BIG BALE Transtacker Standard User manual

Operation and Maintenance Manual

It is the responsibility of the operator to read and understand the contents of this manual before

operating the machine for the first time.

The Operators manual must accompany the machine at all times. If the machine is resold the

Operators manual must be given with the machine to the new owners.

Please read and follow all instructions before operating the machine

2

Contents

4. 1.0 INTRODUCTION

5. 2.0 SPECIFICATION

6. 3.0 MACHINE OVERVIEW

7. 4.0 SAFETY

9. 5.0 OPERATION

25. 6.0 ADJUSTMENTS

29. 7.0 TROUBLE SHOOTING

31. 8.0 MAINTENANCE

32. 9.0 WARRANTY

33. 10.0 ELECTRICAL &HYDRAULIC SYSTEMS

3

Page Title

1.0 Introduction

1.1 Description

In choosing the Big Bale Transtacker you have purchased

amachine of exceptional versatility.

This manual should be regarded as essential reading in the

interest of safety, efficiency and longevity of the machine.

References to Right and Left in this manual are taken as

viewing the machine from the rear facing in the normal

direction of travel.

1.3 Machine Identification Plate

If service parts are required it is necessary to quote the

machine serial number.This is located at the front right

hand side of the machine on top of the drawbar front plate.

It is recommended that this information be transferred to

this page on delivery of the Big Bale Transtacker.

Model ________________________

Serial No. ________________________

Year of Manufacture ________________________

Date of Delivery ________________________

Unladen Weight ________________________

Max Gross Weight ________________________

Max Drawbar Load ________________________

1.2 SAFETY ALERT SYMBOLS

This warning symbol appears throughout this hand book.

Attention is drawn to items or operations that could cause

danger to the operator or to persons nearby.Please read

safety messages carefully and have a full understanding of

their importance.

Always abide by the requirements.

WARNING: Warnings call attention to instructions, which

need to be followed precisely to avoid a hazardous

situation.

CAUTION: Cautions call attention to instructions, which

must be followed precisely to avoid damaging the product,

process or surroundings.

4

CHK PLC

MODEL

PYMS LANE,

CREWE,

CHESHIRE CW1 3PJ,

UNITED KINGDOM

TEL: 0044(0) 1270 252894

SERIAL No.

YEAR OF Man.

UNLADEN WEIGHT

MAX GROSS WEIGHT

MAX DRAWBAR LOAD

Kg

Kg

Kg

Fig. 1

1.4 Intended Use of the Machine

The Big Bale Transtacker is designed to assemble various

sized big bales, 2.4m (8') long, into completed stacks and

erect them into a tower.

The various sizes of bales must have a width or depth

which can, (when arranged side by side in some multiple),

form a rectangle that is 2.4m(8') square. Bale length is

permitted to vary considerably but to tie layers, 2.4m ± 0.1

is preferred.

The machine will also recover previously erected towers

and re-erect them in a new location.

The bales can be of various straws and hays generally

found in agricultural use.

The machine is generally towed with an agricultural tractor

recommended minimum of 6 Tonnes,140 HP.

1.0 Introduction

1.7 Accessories and Attachments

High Speed Axles

Above 30 kph (20 mph), A.B.S. with air brakes may be

required. This can be specified on the initial purchase

specification but can also be retro fitted at extra cost.

It is important to note that high-speed use on highways may

be restricted by a machine width in excess of 2.55 m.

Flashing Beacon

A flashing beacon can be mounted on the panel adjacent to

the number plate. When fitted in conjunction with a tractor

cab top mounted unit, it provides all round visible flashing

lights (Fig. 2).

Hydraulic Pickup Adjuster

For operators who regularly change the bale size, a

hydraulic pickup adjuster is fitted as standard to ease and

speed up pickup height adjustment.

5

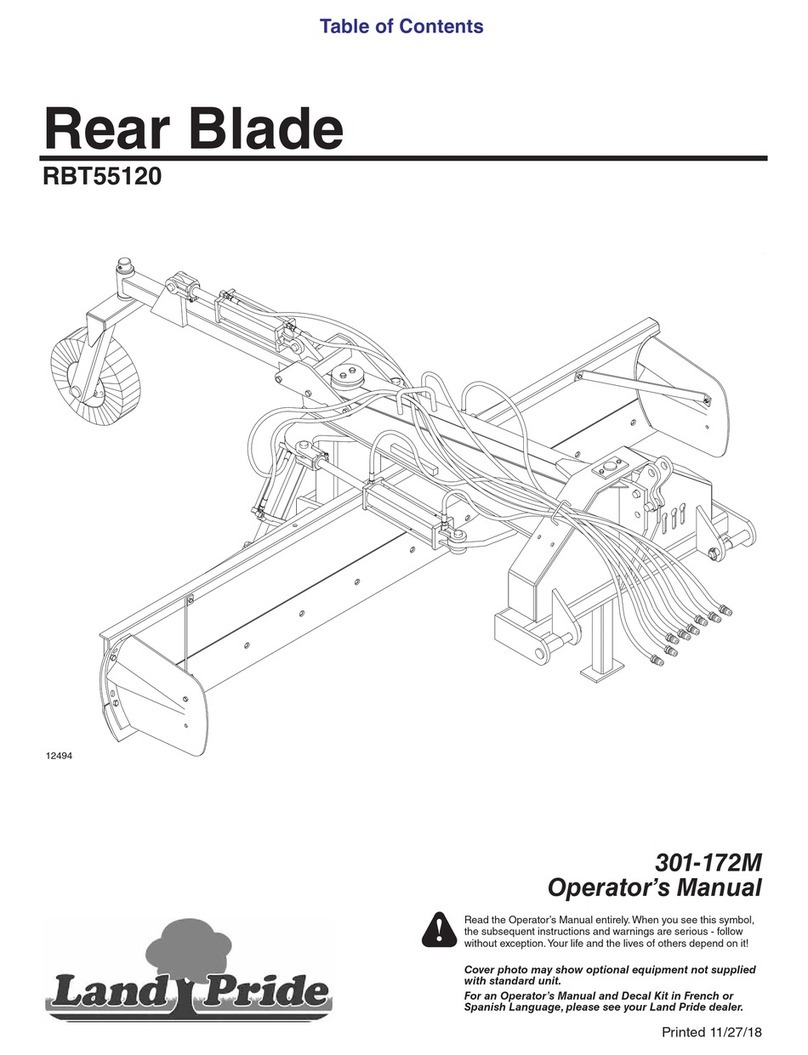

2.0 Specification

Big Bale Transtacker Standard Big Bale Transtacker Extra

Length 10.3m 10.7m

Height 3.7m - 4.1m 3.7m - 4.1m

Automation Semi automatic pick up and stack Semi automatic pick up and stack

80 x 90 x 240 - MF2150 21 24

120 x 70 x 240 - MF2160 18 20

120 x 90 x 240 - MF2170 14 16

120 x 127 x 240 - MF2190* 10 12

Unladen weight 7.0 Tonnes 7.5 Tonnes

Maximum Load 8.0 Tonnes 9.0 Tonnes

Wheels / Tyres (+ sizes) 560/60-22.5 12PR 560/60-22.5 12PR

Oil Supply Required 60L/min @ 3000psi 60L/min @ 3000psi

Electrical Supply Required 30 Amp 12V DC 30 Amp 12V DC

Brakes 4 wheel hydraulic as standard 4 wheel hydraulic as standard

Brake options ABS air,ABS air/hydraulic, TUV air ABS air, ABS air/hydraulic, TUV air

Other options** Bed rollers - Sprung drawbar Scharmuller coupling Bed rollers - Sprung drawbar Scharmuller coupling

*Including additional layer **Some options for non UK models only

Fig. 2

Fig. 3

1.5 Construction and Use Act UK

The machine can be classed as an agricultural appliance

provided the load does not exceed its unladen weight.

1.6 Noise Declaration

Sound Pressure Level

The sound pressure level of the Big Bale Transtacker does

not exceed 70 dB (A).

A

L

N

SOQ

P

R

T

V

D

C

U

E

K

J

I

H

M

F

B

G

G

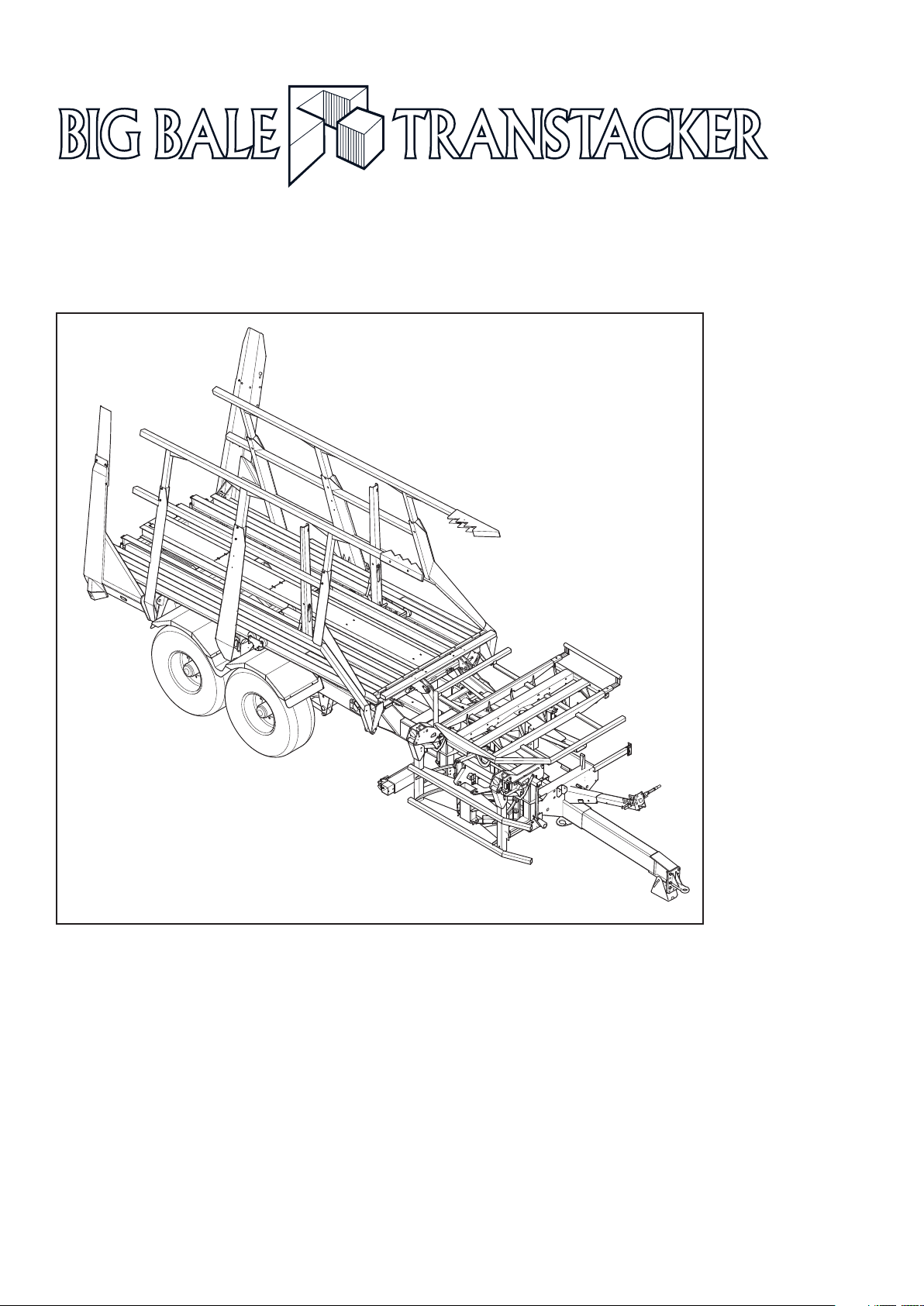

3.0 Machine Overview

6

ARear Clamp

BRear Clamp Beam

CRear Clamp Pads

D Side Gates

EForks

FPlatform Extension

G Location of Parkbrake

HBale Stop

IHooks

JTurn Table

KService Post

L Drawbar

MPickup Latch Indicator

NPickup Latch

OPickup Frame

P Pickup Guide Rails

QPickup Tines

RGuide Bar

SLatch Cable

TChassis

USide Clamp Beam

VPlatform

Fig. 4

4.0 Safety

4.1 Safety in Operation & Maintenance

Operation of the machine without paying heed to fitting and

use of guards or to the safety notices renders you liable to

prosecution.

This applies even if you are the injured party.

Your attention is drawn to the safety notices (decals) that

are displayed on the machine. These notices should be kept

clean and intact so they are legible at all times.

If any of the notices become detached or defaced, they

must be replaced immediately.

These are available from your local Big Bale Transtacker

agent.

They are included in the spare parts list and examples to

aid identification are reproduced on the following pages.

WARNING: Read Owners Manual

This manual contains safety information and

operation and maintenance instructions for your Big Bale

Transtacker. The operator must ensure that he/she has fully

read and understood this manual before operating the

machine.

WARNING: Before Commencing Any

Repairs/Maintenance

Shut off engine, remove ignition key, and unplug electric

control box before performing any maintenance or repair

work.

WARNING:

Keep persons away from the machine during operation.

There is a danger from falling bales and moving machinery.

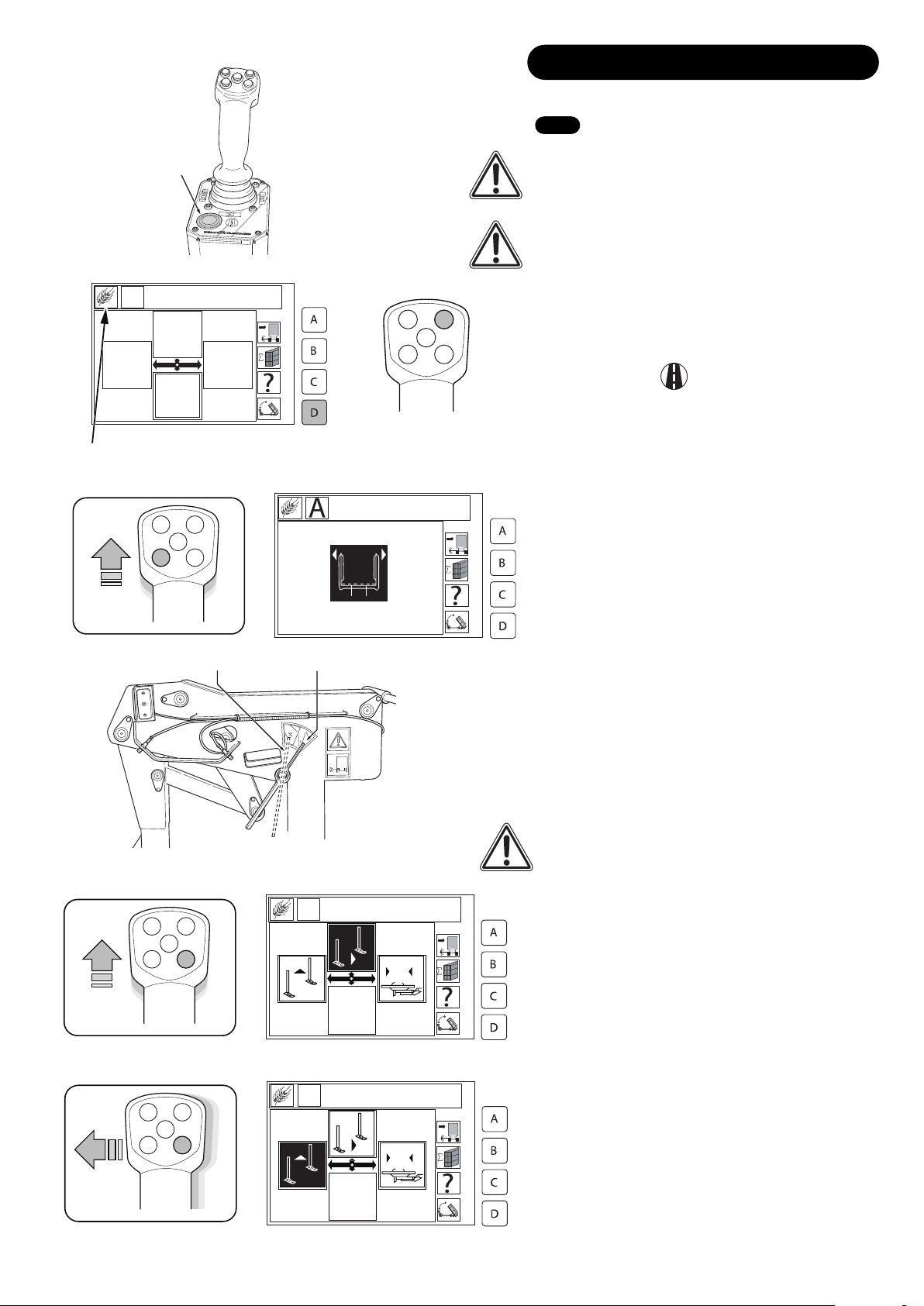

WARNING:

When the pickup guide is out there is a danger that it may

be overlooked by the operator. A flashing light and audible

signal on the control box indicates the guide is out. An

indicator on the pickup latch signals that the guide is in and

the pickup is locked in position (Fig. 5).

WARNING:

Do not raise the platform of the Transtacker while under

high voltage power lines. Some parts of the machine can

exceed 5.2m high and cause electrocution and/or fire.

7

Fig. 5

4.0 Safety

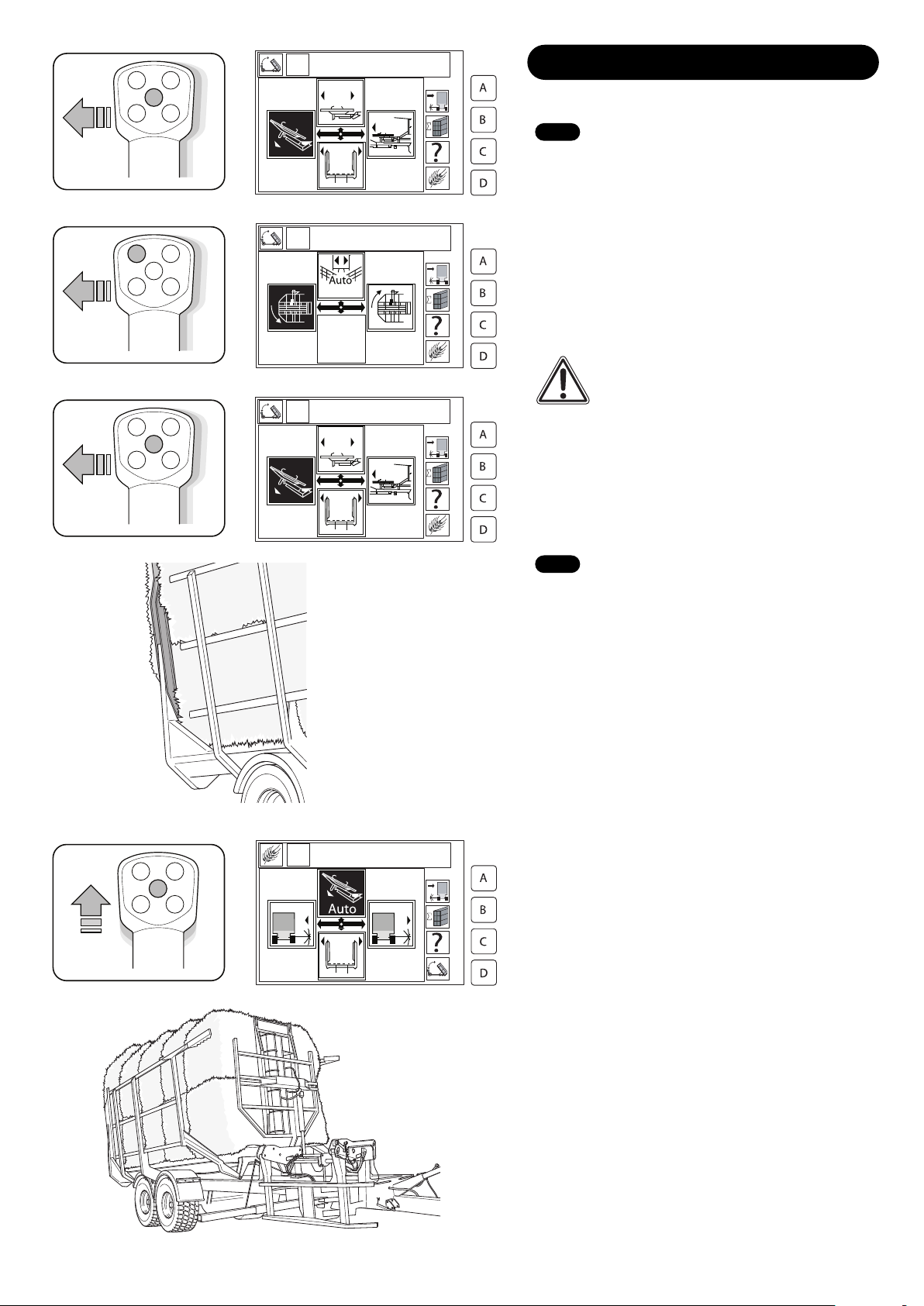

WARNING: Keep clamp side pins in place when

transporting on highways.

When travelling along roads the side clamps are subject to

variable and high loads. Failure or inadvertent operation of

the side clamps could cause very serious injury or damage

to others. Set controls to ‘Road Mode’ prior to road

transport (Fig. 6)

Failure of the hydraulic lines is covered by the load valves

attached to the clamp and lift cylinders. Road Mode should

be used during transport to prevent inadvertent operation.

The safety pins provide a necessary and useful further

safety device should there be a failure of the cylinder.

WARNING:

Take care when operating on sloping ground or when

traversing undulations at speed to prevent overturning of the

stacker. By necessity the machines have a high centre of

gravity when loaded. Caution should always be exercised to

prevent overturning and resulting injury and/or damage.

When picking up bales on sloping ground, always traverse

the slope so that the bales are picked up from the high

(right hand) side.

8

Fig. 6

Road Mode

5.0 Operation

5.1 Attachment to the Tractor

Drawbar

Requirements

The drawbar is normally supplied with a ring hitch, which is

suitable for connection to the pickup hitch found on most

tractors in the UK.

Ensure that your tractor hitch is suitable for this type and

dimension of ring.

Ensure the capacity is a minimum of 3 Tonnes. Additionally,

the recommended minimum horsepower is 140 HP and 6

Tonnes weight.

An oil supply of at least 60 L/min @ 200 bar (8.79

Gallons/min (UK) @ 2900 psi) and a minimum electric

supply of 20 Amps @ 12v DC are required. The tractor must

be fitted with a power beyond unit.

Attaching

Hitch the tractor to the machine. Remove and store the

drawbar stand and pin. The machine should now sit

approximately level at the chassis.

Turn the tractor cautiously and ensure the tractor links etc

do not foul on any part of the machine and that there is

sufficient clearance for hoses etc. Remove links if

necessary.

Connect the brakes to the tractor and ensure correct

operation.

Release the hand brake (Fig. 7),which is under the front

left of the chassis, and obtain assistance to check the

operation of the trailer brake cylinders when the brake pedal

is depressed.

Ensure the tractor lighting voltage is 12 v DC before

connecting the lights.

Connect the lights via the 7-pin plug stored just off centre of

the service post and confirm correct operation.

Tractor connections and identification colours are as follows;

(Fig. 8)

Hose 2 – Pressure – Red - 3/4” Hose

Hose 3 – Return – Blue – 1” Hose

Hose 4 – Load Sense – Yellow – 1/4” Hose

Hose 5 – Pilot drain – Blue- 1/4” Hose

For tractors with only three connections available hoses 3 &

5may be joined together using a tee piece at the tractor

end.

Please ensure that the above connections to the tractor’s

power beyond unit are made in accordance with your

Tractor Manufacturers instructions and Guidelines.

9

Fig. 7

Tank

Blue

No. 5

1/4” Hose

No. 3

1” Hose

No. 1

3/4” Hose

No. 4

1/4” Hose

Tank Pressure Load Sense

Blue Red Yellow

No. 2 3/4” Hose

F1

10

Micron

Fig. 8

WARNING: Oil under pressure can penetrate skin. Seek

medical advice involving any incident where this may occur.

Oil is an irritant. Wear protective gloves when handling.

CAUTION: Ensure the tractor will supply at least 60 L/min

@200 bar (8.79 Gallons/min (UK) @ 2900 psi and does not

exceed 80 L/min (17.6 Gallons/min (UK)).

Set the flow at 40-50 L/min. (8.79 - 11.0 Gallons/min (UK)).

5.2 Hydraulics

5.0 Operation

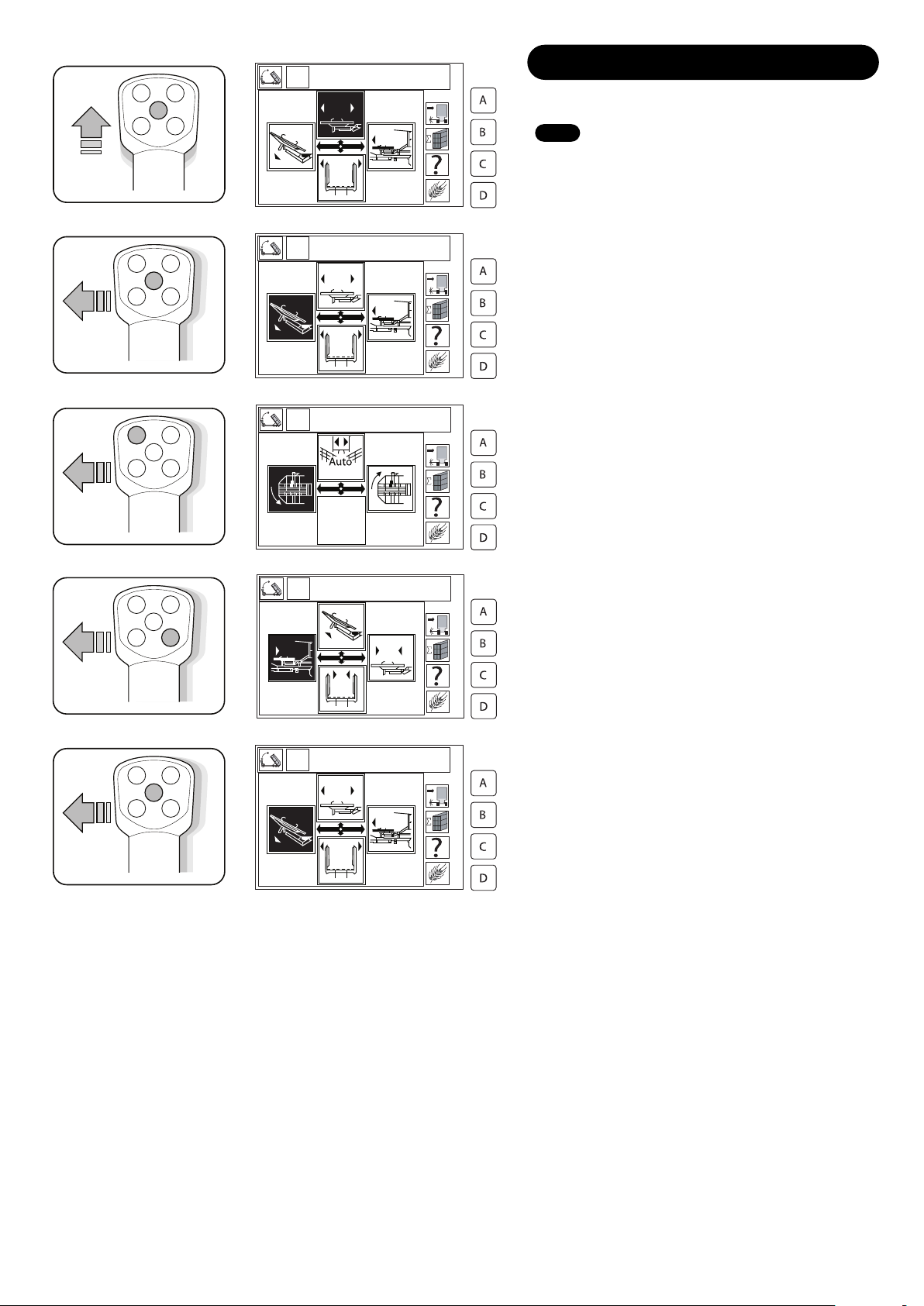

5.3 Electrical

Mounting the Control Box

Mount the control box securely in the tractor cab in a

position that suits you (Fig. 9).

Do not obstruct access to hydraulic levers or other

important controls;

Easy comfortable operation of the joystick and push button

switches is preferable;

Maintain good visibility of the control box lights and decal;

The operator will be most likely observing the pickup over

his right shoulder;

The seat may traverse up and down considerably on rough

ground.

When the control box is mounted, connect it to the tractor

electrical supply via the lead provided. Ensure that the

voltage is correct, 12v DC and that the fused wire is positive

(Fig. 10).

If the control box is connected through sockets provided in

the tractor, ensure they and any fuses are capable of 20

amps continuous supply.

It is recommended to connect the lead provided to the

tractor battery. This is pre fitted with a 20 amp blade fuse.

When the control box is mounted and working, switch off

and connect to the machine using the multi core cable

provided. Carefully connect one end to the base of the

control box. The other end is connected to the junction box,

which is mounted on the chassis rail mid machine (Fig. 11).

Note: this junction box is placed ideally to protect it from the

elements at all times. Loop the cable around after threading

through the front drawbar plate to assist fitting. Do not forget

to thread the cable through the service post and any cab

entry points. Finally secure the cable to the hydraulic hoses

to prevent damage and store surplus cable inside the cab.

CAUTION: The power should be switched off to the control

box via the switch at the rear if the machine is not being

used for long periods (Fig. 11).

The control box and joystick should connect using the cable

provided and the control cable then connected to the main

trailer cable.

10

A

B

C

D

ELE-20120-40

Connection for

Loom to Trailer

Connection for

Loom to joystick

Connection Point

for ELE-20120-80

ELE-20120-02

Rear View ELE-20120-02

ELE-20120-01

ELE-20120-05

Connection to Battery

Including 30A Fuse

ELE-20120-06

ELE-20120-07

Connection for

Joystick to Display

ELE-20120-01

ELE-20120-03

Fig. 9

Fig. 11

Fig. 10

Reset Button

5.0 Operation

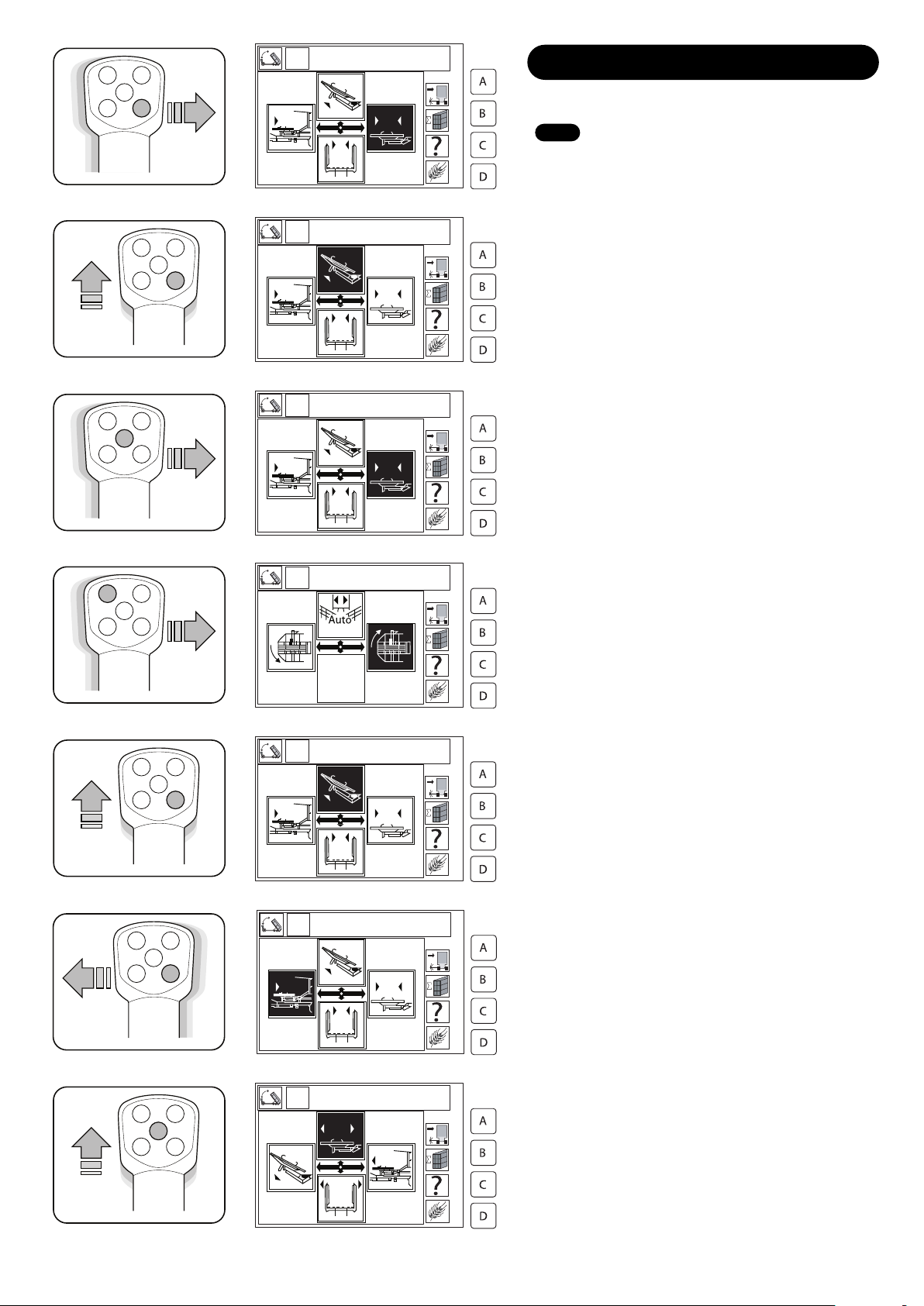

5.4 Joystick functions

11

Fig. 13

Button Joystick position Function in Field Mode Function Stack Mode

Y+ Auto Pickup Main tip down

None Y-Auto stack with tie Main tip up

X+ RHS gate open RHS gate open

X- LHS gate open LHS gate open

Y+ Auto open Auto tip down

1 Y- Auto stack no tie Auto open

X+ RHS gate close RHS gate close

X- LHS gate close LHS gate close

Y+ Auto table down Hooks out

2 Y- Centre clamps open Centre clamps open

X+ Guide bar out Turntable extend

X- Guide bar in Turntable down

Y+ Pickup tines in Drawbar down

3 Y- Pickup lower Drawbar up

X+ Pickup tines out Table turn

X- Pickup lift Table return

Y+ Forks up Turntable up

4 Y- Hooks in Centre clamps close

X+ Hooks out Hooks out

X- Forks forward Turntable retract

3

41

Road Mode Direction

of Travel

Y+

Y-

X- X+

2

Pressing ‘?’ will bring up text prompts for functions

Fig. 12

5.0 Operation

5.5 Controls

WARNING: Keep persons away from the machine while

operating. There is a danger from falling bales and moving

machinery.

CAUTION: When picking up the bales laid across sloping

ground, always traverse below the bale to ensure stability of

the stacking machine during pickup cycles.

Getting Started

Having entered the field, stop and set the machine ready to

operate as follows:

1. Exit ‘Road Mode’ by pressing and holding the

green button on the base of the joystick for 2 seconds

(Fig. 14).

2. Enter Field mode if required by pressing Button ‘D’ or the

top right button on the joystick (Fig. 15).

3. ‘Auto Open’ the clamps by pressing the bottom left button

and pushing forward on the joystick (Fig. 16).The guide will

also extend out fully. This should release the latch

mechanism. Check the guide light is flashing and the latch

pointer is aligned with the yellow sector of the decal

(Fig. 17).

Fig. 17 Note 1

If auto pickup is activated when the guide is in it wont work.

Fig. 17 Note 2

The Dotted Line position indicates the guide is out and the

pickup is free to operate.

Fig. 17 Note 3

The Pointer indicates that the guide is in and the pickup is

locked and ready for transport.

The indicator can in some circumstances indicate that the

guide is in. Whereas in fact the pickup has not been used

and has locked the latch in the transport position. Operate

the pick up return to check.

4. The forks (on newly delivered machines) will be bolted

down. If fork operation is required, undo these bolts. See

6.4 Use of Forks - page 26.If not, ignore Instruction 5 and

proceed to instruction 6.

5. Hold down the bottom right button and push the joystick

forwards (Fig. 18) to bring the forks up. Keep the bottom

right button held down and move the joystick left (Fig. 19),

this will bring the forks to the front of the platform ready to

support the first bales.

12

Road Mode

Indicates ‘Field mode’ active

Or

Fig. 14

Fig. 15

Fig. 16

12

Fig. 17

Fig. 18

Fig. 19

5.0 Operation

5.5 Controls Cont..

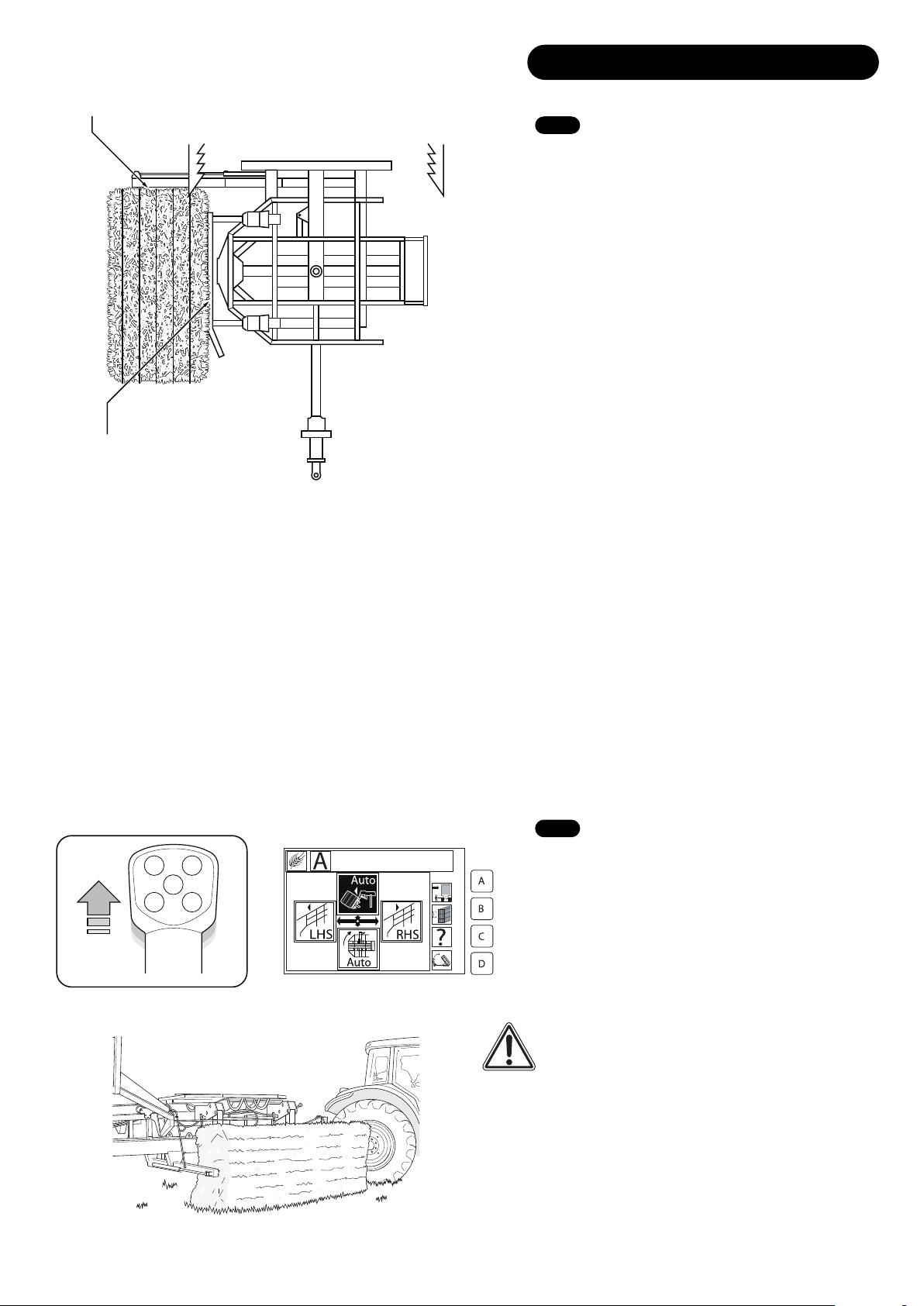

6. Drive along side the first bale. (Select a bale that is on

flat ground). Drive forward until the guide is pushing the

bale along the ground and having turned towards the bale, it

should be tight against the pickup rails (Fig. 20).

Fig. 20 Note 1

The bales should come to rest firmly against the guide.

Fig. 20 Note 2

Turning towards the bale as you pass it will ensure the bale

is kept tight against the guide rails.

1. Drive close along side the bales (it may be beneficial to

turn into the bale as the tractor passes, to ensure the bale

fits tight against the pickup rails), when the bale is in the

correct position, push forward on the joystick (Fig. 21).The

machine will automatically pick up the bale and place it on

the table, before returning to its original position (Fig. 22).

Caution: It is important that the tractor engine is turning fast

enough to maintain a full flow of oil to the machine during

automatic cycles. Select a gear that is best suited to engine

rpm and the distance between the bales. There is no

theoretical limit to the speed at which bales can be picked

up but some damage to bales may occur above (6 mph)

10kph.

13

1

2

Fig. 20

5.6 Pickup (Automatic)

Fig. 22

Fig. 21

2. Approach the next bales in the same manner and repeat

the pickup cycle. Depending upon bale size, it will be noted

that the hooked table will be full after 2 or 3 bales (Fig. 23).

3. The last bale onto the table will push the first against the

stop bar and will squeeze the bales tight together. If for

some reason the bales are not aligned correctly then

re-pressing forward on the joystick (with the pickup at the

top of its cycle) will cause the pickup to return, with the bale,

towards the ground. Releasing the joystick will resume the

pickup cycle and thus effect a re-cycle. This is necessary

with bales of an extreme rectangular shape, to ensure good

and tight alignment of the bales on the hooked table.

Note: You can manually override the automatic pickup cycle

at any stage.

Note: See 6.1 page 25 for correct height adjustment.

5.0 Operation

5.6 Pickup (Automatic) Cont.

14

Fig. 23

Fig. 24

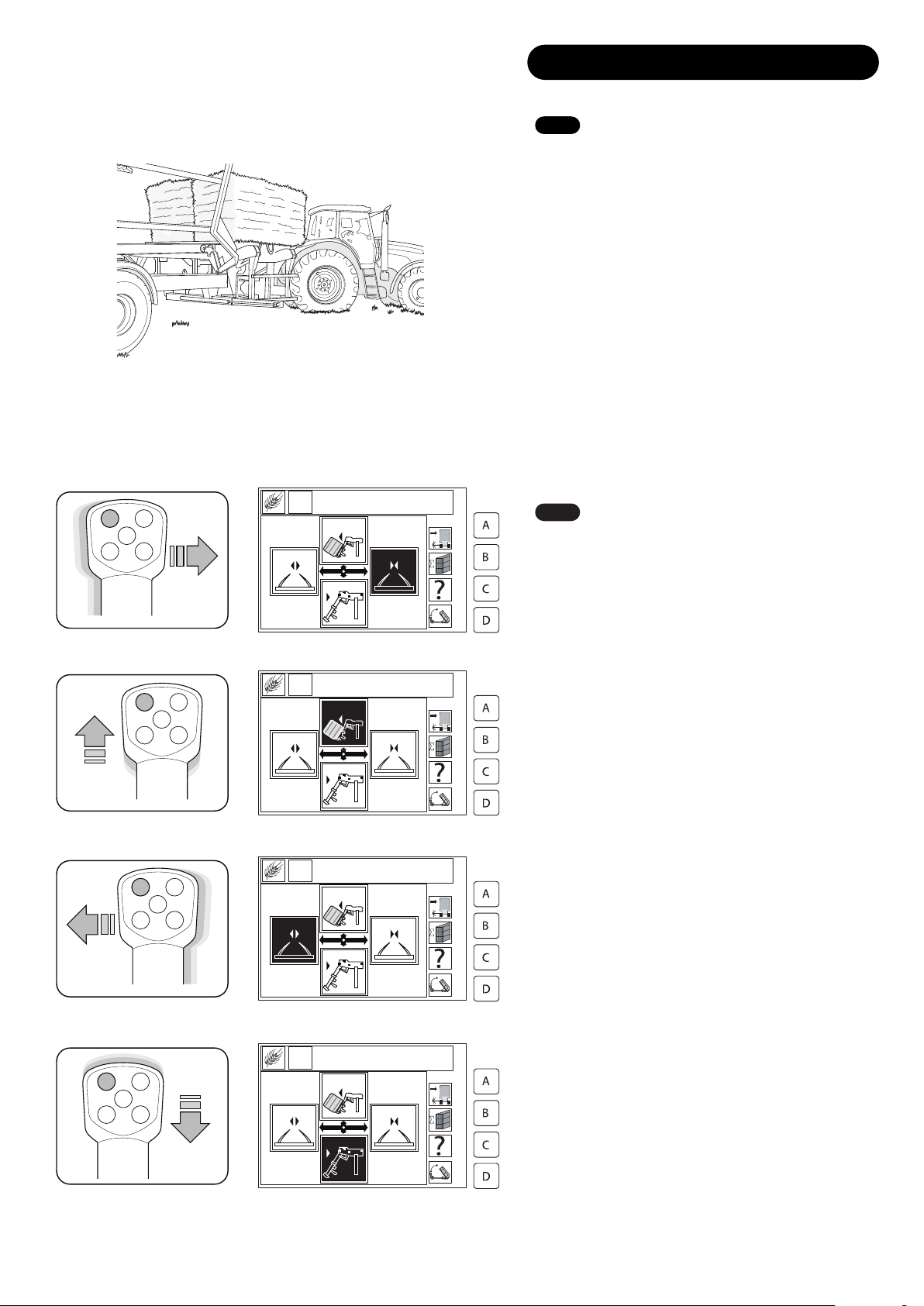

5.7 Pickup (Manual)

1. Follow the instructions as for the Pickup (Automatic).

2. When the bale is in the correct position, hold down the

top left button and push the joystick right (Fig. 24) until the

tines penetrate the bale sufficiently.

3. When it is considered that the tines are in sufficiently,

keep the top left button held down and push the joystick

forward (Fig. 25) and the pickup will raise the bale.

4. When the pickup is at the top of its stroke, stop pushing

the joystick forward, keep holding down the top left button

and move the joystick left (Fig. 26) to withdraw the tines.

As the tines move out of the bale, keep the top left button

held down and pull the joystick back (Fig. 27) to bring the

pickup back to its start position.

Fig. 25

Fig. 26

Fig. 27

5.0 Operation

5.8 Stacking (Automatic)

1. Before operating the stacking function, ensure the

following:

A. The pickup has returned fully (Fig. 28).

B. The table is full and the bales are tight, central and well

aligned. This is very important (Fig. 29).

Fig. 29 Note 1

Note the alignment with the sides of the platform.

Fig. 29 Note 2

The Bales must be tightly packed together, tight up against

the bale stop and central to the machine.

Fig. 29 Note 3

Location of Bale Stop.

C. Ensure the forks are erect, pressurised and forward

enough to support the first layer of bales if required -

(optional depending on bale size).

See 6.3 Stacking adjustments page 26.

D. Check the rear clamp is fully open and the sides are

approximately vertical and parallel.

See 5.5 Getting Started page 12.

E. Ensure you are still in Field mode (Fig. 30).

2. Pull the joystick back (Fig. 31) and the machine will place

the first line of bales on the platform against the forks and

return to its lower position on the nylon bottom stops with

the hooks withdrawn.

See 5.9 Using the Tie Function page 16.

3. The sprung loaded bale keeps should grip the bales and

prevent them falling forward but allow easy sliding of the

bales into the platform. Adjust the sides as necessary.

4. View the Screen on the control panel, this will have

progressed to indicate one layer of bales (Fig. 32).

5. Repeat the above process until the platform is full. This

will be indicated by the LCD flashing full.

15

12 3

Fig. 29

Pick up

Fig. 28

Fig. 30

Fig. 32

Fig. 31

Indicates ‘Field mode’ active

Indicates one layer of bales

5.0 Operation

5.9 Using the Tie Function

To secure completed towers it is necessary to tie at least

one layer during the stacking operation.

1. The tie cycle adds to the stacking cycle time so keep

tying to a minimum.

2. The complete tower is more secure and weather proof

with the tied layer in the top half of the tower.

3. Subsequent handling of the bales may require the top 2

or 3 layers to be picked off together.

4. Turning the first layer of bales may permit simpler,

quicker stacking without the use of the forks. This is

particularly applicable with deep bales. (80-130cm.)

5. The length of bales in a tied layer must be 2.4m ± 0.1m

otherwise they will jam during stacking or make the resulting

stack unstable. If bale length is not correct then it is best to

tie the last layer i.e. the layer at the top of the resulting

tower.

6. If the first/bottom layer is tied there may be problems

experienced erecting the finished tower if bale length is

widely variable.

7. One layer will need to be tied for successful stack

transportation.

Follow the instructions for Stacking (Automatic) but press

the bottom left button and pull the joystick back (Fig. 33).

The machine will complete a stack cycle with tie.

5.10 Combined Pickup and Stack (Automatic)

If AUTO PICKUP is depressed during a stacking cycle the

pickup will take priority and will hold mid cycle until the

stacking cycle is completed. The pickup will automatically

finish its cycle when the stacking is finished. The height at

which the pickup holds the bale during stacking is controlled

by the Pickup Hold Timer.

(See 6.9 Control Box Timers, Page 28).

This feature is designed to smooth and speed up the bale

gathering process.

16

Fig. 33

5.0 Operation

5.11 Stacking (Manual)

WARNING: While it is possible to stack manually,

it is recommended to auto stack. Unless operated

by a competent user, it is likely the machine could

get damaged.

A. Ensure you are in Stack mode.

1. Carry out the same checks as in Stacking (Automatic).

2. Press the bottom right button and push the joystick to the

right (Fig. 34) to hook the bales.

3. Press the bottom right button and move the joystick

forward (Fig. 35) and hold until the table is fully raised and

the bales are positioned on the platform (Fig. 36).

4. Hold down the middle button and push the joystick forward

(Fig. 37), hold until the hooks are fully out.

5. Hold down the middle button and push the joystick left

(Fig. 38), hold until the table returns to its bottom nylon

stops.

17

Fig. 36

Fig. 34

Fig. 35

Fig. 37

Fig. 38

5.0 Operation

18

5.12 The stacking cycle is complete.

To manually tie a layer

A. Ensure you are in Stack mode.

1. Carry out the same checks as in Stacking (Automatic).

2. Hold down the bottom right button and move the joystick

right (Fig. 39) to hook the bales.

3. Hold down the bottom right button and move the joystick

forward (Fig. 40) momentarily to lift the table clear of the

pickup.

4. Hold down the middle button and move the joystick right

(Fig. 41) until the table is forward approximately 150-

300mm and clear of its bottom nylon stops. Hold down the

top left button and push the joystick right (Fig. 42) until the

table is fully rotated 90°.

5. Hold down the bottom right button and move the joystick

forward (Fig. 43) until the table is fully erect.

6. Hold down the bottom right button and push the joystick

left (Fig. 44) until the table is fully retracted.

7. Hold down the middle button and push the joystick

forward (Fig. 45) until the hooks are out.

Fig. 39

Fig. 40

Fig. 41

Fig. 42

Fig. 43

Fig. 44

Fig. 45

5.0 Operation

5.13 Finishing a Stack

When the platform is full a sensor on the rear of the

platform will signal and illuminate the LCD.

The stacking cycle will stop and the rear clamp will

automatically clamp the bales (Fig. 49).This will be

indicated by a flashing ‘FULL’, followed by a constant

‘FULL’, when the bales are clamped.

1. If the table has returned to bottom stops, proceed to

pickup bales. Ensure more bales will clear the bales already

in the platform.

2. If the table has not descended then hold down the middle

button and push the joystick forward (Fig. 50). If the table

descends, more bales can be loaded. If it does not then the

machine is full and the completed tower must be erected

before more bales can be loaded (Fig. 51).

19

Fig. 49

Fig. 50

5.12 The stacking cycle is complete.

To manually tie a layer Cont.

8. Hold down the middle button and move the joystick left

(Fig. 46) to lower the table away from the bales to a point

not fully lowered.

9. Hold down the top right button and move the joystick right

(Fig. 47) until the table is straight.

CAUTION: The table must not be rotated in its

fully lowered position or damage may occur.

10. Hold down the middle button and move the joystick left

(Fig. 48) to return the table to its bottom stops.

Fig. 46

Fig. 47

Fig. 48

Fig. 51

Operation

5.0 Operation

20

5.13 Finishing a Stack Cont.

4. If the table has not descended but it is considered more

bales can be loaded then proceed as follows:

ensure you are in Stack mode.Hold down the middle button

and push forward on the joystick (Fig. 52) to retract the

hooks. Hold down the middle button and push left on the

joystick (Fig. 53) to half lower the table, then hold down the

top left button and push the joystick left (Fig. 54) to return

the table to its fully returned position.

5. Hold down the bottom right button and move the joystick

left (Fig. 55) to fully retract the extension. Hold down the

middle button and move the joystick left (Fig. 56) to fully

lower the table. Now more bales can be loaded.

6. Ensure the extension timer is set to the bale size used

(see 6.9 Control Box Timers, page 28). Some manual

input may be required to position the final layer of bales

firmly against the stack.

Fig. 52

Fig. 53

Fig. 54

Fig. 55

Fig. 56

This manual suits for next models

1

Table of contents

Other BIG BALE Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Kongskilde

Kongskilde R 365 DS Operator's manual

Westeel

Westeel WaterTank Flat Roof Installation and Storage Instructions

Frontier

Frontier DH1276 Operator's manual

Gude

Gude GGF 620 Translation of the original instructions

Gaspardo

Gaspardo Primo E2 Use and maintenance

Land Pride

Land Pride REAR BLADES RBT55120 Operator's manual

Kverneland

Kverneland 4328LT Service manual

CrustBuster

CrustBuster Speed King owner's manual

Cima

Cima Link Operation and maintenance instruction

Sovema

Sovema PL 180 Operation and maintenance manual

AGCO

AGCO Laverda Combines M400 Operator's manual

Ag Leader Technology

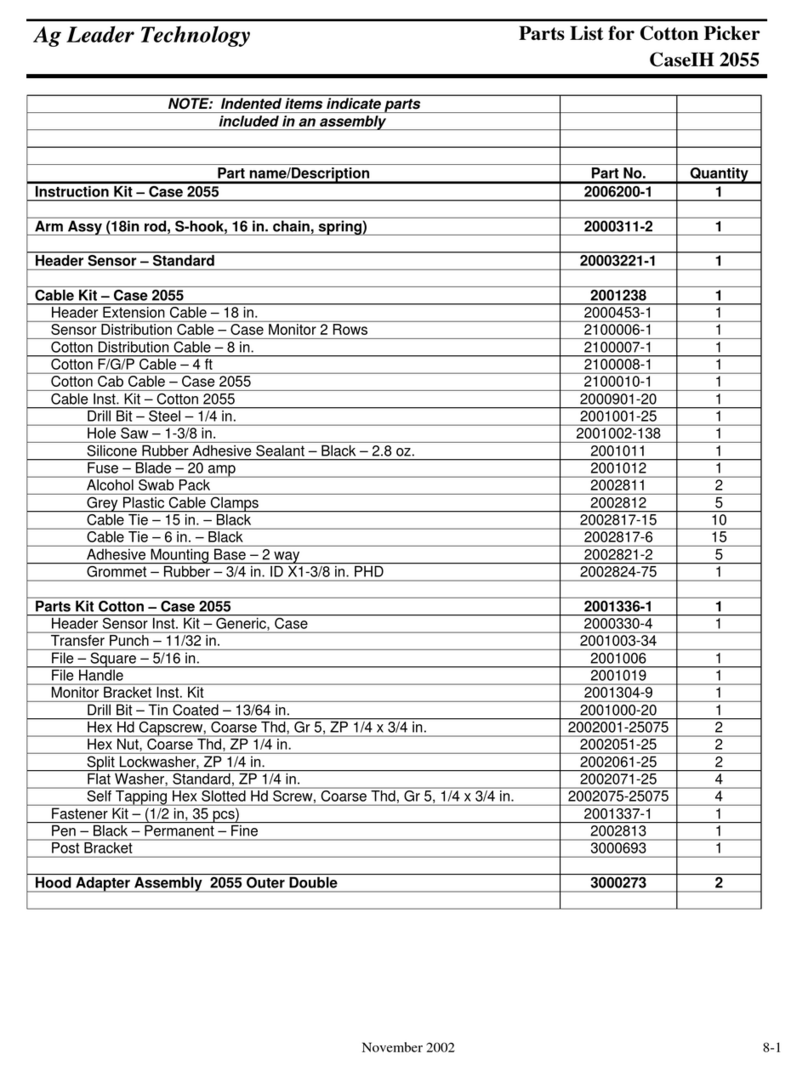

Ag Leader Technology CaseIH 2055 manual