analyzers feature a 1Gb HyperRAM memory running at 4Gbps and is used to store

compressed samples before streaming to host computer. This embedded memory ensures uninter-

rupted captures of high frequency signals for long period of time without needing any reliance on host

computer performances.

1Industrial receivers in the SP259i are multiplexed with one or more of the existing 9 logic channels

(c) Ikalogic SAS 2023 4/26

SP259 Series User Manual SP259 / SP259i

Evolution from older SP209 series

SP259 are meant to replace and superceed older SP209 series of logic analyzers. SP259 devices have

all the features found in older SP209 devices, and have the following enhancements:

New SP259 Series Older SP209 series

250MHz maximum sampling frequency 200MHz maximum sampling frequency

Adjustable sampling frequency Sampling frequency fixed at 200MHz

USB3.0 interface USB2.0 interface

Fine adjustment of Threholds for input frontend Only 3 fixed thresholds

Typical applications

SP259 series logic analyzers are perfectly adapted for demanding applications, where it is needed to

capture logic signals with maximum time resolution on all 9 channels for long periodes of time.

•Embedded systems debugging

•Research and education

•Serial protocols analysis, like I2C, SPI, UART or 1-Wire (non exhaustive list)

•Industrial bus analysis: RS232, RS485, CAN, LIN

•ADC and DAC system diagnostic

(c) Ikalogic SAS 2023 5/26

SP259 Series User Manual SP259 / SP259i

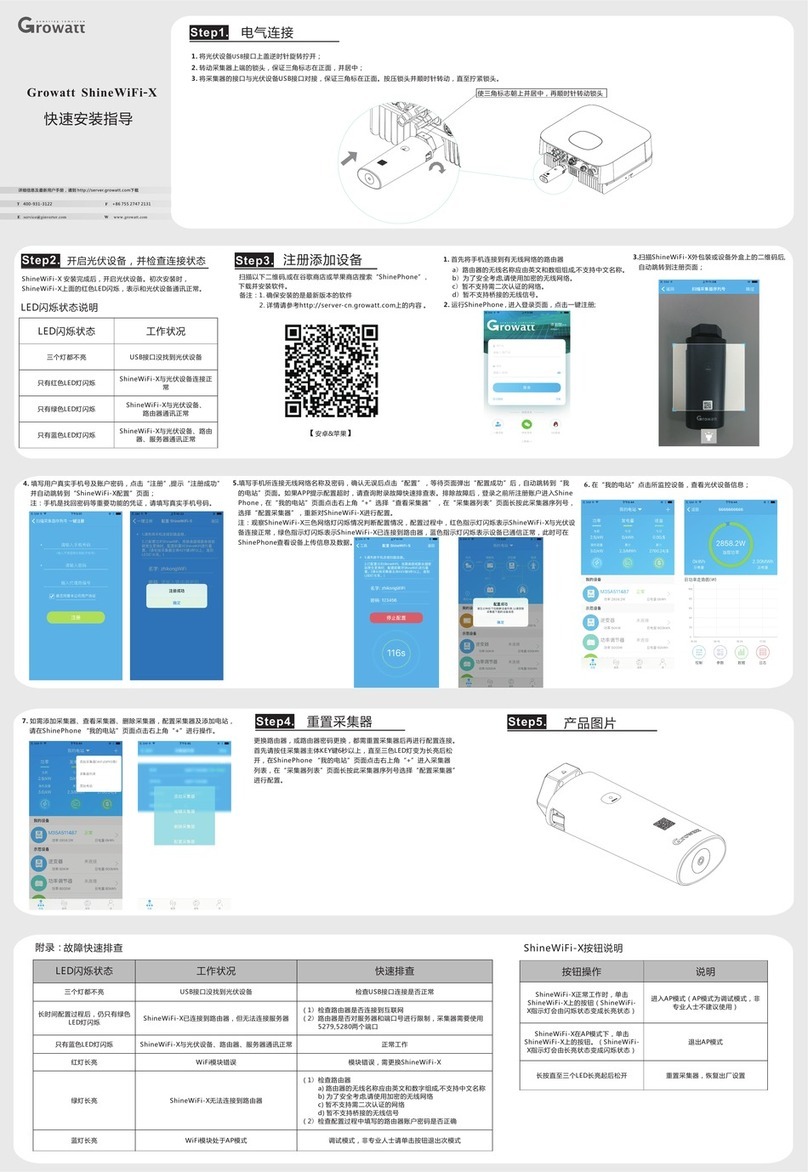

Figure 3: Example of logic signals captured and analyzed by SP259 logic analyzer

Product highlights

•Schmitt trigger input stages with adjustable thresholds (fine tunable)

•250 MHz maximum sampling rate, with all 9 channels used.

•External clock option (state mode), up to 62.5MHz

•Precise trigger-In and trigger-Out signals on dedicated SMA ports

•USB3 interface for fast data visualization on host computer

(c) Ikalogic SAS 2023 6/26

SP259 Series User Manual SP259 / SP259i

SP259 system architecture

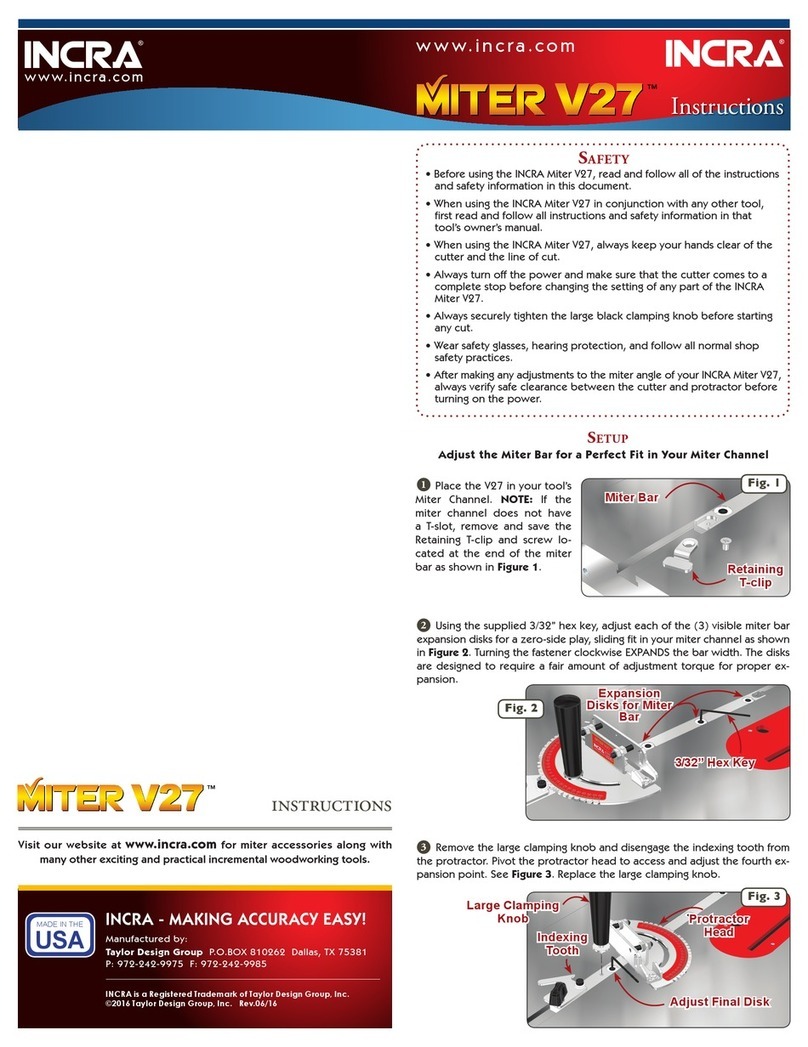

A functional SP259 measurement system consists of several main components that are presented in

the image below.

3

4

1

2

GND

9

8

7

6

5

4

3

2

1

Figure 4: SP259 system architecture

The main labeled components are:

1.

SP259 main host unit that contains the main memory buer and the processing power to capture

and compress signals before sending them over USB.

2. Type A to Micro USB3.0 Cable, 1 meter.

(c) Ikalogic SAS 2023 8/26

SP259 Series User Manual SP259 / SP259i

Main characteristics

Operating conditions

Temperature 10°C to 40°C

Relative humidity < 80% non condensing

Altitude < 2000m

Timing and measurements2

Sampling rate (MAX.) 250 MSPS

External clock Max rate (State mode) 62.5 MHz

Logic Inputs digital bandwidth 75 MHz

Embedded memory 1 Gb

Trigger output Yes, via SMA connector

External trigger input Yes, via SMA connector

Logic inputs specifications

Number of channels 9

Input impedance 200 KΩ|| 8 pF

Threshold circuits 3

Adjustable logic level (Fine tunable with 100mV

steps)

1.1 to 5V

Absolute max voltage on digital inputs

(Continuous or Transient)

±25 V

Power requirements

2HyperRAM sampling memory is used to buer samples before streaming to host computer.

(c) Ikalogic SAS 2023 10/26

SP259 Series User Manual SP259 / SP259i

Input power connector Micro USB 3.0 female

Input current 200 mA

Input voltage 5 V ±0.5 V

SP259(i) Interfaces

SP259(i) logic analyzer ports and interfaces are shown in the diagram below:

1

234

234

6

Figure 5: SP259i ports and interfaces

1. Status LED

2. 9-CH logic probes input

3. Trigger OUT SMA connector

4. Trigger IN SMA connector

5. USB 3.0 (micro-B) port.

6. Industrial port 3

Industrial ports (SP259i version only)

All industrial ports are 3.5mm plugable terminal blocks headers (Wurth Reference 691322110003 or

equivalent). Compatible plugable terminal blocks are provided in the package (Wurth Reference

691361100003 or equivalent).

Read Industrial ports section for detailed information about industrial ports in SP259i devices.

3Only on SP259i (industrial) version.

(c) Ikalogic SAS 2023 11/26

SP259 Series User Manual SP259 / SP259i

Principle of operation

SP259 Series logic analyzers connects to a computer via a USB cable. A free soware - called ScanaStu-

dio - is used to configure the device and display captured signals. The soware can also be used to

further analyze the captured samples by decoding protocols like I2C, SPI or UART.

Embedded memory vs streaming

USB based logic analyzers (ones that don’t have a display and rely on a computer for that matter)

usually operate according to one of two schemes:

•

Using an

embedded memory

to store captured samples. Samples are later downloaded at a

slower speed via the USB interface. This has the advantage of not being limited by USB transfer

rate, but has the disadvantage of limited embedded memory.

•Streaming

captured samples over the USB connection, at the maximum possible speed. While

this oers the advantage of a virtually unlimited memory (only limited by host computer’s

memory), it has the disadvantage of limiting the sampling rate to USB’s throughput.

SP259 combines the advantages of both streaming and embedded memory techniques. An embedded

1Gb HyperRAM memory stores captured and compressed samples at 250 MHz sampling rate on all

channels, while a USB interface transfers the data simultaneously, eectively emptying the embedded

memory and making more room for new samples. This results is a logic analyzer that can capture

dozens of minutes of logic signals activity on 9 channels at 250 MSPS.

Versatile trigger system

SP259 series oer a state of the art trigger system. It’s composed of two FlexiTrig

®

trigger engines, each

FlexiTrig engine can be used in one of those modes:

•Edge trigger

•Pulse trigger (with minimum and maximum pulse width)

•Timed logic sequence

•Protocol based trigger (e.g. I2C bus address or serial UART character)

•External trigger source

Furthermore, the two trigger engines (called A and B hereaer) can be cascaded in one of the following

modes:

•A then B (Wait until A triggers then arm B trigger engine)

•B then A

•A and B (Trigger engines A and B must trigger, but in any order)

(c) Ikalogic SAS 2023 12/26

SP259 Series User Manual SP259 / SP259i

•A or B (whoever triggers first)

Finally, an external trigger output is always active, in all modes and generates a trigger pulse whenever

a trigger condition is met and a capture starts. Signal specifications for External trigger input and

output are detailed in the following section.

Flexitrig®timing performances

Flexitrig®oer the following timing performances:

•Edge or Logic level trigger: Maximum signal frequency is 62.5MHz

•Protocol based trigger or Timed logic sequences: Maximum signal frequency is 25MHz

External trigger OUT specifications

Figure 6: External trigger OUT timings

There is an internal data path delay of 20ns before external signals reach internal trigger engine (T0).

When trigger event occurs, 10ms (T2) pulse is generated on the Trig Out port. This port has a 50

Ω

series

impedance allowing easy interfacing to 50

Ω

input devices. This can be used to synchronise the capture

with other equipment like an oscilloscope. Polarity of the trigger can be set in soware. There is also a

(c) Ikalogic SAS 2023 13/26

SP259 Series User Manual SP259 / SP259i

10 ns delay (T1) between internal trigger detection and Trig Out assertion. Therefore, the total time for

an external event to generate a Trigger OUT pulse is T0+T1 = 30ns.

External trigger IN specifications

Figure 7: External trigger IN timings

The Trig In port allows to start acquisition on an external event generated by another instrument. The

minimum pulse width (T1) is 8ns. Polarity can be set in soware. The input impedance is also soware

selectable (100k Ωor 50 Ω). The threshold level is 0.4V. T2, the time between external trigger in active

edge and internal trigger engine assertion is 20ns.

Industrial port (SP259i only)

SP259i oer the possibility to connect directly to industrial buses, as opposed to logic channels which

can only be connected to single ended logic level such as LVCMOS or LVTTL. Each one of the industrial

inputs integrates a dedicated receiver circuit, perfectly adapted to each standard. For more reliability

in an industrial context, each bus receiver is exposed via screw terminals. Adequate wires (6-30 AWG)

should be used to connect SP259i to the bus being probed

4

. Industrial receivers oer the advantage of

visualizing exactly what a standard o-the-shelf transceiver would receive if connected to that bus.

The list of the industrial inputs is detailed below:

4Wires to connect SP259i to industrial buses are not provided.

(c) Ikalogic SAS 2023 14/26

SP259 Series User Manual SP259 / SP259i

•CAN bus receiver

•2x RS485 bus receivers (can be combined to form a full duplex RS422 bus receiver)

•2x RS232 receivers

•LIN bus receiver

Please refer to the marking on SP259i casing for exact pinout.

RS485 receiver specifications

Transceiver MPN MaxLinear XR33180

Maximum baudrate 50 Mbps

Common Mode Operating range -7 V to +12 V

Common Mode Input Impedance 48 k Ω|| 10 pF

Common Mode voltage (absolute maximum) ±15 V

Dierential Threshold voltage -125 mV

Dierential Fixed hysteresis 25 mV

Dierential Input Impedance 400 k Ωor 120 ΩSoware selectable

RS232 receiver specifications

Transceiver MPN Maxim MAX3180

Max. baudrate 1.5 Mbps

Operating range ±15 V

Input Impedance 5 kΩ|| 50 pF

Absolute max voltage ±20 V

Threshold voltage 1.5 V

Hysteresis 300 mV

CAN receiver specifications

Transceiver MPN Microchip MCP2542

CAN FD compatible Yes (11898-2:2015)

(c) Ikalogic SAS 2023 15/26

SP259 Series User Manual SP259 / SP259i

Max. baudrate 8 Mbps

Common Mode Operating range ±12 V

Common Mode Input Impedance 6 to 50 kΩ|| 20pF

Common Mode Absolute max voltage ±24 V

Dierential Mode Operating range -4 V to +9 V

Dierential Threshold voltage 700 mV

Dierential Fixed hysteresis 30 mV to 200 mV

Dierential Input Impedance 25 kΩ|| 20 pF or 120 ΩSoware selectable

LIN receiver specifications

Transceiver MPN Infineon TLE7257

Main specification ISO 17987-4

Max. baudrate 20 kbps

Operating range (BAT pin) 6 V to 18 V

Operating range (RX pin) 0 V to 18 V

RX pull up resistance (to BAT) 40 kΩ

Absolute max voltage (BAT) ±24 V

Absolute max voltage (RX) ±24 V

Threshold voltage 0.5 x VBAT

Hysteresis 0.12 x VBAT

Please note that SP259i can still only capture 9 channels simultaneously. Industrial inputs are

internally multiplexed with logic inputs.

It is recommended to always connect the ground of the industrial bus being measured to the ground

screw terminal (Refer to marking on SP259i casing for industrial connector pinout).

(c) Ikalogic SAS 2023 16/26

SP259 Series User Manual SP259 / SP259i

What’s in the box

SP259 series is shipped with the following items:

1. SP259(i) device

2. Micro USB3.0 cable (micro-B to A)

3. 10 leads hook-style probes set (9 signals + 1 ground)

4. SMA anti-dust covers

5.

5 Pluggable terminal blocks, Wurth reference 691361100003 or equivalent (for SP259i version

only)

Unpacking and first usage

We recommend the user to start by identifying all the dierent components that are provided. To turn

ON the SP259 device, connect it to a free USB port of your computer using the provided USB cable

5

.

The LED should glow according to the table in the “Status LEDs behavior” section. To switch o the

device, simply disconnect the USB cable.

Status LEDs behavior

Status led can be in one of 3 states:

Status LED Meaning

Orange Device initializing

White Fix Device powered up.

White blinking Device powered up, and detecting activity on one of the logic channels.

Soware Quick Start guide

Start by downloading the latest version of ScanaStudio soware www.ikalogic.com and following

instructions to install both soware and provided drivers. It is recommended to restart your computer

aer the soware and drivers have been installed.

5Do not connect SP259 to anything else than a computer’s USB port. Do not connect to a USB HUB, but connect directly

to the root USB port. Never connect the SP259 to a USB charging adaptor.

(c) Ikalogic SAS 2023 17/26

SP259 Series User Manual SP259 / SP259i

Once the soware is installed, run it, and create a new workspace by selecting “SP259” or “SP259i” as

the device type.

Note

: if at the point the device is not recognized by your computer, the ScanaStudio workspace

is created as a demo workspace or the status LEDs stays orange even aer creating a ScanaStudio

workspace, please follow these steps:

•Ensure the USB port used is USB3 compatible and can deliver at least 250mA.

•Try switching to another machine if one is available.

•If all of the above fails, please contact Ikalogic support.

Capturing your first signal

To capture your first logic signals, please follow these steps:

1. Connect the device via USB

2. Launch ScanaStudio and create an SP259(i) workspace.

3. Connect the probes to SP259(i) and to your signals source

4. Ensure the ground probe is connected

5.

Check if the status LED is blinking: if it’s the case, it means the some logic changes are already

being detected on the probes.

6. Hit the start button in ScanaStudio and wait until signals are captured.

You can adjust the capture duration by adjusting the number of samples in the device configuration

tab.

Mechanical data

All SP259 series devices casing are manufactured from anodized aluminum, able to withstand heavy

duty usage in various harsh environments. All markings are laser engraved, ensuring important pinout

information is not lost over time.

(c) Ikalogic SAS 2023 18/26

This manual suits for next models

2

Table of contents

Other IKALOGIC Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Evoqua

Evoqua WALLACE & TIERNAN DEPOLOX 5 E instruction manual

National Instruments

National Instruments 9775 Getting started guide

LaserLiner

LaserLiner DistanceMaster operating instructions

Keysight Technologies

Keysight Technologies N5241BU-677 installation guide

Bosch

Bosch Zamo manual

Leica

Leica Rugby 640G quick guide