Bigham Lilliston Rolling Cultivator Generation 3 User manual

Lilliston® Rolling Cultivator®

Generation 3

Operators Manual

800-692-4449 705 East Slaton Rd. P.O. Box 3338 Lubbock, TX 79452

®

®

®

Page 2

Form # B15-790

®

®

®

Table of Contents

1...............................Cover Page

2...............................Table of Contents

3...............................Safety First

4...............................Warranty

5...............................Safety Requirements

6...............................General Safety Guidelines

7...............................Serial Tag / Manual Holder Tube

8 - 9 .........................Safety Decal Location

10...............................Safety Decal Care / Tire Safety

11...............................Lighting and Marking / Before Operation

12...............................During Operation

13...............................Highway and Transport Operations

14...............................Following Operation / Performing Maintenance

15...............................Performing Maintenance / Hydraulic Fluid and Equipment Safety

16...............................Hydraulic Fluid and Equipment Safety / Lockout/Tagout

17...............................Lockout / Tagout

18...............................Maintenance Chart

19...............................Trouble Shooting

20...............................Use and Care Tips From the Factory / Assistance

21...............................Lilliston Rolling Cultivator Generation 3 Introduction

22...............................Cultivator Overview

23 - 26 .......................Field Use and Adjustment

27 - 48 .......................Part Breakdowns

49 - 51 .......................Notes

Page 3

Form # B15-790

®

®

®

© 2015 Bigham Ag. This document may not be reproduced in whole or in part without prior written permission of Bigham Ag.

P/N B15-790 Revised 11-10-2015. Printed in the U.S.A. Specications and design subject to change without notice.

Do Not Use or Operate This

Equipment Until You Have Read and

Understand This Manual

The purpose of this manual is to explain maintenance requirements and adjustments which

are necessary for the most efcient operation of the machine. Read this manual thoroughly and

completely before using your machine. Keep this manual handy for reference when questions

arise.

Should you have questions or difculties which your dealer or representative are unable to

answer, please call or write:

Bigham Ag

705 E. Slaton Rd.

P.O. Box 3338

Lubbock, TX 79452

Ofce: (800) 692-4449

Fax: (806) 745-1082

SAFETY FIRST

PREVENT ACCIDENTS BY “THINKING SAFETY” IN

UNLOADING, SETTING UP, MOVING, STORAGE AND

OPERATING ALL EQUIPMENT

Page 4

Form # B15-790

®

®

®

A MESSAGE TO THE OWNER AND OPERATOR

This machine was carefully designed and manufactured to give you dependable service. To keep it

running efciently, read the instructions in this Operator’s Manual. Check each item and acquaint yourself

with the adjustments required to obtain efcient operation and maximum performance. Remember, the

machines performance depends on how you operate and care for it.

After each operating season, thoroughly clean your machine and inspect it. Preventive maintenance

saves time and pays dividends. Your dealer has original equipment parts which assure proper t and best

performance. Record the model number, serial number and date of purchase in the space provided on this

page. Your dealer needs this information to give you efcient service when you order parts or attachments. The

model number and serial number appear on the identication plate on the rear left side of the tool bar mast.

The warranty on your machine is included with this manual. Your dealer will review the manual and

warranty with you when you take delivery of your machine.

WARRANTY

Bigham Ag warrants all products of its manufacture to be free from defects in materials and

workmanship for a period of one year from date of delivery to the retail purchaser. Parts assumed to be

defective must be returned F.O.B. Lubbock, Texas for our inspection or inspected in the eld by our

authorized representative. Our obligation under this warranty is limited to replacement or repair of the

defective part and does not cover other damages to persons or property. Other than the aforesaid, no

warranties of merchantability or tness for a particular purpose will apply. We do not assume liability for

altered or remanufactured components or machines or applications beyond their intended use. Some states

do not allow limitation of how long an implied warranty lasts, or exclusions of, or limitations on relief such

as incidental or consequential damages, so the above limitations or exclusion may not apply to you. This

warranty gives you specic legal rights and you may have other rights which vary from state to state.

Warranty does not cover damage due to abuse, neglect, collision, towing, pulling, normal wear and

tear or any other factor beyond the control of the manufacturer. Tool bars that are bent, bowed or that have

been welded on or modied in any way are specically excluded from any warranties.

Model Number:

Serial Number:

Date Of Purchase:

LIMITED LIFETIME WARRANTY ON TOOL BAR CLAMPS

Bigham Ag will replace any ductile iron clamp body that breaks or cracks under normal use for as

long as the original purchaser owns them. This includes all replaceable bolt ductile iron clamps sold by Big-

ham Ag after December 31, 1987.

Clamps that fail should be returned to Bigham Ag, freight prepaid along with caps, bolts, set screws

and nuts for evaluation. If found to have failed under normal operating conditions, a new clamp body will be

returned along with your old caps, bolts, set screws and nuts. Only clamps that have been used with Grade 2

bolts of the proper size will be replaced. All other provisions of the above warranty apply.

Page 5

Form # B15-790

®

®

®

Safety Requirements

TAKE NOTE! THIS SAFETY ALERTS SYMBOL FOUND THROUGHOUT THIS MANUAL IS USED

TO CALL YOUR ATTENTION TO INSTRUCTIONS INVOLVING YOUR PERSONAL SAFETY AND

THE SAFETY OF OTHERS. FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN

INJURY OR DEATH.

THIS SYMBOL MEANS

• ATTENTION!

• BECOME ALERT!

• YOUR SAFETY IS INVOLVED!

Signal Words

Note the use of the signal words DANGER, WARNING and CAUTION with the safety messages. The

appropriate signal word for each has been selected using the following guidelines:

DANGER: Indicates an imminently hazardous situation that, if not avoided, will result in death or serious

injury. This signal word is to be limited to the most extreme situations typically for machine components

which, for functional purposes, cannot be guarded.

WARNING: Indicates a potentially hazardous situation that, if not avoided, could result in death or serious

injury, an includes hazards that are exposed when guards are removed. It may also be used to alert against

unsafe practices.

CAUTION: Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe practices.

Page 6

Form # B15-790

®

®

®

General Safety Guidelines

Safety of the operator and any bystanders is one of the main concerns in designing and developing a

new piece of equipment. Designers and manufacturers build in as many safety features as possible. However,

every year many accidents occur which could have been avoided by a few seconds of thought and a more

careful approach to handling equipment. You, the operator, can avoid many accidents by observing the

following precautions in this section. To avoid personal injury, study the following precautions and insist

those working with you, or for you, follow them.

• Replace any CAUTION, WARNING, DANGER or instruction safety decal that is not readable or is

missing. Location of such decals is indicated in this booklet.

• Do not attempt to operate this equipment under the inuence of drugs or alcohol. Do not use the

equipment if alertness or coordination is impaired.

• Review the safety instructions with all users annually.

• This equipment is dangerous to children and persons unfamiliar with its operation. The operators

should be a responsible adult familiar with farm machinery and trained in this equipment’s

operations. Do not allow persons to operate or assemble this unit until they have read this

manual and have developed a thorough understanding of the safety precautions and of how it

works.

• Do not read, eat, drink, talk or text or use a mobile phone while using this equipment.

• To prevent injury or death, use a tractor equipped with a Roll Over Protective System (ROPS). Do not

paint over, remove or deface any safety signs or warning decals on your equipment. Observe all

safety signs and practice the instructions on them.

• Never exceed the limits of a piece of machinery. If its ability to do a job, or to do so safely, is

in question.

- DO NOT TRY IT.

• Stay clear of any moving parts, such as shafts, couplings and universal joints.

• If adjustments need to be made, make them in small steps, shutting down all motions for each adjustment.

• Do not allow anyone to ride on any part of the equipment for any reason.

• Assure that all bystanders are at a safe distance before operating or maintaining this equipment.

Page 7

Form # B15-790

®

®

®

Bigham Ag Serial Tag

The Bigham Ag serial tag provides important information for service and warranty work. The

model number and serial number provide Bigham Ag Dealers and the Bigham Ag Customer Service

department with exact specications of your implement.

• Serial tags are located on the rear left side of toolbars that incorporate a top mast. On toolbars that

do not use a top mast the serial tag is located on the front left of the toolbar.

Bigham Ag Manual Holder

Manual holders contain all relevant owners manuals for the product they are attached to.

Please keep the manual in the tube so that it is easily available to reference back to.

• For toolbars with a top mast manual tubes are located on the front left of the toolbar mast. For

toolbars without a top mast manual tube holders a located on the top left side of the toolbar.

Page 8

Form # B15-790

®

®

®

Safety Decal Locations

• Safety decals are located around to toolbar to warn you of potentially dangerous situations.

• Please pay close attentions to all safety decals.

• Please replace any safety decals that are missing or have become illegible.

FRONT

®

®

Page 9

Form # B15-790

®

®

®

®

®

FRONT

REAR

Page 10

Form # B15-790

®

®

®

Safety Decal Care

• Keep safety signs clean and legible at all times.

• Replace safety signs that are missing or have become illegible.

• Replaced parts that displayed a safety sign should also display the current safety sign.

• Safety signs are available from your Distributor or Dealer Parts Department or the factory.

How to Install Safety Signs:

• Be sure that the installation area is clean and dry.

• Decide on the exact position before you remove the backing paper.

• Remove the smallest portion of the split backing paper.

• Align the decal over the specied area and carefully press the small portion with the exposed

sticky backing in place.

• Slowly peel back the remaining paper and carefully smooth the remaining portion of the decal in

place.

• Small air pockets can be pierced with a pin and smoothed out using the piece of decal backing paper.

Tire Safety

• Failure to follow proper procedures when mounting a tire on a wheel or rim can produce an

explosion which may result in serious injury or death.

• Do not attempt to mount a tire unless you have the proper equipment and experience to do the job.

• Inating or servicing tires can be dangerous. Whenever possible, trained personnel should be

called to service and/or mount tires.

• Always order and install tires and wheels with appropriate capacity to meet or exceed the

anticipated weight to be placed on the equipment.

Page 11

Form # B15-790

®

®

®

Lighting and Marking

• It is the responsibility of the customer to know the lighting and marking requirements of the

local highway authorities and to install and maintain the equipment to provide compliance

with the regulations. Add extra lights when transporting at night or during periods of

limited visibility.

• Lighting kits are available from your dealer or from the manufacturer.

Before Operation

• Carefully study and understand this manual.

• Do not wear loose-tting clothing which may catch in moving parts.

• Always wear protective clothing and substantial shoes.

• Keep wheel lug nuts or bolts tightened to specied torque.

• Assure that agricultural implement tires are inated evenly.

• Give the unit a visual inspection for any loose bolts, worn parts or cracked welds, and make

necessary repairs. Follow the maintenance safety instructions included in this manual.

• Be sure that there are no tools lying on or in the equipment.

• Do not use the unit until you are sure that the area is clear, especially children and animals.

• Don’t hurry the learning process or take the unit for granted. Ease into it and become familiar with

your new equipment.

• Practice operation of your equipment and its attachments. Completely familiarize yourself and

other operators with its operation before using.

• Use a tractor equipped with a Roll Over Protective System (ROPS) and fasten your seat belt prior

to starting the engine.

• The manufacturer does not recommend usage of tractor with ROPS removed.

• Securely attach to towing unit. Use a high strength, appropriately-sized hitch pins with a

mechanical retainer.

• Do not allow anyone to stand between the tongue or hitch and the towing vehicle when backing up

to the equipment.

Page 12

Form # B15-790

®

®

®

During Operation

• Children should never be allowed on the equipment.

• Clear the area of small children and bystanders before moving the equipment.

• Securely attach equipment to towing unit, using correct hitch pin , a metal retainer, and safety

chains if required. Shift towing unit to a lower gear before going down steep

downgrades, thus using the engine as a retarding force. Keep towing vehicle in gear at

all times. Slow down for corners and rough terrain.

• Make sure you are in compliance with all local and state regulations regarding transporting

equipment on public roads and highways. Lights and slow moving signs must be clean and

visible by overtaking or oncoming trafc when cultivator is transported.

• Install the safety chain by crossing the chains under the tongue and secure to the draw bar

cage or hitch or bumper frame.

• Beware of bystanders, particularly children! Always look around to make sure that it is safe to

start the engine of the towing vehicle or move the unit. This is particularly important with

higher noise levels and quiet cabs, as you may not hear people shouting.

• NO PASSENGERS ALLOWED - Do not carry passengers anywhere on, or in, the tractor or

equipment, except as required for operation.

• Keep hands and clothing clear of moving parts.

• Always keep all shields and guards in place and securely fastened.

• Do not clean, lubricate or adjust your equipment while it is moving.

• When halting operation, even periodically, set the tractor or towing vehicle brakes, shut off the

engine and remove the ignition key.

• Be especially observant of the operating area and terrain - watch for holes, rocks or other hidden

hazards. Always inspect the area prior to operation.

— DO NOT operate near the edge of drop-offs or banks.

— DO NOT operate on steep slopes as overturn may result.

— Operate up and down (not across) intermediate slopes. Avoid sudden starts and stops.

• Adopt safe driving practices:

— Keep the brake pedals latched together at all times. NEVER USE INDEPENDENT

BRAKING

Page 13

Form # B15-790

®

®

®

Highway and Transport Operations

WITH MACHINE IN TOW A LOSS OF CONTROL AND/OR UPSET OF UNIT CAN RESULT.

— Always drive at a safe speed relative to local conditions and ensure that your speed is

low enough for an emergency stop to be safe and secure. Keep speed to a minimum.

— Reduce speed prior to turns to avoid the risk of overturning.

— Avoid sudden uphill turns on steep slopes.

— Always keep the tractor or towing vehicle in gear to provide engine braking when going

downhill. Do not coast.

— Do not drink and drive!

• Comply with state and local laws governing highway safety and movement of farm machinery

on public roads.

• Use approved accessory lighting ags and necessary warning devices to protect operators of

other vehicles on the highway during daylight and nighttime transport. Various safety lights and

devices are available from your dealer.

• The use of ashing amber lights is acceptable in most localities. However, some localities prohibit

their use. Local laws should be checked for all highway lighting and marking requirements.

• When driving the tractor and equipment on the road or highway under 20 mph at night or during

the day, use ashing amber warning lights and a slow moving vehicle (SMV) identication emblem.

• Plan your route to avoid heavy trafc.

• Be a safe and courteous driver. Always yield to oncoming trafc in all situations, including

narrow bridges, intersections, etc.

• Be observant of bridge loading ratings. Do not cross bridges rated lower than the gross weight

as which you are operating.

• Watch for obstructions overhead and to the side while transporting.

• Always operate equipment in a position to provide maximum visibility at all times. Make

allowances for increased length and weight of the equipment when making turns, stopping

the unit, etc.

• Pick the levelest possible route when transporting across elds. Avoid the edges of ditches or

gullies and steep hillsides.

• Be extra careful when working on inclines.

• Maneuver the tractor or towing vehicle at safe speeds.

Page 14

Form # B15-790

®

®

®

• Avoid overhead wires or other obstacles. Contact with overhead lines could cause serious injury

or death.

• Avoid loose ll, rocks and holes; they can be dangerous for equipment operation or movement.

• Allow for unit length when making turns.

• Operate the towing vehicle from the operator’s seat only.

• Never stand alongside of unit with engine running or attempt to start engine and/or operate

machine while standing alongside of unit.

• Never leave running equipment attachments unattended.

• As a precaution, always recheck the hardware on equipment following every 100 hours of

operation. Correct all problems. Follow the maintenance safety procedures.

Following Operation

• Following operation, or when unhitching, stop the tractor or towing vehicle, set the brakes,

shut off the engine and remove the ignition keys.

• Store the unit in an area away from human activity.

• Do not permit children to play on or around the stored unit.

• Make sure all parked machines are on a hard, level surface and engage all safety devices.

• Wheel chocks may be needed to prevent unit from rolling.

Performing Maintenance

• Good maintenance is your responsibility. Poor maintenance is an invitation to trouble. Proper

servicing and adjustments are key to the long life of any implement. With careful

inspection and routine maintenance, costly downtime and repairs can be avoided.

• Some parts and assemblies can be quite heavy. Before attempting to unfasten any part or

assembly, arrange to support it by means of a hoist, by blocking or by use of an adequate

arrangement to keep it from falling, tipping, swinging or moving in any manner which may

hurt somebody or damage the equipment.

• Always use lifting equipment that is adequately rated to do the job. Never lift equipment over people.

• Make sure there is plenty of ventilation. Never operate the engine of the towing vehicle in a

closed building. The exhaust fumes may cause asphyxiation.

• Before working on the equipment, stop the towing vehicle, set the brakes, disengage all power

drives, shut off the engine and remove the ignition keys.

Page 15

Form # B15-790

®

®

®

• Be certain all moving parts on attachments have come to a complete stop before attempting to

perform maintenance.

• Always use a safety support and block the wheels. Never use a jack to support the equipment.

• Always use the proper tools or equipment for the job at hand.

• Use extreme caution when making adjustments.

• Never replace hex bolts with less than grade ve bolts unless otherwise specied.

• After servicing, be sure all tools, parts and service equipment are removed.

• Where replacement parts are necessary for periodic maintenance and servicing, genuine factory

replacement parts must be used to restore your equipment to original specications. The

manufacturer will not claim responsibility for use of unapproved parts and/or accessories

and other damages as a result of their use.

• If equipment has been altered in any way from original design, the manufacturer does not accept

any liability for injury or warranty.

• If repairs require the use of a torch or electric welder, be sure that all ammable and combustible

materials are removed.

• Do not weld or cut on any tank containing oil, fuel or their fumes or other ammable material, or

any container whose previous contents are unknown.

• Cleaning solvents should be used with care. Petroleum based solvents are ammable and present

a re hazard. Don’t use gasoline. All solvents must be used with adequate ventilation and

their vapors should not be inhaled.

Hydraulic Fluid and Equipment Safety

Only adequately trained and qualied persons should work on hydraulics systems. You may be

severely injured or killed by being crushed under a falling piece of equipment. Always have transport locks

in place and frame sufciently blocked when working on any implement.

Hydraulic uid escaping under pressure can have sufcient force to cause injury. Keep all hoses and

connections in good serviceable condition. Failure to heed may result in serious personal injury or death.

Escaping hydraulic uid under pressure can have sufcient pressure to penetrate the skin causing serious

injury. Avoid the hazard by relieving the pressure before disconnecting lines or performing work on the

system.

Make sure hydraulic uid connections are tight and all hydraulic hoses and lines are in good condition

before applying pressure to the system. Use a piece of paper or cardboard, NOT BODY PARTS, to check

Page 16

Form # B15-790

®

®

®

for suspected leaks. Wear protective gloves and safety glasses or goggles when working with hydraulic

systems. DO NOT DELAY! If an accident occurs, see a doctor familiar with this type of injury immediately.

Any uid injected into the skin or eyes must be treated within a few hours or gangrene may result.

Always secure equipment with solid supports before working on or under it. Never work under

equipment supported by hydraulics. Hydraulics can drop equipment if controls are actuated or hydraulic lines

burst or pressure is lost while disconnecting lines. Either situation can drop machinery instantly even when

power to hydraulics is off. Do not attempt to disconnect a hydraulic cylinder or hose while the system is

under pressure! Check hydraulic hoses and ttings frequently. Brush and other debris can damage hoses and

ttings. Inspect and maintain equipment daily. Loose, broken, and missing hardware can cause equipment

to not perform properly and can result in bodily injury or death.

Hydraulic systems and oil can be hot and cause burns. Before working on any system, wait until the

oil has cooled.

Lockout / Tagout

Think, plan and check. Think through the entire procedure and identify all the steps that are required.

Plan what personnel will be involved, what needs to be shut down, what guards need to be removed, and how

(and under what conditions) the power will be restarted. Check the machine over to verify all power sources

and stored energy have been identied including engines, hydraulic and pneumatic systems, springs and

accumulators, and suspended loads, Shutoff and lockout power before adjusting, servicing, maintaining, or

clearing an obstruction from this machine. Failure to heed may result in serious injury or death. Communicate

with everyone involved in a repair or maintenance operation, including bystanders, that work is being done

which involves keeping this machine safety at a ZERO ENERGY STATE.

OSHA’s requirements for lockout/tagout are covered in Section 1910.147 of the OSHA standards.

The LOTO standard establishes the employer’s responsibility to protect workers from hazardous energy.

Employers are required to train each worker to ensure that they know, understand, and are able to follow the

applicable provisions of the hazardous energy control procedures:

• Proper lockout/tagout (LOTO) practices and procedures safeguard workers from the release of

hazardous energy. The OSHA standard for The Control of Hazardous Energy (Lockout/Tagout)

for general industry, outlines specic action and procedures for addressing and controlling

hazardous energy during servicing and maintenance of machines and equipment. Employers

are also required to train each worker to ensure that they know, understand, and

are able to follow the applicable provisions of the hazardous energy control procedures.

Workers must be trained in the purpose and function of the energy control program and have

the knowledge and skills required for the safe application, usage and removal of the energy

control devices.

•

Page 17

Form # B15-790

®

®

®

• All employees who work in the area where the energy control procedure(s) are utilized need to

be instructed in the purpose and use of the energy control procedure(s) and about the prohibition

against attempting to restart or reenergize machines or equipment that is locked or tagged out.

• All employees who are authorized to lockout machines or equipment and perform the service

and maintenance operations need to be trained in recognition of applicable hazardous energy

sources in the workplace, the type and magnitude of energy found in the workplace, and the means

and methods of isolating and/or controlling the energy.

• Specic procedures and limitations relating to tagout systems where they are allowed.

• Retraining of all employees to maintain prociency or introduce new or changed control methods.

OSHA outlines a six-step procedure for controlling hazardous energy:

• Step 1: Prepare for shutdown. It must be determined what type of power system is going to be

deactivated including electrical, hydraulic, pneumatic or other energy sources. Knowledge of

shut down methods is necessary.

• Step 2: Shutdown the equipment. This should be completed consistent with the

manufacturer’s instructions for the shutdown procedure and could be a simple as placing a

switch in the “off” position or pressing a button.

• Step 3: Isolate the equipment. This step involves closing of valves, throwing the main

disconnects or circuit breakers and disconnecting or capping any auxiliary power sources or

secondary electrical systems.

• Step 4: Apply the lockout/tagout device. This is done to prevent restoration of the ow of

energy and is done at all disconnect switches, valves or other energy isolating devices. Locks

are the preferred method of controlling energy and should be supplemented with tags.

Various lockout devices are available including group lockout hasps. Locks should be individually

assigned and have only one key.

• Step 5: Control the stored energy. This step includes the release, disconnect or restraint of any

residual hazardous energy which may be present and a check that all moving parts have stopped

moving. It may also include the installation of “pancakes” or blanking of pipe anges, the

installation of ground wires to discharge electrical capacitors and the blocking or supporting

of elevated equipment.

• Step 6: Verify isolation of equipment. Double-check the steps and verify that the equipment

indeed has been shut down and that the lock and tag do control the stored energy. Employees

should be warned and the system tested, including pressing of all start buttons to assure that

the equipment will not start.

Page 18

Form # B15-790

®

®

®

Maintenance Chart

Lubrication

• Lubricate the grease tting in the hinge pivots of the folding toolbars with a multi purpose grease every

50 hours of operation.

Fasteners

• All fasteners should be checked and re-tightened after the initial thirty minutes of operation.

• All fasteners should be checked and re-tightned after every 25 hours of operation.

Seasonal Maintenance

• Clean the cultivator thoroughly to remove dirt and trash which could hold moisture and cause rusting.

• Apply a good rust preventative to all land polished surfaces, such as spiders and sweeps.

• Lubricate all toolbar grease ttings to ll cavities and prevent moisture build up.

Page 19

Form # B15-790

®

®

®

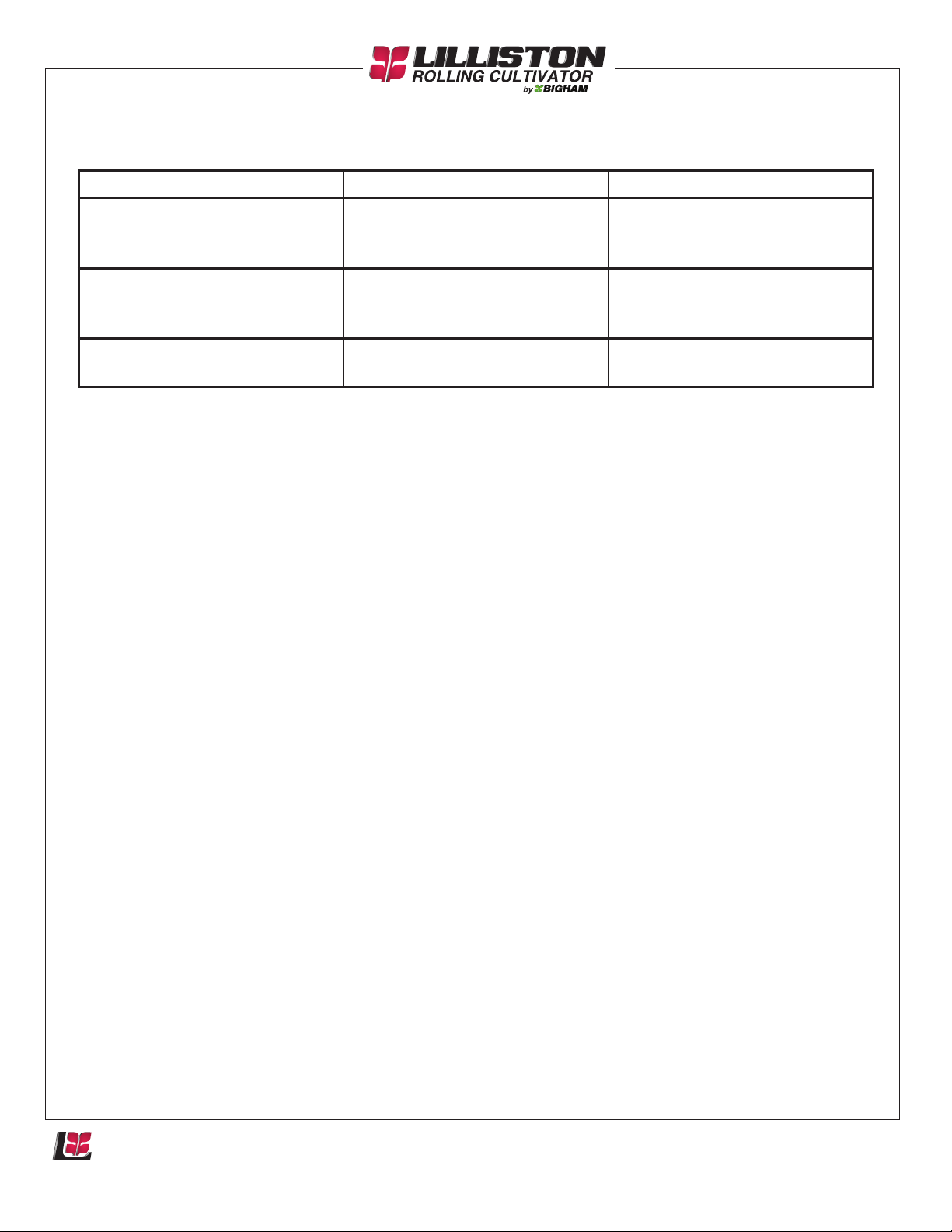

Troubleshooting

Problem Cause Correction

Insufcient penetration of rear

gangs while cultivating or

mulching beds.

Gangs angled in the wrong direc-

tion.

Reverse angle. Gang number 1

cuts and moves soil to the left.

Gang number 2 cuts and moves

soil to the right.

Not enough angle. Increase angle of gangs. Tilt gang

an additional 10 degrees on tilt

adjustment plate.

Incorrect toolbar angle. Lengthen top link linkage to

roll the toolbar backward until

the front and rear spider gangs

engage the soil evenly.

Not enough pressure on gangs. Decrease implement height on

three point lift.

Excessive penetration of rear

gangs while cultivating or

mulching beds.

Incorrect toolbar angle. Shorten top link linkage to roll

the toobar forward until the front

and rear spider gangs engage to

soil evenly.

Gangs clogging between fork and

spider.

Soil contains rocks, hard clods,

crop residue.

Add scraper between fork and

spider.

Covering small crop when

cultivating.

Too much angle on the spider

gangs.

Decrease spider gang angle unit

until the crop is bigger.

Insufcient dirt movement

towards the row crop.

Not enough angle on the spider

gangs.

Increase spider gang angle until a

sufcient amount of dirt is mov-

ing towards the row crop.

Side draft on tractor. (Cultivator

does not trail behind tractor)

Row units not in the center of the

furrow.

Check row spacing at the point of

the sweep. Adjust units on bar as

necessary.

Toolbar not level Adjust three point lift arm link-

ages to level the toolbar.

Unequal penetration of rear

gangs.

Decrease implement height on

three point lift.

Row gangs wearing unevenly. Soil compaction behind tractor. Rotate rear gangs that operate

behind tractor tires.

Row gangs wearing rapidly or

unevenly.

Cultivator toolbar not positioned

properly.

Adjust top link until the front

and rear spider gangs are evenly

engaging the ground.

Row gangs are being run too

deep.

Increase the set height of the

three point lift.

Page 20

Form # B15-790

®

®

®

Troubleshooting Continued

Problem Cause Correction

Toolbar bending. Loading beyond design limit with

deep tillage tools such as bed rip-

pers, irrigation shovels, etc.

Attach cable pull ears from each

end of the toolbar to the front of

the tractor.

Bending and twisting of coulter

assembly.

Turning with the coulter in the

ground with rigid tractor hitch.

Make sure coulter clears ground

before turning at the end of the

row.

Coulter bearing failure. Running coulter too deep. Adjust coulter setting. Never run

coulter hub or bearing in the dirt.

Use and Care Tips From the Factory

• Spending the time to properly set your cultivator in the beginning will pay dividends in the end.

• When rebuilding spider gangs make sure the spiders are timed properly. Number 1 spiders are

equipped with a single timing mark and number 2 spiders are equipped with a double timing mark. Timing

marks are to be set 90 degrees out from any adjacent spiders.

Assistance

• If you have questions not answered in this manual or require additional copies, please contact your dealer

or Bigham Ag.

705 East Slaton Road, Lubbock, Texas, 79452

Ofce: (800) 692-4449 Fax: (806) 745-1082

www.bighamag.com

Table of contents

Other Bigham Farm Equipment manuals

Popular Farm Equipment manuals by other brands

HARVEST

HARVEST A1072 Operator's manual

New Holland

New Holland BR6080 Operator's manual

H&S

H&S TWM9 Operator's manual

EASY COOPS

EASY COOPS 24x8 Chicken Coop Plan manual

Degelman

Degelman Pro-till 26 quick start guide

FPM Agromehanika

FPM Agromehanika 627 152 ASSEMBLY / OPERATION/ MAINTENANCE, SPARE PARTS LIST