CESAB BT BLITZ 312 User manual

SERVICE MANUAL

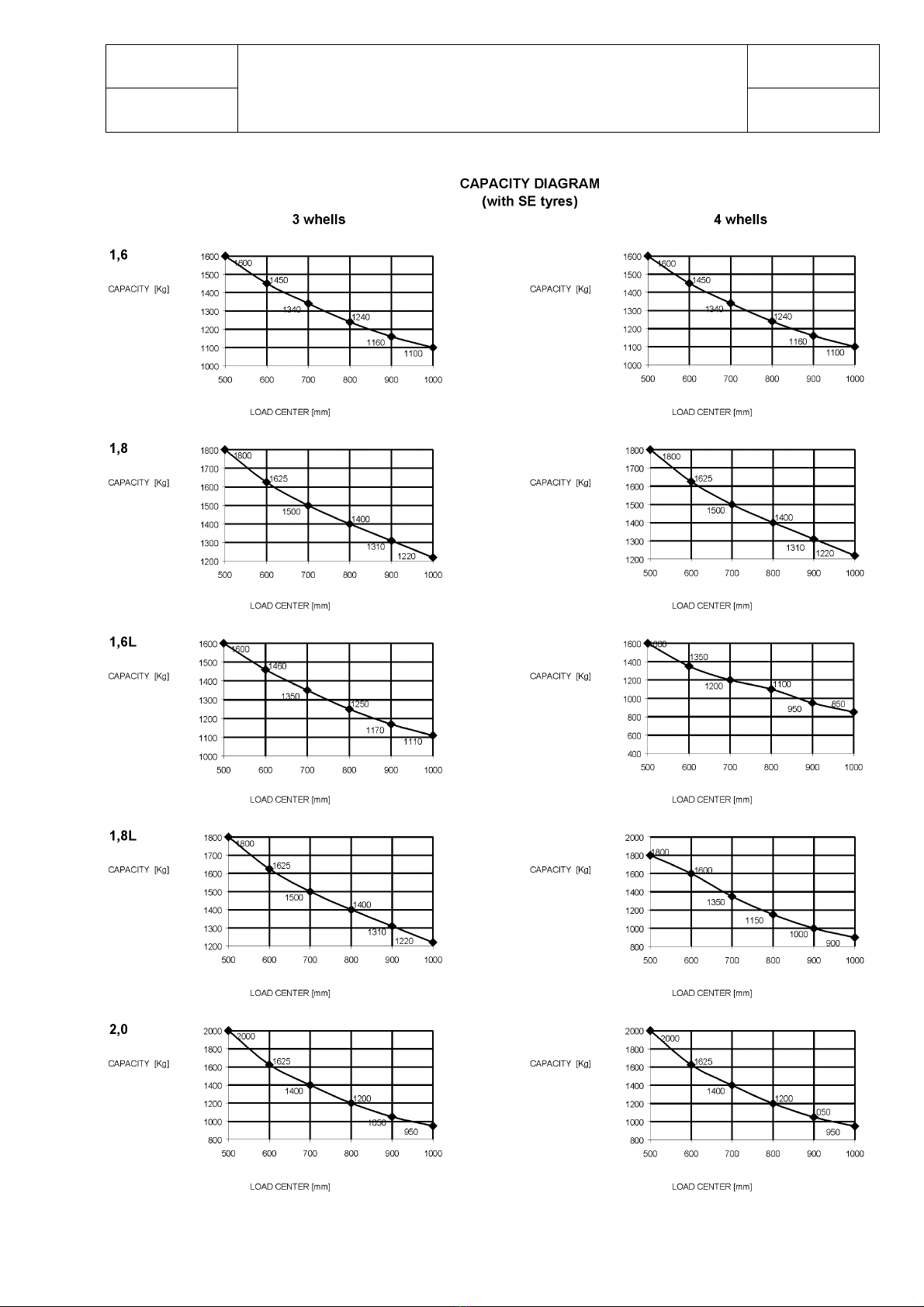

C3E120 C4E120

C3E150 C4E150

C3E160 C4E160

C3E160L C4E160L

C3E180 C4E180

C3E180L C4E180L

C3E200 C4E200

036-0410-07 04/2005

PAGINA INTENZIONALMENTE BIANCA

INTENTIONALLY LEFT BLANK

PAGE INTENTIONNELLEMENT BLANCHE

ABSICHTLICH FREIGELASSENE SEITE

PÁGINA INTENCIONALMENTE BLANCA

index

page 1

1,2 - 2,0 t A.C.

SERVICE MANUAL

Electric

036-0410-07

CESAB S.p.A

via Persicetana Vecchia, 10

40132 Bologna - Italy

Tel. (0039) 051.20 54 11

Fax (0039) 051.72 80 07

E-mail: [email protected]

CESAB S.p.a. reserves all rights of

reproduction of this handbook

The text and the numbering system

may not be used in other printed matter,

reprinted or translated, whether entirely

or in part, without written authorization

from

CESAB reserves the right to make any

necessary modifications without obligation

to promptly update this handbook.

Copyright by

BOLOGNA’S FACTORY, AFTER SALES SERVICE

index

page 2

1,2 - 2,0 t A.C. SERVICE MANUAL Electric

036-0410-07

INDEX

GENERAL INFORMATION chapter A

CHASSIS chapter 0000

MOTORS / ENGINES chapter 1000

TRANSMISSION / DRIVE GEAR chapter 2000

BRAKE / WHEEL chapter 3000

STEERING SYSTEM chapter 4000

ELECTRICAL SYSTEM chapter 5000

HYDRAULIC / PNEUMATIC SYSTEM chapter 6000

MAST GROUP chapter 7000

ATTACHEMENT chapter 8000

OPTIONS chapter 9000

MAINTENANCE TABLES chapter B

SAFETY INFORMATION chapter C

chapter A

page 1

1,2 - 2,0 t A.C.

SERVICE MANUAL

Electric

036-0410-07

CHAPTER A

GENERAL INFORMATION

chapter A

page 2

1,2 - 2,0 t A.C.

SERVICE MANUAL Electric

036-0410-07

GENERAL INFORMATION INDEX

TECHNICAL DATA page3

chapter A

page 3

1,2 - 2,0 t A.C.

SERVICE MANUAL

Electric

036-0410-07

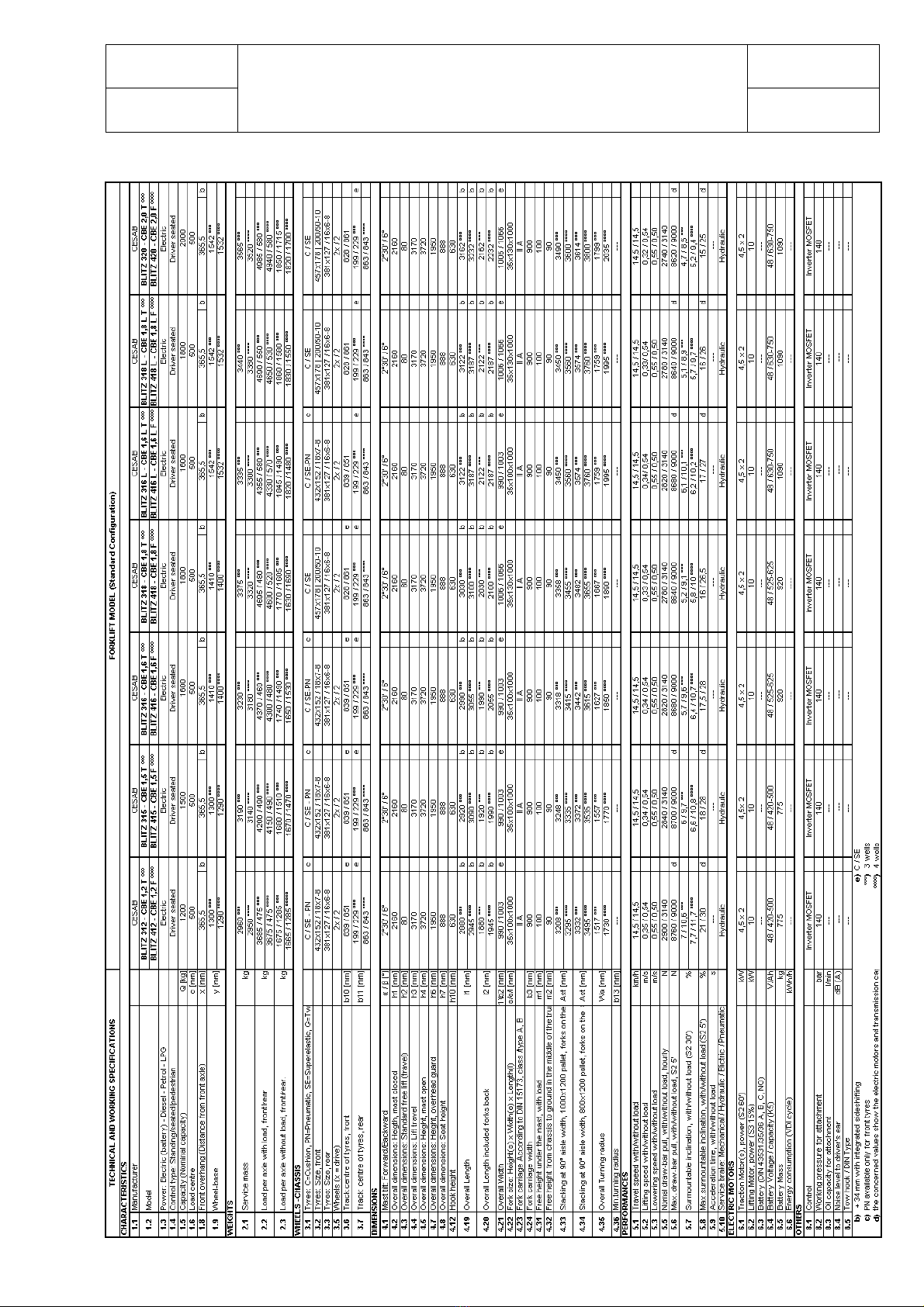

TECHNICAL DATA

chapter A

page 4

1,2 - 2,0 t A.C.

SERVICE MANUAL Electric

036-0410-07

chapter A

page 5

1,2 - 2,0 t A.C.

SERVICE MANUAL

Electric

036-0410-07

chapter A

page 6

1,2 - 2,0 t A.C.

SERVICE MANUAL Electric

036-0410-07

PAGINA INTENZIONALMENTE BIANCA

INTENTIONALLY LEFT BLANK

PAGE INTENTIONNELLEMENT BLANCHE

ABSICHTLICH FREIGELASSENE SEITE

PÁGINA INTENCIONALMENTE BLANCA

chapter 0000

page 1

1,2 - 2,0 t A.C.

SERVICE MANUAL

Electric

036-0410-07

CHAPTER 0000

CHASSIS

chapter 0000

page 2

1,2 - 2,0 t A.C. SERVICE MANUAL Electric

036-0410-07

CHASSIS INDEX

TRUCK’S LAY OUT page3

PEDALS page4

DRIVE DIRECTION LEVER ON STEERING COLUMN page4

STEERING COLUMN PUSH BUTTONS page5

LOAD HANDLING COMMANDS page6

DASHBOARD page7

DASHBOARD CONTROLS page8

PLATES page 9

LIFTING OF THE TRUCK page10

chapter 0000

page 3

1,2 - 2,0 t A.C.

SERVICE MANUAL

Electric

036-0410-07

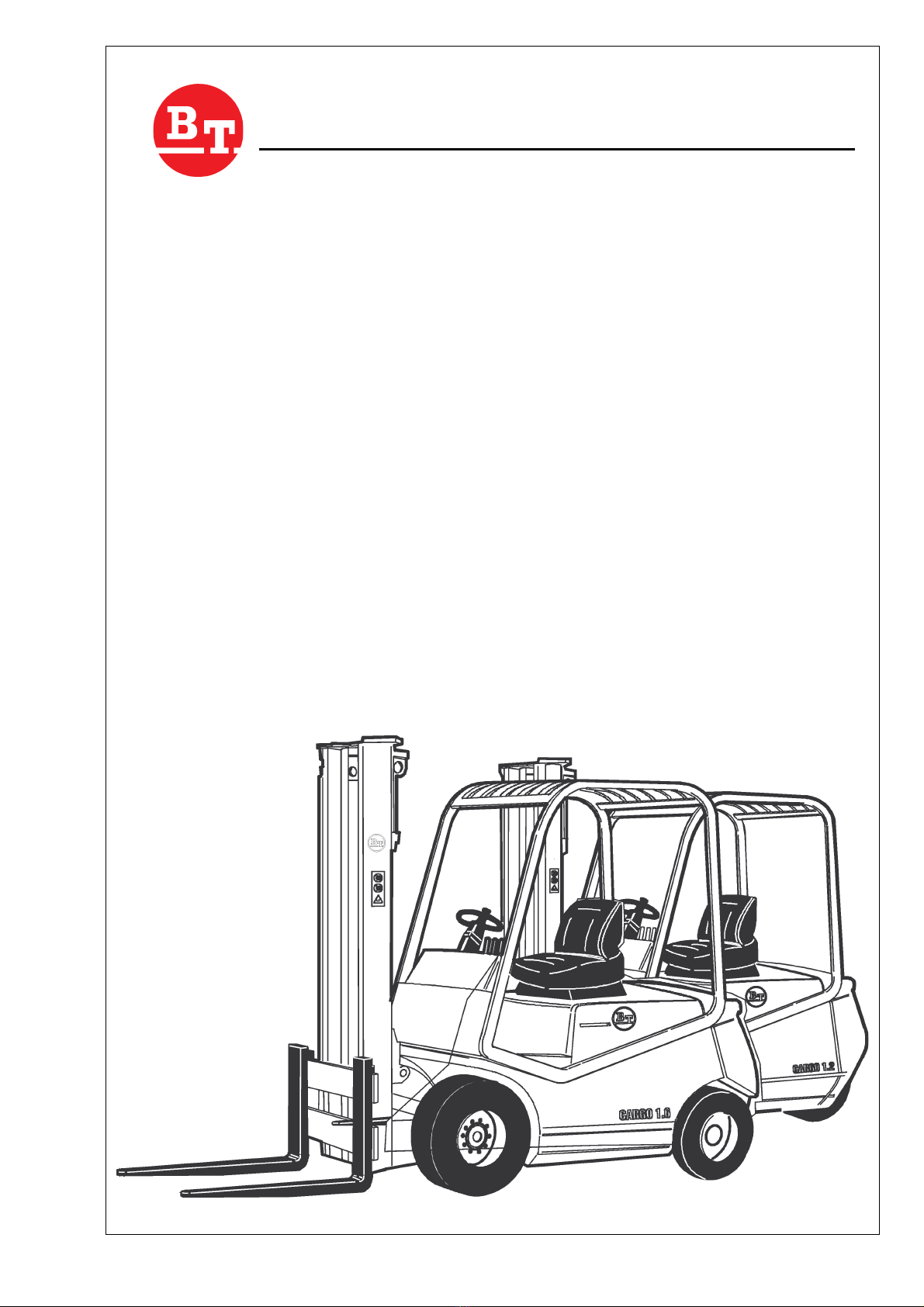

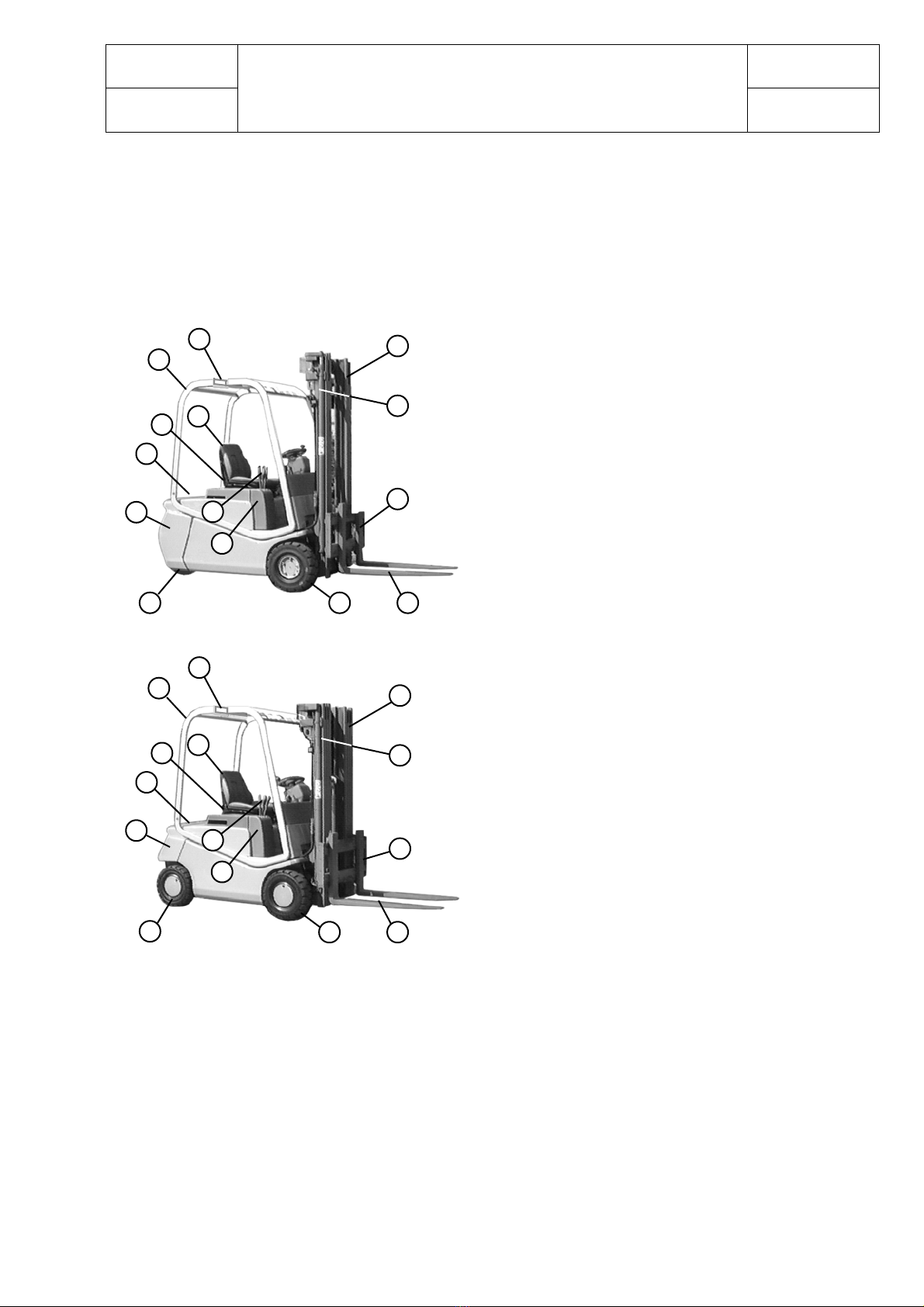

TRUCK’S LAY OUT

DESCRIPTION OF MAIN PARTS

A) Mast frame

B) Opening for lifting battery

C) Seat

D) Electronic control unit compartment

E) Counterweight

F) Hydraulic valve commands

G) Control valve cover

H) Lifting jack

I) Lifting fork carriage

J) Overhead guard

K) Present man device

M) Driven wheels

N) Steered wheels

Q) Forks

A

B

FI

E

C

D

G

N M

J

K

Q

H

B

F

E

C

D

G

N

J

K

M Q

A

I

H

chapter 0000

page 4

1,2 - 2,0 t A.C. SERVICE MANUAL Electric

036-0410-07

BD E

O

P

o

é

ê

Q

OPERATOR'S SEAT

FOOT PEDALS VERSION

FOOT DRIVE DIRECTION

(Standard version)

- Forward direction (D)

- Backward direction (E)

- Service brake pedal (B)

DRIVE DIRECTION LEVER ON STEERING

COLUMN (Alternative version)

Direction selector lever (F)

1Forward direction

0Neutral

2Backward direction

Parking brake lever (A)

Emergency push button (H)

Single drive pedal (G)

Horn push button (O)

Ignition key (P)

The steering column position can be adjusted forward or backward.

In order to do it, unloose the lever (Q) then secure the steering

column in the desired position. Do not adjust the steering column

while the truck is moving.

A

H

F

1

o

2

G

B

chapter 0000

page 5

1,2 - 2,0 t A.C.

SERVICE MANUAL

Electric

036-0410-07

M

M

N

N

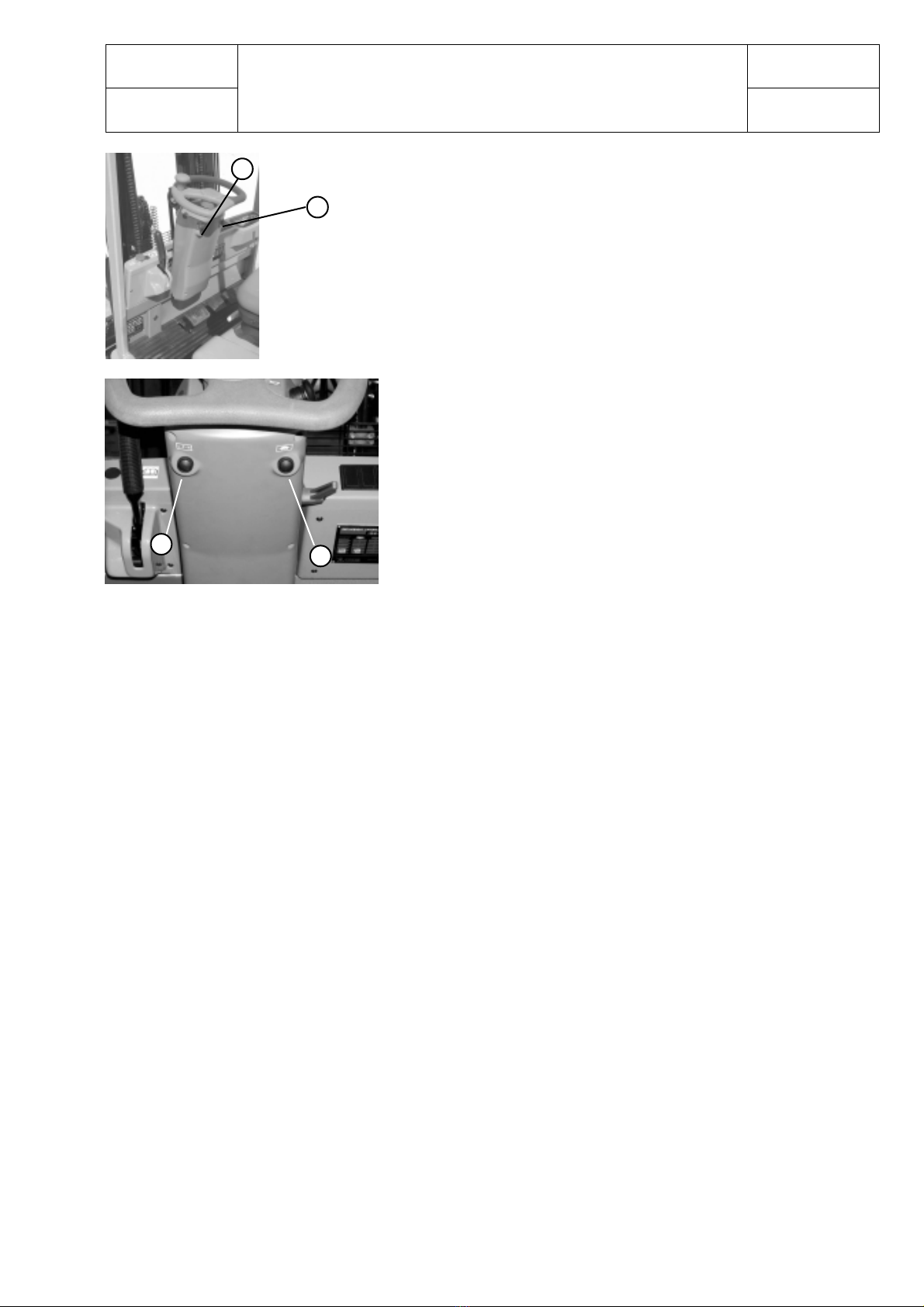

STEERING COLUMN PUSH BUTTONS

It is strongly recommended to avoid operating

both push buttons when the truck is running.

Selected setting push button (M):

P (programmable), H (high), L (low)

Speed reduction push button (N) (turtle function)

M) Selected setting push button:

at the start up, the truck is setted in the same condition as it was turned off. The available settings are:

P (programmable), H (high) or L (low).

Settings can be selected pulling the push button several times.Three leds will show the selected program

as indicated at the dashboard description page, item 11.

P: - Maximum drive speed.

- Acceleration and braking action are optimised for low energy consumption.

- Parameter change function enabled.

H: - High drive speed.

- Strong action of the traction parameters.

- Parameter change function disabled.

L: - Low drive speed.

- Soft action of the traction parameters.

- Parameter change function disabled.

N) Speed reduction push putton:

it limits the maximum drive speed of the truck by the set percentage ( from 10% up to 90% ). See

chapter 5000 (Parameter change function, DualAC2 traction unit) paragraph “CUTBACK SPEED”.

chapter 0000

page 6

1,2 - 2,0 t A.C. SERVICE MANUAL Electric

036-0410-07

3

12

A

L

B

C

H K J

The truck can be equipped with three types of commands for load handling

CONTROL VALVE VERSION (A)

JOYSTICK VERSION (B)

FINGERTIPS VERSION (C)

Levers unit

H) Lifting control lever (yellow cap)

K) Tilting control lever (green cap)

J) Sideshift control lever (red cap)

L) Device control lever (optional) (black cap)

Functions

- Handle for a better opening / closing (1)

- Hook with opening button(2)

Battery plug fixing position

- Battery Plug (3)

BATTERY COVER

LOAD HANDLING COMMANDS

chapter 0000

page 7

1,2 - 2,0 t A.C.

SERVICE MANUAL

Electric

036-0410-07

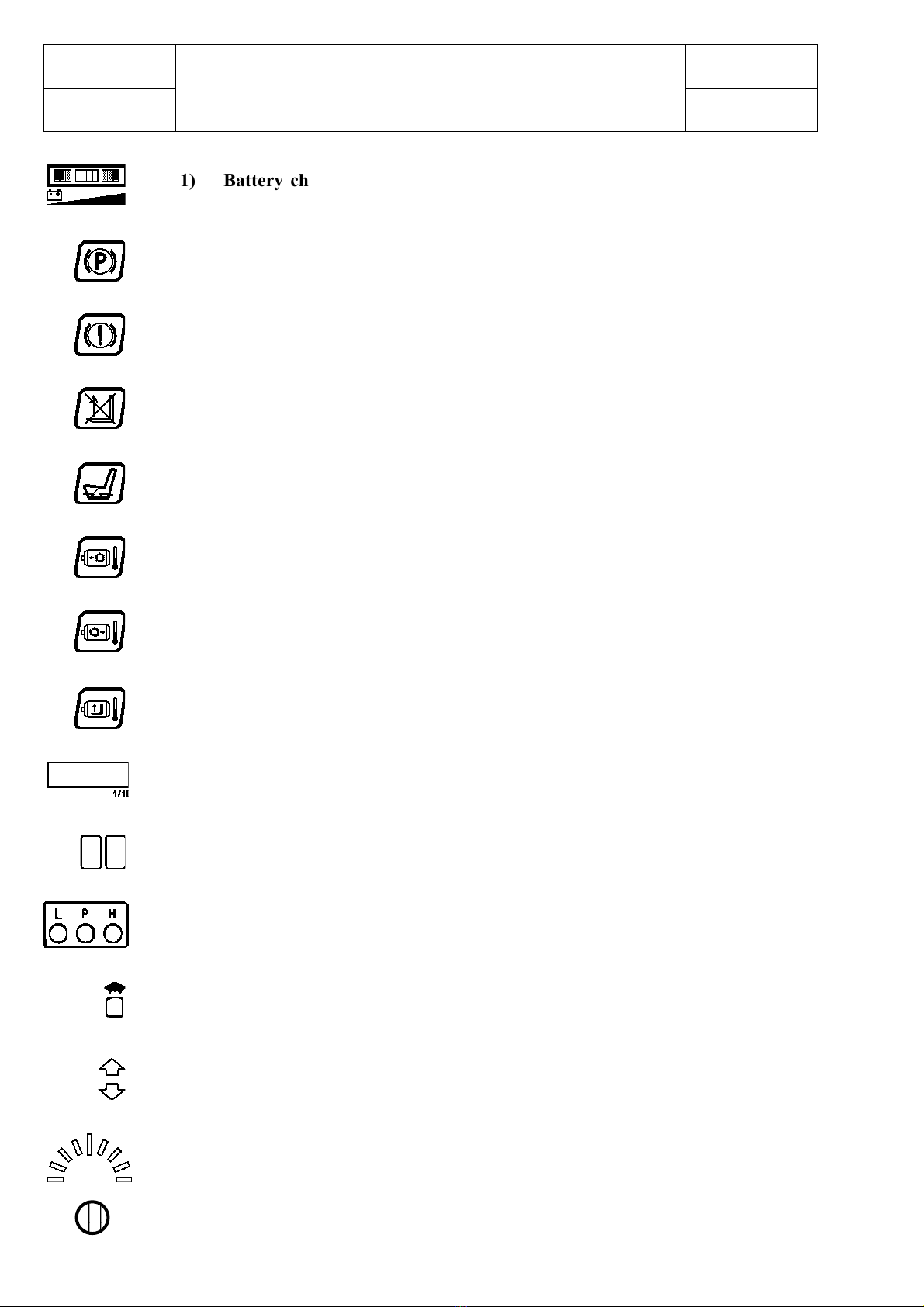

The dashboard consists of a series of instruments and warning lights to check the correct operation of

the truck.

DASHBOARD

1) Battery charge status indicator.

2) Parking brake ON warning light.

3) Brake fluid low level warning light.

4) Lifting speed reduction due to flat battery.

5) “Present man device” warning light.

6) Drive left motor temperature warning light.

7) Drive right motor temperature warning light.

8) Liftingmotortemperaturewarninglight.

9) Electronic hour meter.

10) Diagnosticcodealphanumericdisplay.

11) Selectedsettingdisplay.

12) Speedreductionindication light

13) Forward/backward indication lights

14) Steeringindicationdisplay

15) Lightsensor

8

14

121110 7

4

13

32115 56

9

chapter 0000

page 8

1,2 - 2,0 t A.C. SERVICE MANUAL Electric

036-0410-07

1234

1234

1234

1) Battery charge status indicator:

This bar consists of 3 green LEDS on the right side, 4 orange LEDS in the

middle and 3 red LEDS on the left side; when the battery is charged the

first green LED on the right is On; while the battery discharges, the LEDS

turn On or Off, one per time, from the right to the left according with the

battery charging status. When the battery is 80% discharged, the first red

LED on the left is On, the display (10) shows the alarm code 1C so the

battery must be recharged (reserve). There is an indication on the dashboard

(4) and thelifting speed is reduced because there is a current cutback by

50%. The battery charge indicator does not rearm if the battery charging

status is between 70% and 100%. It can be adjusted (see at chapter 5000).

2) Parking brake ON warning light

3) Brake fluid low level warning light:

This warning light comes ON when the level of brake fluid in the tank has

reached the minimum level.

4) Lifting speed reduction due to flat battery

5) ”Present man device” warning light:

The pilot light comes ON when the driver leaves the driving seat without

switching OFF the truck; under these conditions, the traction and the lifting

movement are disabled.

6) Drive left motor temperature warning light:

lights up when the temperature is 140°C.

7) Drive right motor temperature warning light:

lights up when the temperature is 140°C.

8) Lifting motor temperature warning light:

lights up when the temperature is 140°C.

9) Electronic hour meter:

It is activated by insertion of the ignition key and it conts the real working

time of the truck. It shows the working hoursand hours fractions (in tenth).

It can be adjusted (see chapter 5000, dashboard map)

10) Diagnostic code alphanumeric display:

When a malfunction occurs in the truck, this display identifies the error

through a corresponding code (see Alarm function chapter 5000).

11) Selected setting display:

Indicates the running setting selected: L (low), P (programmable), H (high):

12) Speed reduction indication light:

When the reduction speed is selected the blue light is on.

13) Forward/backward indication lights.

14) Steering indication display.

15) Light sensor:

It changes automatically the light intensity of the LEDS in the dashboard

according to the light of the environment.

DASHBOARD CONTROLS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

chapter 0000

page 9

1,2 - 2,0 t A.C.

SERVICE MANUAL

Electric

036-0410-07

LOAD PLATE

It identifies the load capacity with a load center

of 500 mm (except for different indications)

IDENTIFICATION PLATE

It identifies the lift truck technical data

B

Cod. 0312004

CARRELLI ELEVATORI S.p.A.

via Persicetana vecchia, 10

40132 - Bologna - Italia

MODELType MOTOR RATED CAPACITY

SERIAL N° DRAW-BAR PULL (1h)

SERVICE MASS

BATTERY MASS

MANUFACT. YEAR TENSION

kW k g

N

Without

Battery kg

kg

min. kg

max.

V

CESAB LDT

Bevan Way

Smethwick - Warley

West Midla 1ds B66 1BZ

A

CAPACITY PLATE

ATTACHMENT OR SPECIAL CONDITION OF USE

TYRES SERIAL N°

CENTER OF LOAD DISTANCE mm

LIFT HEIGHT

mm

DERATED CAPACITY Kg

Cod. 0312005

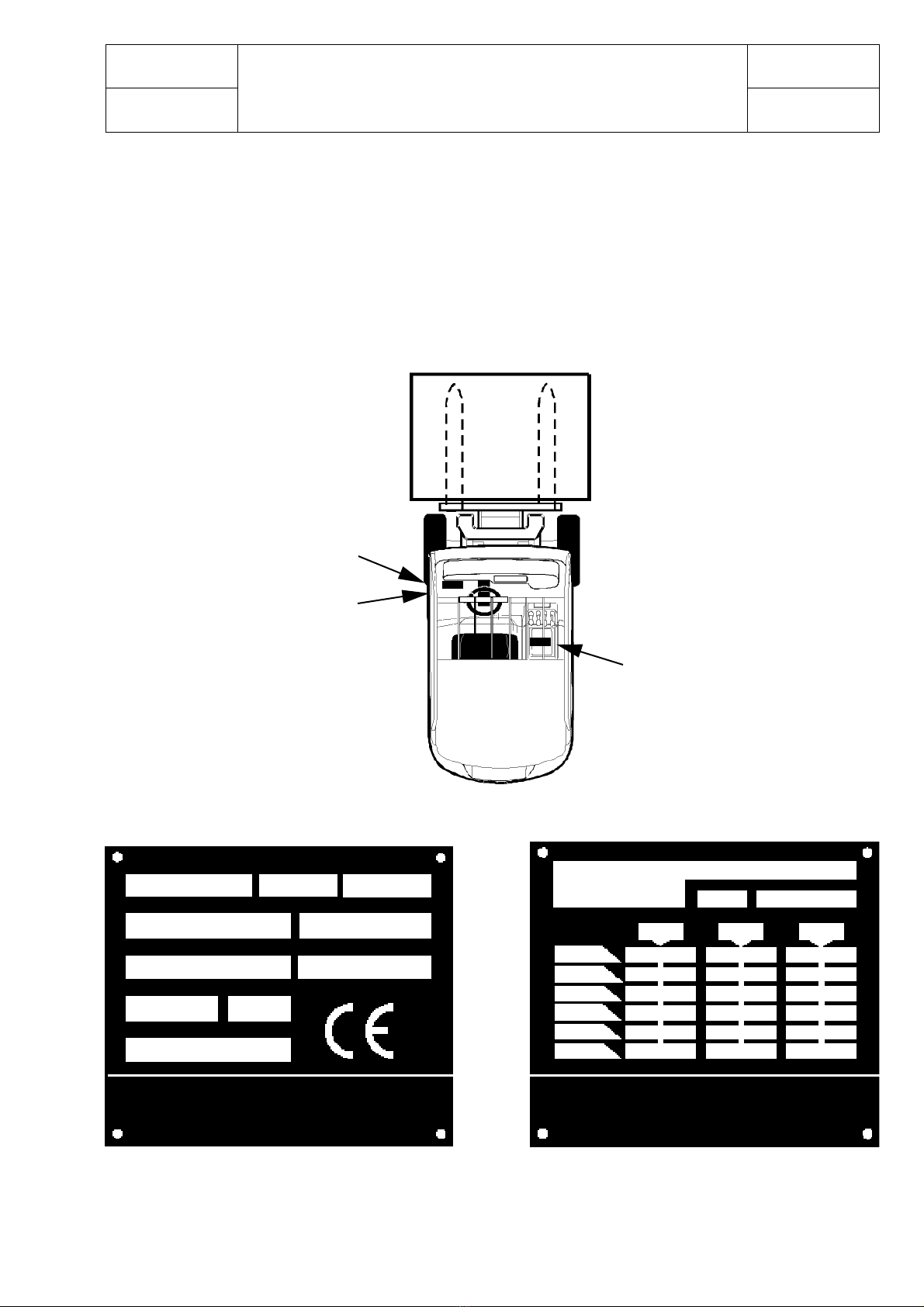

PLATES

A IDENTIFICATION PLATE

B CAPACITY PLATE

The plates positions, as shown in the picture, are refered to the standard fork lift trucks; those positions

can be modified in case of special truck configuration.

B (1,2 - 1,5 t)

B (1,6 - 2,0 t)

A

chapter 0000

page 10

1,2 - 2,0 t A.C. SERVICE MANUAL Electric

036-0410-07

LIFTING OF THE TRUCK

TYPE WHEELS TRUCK WEIGHT WITH WEIGHT ONAXLES WITHOUT LOAD

t. STANDARD BATTERY (FRONT / REAR)

1.2 3 2960 kg 1675 / 1285 kg

1.5 3 3190 kg 1680 / 1510 kg

1.6 3 3230 kg 1740 / 1490 kg

1.8 3 3375 kg 1770 / 1605 kg

2.0 3 3565 kg 1850 / 1715 kg

1.6L 3 3335 kg 1845 / 1490 kg

1.8L 3 3440 kg 1860 / 1580 kg

1.2 4 2950 kg 1665 / 1285 kg

1.5 4 3140 kg 1670 / 1470 kg

1.6 4 3180 kg 1650 / 1530 kg

1.8 4 3320 kg 1630 / 1690 kg

2.0 4 3520 kg 1820 / 1700 kg

1.6L 4 3300 kg 1820 / 1480 kg

1.8L 4 3380 kg 1830 / 1550 kg

A

B

A

If the truck is equipped with mudguard extensions, the chains can

be hooked only after the extensions disassembling.

HOOK ATTACHMENT POINTS FOR LIFTING THE TRUCK

The hooking points are shown on the carriage with the symbol shown on

the side (see picture).

LIFTING OF THE FORKLIFT TRUCK WITH OVERHEAD

GUARD

The following equipments must be used to lift the forklift truck with

overhead guard (standard):

- N° 2 slings (A): in accordance with DIN B2N -UNI 9531,

minimum length 9 m and capacity of 2800 kg.

LIFTING OF THE FORKLIFT TRUCK WITH CABIN

The following equipments must be used to lift the forklift truck with

cabin:

- N° 2 slings (A): in accordance with DIN B2N -UNI 9531,

minimum length 9 m and capacity of 2800 kg.

- N° 2 upper brackets (B) to hold the chains.

It is important to remember that the chains or slings length must be

sufficient to lift the truck in a horizontal position, with the lifting angles

(ß) ≤45° with respect to the vertical lifting line. Ensure that the chains

or slings are protected where it comes into contact with edges, then

arrange the chains or slings on the truck so that it remains in a horizontal

position during the entire lifting operation.

Make sure that there are no personnel in the vicinity of the truck, before

carrying out the lifting operation.

If any maintenance operations need to be performed on the truck in a

raised position, the vehicle must be rested on appropriate

supports, sufficient to bear the overall weight of the vehicle, keeping the

chains or slings taut.

This manual suits for next models

27

Table of contents

Other CESAB Forklift manuals

Popular Forklift manuals by other brands

Strongway

Strongway 61134 owner's manual

Lift-Rite

Lift-Rite LCF55 Owner's Manual, Operating Instructions Manual, and Replacement Parts Manual

Manitou

Manitou MSI20 T 4ST3B Operator's manual

RC4WD

RC4WD VV-JD00055 quick start guide

Clark

Clark CER10 Operation and maintenance manual

Hyster

Hyster T5ZAC PERIODIC MAINTENANCE