Big Joe PTE 30 Series Use and care manual

Big Joe Manufacturing Company • Des Plaines, IL 60018 MANUAL NO. 901467

06/20/2017

PTE 30 SERIES

SELF-PROPELLED, PALLET

LIFT TRUCK

Operation

Maintenance

Repair Parts List

WARNING

Do not operate this truck unless you have been autho-

rized and trained to do so, and have read all warnings

and instructions in Operator’s Manual and on this

truck.

Do not operate this truck until you have checked its

condition. Give special attention to tires, horn, battery,

controller, lift system, brakes, steering mechanism,

guards and safety devices.

Operate truck only from designated operating position.

Do not carry passengers. Keep feet clear of truck and

wear foot protection.

Observe applicable traffic regulations. Yield right of

way to pedestrians. Slow down and sound horn at

cross aisles and wherever vision is obstructed.

Start, stop, travel, steer and brake smoothly. Slow

down for turns and on uneven or slippery surfaces that

could cause truck to slide or overturn. Use special

care when traveling without load as the risk of overturn

may be greater.

Always look in direction of travel. Keep a clear view,

and when load interferes with visibility, travel with load

trailing.

Use special care when operating on ramps travel

slowly, and do not angle or turn. Travel with lifting

mechanism downhill.

Do not handle loads which are higher than the load

backrest or load backrest extension unless load is

secured so that no part of it could fall backward.

Before lifting, be sure load is centered, forks are com-

pletely under load, and load is as far back as possible

against load backrest.

When leaving truck, neutralize travel control, fully

lower lifting mechanism and set brake. When leaving

truck unattended, also shut off power.

901467 i

TABLE OF CONTENTS

Section Page Section Page

1 DESCRIPTION............................................................1-1

1-1. INTRODUCTION..............................................1-1

1-2. GENERAL DESCRIPTION...............................1-1

1-3. SAFETY FEATURES. ......................................1-2

2 OPERATION ...............................................................2-1

2-1. GENERAL. .......................................................2-1

2-2. OPERATING PRECAUTIONS. ........................2-1

2-3. BEFORE OPERATION.....................................2-1

2-4. GENERAL CONTROL OPERATION................2-4

2-5. DRIVING AND STOPPING PROCEDURES....2-4

2-6. BELLY-BUTTON SWITCH...............................2-4

2-7. STEERING ARM PNEUMATIC SPRING.........2-5

2-8. LIFT AND LOWER CONTROLS. .....................2-5

2-9. LOADING AND UNLOADING. .........................2-5

2-10. PARKING. ........................................................2-5

3 PLANNED MAINTENANCE ........................................3-1

3-1. GENERAL. .......................................................3-1

3-2. MONTHLY AND QUARTERLY CHECKS........3-1

3-3. BATTERY CARE.............................................3-1

3-4. CHARGING BATTERIES.................................3-1

3-5. LUBRICATION. ................................................3-2

4 TROUBLESHOOTING ................................................4-1

4-1. GENERAL ........................................................4-1

4-2. TRANSISTOR CONTROLLER

TROUBLESHOOTING .....................................4-4

4-2.1. FAULT DETECTION. .......................................4-4

4-2.2. HAND HELD PROGRAMMER (OPTIONAL)....4-5

4-2.3. FAULT RECORDING.......................................4-5

4-2.4. FAULT RECOVERY.........................................4-5

4-2.5. GENERAL CHECKOUT...................................4-5

4-2.6. ADJUSTMENT .................................................4-6

4-2.7. DIAGNOSTICS AND TROUBLESHOOTING...4-7

4-2.8. PROGRAMMER DIAGNOSTICS.....................4-7

5 STEERING ARM AND CONTROL HEAD SERIVCE ..5-1

5-1. CONTROL HEAD.............................................5-1

5-1.1. CONTROL HEAD REMOVAL. .........................5-1

5-1.2. BELLY-BUTTON SWITCH REPLACEMENT...5-1

5-1.3. LIFT, LOWER AND HORN SWITCH

REPLACEMENT...............................................5-1

5-1.4. DIRECTIONAL SWITCH REMOVAL AND

ADJUSTMENT. ................................................5-1

5-1.5. POTENTIOMETER REMOVAL TESTING

AND ADJUSTMENT.........................................5-4

5-1.6. CONTROL HEAD INSTALLATION. .................5-5

5-2. STEERING ARM..............................................5-5

5-2.1. PNEUMATIC SPRING REPLACEMENT..........5-5

5-2.2. STEERING ARM REMOVAL............................5-5

5-2.3. STEERING ARM INSTALLATION....................5-5

6 BRAKE SERVICING................................................... 6-1

6-1. BRAKES. ......................................................... 6-1

6-1.1. BRAKE REMOVAL.......................................... 6-1

6-1.2. BRAKE INSTALLATION.................................. 6-1

7 TRANSMISSION, DRIVE WHEEL, LOAD

WHEEL, BALANCE WHEEL AND ENTRY

ROLLER SERVICING................................................. 7-1

7-1. DRIVE WHEEL................................................ 7-1

7-2. DRIVE ASSEMBLY ......................................... 7-1

7-2.1. REMOVAL. ...................................................... 7-1

7-2.2. REPAIR ........................................................... 7-1

7-2.3. INSTALLATION. .............................................. 7-1

7-3. LOAD WHEEL. ................................................ 7-1

7-3.1. REMOVAL ....................................................... 7-1

7-3.2. REPAIR .......................................................... 7-4

7-3.3. LOAD WHEEL INSTALLATION....................... 7-4

7-4. CASTERS........................................................ 7-5

7-4.1. REMOVAL ....................................................... 7-5

7-4.2. REPAIR ........................................................... 7-5

7-4.3. INSTALLATION ............................................... 7-5

7-5. ENTRY ROLLERS........................................... 7-6

7-5.1. ENTRY ROLLER REMOVAL........................... 7-6

7-5.2. ENTRY ROLLER REMOVAL........................... 7-6

8 ELEVATION SYSTEM SERVICING........................... 8-1

8-1. GENERAL........................................................ 8-1

8-2. LIFT LINKAGE................................................. 8-1

8-2.1. REMOVAL ....................................................... 8-1

8-2.2. REASSEMBLY ................................................ 8-1

8-3. POWER SECTION AND FORK SECTION...... 8-1

8-3.1. SEPARATING POWER SECTION AND

FORK SECTION.............................................. 8-1

8-3.2. FORK FRAME REPAIR................................... 8-1

8-3.3. FRAME REPAIR.............................................. 8-1

8-3.4. MATING POWER SECTION AND FORK

SECTION......................................................... 8-1

9 HYDRAULIC SYSTEM SERVICING........................... 9-1

9-1. LINES AND FITTINGS .................................... 9-1

9-2. HYDRAULIC PUMP, MOTOR, AND

RESERVOIR ASSY......................................... 9-3

9-2.1. REMOVAL ....................................................... 9-3

9-2.2. DISASSEMBLY AND REASSEMBLY ............. 9-3

9-2.3. INSTALLATION ............................................... 9-3

9-2.4. LIFT CYLINDER .............................................. 9-4

9-2.5. HYDRAULIC PRESSURE ADJUSTMENT...... 9-5

10 ELECTRICAL COMPONENTS................................. 10-1

10-1. KEY SWITCH REPLACEMENT..................... 10-1

10-2. BATTERY INDICATOR REPLACEMENT...... 10-2

ii 901467

TABLE OF CONTENTS - Continued

Section Page Section Page

10-3. EMERGENCY DISCONNECT SWITCH

REPLACEMENT............................................ 10-2

10-4. DEADMAN SWITCH......................................10-2

10-4.1.REPLACEMENT............................................ 10-2

10-4.2.ADJUSTMENT............................................... 10-4

10-5. BATTERY DISCONNECT SWITCH. ............. 10-4

10-6. LIFT LIMIT SWITCH......................................10-4

10-7. ELECTRICAL CONTROL PANEL .................10-4

10-7.1.MAINTENANCE............................................. 10-4

10-7.2.CLEANING .................................................... 10-4

10-7.3.DIAGNOSTIC HISTORY................................ 10-6

10-7.4.TEST THE FAULT DETECTION CIRCUITRY10-6

10-7.5.PANEL REMOVAL.........................................10-6

10-7.6.PANEL DISASSEMBLY.................................10-6

10-7.7.PANEL INSTALLATION.................................10-7

10-8. PUMP MOTOR...............................................10-8

10-9. DRIVE MOTOR..............................................10-8

11 OPTIONAL EQUIPMENT..........................................11-1

12 ILLUSTRATED PARTS BREAKDOWN ....................12-1

LIST OF FIGURES

Figure Page Figure Page

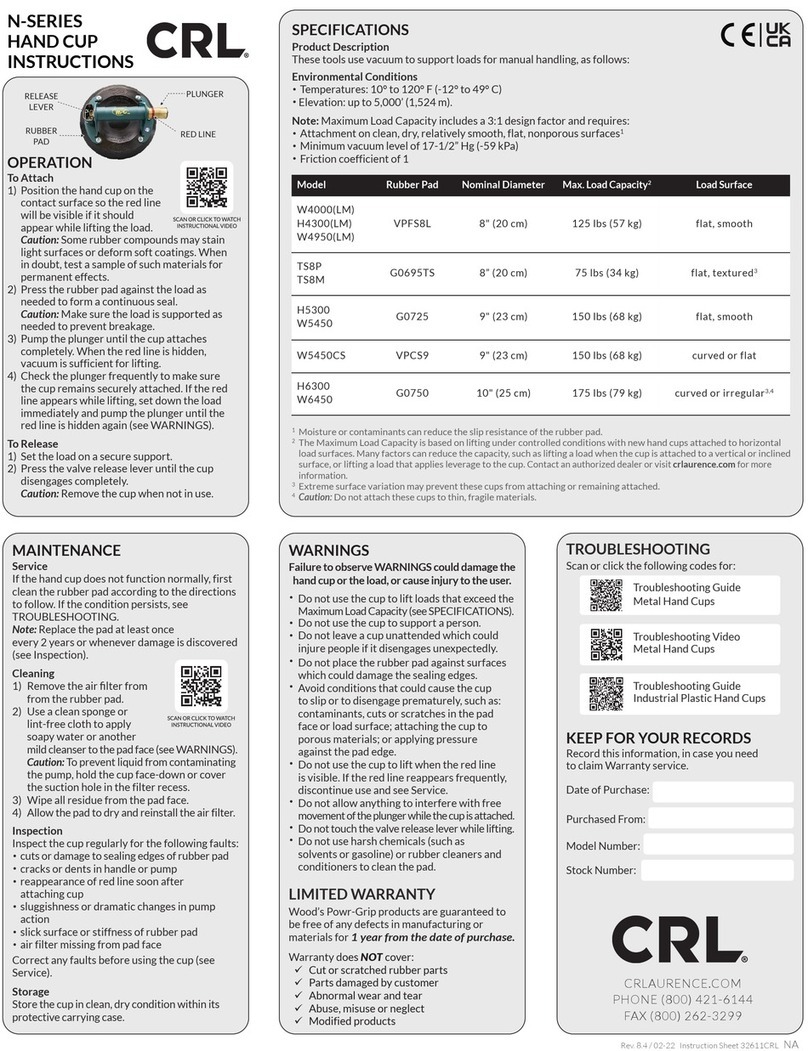

1-1 NAME PLATE...................................................... 1-1

1-2 PTE 45 LIFT TRUCK........................................... 1-1

2-1 SAMPLE OF OPERATOR CHECK LIST............. 2-3

2-2 FORWARD/REVERSE CONTROL ..................... 2-4

2-3 PUSHBUTTON SWITCHES................................ 2-4

2-4 BRAKE ACTUATION........................................... 2-4

2-5 BELLY-BUTTON SWITCH .................................. 2-5

3-1 LUBRICATION DIAGRAM................................... 3-3

4-1 STATUS LED....................................................... 4-4

4-2 ELECTRICAL PANEL PARTS............................. 4-4

4-3 CONTROLLER TERMINALS............................... 4-5

4-4 HAND HELD PROGRAMMER ............................ 4-6

4-5 WIRING DIAGRAM (SHEET 1) ......................... 4-12

5-1 CONTROL HEAD SWITCHES ............................ 5-2

5-2 CONTROL HEAD AND STEERING ARM........... 5-3

5-3 DRIVE CONTROLS............................................. 5-4

5-4 STEERING CONTROL........................................ 5-6

6-1 TRANSMISSION, BRAKE AND DRIVE

MOTOR ASSEMBLY........................................... 6-1

7-1 DRIVE ASSEMBLY ............................................. 7-2

7-2 FORK SECTION.................................................. 7-3

7-3 WHEEL ASSEMBLY............................................ 7-4

7-4 FRAME................................................................ 7-5

8-1 FORK SECTION.................................................. 8-2

8-2 FRAME................................................................ 8-3

9-1 COMPARTMENT................................................. 9-1

9-2 HYDRAULIC SYSTEM......................................... 9-2

10-1 COMPARTMENT............................................... 10-1

10-2 STEERING CONTROL ...................................... 10-3

10-3 BRAKE ACTUATION......................................... 10-4

10-4 FRAME............................................................... 10-5

10-5 ELECTRICAL PANEL........................................ 10-7

12-1 STEERING CONTROL ...................................... 12-2

12-2 STEERING ARM................................................ 12-4

12-3 CONTROL HEAD............................................... 12-6

12-4 CONTROL HEAD............................................... 12-7

12-5 DRIVE ASSEMBLY............................................ 12-8

12-6 TRANSMISSION, BRAKE AND DRIVE

MOTOR ASSY................................................... 12-9

12-7 COMPARTMENT............................................. 12-10

12-8 DECALS........................................................... 12-12

12-9 FRAME............................................................. 12-14

12-10 FORK SECTION.............................................. 12-16

12-11 CASTER ASSEMBLY...................................... 12-18

12-12 LOAD WHEEL ASSEMBLY............................. 12-20

12-13 ELECTRICAL PANEL...................................... 12-21

12-14 HYDRAULIC SYSTEM..................................... 12-22

12-15 PUMP, MOTOR & RESERVOIR ASSEMBLY . 12-24

12-16 CYLINDER ASSEMBLY................................... 12-26

12-17 VALVE ASSEMBLY......................................... 12-28

LIST OF TABLES

Table Page Table Page

2-1 OPERATOR CHECKS.......................................... 2-2

3-1 MONTHLY AND QUARTERLY INSPECTION

AND SERVICE CHART........................................ 3-1

3-2 RECOMMENDED LUBRICANTS......................... 3-2

3-3 LUBRICATION CHART ........................................ 3-3

4-1 TROUBLESHOOTING CHART.............................4-1

4-2 ADJUSTMENT SETTINGS...................................4-7

4-3 LED CODES .........................................................4-8

4-4 TROUBLESHOOTING CHART.............................4-9

901467 1-1

SECTION 1

DESCRIPTION

1-1. INTRODUCTION.

This publication describes the 24 volt transistor

PTE 30 lift truck distributed by Big Joe Manufacturing

Company, Des Plaines, Illinois, 60018. Included are

operating instructions, planned maintenance instruc-

tions, lubrication procedures, corrective maintenance

procedures and a complete parts list with part location

illustrations.

Users shall comply with all requirements indicated in

applicable OSHA standards and current edition of

A.N.S.I. B56.1 Part II. By following these requirements

and the recommendations contained in this manual,

you will receive many years of dependable service

from your Big Joe lift truck.

1-2. GENERAL DESCRIPTION.

The self-propelled PTE 30 truck, Figure 1-2, lifts and

transports payloads up to 3000 pounds on rigid forks.

The forward and reverse motion is controlled by either

of two controller levers mounted on the control head.

Stopping and turning is controlled by the steering arm.

Lift and Lower is controlled by pushbuttons on the con-

trol head. The battery powered lift truck is quite and

without exhaust fumes.

The reversible DC motor propels the lift truck in for-

ward or reverse direction throughout the available

speed range. The PTE 30 lift truck can be driven with

forks raised of lowered. The lift truck must be pro-

tected from the elements.

The model number will be found on the name plate

(Figure 1-1) along with the serial number, lifting capac-

ity, and load center. Figure 1-2 shows the locations of

the truck’s main components and controls.

Figure 1-1 Name Plate

Figure 1-2. PTE 45 Lift Truck

R6209

R6525

1-2 901467

1-3. SAFETY FEATURES.

The PTE 30 is designed and engineered to provide

maximum safety for operator and payload. Some of

the safety features incorporated into the design are:

• Dead-man brake to apply the brake and cut off drive

power when the steering arm is released.

• Belly-button switch to reverse truck should the oper-

ator accidentally pin himself against a wall or

obstruction when backing up in slow speed.

• All control functions automatically return to “OFF”

when released.

• Externally accessible emergency disconnect switch

within operator's reach.

• Separately fused control circuits and power circuits.

• Readily accessible HORN button.

• Slip-resistance hand to provide a firm hand hold for

operator.

• Flow control valve regulates maximum lowering

speed within prescribed limits.

• Relief valve maintains hydraulic pressure within pre-

scribed limits.

• High visibility color scheme of truck provides visual

alert of truck’s presence.

• Battery Indicator

•Casters

901467 2-1

SECTION 2

OPERATION

2-1. GENERAL.

This section gives detailed operating instructions for

the PTE 30 lift truck. The instructions are divided into

the various phases of operations, such as operating

lift, driving, and stopping. Routine precautions are

included for safe operation.

2-2. OPERATING PRECAUTIONS.

WARNING: Improper operation of the lift truck may

result in operator injury, or load and/or lift

truck damage. Observe the following

precautions when operating the PTE 30

lift truck.

The following safety precautions must be adhered to

at all times.

• Do not operate this truck unless you have been

trained and authorized to do so and have read all

warnings and instructions in this manual and on the

truck.

• All warnings and instructions must be read and

understood before using the equipment.

• Equipment must be inspected by a qualified person

on a regular basis.

• Do not operate this truck until you have checked its

condition. Give special attention to Tires, Horn, Bat-

teries, Controller, Lift System, Brakes, Steering

Mechanism, Guards and Safety Devices

• Operate truck only from designated operation posi-

tion. Wear foot protection. Do not carry passengers.

• Observe applicable traffic regulations. Yield right of

way to pedestrians. Slow down and sound horn at

cross aisles and wherever vision is obstructed.

• Start, stop, travel, steer and brake smoothly. Slow

down for turns and on uneven or slippery surfaces

that could cause truck to slide or overturn. Use spe-

cial care when traveling without load as the risk of

overturn may be greater.

• Always look in direction of travel. Keep a clear view,

and when load interferes with visibility, travel with

load or lifting mechanism trailing.

• Do not overload truck. Check nameplate for load

weight and load center information.

• Before lifting, be sure load is centered, forks are

completely under load, and load is as far back as

possible against load backrest.

• Do not handle loads which are higher than the load

backrest unless load is secured so that no part of it

could fall backward.

• When leaving truck, neutralize travel control. Fully

lower lifting mechanism and set brake. When leaving

truck unattended, turn off key switch and push in the

emergency disconnect switch and remove key.

2-3. BEFORE OPERATION

Table 2-1 covers important inspection points on the

PTE 30 lift truck which should be checked prior to

operation. Depending on use, some trucks may

require additional checks.

Figure 2-1 shows a sample format for a Operator

Checklist, which can be modified as necessary to fit

your operation.

WARNING: Periodic maintenance of this truck by a

QUALIFIED TECHNICIAN is required.

CAUTION: A QUALIFIED SERVICE TECHNICIAN

should check the truck monthly for

proper lubrication, proper fluid levels,

brake maintenance, motor maintenance

and other areas specified in the SEC-

TION 3.

WARNING: If the truck is found to be unsafe and in

need of repair, or contributes to an

unsafe condition, report it immediately to

the designated authority. Do not operate

it until it has been restored to a safe

operating condition. Do not make any

unauthorized repairs or adjustments. All

service must be performed by a qualified

maintenance technician.

2-2 901467

Table 2-1 Operator Checks

ITEM PROCEDURE

Transmissionand

hydraulic sys-

tems.

Check for signs of fluid leakage.

Forks Check for cracks and damage.

Guards and load

backrest Check that safety guards are in

place, properly secured and not

damaged.

Safety signs Check that warning labels,

nameplate, etc., are in good

condition and legible.

Horn Check that horn sounds when

operated.

Steering Check for binding or looseness in

steering arm when steering.

Travel controls Check that speed controls on

control head operate in all

speed ranges in forward and

reverse and that belly button

switch functions.

Wheels Check drive wheel for cracks or

damage. Move truck to check

load for freedom of rotation.

Hydraulic

controls Check operation of lift and lower

to their maximum positions.

Brakes Check that brakes actuate when

steering arm is raised to upright

position, and when lowered to

horizontal position.

Deadman/

Parking brake Check that steering arm raises to

upright position when released

and brake applies.

Emergency

disconnect Check that emergency discon-

nect switch can be depressed

and turns off power to the truck.

Battery charge Check that battery indicator is on

“1”.

ITEM PROCEDURE

901467 2-3

Figure 2-1 Sample of Operator Check List

R6479

Electric Truck

Daily Operator Check-Off List

Date

Big Joe Manufacturing Company

Operator

Truck No. Model No.

Dept.

Check

Tires

Load Wheels

Horn

Lift Lower Control

Need MaintenanceO.K. ( )

Shift

Hour Meter

Reading Drive Hoist

Attachment Operation

Forward & Reverse Controls

Steering

Brakes

Hydraulic Leaks, Cylinders,

Valves, Hoses, Etc.

2-4 901467

2-4. GENERAL CONTROL OPERATION.

The speed control (See Figure 2-2) located on each

side of the control head provides fingertip control for

driving the truck. Rotate the control in the direction you

want to travel. The farther you rotate the control from

the neutral position, the faster the truck will travel.

Figure 2-2. Forward/Reverse Control

The pushbutton switches (See Figure 2-3), located on

the front of the control head activate the lift-lower con-

trols and the horn.

Figure 2-3. Pushbutton Switches

The brake is fully applied by lowering or raising the

steering arm. (See Figure 2-4) All traction control

power is shut off when the brake is engaged. When

the steering arm is in the upright position, the brake

acts as a parking brake. Deadman braking occurs

when the handle is released and spring action raises

steering arm to the upright position.

Figure 2-4. Brake Actuation

2-5. DRIVING AND STOPPING PROCEDURES.

1. Turn on the key switch and pull the emergency

disconnect switch out. Grasp the grips of the

steering head so that the speed control can be

comfortably operated by either thumb.

2. Lower the steering arm to a comfortable position

above horizontal to disengage the brake and to

energize the electrical circuits. See Figure 2-4.

3. To move forward (with load in front), slowly press

the speed control forward. See Figure 2-2. Press

the forward speed control farther to increase

speed.

4. To slow down or stop, release the speed control

and lower or raise the steering arm to the horizon-

tal or vertical position. See Figure 2-4. In those

positions, the brake engages, slowing or stopping

the truck.

5. Procedures for movement in reverse are the

same as in the forward direction except slowly

press the speed control backward. See

Figure 2-2.

2-6. BELLY-BUTTON SWITCH.

The belly-button switch (Figure 2-5) minimizes the

possibility of the driver being pinned by the steering

arm while driving the lift truck in slow speed. If the

switch presses against the operator while the lift truck

is being driven toward the operator, the switch

changes the direction of the lift truck.

R6453

R6452

R6526

901467 2-5

Figure 2-5. Belly-Button Switch

2-7. STEERING ARM PNEUMATIC SPRING.

The steering arm pneumatic spring automatically

raises the steering arm to the upright position when

the steering arm is released. If the steering arm does

not return fully, the steering arm pneumatic spring

requires replacement. Return truck to maintenance for

repair.

2-8. LIFT AND LOWER CONTROLS.

Lift/Lower Control buttons are located on the steering

control head. (Figure 2-3)

To lift forks, push in LIFT button and hold until forks

reach desired height. To lower forks, push in LOWER

button and hold until forks descend to desired height.

2-9. LOADING AND UNLOADING.

1. Move truck to location where load is to be picked

up.

2. Move the truck into position so forks are within

pallet or skid, and the load is centered over the

forks and as far back as possible.

3. Raise forks to lift load.

4. Drive to area where load is to be placed.

5. Move truck to align load with its new position.

6. Lower the load until it rests squarely in place and

the forks are free.

7. Slowly move the truck out from under the load.

2-10.PARKING.

When finished with moving loads, drive truck to its

maintenance or storage area. Push the emergency

disconnect switch in and turn off the key switch.

Charge batteries as necessary. Refer to battery care

instructions, SECTION 3.

R6455

2-6 901467

NOTES

901467 3-1

SECTION 3

PLANNED MAINTENANCE

3-1. GENERAL.

Planned maintenance consists of periodic visual and

operational checks, parts inspection, lubrication, and

scheduled maintenance designed to prevent or dis-

cover malfunctions and defective parts. The operator

performs the checks in SECTION 2, and refers any

required servicing to a qualified maintenance techni-

cian who performs the scheduled maintenance and

any required servicing.

3-2. MONTHLY AND QUARTERLY CHECKS.

Table 3-1 is a monthly and quarterly inspection and

service chart based on normal usage of equipment

eight hours per day, five days per week. If the lift truck

is used in excess of forty hours per week, the fre-

quency of inspection and service should be increased

accordingly. These procedures must be performed by

a qualified service technician or your Big Joe service

representative.

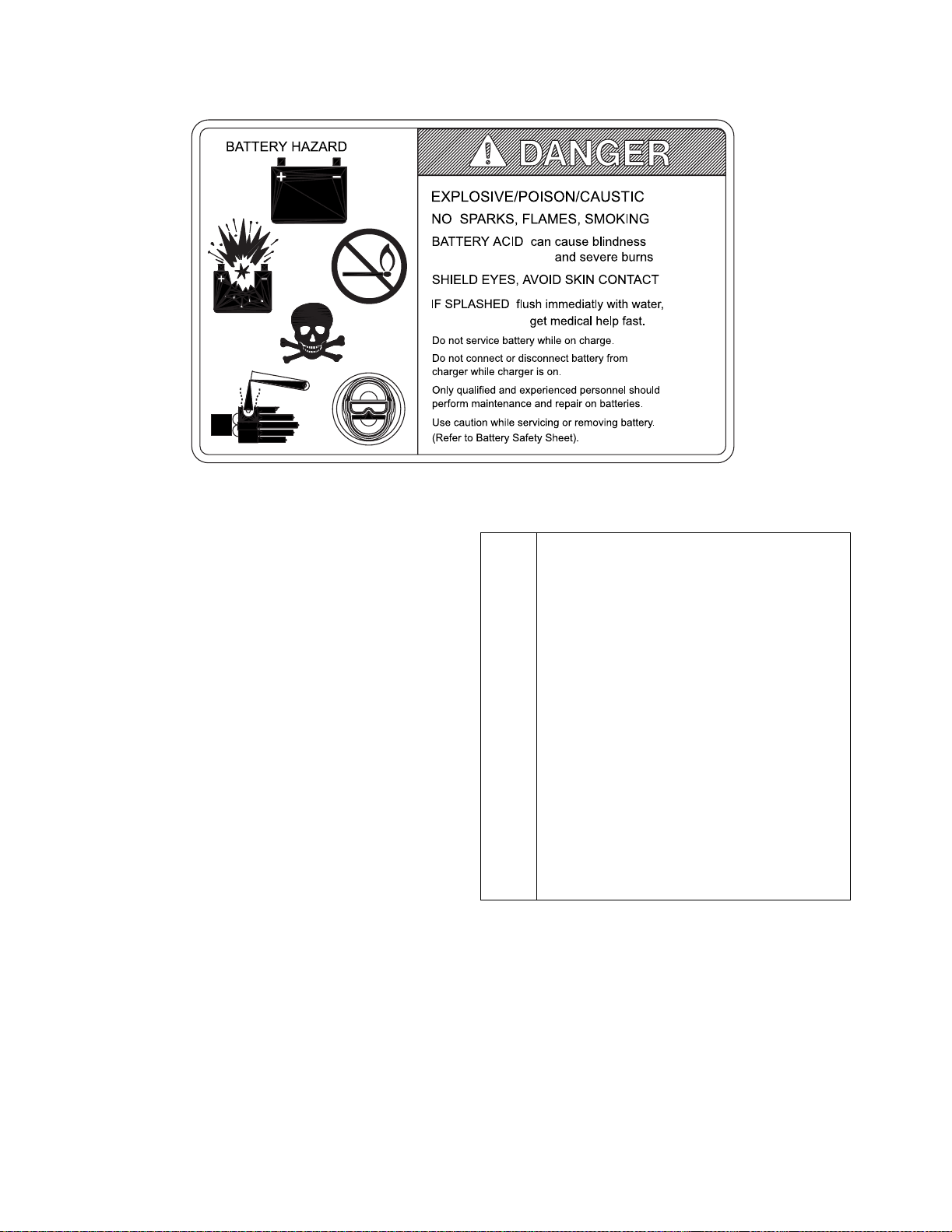

3-3. BATTERY CARE.

These batteries are maintenance-free. Any attempt to

open the battery will void the warranty.

Ultra-deep discharging of brand new batteries

should be avoided for at least 15 cycles. To dramat-

ically extend battery life, ultra-deep discharge should

be avoided. The shallower the average discharge, the

longer the battery life.

Charge the battery as described in paragraph 3-4.

3-4. CHARGING BATTERIES

Charging requirements will vary depending on depth of

discharge and temperature. Follow safety rules when

placing a battery on charge.

Proceed as follows:

1. Park truck at charging station with carriage low-

ered and key switch and disconnect switch off.

2. Check the condition of the AC cord, the battery

connector and battery cables. If there are any cuts

in the cable, any exposed wires, loose plugs or

connectors, DO NOT attempt to charge the bat-

teries. Contact appropriate personnel for repairs

to be made.

3. Connect the charger to connector (13, Figure 12-

9). Switch (8) will automatically disconnect the

batteries to from the truck. Make sure connectors

are mated properly.

4. Connect the charger AC cord to the appropriate

power supply and follow the instructions supplied

with the charger.

Table 3-1 Monthly and Quarterly Inspection and Service Chart

VISUAL CHECKS

INTERVAL INSPECTION OR SERVICE

Monthly Check electrical brake for proper operation.

Monthly Check load wheels for wear. A poly load wheel must be replace if worn to within 1/16 inch of

hub. Check for separation from hub.

Monthly Check drive wheel for wear. A poly drive wheel must be replace if worn to within 1 inch of

hub. Check for separation from hub.

Monthly Check entry wheels for wear or damage.

Monthly Inspect wiring for loose connections and damaged insulation.

Monthly Check deadman brake switch for proper operation.

Quarterly Check lift cylinder for leakage.

Quarterly Check for excessive jerking of steering arm when stopping or starting.

3-2 901467

3-5. LUBRICATION.

Refer to Table 3-2 for the recommended types of

grease and oil. Table 3-3 in conjunction with Figure 3-1

identifies the items requiring lubrication.

Table 3-2 Recommended Lubricants

(See Table 3-3 for Application)

No. 1 Transmission oil—EP SAE 80W-90,

Part Number 055780

Transmission oil—EP SAE 10W-30,

Part Number 055790 (Note)

No. 2 Grease—Lithium base, general purpose.

Part Number 055750

Part Number 055753 (Note)

No. 3 Hydraulic oil-Heavy duty with a viscosity of

150 SUS foam suppressing agent and

rust and oxidation inhibitors

Part Number 055779

Hydraulic oil-Heavy duty with a viscosity of

100 SUS foam suppressing agent and

rust and oxidation inhibitors

Part Number 055784 (Note)

No. 4 SAE 30 or 40 Engine lubricating oil

NOTE: USED ON COLD CONDITIONED TRUCKS

901467 3-3

Figure 3-1 Lubrication Diagram

Table 3-3 Lubrication Chart

FIG 3-2

INDEX

NO.

LOCATION METHOD OF

APPLICATION TYPE

(Table

3-3)

APPLICATION

OF

LUBRICANT

1 Steering arm pivot Can No. 4 1 or 2 drops each time serviced.

2 Lift Linkage * Can No. 4 1 or 2 drops each time serviced.

3 Lift Linkage Fittings** Gun No. 2 Pressure lubricate.

4 Entry Rollers Can No. 3 1 or 2 drops each time serviced.

5 Load Wheel Fittings** Gun No. 2 Pressure lubricate.

6 Casters Can No. 2 1 or 2 drops each time serviced.

* Remove covers to gain access to pivot points.

** Raise lift carriage to gain access to grease fittings.

R6527

3-4 901467

NOTES

901467 4-1

SECTION 4

TROUBLESHOOTING

4-1. GENERAL

Table 4-1 services as a guide to determine possible

causes of trouble. The table is divided into five main

categories: Truck Dead: Trouble With Travel: Trouble

With Braking: Trouble With Lifting Or Lowering, and

Miscellaneous malfunctions. Refer to electrical wiring

schematic (Figure 4-5) as a supplement to the trouble-

shooting chart or when tracing an electrical circuit.

Table 4-1 Troubleshooting Chart

MALFUNCTION PROBABLE CAUSE CORRECTIVE ACTION

TRUCK DEAD

Truck will not run nor will lift sys-

tem operate. a. Fuse (2, Figure 4-2) blown. Check fuse and replace if neces-

sary.

b. Battery dead or disconnected. Check battery quick-disconnect

switch (8, Figure 12-9) and

check battery voltage.

c. Keyswitch (4, Figure 12-7) or

emergency disconnect switch (6)

defective.

Bypass keyswitch to determine if it

is malfunctioning. Then bypass

emergency disconnect switch to

determine if it is malfunctioning.

d. Defective wiring. Check for open circuit. Repair as

required.

TROUBLE WITH TRAVEL

Truck does not run forward or

reverse. All other functions oper-

ate normally.

a. Check all wiring. A loose con-

nection may be the cause of

malfunction.

Tighten all loose connections

before further troubleshooting.

b. Defective deadman switch (19,

Figure 12-1). Check and replace switch if defec-

tive.

c. Defective main contactor (5,

Figure 4-2). Check for proper operation and

replace if necessary.

d. Defective potentiometer (14,

Figure 12-4). Check and replace potentiometer

if defective.

e. Transistor control fault may

need to be reset. Move control arm up into the neu-

tral position to reset.

Truck runs forward but not in

reverse. Defective reverse switch (6, Fig-

ure 12-4) in control head. Check for proper operation of

reverse switch with steering arm

in operating position and replace

if necessary.

Truck runs reverse but not in for-

ward. Defective forward switch (6, Fig-

ure 12-4) in control head. Check for proper operation of

reverse switch with steering arm

in operating position and replace

if necessary.

4-2 901467

Table 4-1 Troubleshooting Chart - Continued

MALFUNCTION PROBABLE CAUSE CORRECTIVE ACTION

Truck runs forward and in reverse

at lower speeds; will not run at

high speed.

Defective potentiometer (14, Fig-

ure 12-4) in control head. Check for variable resistance at

the potentiometer when direction

control is activated. If not noted,

replace potentiometer.

TROUBLE WITH BRAKING

Truck does not slow with brake, or

brake does not engage. a. Defective deadman switch (1,

Figure 12-1). Check deadman switch for conti-

nuity. If none found when the

control arm is in the brake posi-

tion, replace switch.

b. Defective electrical brake (24,

Figure 12-6). Replace brake.

TROUBLE WITH LIFTING OR

LOWERING

Oil sprays or flows from the top of

the lift cylinder. Defective packing in lift cylinder. Repair or replace lift cylinder.

Squealing sounds when lifting

forks. a. Oil level too low. Add oil to reservoir.

b. Lift linkage binding. Apply grease.

Forks do not lift to top. Oil level too low. Add oil to reservoir.

Weak, slow or uneven action of

hydraulic system. a. Defective pump or relief valve. Check pressure. Adjust as neces-

sary.

b. Worn lift cylinder. Repair or replace cylinder.

c. Load larger than capacity. Refer to I.D.platefor capacity.

d. Defective lift motor solenoid. Replace solenoid (9, Figure 4-2)

on electrical panel.

e. Battery charge low. Charge battery.

Forks do not lift, pump motor does

not run. a. Battery is dead or discon-

nected. Check and recharge if required.

b. Defective wiring. Check and repair as required.

c. Defect in electrical system for

operating pump motor. Check lift switch in control head,

as well as the solenoid (9, Figure

4-2) on electrical panel. Replace.

Forks do not lift, motor runs. Defect in hydraulic system. Check the oil level in the reservoir

and the oil lines to the lift cylin-

der, and repair as required. If

normal, check the hydraulic

pump, and relief valve. Repair, or

adjust.

Forks lift, but will not go down. Defect in hydraulic system Check lowering control switch (6,

Figure 12-4) and lowering sole-

noid on valve assembly (11, Fig-

ure 12-17). Replace as required.

Load will not hold a. Oil bypassing internally in con-

trol valve Replace valve assembly (11, Fig-

ure 12-17).

b. Worn lift cylinder. Repair or replace cylinder.

901467 4-3

Table 4-1 Troubleshooting Chart - Continued

MALFUNCTION PROBABLE CAUSE CORRECTIVE ACTION

TROUBLE WITH LIFTING OR

LOWERING - Continued

Platform does not lift to top. Pump

motor runs. a. Oil level too low. Add oil to reservoir.

b. Load larger than capacity. Refer to nameplate on side of

mast for maximum load capacity.

c. Batteries need charging. Charge batteries.

Forks creep downward under load

when in a raised position. Leak in hydraulic system, lift cylin-

der or lowering valve. Check for leaking fitting in hydrau-

lic line and repair as required.

Replace lift cylinder or valve

assembly (21, Figure 12-14).

MISCELLANEOUS

Steering arm does not return to

the upright position. a. Week pneumatic spring. Replace spring.

b. Binding. Check and free the binding item.

Verify that the electrical cable

has not been damaged. Repair

or replace as needed.

Truck moves forward when arm is

pulled down. a. Belly-button switch defective. Check for short, and repair or

replace as necessary.

b. Short in control head. Check wiring and repair as

required.

Steering arm jerks excessively

starting or stopping the truck. Drive wheel worn. Replace drive wheel if worn to

within 3/8 inch of hub.

Drive motor is jerky. Motor worn. Repair motor.

4-4 901467

4-2. TRANSISTOR CONTROLLER TROUBLE-

SHOOTING

4-2.1. Fault Detection.

The controller provides diagnostics information to

assist technicians in troubleshooting drive system

problems. When a fault is detected, the appropriate

fault code is signaled via the LED, externally visible on

the side of controller (See Figure 4-1 for LED location

on controller). The diagnostic codes flashed by the

LED are listed in Table 4-3.

If the fault is critical, the controller is automatically dis-

abled. Faults can be caused internally (e.g. shorted

transistors) or externally (e.g., wrench or hardware

dropped across controller terminals).

To recover from a fault, the F/R switch must be turned

off and back on again. If the fault has been corrected,

the controller will turn back on. Figure 4-1. Status LED

Figure 4-2. Electrical Panel Parts

R6528

R6517A

Table of contents

Popular Lifting System manuals by other brands

Dhollandia

Dhollandia DH-CH101 Maintenance & Repair Manual

Simon, Evers & Co

Simon, Evers & Co HTF-E operating manual

MIR

MIR 1000 Shelf Lift quick start

Genie

Genie Z-45/25 Operator's manual

JLG

JLG Skytrak 6036 Operation & safety manual

Smiley Lifting Solutions

Smiley Lifting Solutions URW706 quick start guide