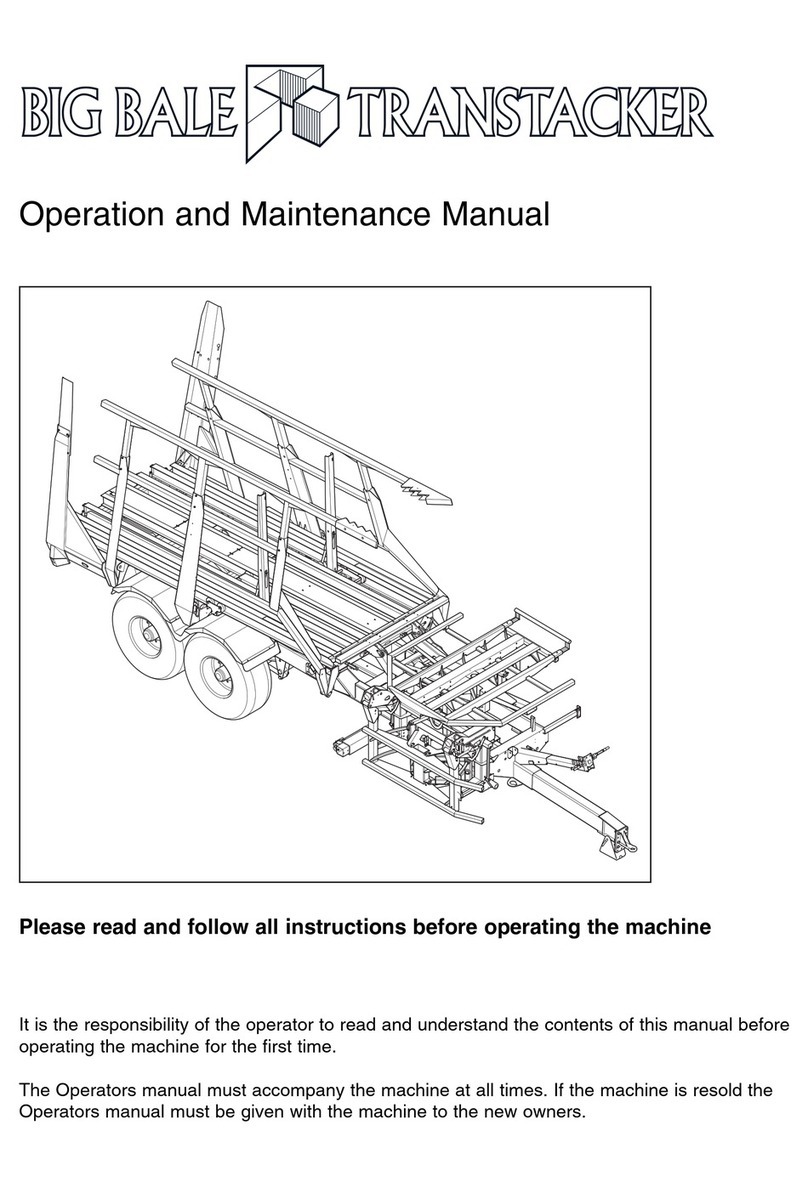

BIG BALE Transtacker 4100 User manual

Operation and Maintenance

Manual Transtacker 4100

Please read and follow all instructions before operating the machine

It is the responsibility of the operator to read and understand the contents of this manual

before operating the machine for the first time.

The Operators manual must accompany the machine at all times. If the machine is resold

the Operators manual must be given with the machine to the new owners.

Contents

Page

Title

1.0 Introduction …………………………………………………………………………….. 1

Description ……………………………………………………….... 1

……………………………………. 1

……………………………….. 1

………………………………. 1

………………………………. 2

……………………………………………….. 2

1.1

1.2

1.3

1.4

1.5

1.6

1.7

SAFETY ALERT SYSMBOLS

Machine Identification Plate

Intended Use of the Machine

Construction and Use Act UK

Noise Declaration

Accessories and Attachments ……………………………… 2

2.0 …………………………………………………………………………….. 2

3.0 …………………………………………………………………… 3

4.0

Specification

Machine Overview

Safety ………………………………………………………………………………………. 4

4.1 Safety in Operation & Maintenance ……………………. 4

5.0 Operation ………………………………………………………………………………….6

5.1 Attachment to the Tractor ………………………………….. 6

5.2 Hydraulics …………………………………………………………… 6

5.3 PTO (Power Take-Off) …………………………………………. 6

5.4 Electrical ……………………………………………………………… 7

5.5 Joystick Functions ……………………………………………….. 8

5.6 Screen Functions ………………………………………………… 9

5.7 Auto Function ……………………………………………………… 10

5.8 …………………………………. 12

5.9

Erecting a Complete Tower

Placing Towers Against Existing Towers ………………. 13

5.10 Erecting a Part Load Tower …………………………………. 14

5.11 Re-Picking a Complete Tower ……………………………… 15

5.12 Getting started Manually ……………………………………. 17

5.13 Pickup Manual With Grab Arm ……………………………. 17

5.14 Stacking (Automatic) …………………………………………… 19

5.15 Stacking Without Tie (Manual) ……………………………. 20

5.16 Stacking Tie (Manual) …………………………………………. 21

5.17 Finishing a Stack …………………………………………………. 23

5.18 Operation as a Bale Transporter …………………………. 23

6.0 Adjustments ……………………………………………………………………………. 24

6.1 ……….…………………………………………….. 24

6.2 ………………………………………. 25

6.3

Pickup Height

Fork Cable Adjustments

Turntable Bale Stop …………………………………………….. 25

6.4 ….………………………………………………….. 26

6.5 ………………………………………………………… 26

6.6

900mm Stop

Pickup Tines

Pickup Shoe …………………………………………………………. 26

6.7 ………………………………………….. 27

6.8

Grab Arm CTF Paddle

Proximity Sensors ……………………………………………….. 27

Turntable - Middle ……………………………………. 28

……………………………….…… 28

………………..………………….. 29

6.8.1

6.8.2

6.8.3

6.8.4

Turntable – Extend

Gates Open LH/RH

Tip Bed Up Partial ……………………………………... 29

6.9 Rotary Sensors ……………………………………………………. 30

6.10 Adjustable Stop on Grab Arm and Turntable Rotate …… 31

6.11 Pressurizing the Bump Paddle …………………………..… 32

6.12 Guide Bar Wear Pads ……………………………………….…. 32

6.13 Pulley Beam Trolley Wear Pads …………………………… 33

6.14 Fork Trolley Stops ……………………………………………….. 33

6.15 Removal of Side Gate Safety Pins ……………………….. 33

7.0 Diagnostics / Settings ………………………………………………………………. 34

……………… 34

……………….. 34

…………………… 34

……… 35

…………………. 35

7.1

7.2

7.3

7.4

7.5

7.6

Diagnostics Page 1 – Proximity Sensors

Diagnostics Page 2 – Pressure Sensors

Diagnostics Page 3 – Rotary Sensors

Setting Page 1 – Rotary Transducers Address

Setting Page 2 – Valve Demand Rates

Setting Page 3 – Demand/Angle Curves ………………. 35

Contents

Page

Title

Setting Page 4 – Pressure Transducer Address …… 35

Setting Page 5 – Settings …………………………….………. 35

7.7

7.8

7.9 Bale Counter ……………………………………………………….. 36

8.0 Trouble Shooting ……………………………………………………………………… 37

…………………………………… 37

…………………………………………………………………. 37

………………………………………………………………. 37

………………………………………… 38

…………………………………………………. 38

………………………………….. 39

……………………………………. 39

………………………………… 40

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.8

8.9

Connecting to the Tractor

Pickup

Stacking

Initial Troubleshooting

Sensor Error Log

Hydraulic Troubleshooting

CAN Bus Troubleshooting

Auto Open Troubleshooting

Auto Pickup Troubleshooting ……………………………… 42

8.10 Auto Stack Troubleshooting ………………………………...44

8.11 Auto Tip Bed Down Troubleshooting …………………… 46

8.12 Auto Tip Bed Up Troubleshooting ……………………….. 47

9.0 Tips and Information ………………………………………………………………… 48

……………………………………….….. 48

……………………………………………….. 48

……………………………………………...... 49

9.1

9.2

9.3

9.4

Side by Side Stacking

Stacking Off Stack

Extra Pickup Bale

Adding Layer Count …………………………………………….. 49

10.0 Electrical System ………………………………………………………………………. 50

10.1 Electrical System Structure …………………………………. 50

10.1.1 CAN Bus Structure …………………………………….. 51

10.1.2 Lighting Wiring ………………………………………….. 52

10.1.3 Transtacker Wiring Loom Layout ………………. 54

10.2 Sensor Functions ………………………………………………… 55

11.0 Hydraulic System ……………………………………………………………………… 55

11.1 Hydraulic Standby Pressure (Loading Sensing) ……. 56

11.2 General Hydraulic Information ……………………………. 56

11.3 Valve Block Details ……………………………………………… 57

11.4 Valve Block Schematic ………………………………………… 60

12.0 Electrical & Hydraulic Systems ………………………………………………….. 61

12.1 Chassis Sensor Locations …………………………………….. 61

12.2 Platform Sensor Locations …………………………………. 62

13.0 Maintenance ……………………………………………………………………………. 63

13.1 Service Schedule …………………………………………………. 63

13.2 Pickup Grease Points ………………………………………….. 64

13.3 Grab Arm Grease Points ……………………………………… 65

13.4 Turntable/A-Frame Grease Points ………………………. 66

13.5 Side Gate Grease Points ……………………………………… 67

13.6 Rear Clamps Grease Points …………………………………. 68

13.7 Chassis Grease Points …………………………………………. 69

13.8 Platform Grease Points ……………………………………….. 70

13.9 Axle Grease Points ………………………………………………. 71

13.10 Storage ……………………………………………………………….. 72

13.11 Dismantling and Disposal ……………………………………. 72

………………………………………………………………………………….. 72

………………………………………………………………………………. 73

14.0 Warranty

15.0 Error Codes

16.0 Operator Notes ………………………………………………………………………… 81

1.0 Introduction

1.1 Description

In choosing the Big Bale Transtacker 4100 you have

purchased a machine of exceptional versatility.

This manual should be regarded as essential reading in the

interest of safety, efficiency and longevity of the machine.

References to Right and Left in this manual are taken as

viewing the machine from the rear facing in the normal

direction of travel.

1.3 Machine Identification Plate

If service parts are required it is necessary to quote the

machine serial number. This is located at the front right

hand side of the machine on top of the drawbar front

plate. It is recommended that this information be

transferred to this page on delivery of the Transtacker

4100.

Model ________________________

Serial No. ________________________

Year of Manufacture ________________________

Date of Delivery ________________________

Unladen Weight ________________________

Max Gross Weight ________________________

Max Drawbar Load ________________________

1.2 SAFETY ALERT SYMBOLS

This warning symbol appears throughout this hand book.

Attention is drawn to items or operations that could cause

danger to the operator or to persons nearby.Please read

safety messages carefully and have a full understanding of

their importance.

Always abide by the requirements.

WARNING: Warnings call attention to instructions, which

need to be followed precisely to avoid a hazardous

situation.

CAUTION: Cautions call attention to instructions, which

must be followed precisely to avoid damaging the product,

process or surroundings.

Fig. 1

1.4 Intended Use of the Machine

The Big Bale Transtacker is designed to assemble

various sized big bales, 2.4m (8') long, into completed

stacks and erect them into a tower.

The various sizes of bales must have a width or depth

which can, (when arranged side by side in some multiple),

form a rectangle that is 2.4m(8') square. Bale length is

permitted to vary considerably but to tie layers, 2.4m(8") ±

0.1 is preferred.

The machine will also recover previously erected towers

and re-erect them in a new location.

The bales can be of various straws and hays generally

found in agricultural use.

The machine is generally towed with an agricultural

tractor recommended minimum of 6 Tonnes,150 HP.

1

1.0 Introduction

1.7 Accessories and Attachments

High Speed Axles

Above 30 kph (20 mph), A.B.S. with air brakes may be

required. Air Brakes and A.B.S comes standard with the

Transtacker 4100 but needs installing into the tractor if it is

not already standard on the tractor.

It is important to note that high-speed use on highways

may be restricted by a machine width in excess of 2.55 m.

Flashing Beacon

A flashing beacon is mounted on the panel adjacent to the

number plate. These flashing beacon is attached to your

tractor side lights when the lights are fitting. When paired

in conjunction with a tractor cab top mounted unit, it

provides all round visible flashing lights (Fig. 2).

Hydraulic Sprung Drawbar

The drawbar suspension consists of 2 hydraulic cylinders

that are dampened for a more superior ride and control to

the Transtacker and Tractor. The height of the drawbar can

be adjusted by one of the spools in the tractor allowing for

more accurate bale chasing for operators who regularly

change the bale size.

2.0 Specification

Big Bale Transtacker 4100

Length 10.7m

Height 3.7m - 4.1m

Automation Automatic pick up and stack

80 x 90 x 240 - MF2150 24

120 x 70 x 240 - MF2160 20

120 x 90 x 240 - MF2170 16

120 x 127 x 240 - MF2190* 12

Unladen weight 10.32 Tonnes

Maximum Load 8.0 Tonnes (On-Road), 13 Tonnes (Off-Road)

Wheels / Tyres (+ sizes) 560/45-22.5 Flotations

Oil Type Hydraulic HV46

Electrical Supply Required 20 Amp 12V DC

Brakes 4 Wheel ABS Hydraulic & Air As Standard

Other options** Scharmuller coupling, Telematics, Drawbar Suspension,

Reversing Camera, LED Lights, Weigh Scale Kit, GPS

Tracking System.

*Including additional layer **Some options for non UK models only

Fig. 2

1.5 Construction and Use Act UK

The machine can be classed as an agricultural appliance

provided the load does not exceed its unladen weight.

1.6 Noise Declaration

Sound Pressure Level

The sound pressure level of the Big Bale Transtacker does

not exceed 70 dB (A).

2

14

1

16

1

17

211

1

12

1

8

1

7

1

6

1

3

1

1

1

10

1

9

1

2

1

13

1

15

1

5

1

4

1

Item Number Assembly Number Description Quantity

1 1.0 Chassis 1

2 2.0 Platform 1

3 3.0 Pick-Up 1

4 4.0 Guide Bar Cross Member 1

5 5.0 Grab Arm & Guide Bar 1

6 6.0 Bump Paddle 1

7 7.0 Oil Tank 1

8 8.0 Drawbar 1

9 9.0 Extension Frame 1

10 10.0 A-Frame 1

11 11.0 Turntable 1

12 12.0 Pulley Beam 1

13 13.0 LHS Side Gate 1

14 RHS Side Gate 1

15 14.0 LHS Rear Clamp 1

16 RHS Rear Clamp 1

17 15.0 Forks 2

Exploded View of the Transtacker 4100 Main Assembly Components

3.0 Machine Overview

3

4.0 Safety

4.1 Safety in Operation & Maintenance

Operation of the machine without paying heed to fitting and

use of guards or to the safety notices renders you liable to

prosecution.

This applies even if you are the injured party.

Your attention is drawn to the safety notices (decals) that are

displayed on the machine. These notices should be kept

clean and intact so they are legible at all times.

If any of the notices become detached or defaced, they must

be replaced immediately.

These are available from your local Big Bale Transtacker

agent.

They are included in the spare parts list and examples to aid

identification are reproduced on the following pages.

WARNING: Read Owners Manual

This manual contains safety information and

operation and maintenance instructions for your Big Bale

Transtacker. The operator must ensure that he/she has fully

read and understood this manual before operating the

machine.

WARNING: Before Commencing Any Repairs/

Maintenance

Shut off engine, remove ignition key, and unplug

electric control box before performing any maintenance

or repair work.

WARNING: Keep persons away from the machine during

operation. There is a danger from falling bales and moving

machinery.

WARNING: When the Guide Bar is out there is a danger

that it may be overlooked by the operator. Ensure

Transtacker is in Road Mode when traveling at high speeds.

WARNING: Do not raise the platform of the Transtacker

while under high voltage power lines. Some parts of the

machine can exceed 5.2m high and cause electrocution and/

or fire.

4

4.0 Safety

WARNING: Keep side Gate pins in place when

transporting on highways.

When traveling along roads the side clamps are subject to

variable and high loads. Failure or inadvertent operation of

the side clamps could cause very serious injury or damage

to others. Set controls to ‘Road Mode’ prior to road

transport (Fig. 5)

Failure of the hydraulic lines is covered by the load valves

attached to the clamp and lift cylinders. Road Mode should

be used during transport to prevent inadvertent operation.

The safety pins provide a necessary and useful further

safety device should there be a failure of the cylinder.

WARNING:

Take care when operating on sloping ground or when

traversing undulations at speed to prevent overturning of

the stacker. By necessity the machines have a high centre

of gravity when loaded. Caution should always be exercised

to prevent overturning and resulting injury and/or damage.

When picking up bales on sloping ground, always traverse

the slope so that the bales are picked up from the high

(right hand) side.

WARNING: If at any times you need to stop the machine

during one of its auto functions, press the E-Stop button

located by the side of your Transtacker screen (Fig. 5).

Fig. 5

5

5.0 Operation

5.1 Attachment to the Tractor

Requirements

The drawbar is normally supplied with a ring hitch, which is

suitable for connection to the pickup hitch found on most

tractors in the UK. Ensure that your tractor hitch is suitable

for this type and dimension of ring. Ensure the capacity is

a minimum of 3 Tonnes. Additionally, the recommended

minimum horsepower is 150HP+ and 6 Tonnes weight.

With a 540RPM PTO.

Minimum electric supply of 30 Amps @ 12v DC are

required.

2 double acting spools for the Drawbar (If fitted) and the

bump paddle (Standard).

Attaching

Hitch the tractor to the machine. Remove and store the

drawbar stand and pin on the middle left hand chassis rail.

The machine should now sit approximately level at the

chassis.

Connect the Air or Hydraulic brakes to the tractor and

ensure correct operation.

Release the hand brake (Fig. 6), which is under the middle

left of the chassis, and obtain assistance to check the

operation of the trailer brake cylinders when the brake

pedal is depressed.

Ensure the tractor lighting voltage is 12v DC before

connecting the lights.

Connect the lights via the 7-pin plug stored centre of the

service post and confirm correct operation.

Turn the tractor cautiously and ensure the tractor links etc

do not foul on any part of the machine and that there is

sufficient clearance for hoses etc. Remove links if

necessary. Big Bale will not be responsible if the operator

turns to tight and damages the machine or any component.

Clean the connectors and the tractor ports before the

hydraulic hoses are connected.

Tractor connections consist of 4 hoses. See below

for details:

Hose 17 - Drawbar Raise - 3/8" Hose

Hose 18 - Drawbar Lower - 3/8" Hose

Hose 117 - Bump Paddle Decrease - 1/2" Hose

Hose 118 - Bump Paddle Increase - 1/4" Hose

Please ensure that the above connections to the

tractor's power beyond unit are made in accordance with

your Tractor Manufacturers Instructions and Guidelines.

5.2Hydraulics

Fig. 6

5.3

WARNING: Oil under pressure can penetrate skin. Seek

medical advice involving any incident where this may occur.

Oil is an irritant. Wear protective gloves when handling.

CAUTION: Ensure the tractor will supply at least 60 L/min

@ 200 bar (8.79 Gallons/min (UK) @ 2900 psi and does not

exceed 80 L/min (17.6 Gallons/min (UK)).

Set the flow at 40-50 L/min. (8.79 - 11.0 Gallons/min (UK)).

WARNING: Component failure hazard.

Injury or machine damage can occur.

The lock mechanism of the quick disconnect yoke must be

in the groove on the shaft. Pull on the yoke after installation

to make sure that the yoke will not pull of the shaft.

A yoke that is not installed correctly can slip off a shaft and

result in personal injury, or damage to the machine.

Lubricate the splines of the PTO with oil or grease to help

prevent wear of the splines. Pull the lock collar of the

quick disconnect yoke to the rear. Place quick disconnect

yoke onto the PTO until the yoke makes a sound when the

yoke connects to the PTO. Pull on the yoke to ensure it is

connected securely. Connect the safety chain from the

implement driveline (IDL) guard to the rear of the tractor.

PTO (Power Take-Off)

6

5.0 Operation

5.4Electrical

Mounting the Control Box

Mount the Screen and Joystick securely in the tractor cab

in a position that suits you (Fig. 7).

Do not obstruct access to hydraulic levers or other

important controls;

Easy comfortable operation of the joystick and push button

switches is preferable;

Maintain good visibility of the control box lights and decal;

The operator will be most likely observing the pickup over

his right shoulder;

The seat may traverse up and down considerably on rough

ground.

When the Screen and Joystick is mounted, connect it to the

tractor electrical supply via the lead provided. Ensure that

the voltage is correct, 12v DC and that the fused wire

is positive (Fig. 8). It is recommended to connect the

lead provided straight to the tractor battery. This is pre-

fitted with a 30 amp blade fuse. Not connecting straight

to the battery can cause electrical problems and unwanted

faults.

When the Screen and Joystick is mounted and working,

switch off and connect to the machine using the multi core

cable provided. Carefully connect the cab harness end to the

machine's multi core cable that is located by the service post

on the drawbar.

Ram Mounts will be provided with both Screen and Joystick.

This allows you to securely fasten them safely to the tractor

cab. If additional fasteners are needed, contact Big Bale Co

South Ltd.

Note: Do not forget to thread any cable through the

service post and any cab entry points. Finally secure the

cable to the hydraulic hoses to prevent damage and store

surplus cable inside the cab.

CAUTION: The power should be switched off to the control

box via the emergency switch on the side of the screen

bracket, if the machine is not being used for long periods.

Connection for

screen loom

Connection for

Joystick to Display

Fig. 8

Fig. 7

Connection to Battery

Including 30A Fuse

Connection for

emergency button Loom

Cab Harness

Cab to ECU Harness

Diagnotics Connections

Ram Mount

7

5.0 Operation

5.5Joystick Functions

Fig. 9

Button Joystick position Function in Field Mode Function Stack Mode

Y+ Tip Bed Down

None Y-Auto Stack Auto Tip Bed Up

X+ Open RH Gate Open RH Gate

X- Open LH Gate Open LH Gate

Y+ Raise Pickup

1 (Yellow) Y-Lower Pickup

X+ Insert Tines Rotate CW

X- Retract Tines Rotate ACW

Y+ Auto Open Auto Tip Bed Down

2 (White) Y-Open Clamps

X+ Close RH Gate Close RH Gate

X- Close LH Gate Close LH Gate

Y+ Close Grab Arm Retract Hooks

3 (Black) Y-Open Grab Arm Open Clamps

X+ Extend Guidebar Extend Turntable

X- Retract Guidebar Lower Turntable

Y+ Fork Forward Raise Turntable

4 (Red) Y-Raise Forks Close Clamps

X+ Insert Hooks Insert Hooks

X- Retract Hooks Retract Turntable

Direction

of Travel

Y+

Y-

X- X+

3

42

1

OPS (Operator Pressure Switch)

Fig.10

Fig. 10 Note:

This trigger has to be

compressed for any function on

the joystick to work.

Fig. 11

8

5.0 Operation

5.6Screen Functions

Road Mode

Auto Mode

Field Manual

Mode

Stack

Manual Mode

Stack

Configuration

Diagnostics

Settings

Bale Count

Back / Cancel

Scroll Left

Scroll Down

Scroll Up

Scroll Right

OK / Save

Fig. 12

9

5.0 Operation

5.7 Auto Function

WARNING: Keep persons away from the machine while

operating. There is a danger from falling bales and moving

machinery.

CAUTION: When picking up the bales laid across sloping

ground, always traverse below the bale to ensure stability

of the stacking machine during pickup cycles.

Getting Started

Having entered the field, stop and set the machine ready to

operate as follows:

Fig. 13

1. First start the PTO if it is safe to do so as instructed on the

main screen (Fig.13).

2. Or exit ‘Road Mode’ by pressing and holding

Button 'Road Mode' for 3 seconds (Fig. 12).

3. Enter 'Stack Configuration' (Fig. 12) before using the

Transtacker 4100 for the first time. Or if you have changed bale

sizes (Fig. 14).

3.1. Once you have entered 'Stack Configuration', use keys D

and H to navigate to your chosen bale size (Fig. 15).

Fig. 15 Note 1

(For an example this Owners Manual will always reference to

120x90cm Bales).

3.2. Buttons B and C will move the 'White Line' that is displayed

on the screen left and right. This 'White Line' should be

positioned normally in the bottom half of the Stack (to the right

of the middle). As seen in Fig. 16. Any stack level below this

line encourages the A-Frame to push the bales to the rear and

the extension frame to extend only enough for the bales to

rotate. If the A-Frame is not able to lift fully to push the bales to

the back. Drop this level to the rear of the Transtacker to level

3. Any stack level on top of this white line, the extension frame

will extend, the A-Frame will lift to 90 Degrees and the

extension frame will then retract, pushing the bales towards the

rear (this is a longer cycle time).

3.3. Button A is for the use of the optional final layer. For

standard 120x90cm bales. This will either activate or de-

activate the 8th layer (Fig 15). This function only works on the

following bale sizes: a. 80x90cm

b. 120x90cm

c. 120x130cm

For the use of the full 6 layer with the 120x130cm bales. You

will have to 'roll' these bales onto their sides. Otherwise you will

not be able to put 6 layers on. 'Roll' these bales by using a

'Quarter Turn Chute' or a front tractor mounted turner.

3.4. Use the Left and Right arrows to highlight an individual

layer from the stack with the blue box (Fig. 16). Using the up

and down arrows (Fig. 17), this will change the stack

configuration to integrate tied or non-tied layers. The up arrow

will place a tied layer on the level the blue box is highlighted.

The down arrow will place a non-tied layer.

3.5. Once all settings of the 'Stack Configuration' is to the

users satisfaction. Press ' OK / Save' (Fig. 12). If you do NOT

want to save these settings, press 'Back / Cancel' (Fig. 12).

4. After all of the above points have been completed, refer to

section 6.0 Adjustments to correctly set up the Transtacker

to your desired bale size.

Fig. 14

Fig. 15

Fig. 16

Fig. 17

10

5.0 Operation

5.7 Auto Function Continued......

Fig. 19

4. Once 'Stack Configuration' is set up, click 'Auto Mode' (Fig. 12). This will start the

process of getting the Transtacker ready for collecting bales. The following functions

will start to open:

a. Side Gates

b. Rear Clamps

c. Guide Bar

d. Grab Arm

e. Forks Forward and Raise

f. The Pickup will drop to desire height.

Note: After these function have finished completely, the Transtacker is now 'Live' this

means that you can now start collecting bales with the following instructions. You will be

presented with the standard 'Auto Mode' screen. Here you will be able to keep track of

what layer you are on (Fig. 18).

Note: If you already have layers stacked, when you go into 'Auto Mode' it will not unfold

the machine as it needs to secure bales. For this, you need to open the above stated

functions manually, see Section 5.12 Getting Started Manually.

WARNING: Keep persons away from the machine while operating. There

is a danger from falling bales and moving machinery. 'Auto Mode' is an

automatic function and will cause injury or damage if not used correctly and

in an open space. Use 'Emergency Button' if there is any chance of

causing damage or injury (Fig. 19).

WARNING: When the machine has been activated into 'Auto Mode' and is

now 'Live', beware that if certain sensors are triggered, this may cause

areas of the Transtacker to become active and start to move. When you

are in 'Auto' mode, stay inside your tractor cab and make sure no other

personnel is standing within moving parts of the Transtacker.

Caution: It is important that the tractor engine is turning fast enough to

maintain a full flow of oil to the machine during automatic cycles. Select a

gear that is best suited to engine rpm and the distance between the bales.

There is no theoretical limit to the speed at which bales can be picked up

but damage may occur above (7.5 mph) 12kph.

Fig. 20

Fig. 21

Fig. 22

Fig. 18

Fig. 23

Fig. 24

Fig. 25

5. Drive along side the first bale. (Select a bale that is on flat ground). Drive towards

a bale aiming the bale within the 'Jaw' of the 'Grab Arm' (Fig. 20).

5.1. Drive forward until the Bump Paddle is compressed (Fig. 21). This will trigger the

'Bale Detect - Pickup' Sensor on the 'Bump Paddle' and will automatically bring in the

'Grab Arm'. The 'Grab Arm' will help put the bale parallel tight up against the

'Pickup' (Fig. 22).

6. Once step 5 has been completed, the 'Auto Mode' will proceed automatically in the

following order;

6.1. The 'Pickup Tines' will insert while the 'Grab Arm' is still closed. Once inserted,

the 'Grab Arm' will release and open.

6.2. The 'Pickup' will pick the bale and place it on the 'Turntable', where the

'Hooks' will insert allowing the 'Pickup' to return to its original position.

6.3. When the 'Pickup' has filled the 'Turntable' with the correct amount of bales. The

'Bale Detect - Turntable Full' sensor will be triggered, automatically placing the bales

on the 'Platform' according to your chosen 'Stack Configuration' (Fig. 23). The 'Side

Gates' will open and close automatically when the 'Turntable' is in motion to always

ensure that the stack on the 'Platform' is secured.

Note: When the 'Turntable' is placing the bales on the platform, while this is

functioning, you can start to pickup a 3rd bale with the pickup. The pickup will hold the

3rd bale at 90 degrees until the 'turntable' is back in its home position. Then the pickup

will automatically place the 3rd bale on the ready 'Turntable'.

6.4. For every layer that is placed onto the 'Platform', the 'Forks' will be pushed back

automatically supporting the rear end layer.

6.5. When all layers have been placed, the 'Bale Detect - Bed Full' sensor will be

triggered showing the Transtacker is full (Fig. 24) which will automatically place the

Transtacker into 'Road Mode' (Fig. 25).

Caution: For any reason you need to exit 'Auto Mode', press button F or G or H (Fig.

14). Another option would be to depress the 'Operator Pressure Switch' (Fig. 10).

Caution: Encase of an emergency in 'Auto Mode', press the 'Emergency

Button' (Fig. 19).

11

5.0 Operation

5.8 Erecting a Complete Tower

Manoeuvre the machine to the stack site. Check the

following:

A. The ground is firm and flat and not sloping excessively to

either side or forward i.e. more than 5°.

B. Check there are no overhead obstacles or power lines. It

is recommended to keep 10 meters away from power lines.

C. Check the load is still secure within the Transtacker.

D. Check there are no by-standers, animals or property that

will be damaged if any bales were to fall.

1. Press and hold button to exit ‘Road Mode' and enter

'Stack Manual Mode' (Fig. 12) if required.

2. Pull the joystick back (Fig. 26) to perform 'Auto Tip Bed

Up'. Before the 'Platform' starts to raise, the Transtacker will

automatically lower your forks and bring them to the front.

The 'Platform' wont raise until the left and right 'Forks

Forward' sensor has been met. Be careful that the top bales

remain secure on the 'Extension Frame' during the first

stages of tipping.

3. When the platform is half raised, the curved skids will

contact the ground (Fig. 27). At this point release the

brakes, dip the clutch and allow the machine to roll back as

the platform is raised.

4. Continue to raise the stack until you are satisfied it is

vertical and secure.

5. Move the joystick left and right (Fig. 28) to open the side

gates.

6. Hold the 'BLACK' button on the joystick and push forward

to release the 'Hooks' (Fig. 29).

7. Keep the 'BLACK' button held down and move the

joystick left (Fig. 30) to lower the 'Turntable' and lift off the

stack.

8. Keep the 'BLACK' button held down and move the

joystick right (Fig. 31) to extend the 'Extension Frame' and

'Turntable'.

9.. Still holding the 'BLACK' button move the joystick back

(Fig. 32) to remove the 'Rear Clamps'.

Curved skid

Fig. 26

Fig. 27

Fig. 28

Fig. 29

Fig. 30

Fig. 31

Fig. 32

12

5.0 Operation

5.8 Erecting a Complete Tower Continued.

Fig. 34

5.9 Placing Towers Against Existing Towers

1. Half tip the machine, reverse gently into the previous

stack until it touches. Drive forward counting the lugs on the

tyres (Fig. 36). After 4 lugs, stop and continue tipping and

allow the machine to roll back as it tips. Adjust the number of

lugs to tighten or open the contact with previous stacks.

2. Use a tramline or convenient features to maintain

alignment of subsequent stacks.

3. When erecting towers side by side, either side gate can

be opened 90 degrees to its home position to enable closer

placing of adjacent stacks. Removal of the safety pins will be

required (Section 6.15) but do not lower the sides until the

platform is half tipped and the individual bales are secured

by inter layer friction (Fig. 37). Move the joystick left and

right to open the gates (Fig. 28).

4. Once the machine is half tipped, carefully lower the

appropriate side and gently manoeuvre the stack into

position before raising fully. Remember the machine will roll

back as it tips, so ensure good alignment with the base of

the adjacent stack so that the open side is not stressed by

contact with the existing stack Section 9.1 for further details.

Fig. 37 Note 1

Tip to at least 45° before opening the side clamps, to

ensure bales are secured by inter-layer friction. This will

also reduce stress on the side gates cylinder pins also

reducing damage to the mud guards.

Fig. 37 Note 2

Ensure good alignment of the stack bases so that an open

side clamp is not stressed by contact with an existing stack.

Fig. 33

1

2

Fig. 37

Fig. 36

Fig. 35

10a. After you have released the stack vertically, drive

away from the stack (make sure it is stable). Move the

joystick forward (Fig. 33) to bring the machine down

manually about 5-10 degrees.

10b. If the machine is clear and the stack is stable, press

the 'GREY' button and move the joystick forward (Fig. 34)

to 'Auto Bed Tip Down'. This function will bring the

Transtacker down automatically and bring everything into a

home position except the rear clamps. These are kept open

it increase speed when engaging 'Auto Mode'.

Note: The side gates will not close on 'Auto Bed Tip Down'.

Make sure you close the side gates before activating this

function or it may cause damage to the Transtacker.

Note: To reset the layer counter, you will need to activate

'Auto Bed Tip Down' before going into 'Auto Mode' or

operating the machine manually. Make sure the top middle

of the screen is clear of any layers before starting another

stack.

11. If you want to close the rear clamps, press the 'RED'

button and move the joystick backwards (Fig. 35) to 'Close

Clamps'.

13

5.0 Operation

5.10 Erecting a Part Load Tower

1. Performing a 'Part Load' is done automatically by the

Transtacker. To do a 'Part Load' successfully there are

some pointers you have to obied by:

i. The recommended minimum amount of layers a 'Part

Load' can be is;

a. 2 for 120x130cm bales

b. 3 for 120x90cm bales

c. 3 for 120x70cm bales

d. 3 for 80x90cm bales

e. 3 for 80x70cm bales

ii. Make sure the top layer of your 'Part Load' is not tied.

The top layer must lay along the bed (Fig. 39).

iii. If you have the 'Turntable' left up, make sure your

'Hooks' are retracted from your last stack layer.

iv. The 'Side Gates' and 'Rear Clamps' must be open

when performing a Part Load (Fig. 39).

Note: If there is only 2 bales left. Make sure you place the

bales on top of each other (Fig. 40) creating 2 single layers.

Do NOT make a single layer as there will not be enough

weight to push the forks back to the rear.

CAUTION: If you are traveling with a part load. Ensure that

the turntable is up with the hooks inserted into the last layer

of bales. Then perform 'Road Mode' to close all other

components of the Transtacker.

2. In 'Stack Manual Mode' pull and hold the joystick back to

'Auto Tip Bed Up' (Fig. 38). This will engage the

Transtacker to recognize that it is only a part load. The

Transtacker will immediately start to tip up until it makes

connection with the 'Tip Bed Up Partial' sensor at a

recommended adjusted height of 20 degrees. Look at

Section 6.8.4 on how to alter the proximity sensors.

Fig. 38

WARNING: When performing a 'Part Load', if the

sensor is not in contactable range, the 'Platform' will

lift all the way up. It is critical that you do NOT lift the

Transtacker's 'Platform' over 40 Degrees (Fig. 42).

This could cause large damage to the 'Fork System'.

Fig. 41

Fig. 42

3. When the connection is made with the 'Tip Bed Up Partial',

the 'Fork System' will start to release the bales to the rear of

the Transtacker ready for further tipping.

4. Still holding the joystick on 'Auto Bed Tip Up', when the

bales reach the 'Bale Detect - Bed Full' sensor. The

Transtacker will automatically close the rear clamps and side

gates, securing the 'Part Load' Stack. The forks will fold down

and come to the front of the platform, contacting their

appropriate sensor. The 'Platform' will continue to tip up freely

now. Carry on the procedure from Section 5.8 point 3.

Fig. 39

Fig. 40

14

5.0 Operation

5.11Re-Picking a Complete Tower

1. Exit ‘Road mode’ and ensure 'Stack Mode' is selected.

2. Hold down the 'BLACK' button and move the joystick

back (Fig. 43) to ‘Open Clamps’.

3. Move the joystick left and right (Fig. 44) to open the

'LH / RH Gates'. Open the 'Side Gates' and 'Rear Clamps'

to a 15 degree angle off vertical. (Fig. 45).

Fig. 43

Fig. 44

Fig. 45

Caution: Before proceeding with the re-picking of stacks, it

is recommended to remove the bolt on back plate at the

rear of the Transtacker. This sometimes stop the bales lying

flat on the bed of the 'Platform'.

WARNING: If the bolt on back plate is removed, it MUST be

put back on before you go into 'Auto Mode' or 'Field Manual

Mode'. It may cause damage to the 'Fork System'.

WARNING: Ensure the Forks are folded down inside the

platform and are to the front of the platform. To perform this,

raise the platform up half way, press and hold the

'RED' button and push forward, this will bring the forks to

the front and release the pressure in the forks raise allowing

the forks to lower. Return platform to home position when

completed.

4. Hold the 'RED' button down and push the joystick forward

to raise the 'Turntable' to 90 degree (Fig. 46).

5. Hold the 'BLACK' button while moving the joystick to the

right to extend the 'Extension Frame' (Fig. 47).

6. Hold back the joystick to 'Auto Tip Bed Up' till the platform

is half way up (Fig. 38).

CAUTION: Do not reverse with the Transtacker tipped all

the way up. It may damage the 'Lighting Board' at the back if

there is uneven ground.

7. Align the Transtacker evenly in front of the Stacked bales.

when close enough to the stack, raise the platform up to its

maximum and reverse till you have created contact. When

the platform is lying against the stack, hold the

'GREY' button down and move the joystick left and right.

This will 'Close RH / LH Gates' (Fig. 48).

Fig. 46

Fig. 47

Fig. 48

15

5.0 Operation

5.11Re-Picking a Complete Tower Continued.

Fig. 49

Fig. 50

Fig. 51

Fig. 52

Fig. 53

Eye Ratchet Strap, Rope or Chain

Rear Clamps

7. Hold the 'RED' button and pull the joystick back to close

the 'Rear Clamps' (Fig. 49). Ensure that the rear clamp

'Paddles' has gripped under the bales tight.

8. Whilst still holding the 'RED' button, push the joystick left

to 'Retract Turntable' (Fig. 50). Ensure you tightly squeeze

the top bales with the turntable. This will squeeze all the

layer of bales between the 'Rear Clamps' and the

'Turntable'.

WARNING: Do NOT Retract Turntable unless the Turntable

is at 90 degrees. This could causes damage to the machine.

9. Holding the 'RED' button push the joystick right (Fig.

51) to insert the hooks into the top layer of the stack. This will

help pull the top layer over with the Transtacker 'Platform'.

10. Push the joystick forward to start to bring the bed down

(Fig. 52).

CAUTION: The security of the load is dependent upon the

maintenance of hydraulic pressure in the clamp cylinders.

On long journeys, particularly with older machines, it is

advisable to secure the rear clamp with a suitable ratchet

strap, rope or chains threaded through

the eyes provided (Fig. 53).

16

5.0 Operation

5.12 Getting Started Manually

Having entered the field, stop and set up the machine ready

to operate as follows. Some adjustments to your

Transtacker 4100 will be needed, follow Section 6.0

Adjustments for further details.

1. Engage PTO if it is safe to do so as instructed on the

main screen (Fig. 13).

2. Enter 'Field Manual Mode' (Fig. 12).

3. 'Auto Open' the Transtacker by pressing the 'GREY'

button and pushing the 'Joystick' forward (Fig. 54). The

following functions will start to open:

a. Side Gates

b. Rear Clamps

c. Guide Bar

d. Grab Arm

e. Forks Forward and Raise

f. The Pickup will drop to desire height.

Note 1:

If the 'Guide Bar' is in, the 'Pick up' will not work.

Note 2:

Make sure the forks are pressured in the raised position.

4.Drive along side the first bale (select a bale that is on flat

ground). Drive forward until the 'Bump Paddle' is pushing the

bale along the ground (Fig. 55).

Fig. 54

5.13 Pickup Manual with Grab Arm

Fig. 55

Note: See Section 6.0 Adjustments for the

correct height adjustment for the 'Pickup'.

Note 1:

If the 'Guide Bar' is retracted, the 'Pick up' will not raise.

Note 2:

If the 'Guide Bar' is retracted, the 'Grab Arm' will not open.

1. Drive along side the bale (carry on driving when the bale

has bale connection with the bump paddle). When the bale is

in the correct position, push the joystick forward (Fig. 56).

the machine will automatically pick u the bale and place it on

the table, before returning to its original position.

CAUTION: It is important that the tractor engine is turning

fast enough to maintain a full flow of oil to the machine

during automatic cycles. Select a gear that is best suited to

engine rpm and the distance between the bales. there is no

theoretical limit to the speed at which bales can be picked up

but some damage to bales may occur above (7.5mph) 12kph.

2. Approach the next bale in the same manner and repeat the

pickup cycle. Depending upon bale size, it will be noted that

the turntable will be full after 2 or 3 bales (Fig. 57).

Note: you can manually override the automatic pickup cycle

at any time by pressing the emergency button or by pressing

button 'F', 'G', 'H'.

Fig. 56

Fig. 57

17

Table of contents

Other BIG BALE Farm Equipment manuals

Popular Farm Equipment manuals by other brands

IDROFOGLIA

IDROFOGLIA TURBOCAR J1 Operating instructions manual

Duratech

Duratech HAYBUSTER 107 DRILL Operating Instructions and Parts Reference

Taege

Taege Uni Drill owner's manual

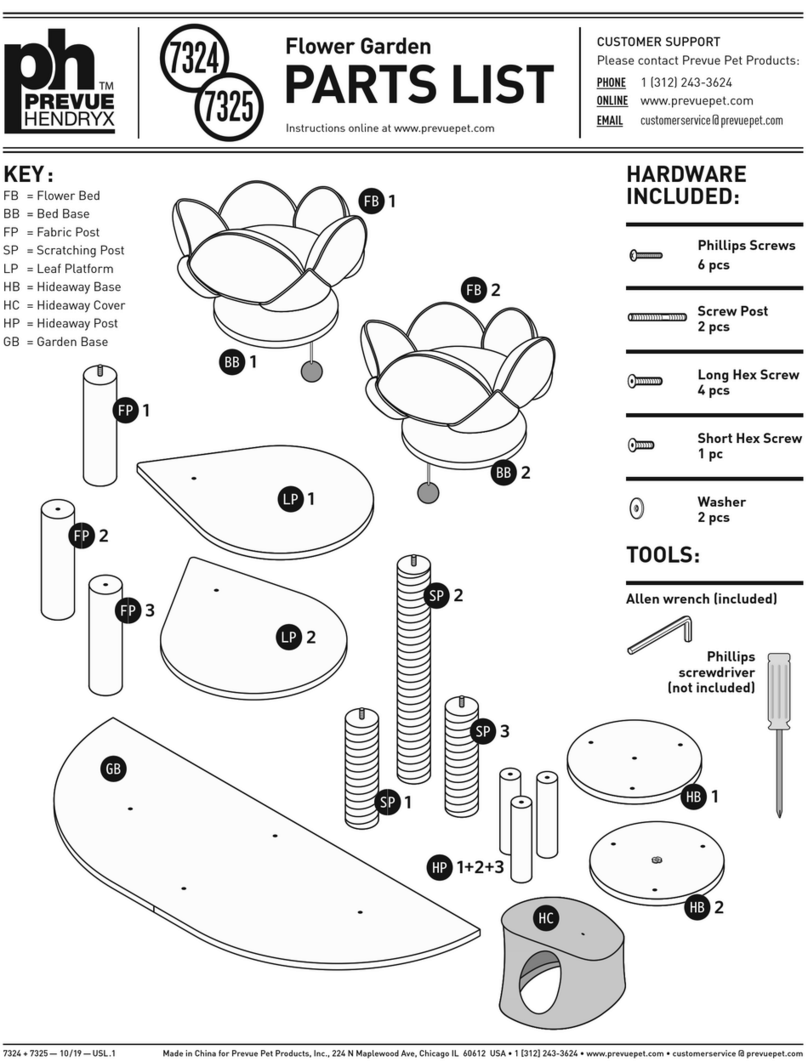

Prevue Hendryx

Prevue Hendryx 7324 parts list

Redexim

Redexim RINK DS 3800 Operating Instructions and Spare Parts Book

Headsight

Headsight CORN GERINGHOFF RD installation manual