Big Joe CB22 User manual

OPERATOR’S MANUAL

Big Lift LLC

www.bigjoeforklifts.com BL-COUNTERBALANCE-1016

08/02/2018

COUNTER-

BALANCE

LIFT TRUCK

1

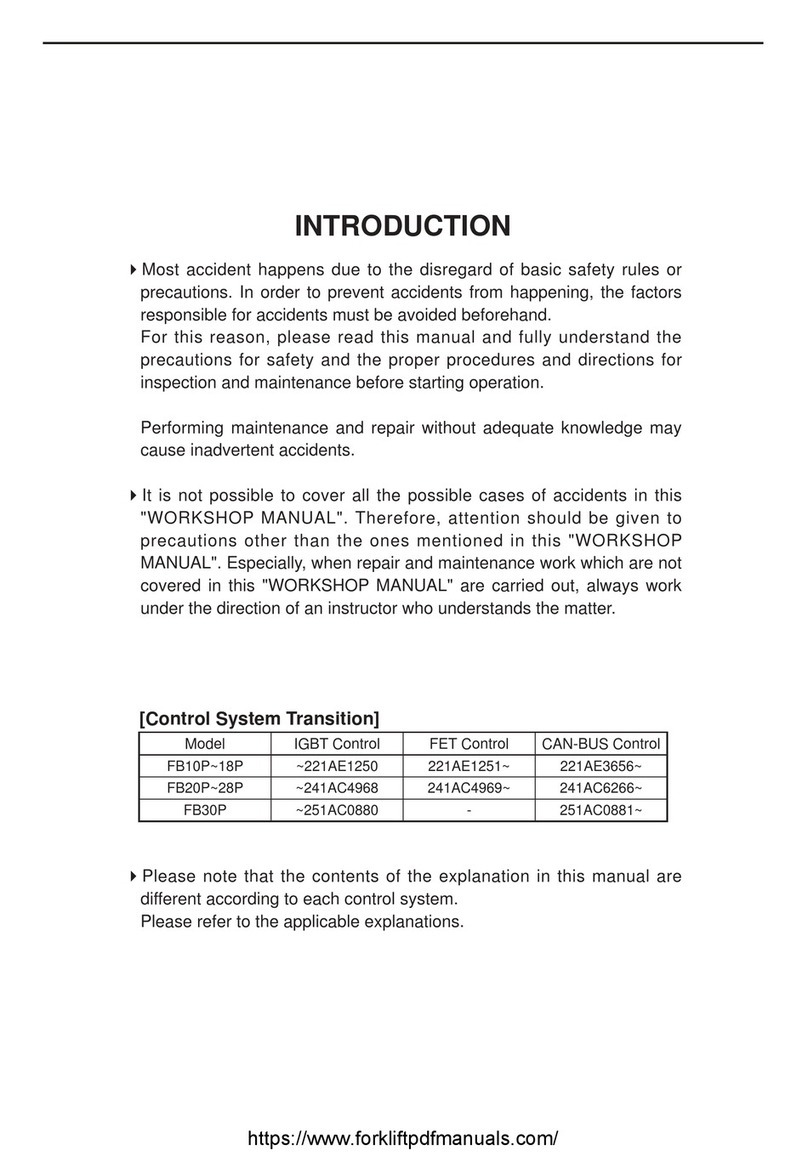

FOREWORD

As a lifttruck operator, you are respon-

sible for a machine that is useful, pow-

erful, and can be hazardous if not

operated as described. Your Big Joe

truck may weigh more than some cars,

depending on the model. Observing

and practicing the safety warnings in

this manual cannot be overempha-

sized.Justknowingthewarnings,how-

ever, is no substitute for common

sense. Using your common sense will,

in almost all cases, prevent accidents.

Think of the truck as your own. In this

way you will learn its capabilities and

limitations.

This manual is intended to remain with

the truck at all times as a handy refer-

enceguidetooperation.Detailedmain-

tenance procedures are found in the

parts and service manual for the spe-

cific truck model, and are to be per-

formed only by a qualified technician.

For further information on obtaining a

completepartsandservicemanual,see

page 25 of this manual.

The operator who knows his truck will

learntospotproblemsastheydevelop.

Thisisaccomplishedby performingthe

Daily Checks and reporting any prob-

lems to the designated authority.

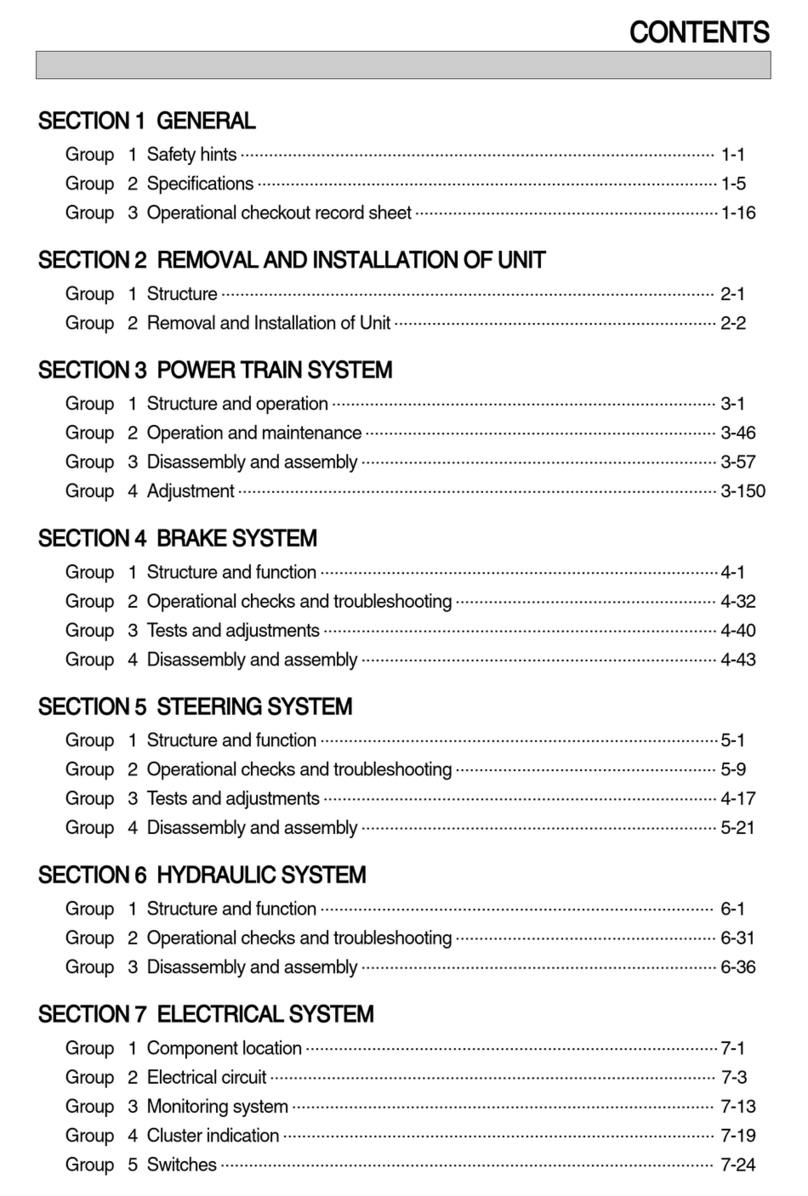

TABLE OF CONTENTS

SAFETY SYMBOLS..............................................................................................2

GENERAL DESCRIPTION....................................................................................2

NAME PLATE AND WARNING DECAL ...............................................................2

LOAD CAPACITY..................................................................................................5

BEFORE OPERATION..........................................................................................6

INSTRUMENTS AND CONTROLS - CB22 & CB33.............................................8

OPERATION........................................................................................................11

Forward and Reverse Travel and Speed Control ...............................11

Steering..................................................................................................13

Stopping.................................................................................................13

Parking...................................................................................................14

Battery Charging...................................................................................14

Load Handling .......................................................................................15

Moving a Disabled Truck......................................................................15

NOTICE - OBTAINING A PARTS AND SERVICE MANUAL..............................25

2

SAFETY SYMBOLS

WARNING and CAUTION are both signal words intended to alert the viewer to the

existence and relative degree of a hazard. They are both preceded by a safety alert

symbol consisting of an exclamation mark enclosed by a triangle.

A Warning indicates a hazard which could result in injury or death if proper precau-

tions are not taken.

A Caution indicates a reminder of routine safety practices.

A prohibition slash (circle with diagonal slash through it) indicates a procedure or

actionthatshouldnotbeperformedunderanycircumstances,asbothpersonalinjury

and/or damage to equipment will result.

GENERAL DESCRIPTION

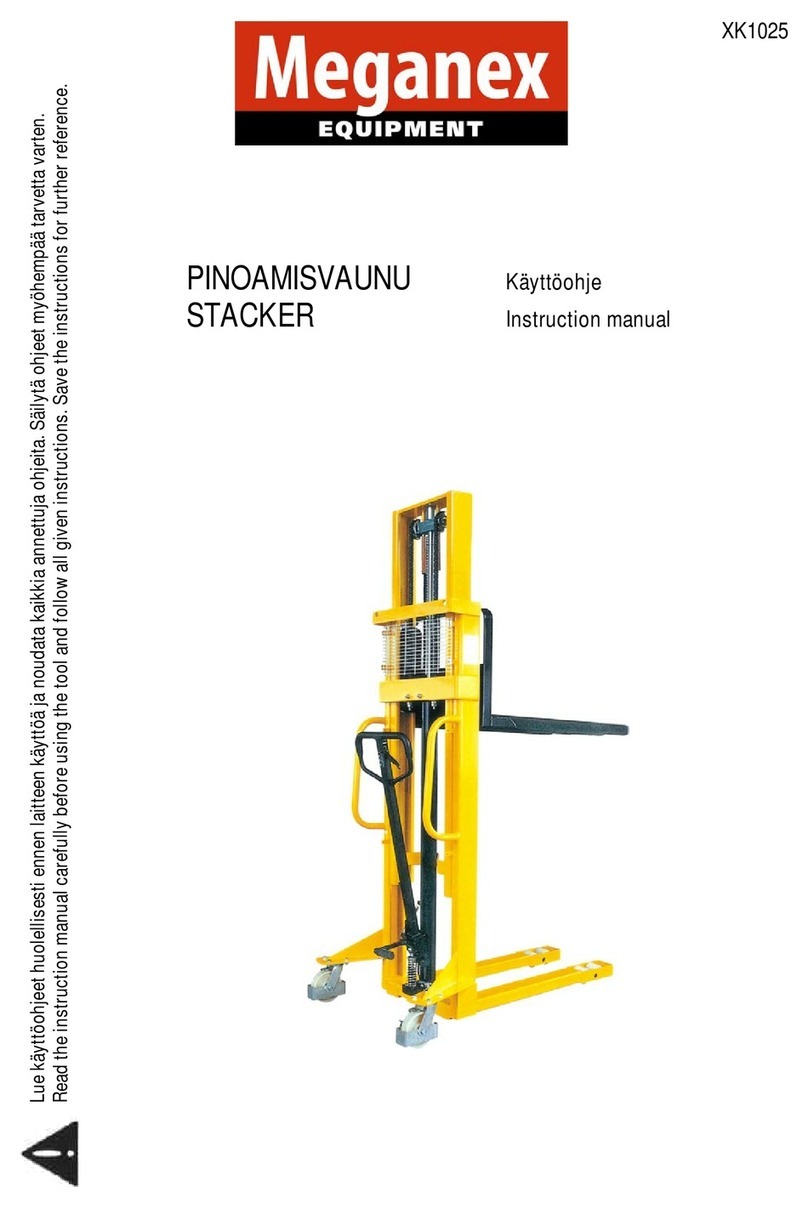

Trucks in the Big Joe Counterbalance

seriesutilize a weightedframetocoun-

terbalance the load. Most models are

equipped with tilt cylinders used to tilt

the mast back during transport.

Control for steering, braking, forward

andreversetravel,hornandspeedcon-

trolarealllocatedonthecontrolhandle.

All trucks feature an automatic high

speed cut-off circuit which locks out

highspeedwhentheforksareelevated.

Trucks in this series may vary in load

capacity, battery arrangement, instru-

mentation and lift/lower controls,

depending on model and options.

NAME PLATE AND WARNING DECAL

Name plate and warning decal loca-

tions may vary between models, but

they are always near the steering arm

within sight of the operator.

Ifthenameplateorwarningdealarelost

or damaged they should be replaced

immediately. Have your supervisor or

the designated authority contact Big

JoeAuthorizedDealerforreplacement.

Thename plate shows the model num-

ber, serial number, truck type, battery

type, voltage, minimum weight, and

maximum lift height. It also contains

information on the load capacity and

loadcenter.Thewarningdecalcontains

warnings which also appear, with illus-

trations,in theOperationsectionofthis

manual.

3

CB22 Name Plate and Warning Decal Locations - Typical

CB33 Name Plate and Warning Decal Locations - Typical

R7304

4

PDC Name Plate and Warning Decal Locations - Typical

This truck is equipped with a battery. Read and heed the following warning plus any

other warnings located near or on the battery.

WARNING:

5

LOAD CAPACITY

The further the load center is from the

backrest, the lower the load capacity.

Theload centermust alsobe no higher

thanthatspecifiedabovetheliftingsur-

face(Top side offorks).Forexample,a

load capacity of 3,000 pounds with a

loadcenterof24inchesmeansthatthe

truck can be used to lift 3,000 pounds

onlywhentheload’scenterofgravity is

nomorethan24inchesfromthefaceof

theforksor24inchesabovethetopside

of the forks. Note that a truck undergo-

ingspeedchangesis lessstablethana

standing truck. If you are not sure that

the truck can lift a certain load, consult

your supervisor or the designated

authority.

Load Center

R3814

6

BEFORE OPERATION

The table on page 7 covers important

inspection points on trucks which

should be checked prior to operation.

Depending on use, some trucks may

require additional checks.

The illustration below shows a sample

format for a Operator Checklist, which

canbemodifiedasnecessarytofityour

operation.

Periodic maintenance of this

truck by a qualified service

technician is required.

A qualified service technician

should check the truck monthly

for proper lubrication, proper

fluid levels, brake maintenance,

motor maintenance and other

areas specified in the parts and

service manual maintenance

section.

If the truck is found to be unsafe

and in need of repair, or contrib-

utes to an unsafe condition,

report it immediately to the des-

ignatedauthority.Donotoperate

it until it has been restored to a

safe operating condition. Do not

make any unauthorized repairs

or adjustments. All service must

be performed by qualified ser-

vice technician.

Sample of Operator Check List

WARNING:

WARNING:

WARNING:

R6235

7

Operator Checks

ITEM PROCEDURE

Transmission and hydraulic

systems Check for signs of fluid leakage.

Forks Check for cracks and damage and that they

are properly secured.

Chains, cables and hoses Check that they are in place, properly secured

and not damaged.

Guards and load backrest Check that safety guards are in place, prop-

erly secured and not damaged.

Safety signs Check that warning labels, nameplate, etc.,

are in good condition and legible.

Horn Check that horn sounds when operated.

Steering Check for binding or looseness in steering

arm when steering.

Travel controls Check that speed controls on control handle

operate in all speed ranges in forward and

reverse and that belly button switch functions.

Wheels Check drive wheel for cracks or damage.

Move truck to check load wheels for freedom

of rotation.

Hydraulic controls Check operation of lift and lower, and tilt to

their maximum positions.

Brakes Check that brakes actuate when steering arm

is raised to upright position, and when lowered

to horizontal position.

OPTION ON PDC TRUCKS: Check that

dynamic brake (if so equipped) actuates when

dynamic brake pushbutton on control handle

is pressed.

Deadman/Parking brake Check that steering arm raises to upright posi-

tion when released and brake applies.

Battery disconnect Check that battery can be disconnected and

reconnected. Check for connector damage.

High speed limit switch Allow for enough space to operate truck in

high speed. Elevate forks approximately two

feet, then test drive truck to check if high

speed is cut out.

8

INSTRUMENTS AND CONTROLS - CB22 & CB33

The steering arm and control handle

provide controls for steering, forward

and reverse speed control, braking,

horn,tiltingandraisingandloweringthe

forks. Control handles on all models

have a “belly-button” reversing switch

whichreversesthedirectionofthetruck

upon contact with the operator.

Detailed operating instructions are in

the Operation section of this manual.

A battery disconnect is mounted near

thesteeringarm.Pullingthedisconnect

removesall power from truck circuits in

the event of an emergency.

CB22 Control Handle

CB33 Control Handle

R7305

R7306

9

INSTRUMENTS AND CONTROLS - PDC

The steering arm and control handle

provide controls for steering, forward

andreversespeedcontrol,braking,

and

horn. Control handles on some

models

have pushbuttons for raising

and low-

ering the forks, and for an

additional

"dynamicbrake" independentfromthe

mechanical brake (dynamic brake no

longeravailableonnewtrucks).Control

handlesonallmodelshave a

"belly-but-

ton" reversing switch which reverses

the direction of the truck

upon contact

with theoperator.

Detailed operating instructions are in

the Operation section of this manual.

A battery disconnect is mounted near

thesteeringarm.Pullingthedisconnect

removesallpowerfrom truck circuitsin

the event of an emergency.

PDC Control Handle

All models come standard with a lift/

lower control lever mounted near the

steering arm. Some models have addi-

tional control levers for operating a tilt

mechanismwhichtiltsthemastforward

or back. Other models have additional

controlleversfortheoperationsofaddi-

tional accessories.

Lift/Lower and Tilt Control Lever

Optional Features

R7306

10

Theoptionalremotelift/lower control

(if

equipped) allows the operator to raise

andlowertheforkswhile standingaway

from the control handle.

Optional Remote Lift/Lower Control

Other options are the battery capacity

indicator, hourmeter and keyswitch

whichmountonthepanelnear the

con-

trol handle. The battery capacity

indi-

cator monitors the battery discharge

rate to indicate the remaining

battery

capacity. The hour meter

records the

accumulated hours that

electrical

energy is being drawn from

the battery

to run the pump and drive

motors. The

keyswitch provides

added security to

the truck,preventing

unauthorized per-

sonnel from operating themachine.

11

OPERATION

Forward and Reverse Travel and

Speed Control

All directional and speed controls are

located on the control handle.

Forward and reverse are controlled by

rotating the speed control lever as

shown. The lever is spring loaded to

returntoneutralwhenreleased.Further

rotation in either direction will progress

the truck from slow to maximum travel

speed.

Tochangedirectionsortostopthetruck,

rotate the speed control lever in the

opposite direction. The truck will come

to a stop and then, unless the controls

are returned to the center neutral posi-

tion, accelerate in the opposite direc-

tion.

CB22 Control Handle

CB33 Control Handle

R7305

R7306

12

PDC Control Handle

R3961

13

Steering

Moving the control handle (which con-

nectstothesteeringarm)rightorleftwill

turnthetruckrightorleft.Whenmaneu-

vering around corners, make square

turns and be sure there is

adequate clearance.

Stopping

Stopthetruckasgraduallyaspossible.

Unnecessary rapid stopping could be

hazardous. Load could become unsta-

ble.

Therearefourpossiblewaystostopthe

truck:

1. Plugging: This electrical braking

function consists of rotating the

speedcontrolleverin theopposite

direction of travel and then releas-

ing it when the truck stops. Plug-

gingisaconvenientwaytostopthe

truck during normal operation. If

the control is not released, the

truckwillaccelerateintheopposite

direction.

2. Steering arm: The brake is fully

applied by lowering or raising the

steering arm. All traction control

powerisshutoffwhenthebrakeis

engaged.Whenthesteeringarmis

in the upright position, the brake

actsas a parkingbrake. Deadman

braking occurs when the handle is

released and spring action raises

steering arm to the upright posi-

tion.

CB22 & CB33 Steering Arm Braking Positions

14

PDC Steering Arm Braking Positions

Steering Arm Braking Positions

3. Regenerative Braking (CB22 &

CB33):Ifthespeedcontrolleveris

released, the truck automatically

brakes regeneratively. When the

speedisbelow0.5MPH,thebrake

applies.

4. Dynamic Brake (PDC Only): -

(Dynamic brake is no longer avail-

able on new trucks). The dynamic

brake (optional) serves as a sec-

ondarybrakingsystemcompletely

independent from the mechanical

brake.Pressingthedynamicbrake

pushbutton applies a constant DC

voltageacrossthedrivemotorfield

coils to stop the motor.

The dynamic brake pushbutton

shouldnotbeheldinplacelonger

thanoneortwoseconds.Exces-

sive use may blow the 40 Amp

fuse, which will render dynamic

brake inoperative

Parking

Whenparkingthetruck,donotobstruct

traffic lanes or aisles.

1. Park the truck in its designated

parking area.

2. Raisethesteeringarmuntilvertical

to apply the parking brake.

3. Fully lower forks.

4. Turn key switch to off position.

Remove key for added security.

5. Pull out battery disconnect.

Battery Charging

RefertoDOC245forbatterysafetyand

maintenance.

NOTE: Battery charging instructions

are contained in the service

manual.

WARNING:

15

Load Handling

Handle only loads arranged for

stabilityandalways use caution.

Raise and lower the load

smoothly to prevent the load

from falling.

Alwaysbesuretheloadandload

center are within the capacity of

the truck. If in doubt check the

nameplate.

1. Approach the load slowly.

2. Stop the truck when the forks are

just in front of the load.

3. Adjust the forks to the maximum

practical width to support the load

to be lifted.

4. Raise or lower the forks until they

areproperlyalignedwith thepallet

openings.

5. Movethe truck slowly intoposition

sothattheforksarecenteredabout

the load.

6. Make sure the load is against the

backrest and then raise the forks

until the pallet clears the rack. Tilt

the forks slightly backward.

7. Move the truckaway fromthe rack

until the load clears the rack and

then lower the forks.

8. Lead the truck by the control han-

dle with the load trailing except

when in confined areas. Ramps

should always be traveled with

operator uphill of truck.

9. Always look in the direction of

travel. Move slowly and check

clearances when approaching

obstructions.

10. Do not make sudden starts and

stops.Operatetrucksmoothlyand

gradually.

11. Travelslowlyandsquarelyaround

corners. Remember that the trail-

ing load wheels do not follow the

turn path of the drive wheel;

instead,theytendtocutthecorner.

12. Lineupthetruckwiththeunloading

area.

13. Stop the truck and raise or lower

the forks until the pallet is in posi-

tion with the unloading area.

14. Checktheloadalignmentwithsur-

rounding objects.

15. Be careful not to damage or move

adjacent loads and objects.

16. Slowly move into position.

17. Lowertheforksandtiltforwarduntil

the load is resting on its own. Be

surethereisnodownwardforceon

the forks on the rack or floor.

18. Move the truck back until the forks

are clear of the pallet.

19. Ifforksareelevated,lowertotravel

position.

Moving a Disabled Truck

Donotattempttomoveadisabledtruck;

notifyyoursupervisor orproper author-

ity.

WARNING:

WARNING:

16

The following operating instructions appear on the truck warning decal, which is

located near the steering arm.

R4050

Donotoperatethistruckunlessyou

have been trained and authorized

to do so, and have read and under-

stand all warnings and instructions

containedinthisoperator’smanual

and on this truck.

Do not operate this truck until you have

checkeditscondition.Givespecialattention

to tires, horn, lights, battery, controller, lift

systems (including forks or attachments,

chains, cables and limit switches), brakes,

steering mechanism, guards and safety

devices. If you have any questions,

notify your supervisor or proper

authority.

R7060

17

R4052

Operate truck only from walking position.

R4053

Never place any part of the body into

themaststructureorbetweenthemast

and the truck.

18

Do not carry passengers.

R4054

Keep feet clear of truck and

always wear foot protection.

R4053

This manual suits for next models

2

Table of contents

Other Big Joe Forklift manuals

Big Joe

Big Joe PPT 45 Series Use and care manual

Big Joe

Big Joe E30 User manual

Big Joe

Big Joe V Series User manual

Big Joe

Big Joe T15 User manual

Big Joe

Big Joe EZ30 Use and care manual

Big Joe

Big Joe PDSR User manual

Big Joe

Big Joe CB33 User manual

Big Joe

Big Joe PDI Series User manual

Big Joe

Big Joe PDS 20 User manual

Big Joe

Big Joe M22 Use and care manual