Bin Master Smart Sonic User manual

Smart Sonic

Ultrasonic Transmitters

Instruction Manual

925-0156 Rev 1

2

Table of Contents

Contact Information……...…………………………….……..3

General Specifications……………………………………….4

Operation………………………………………………………5

Wiring…………………………………………………………..6

Calibration………………………………….…………………7

Mounting………………… …..……………………………….8

Technical Specifications……………………………………..9

SmartSonic 2

3

Contact Information

Customer Service and

Technical Support Personnel

Robin Kozisek

Customer Service/Order Entry

Matt Virgillito

Application Specialist

Nathan Grube

Application Specialist

Todd Peterson

Sales Manager

Dave Etherton

Technical Support

Customer Service Hotline

Call or Fax one of the following numbers if you have

installation or application questions.

1-800-278-4241 8:00 am —5:00 pm CST

(402) 434-9102 Voice

(402) 434–9133 Fax

www.binmaster.com

Division of Garner Industries

PO Box 29709 / Lincoln, NE 68529 / 7201 North 98th St. / Lincoln, NE 68507

Phone: 800-278-4241 or 402-434-9102 / Fax: 402-434-9133

SmartSonic 3

4

Conduit Entry:

1/2” NPT (PVC conduit only)

Enclosure:

PVC-94VO

Enclosure Rating:

NEMA 4X(IP65)

Temperature: -40 to +140° F (-40 to 60° C)

Pressure:

1 bar

Approvals: Entela—CSA/UL

Accuracy:

+/-0.25% of maximum range

Beam Angle:

6°-12° conical at –3dB

Loss of Echo: Hold 30 seconds, 22 mA

Temperature Compensation:

Continuous in transducer

Temperature Sensor failure: 23 mA

Calibration: Push-button or programmable via optional communication port

Diagnostics:

Via communication port (echo profile, echo stability, operation errors)

Power AC: AC units 115 VAC 60Hz or 230 VAC 50Hz, 1.7 VA

Power DC 3 Wire:

DC 2 Wire Loop Powered:

DC units 12 to 30 VDC, 0.07 A max @ 24 VDC

DC Loop Powered units, 12 to 28 VDC, 0.025 A max @ 24 VDC

Output:

4-20 mA, optional RS-232, RS-485, or Modbus

4 to 20 mA Max. Loop Resistance 110 VAC @ 750 Ohms (isolated)

12 VDC @ 250 Ohms

24 VDC @ 750 Ohms

General Specifications SmartSonic 4

5

Operation

The new SmartSonic transmitter features high efficiency, narrow beam design technology using a wide frequency bandwidth

to enhance operation in difficult applications. The transmitter performs particularly well in harsh environments where vessel

temperatures vary. SmartSonic uses smart signal processing to eliminate unwanted echoes from tank walls, standpipes,

and other tank structures that often cause error readings by other ultrasonic devices. The unit’s transducer uses a built-in,

self-cleaning operation to eliminate buildup or condensation. SmartSonic’s sensor probes are designed to adapt to the

internal tank conditions, automatically adjusting power and receiver sensitivity to any distance and reflecting surface. This

technology ensures the same echo is maintained over the entire operating range which enhances measurement accuracy.

The transmitter can be programmed to simply send a 4-20 mA analog output signal directly to an existing control system or

send data by RS-232 or RS-485 to a PC running SmartSonic’s calibration/data logging software program.

SmartSonic 5

6

Interconnecting Wire Diagram

DC Power input

Note—TB #7 is

Connected to TB #4

Control Panel

Fastening Screw

Terminal Block

Status LED

Calibration

Pushbutton

8

L1 120 VAC

Ground

L2 Neutral

4 to 20 mA +

4 to 20 mA -

DC Power

Supply

12—30 VDC

+-

4 to 20 mA -

4 to 20 mA +

AC Wire Diagram

DC 3 Wire Diagram

1/2” Conduit NPT

Conduit Connection

Wire/Cable for AC Units

115/230 VAC…………..3 wire unshielded, 22AWG (7X30), 300V

4-20 mA………………..1 pair shielded, 24AWG (7X32), 300V

Wire/Cable Recommendation for 3—Wire DC Units

24 VDC + 4-20 mA…….3 wire shielded, 24AWG (7X32), 300V

SmartSonic 6

NOTE: When installing the SmartSonic in

locations where moisture or moist air could

enter the enclosure through the electrical

conduit, use a duct seal compound to seal

the conduit opening.

7

Operation—An acoustic pulse is transmitted from the SmartSonics sensor face. The pulse travels to the surface being

monitored and is reflected off this surface back to the sensor face. The time of flight is divided by 2 and converted to an

output signal directly proportional to the material level.

Calibration Pushbutton/ LED

Indicator for 4—20 mA (750

ohm max.) Output

Deadzone FULL

20 or 4 mA

Yellow

Red

EMPTY

4 or 20 mA

6° to 12°

Span Material Level

Full—Calibration 20 mA or 4 mA (set near target)

1. Calibration mode LED color

2. Push button

Hold for 3 seconds (20 mA) until LED turns

or hold for 7 seconds (4 mA) until LED turns

3. Release button, observe, LED flashes to

acknowledge

Empty—Calibration 4 mA or 20 mA (set far target)

1. Calibration mode LED color

2. Push Button

Hold for 7 seconds (4 mA) until LED turns

or hold for 3 seconds (20 mA) until LED turns

3. Release button, observe, LED flashes to

Calibration—4-20 or 20-4 mA Output

SmartSonic 7

Green

Yellow

Red

Green

Red

Yellow

2 Wire DC 4/20 mA Loop Powered

8

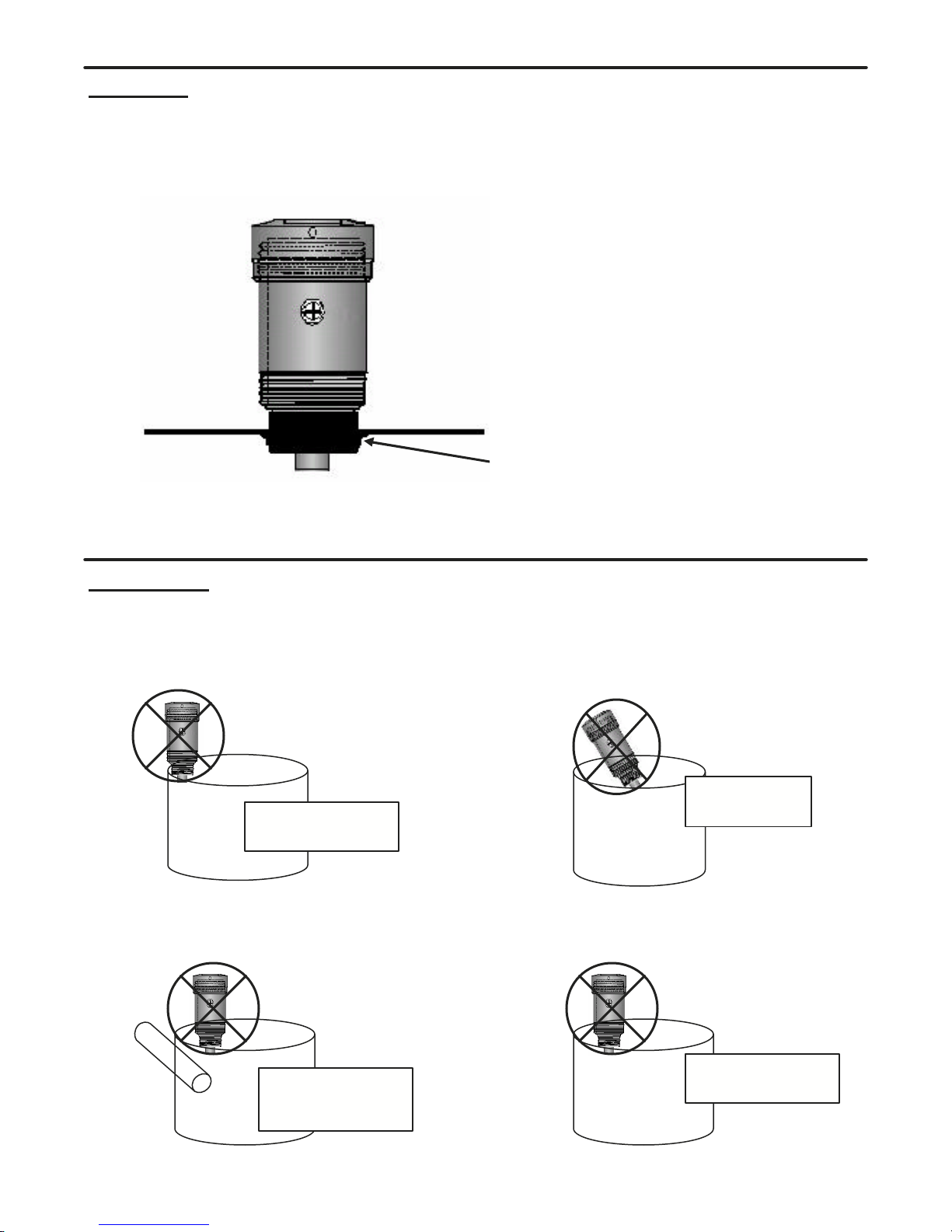

Avoid interference

from side of vessel

Do not install at

an angle

Avoid interference

from obstructions in

vessel

Will not operate in a

vacuum

Vacuum

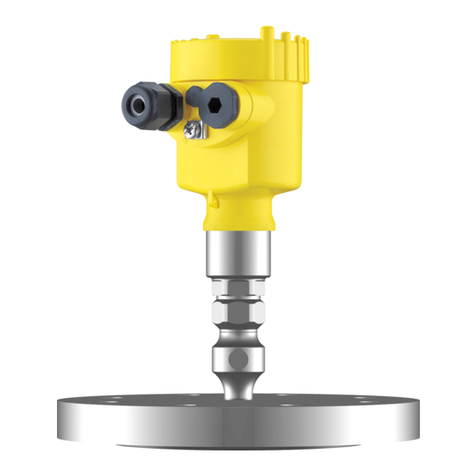

Mounting:

Mounting the SmartSonic Transmitter is critical to the

proper operation of the unit. The unit can be directly

mounted by simply threading the sensor directly into a

metal or plastic mounting flange. If an extended standpipe

is used for mounting, please consult the factory for

assistance. The thread size of the unit is dependent upon

thespecificmodel(seespecifications).

Threaded Mounting Flange (1”, 1 1/2”, 2”, or 3” NPT)

Mounting

Positioning

SmartSonic 8

9

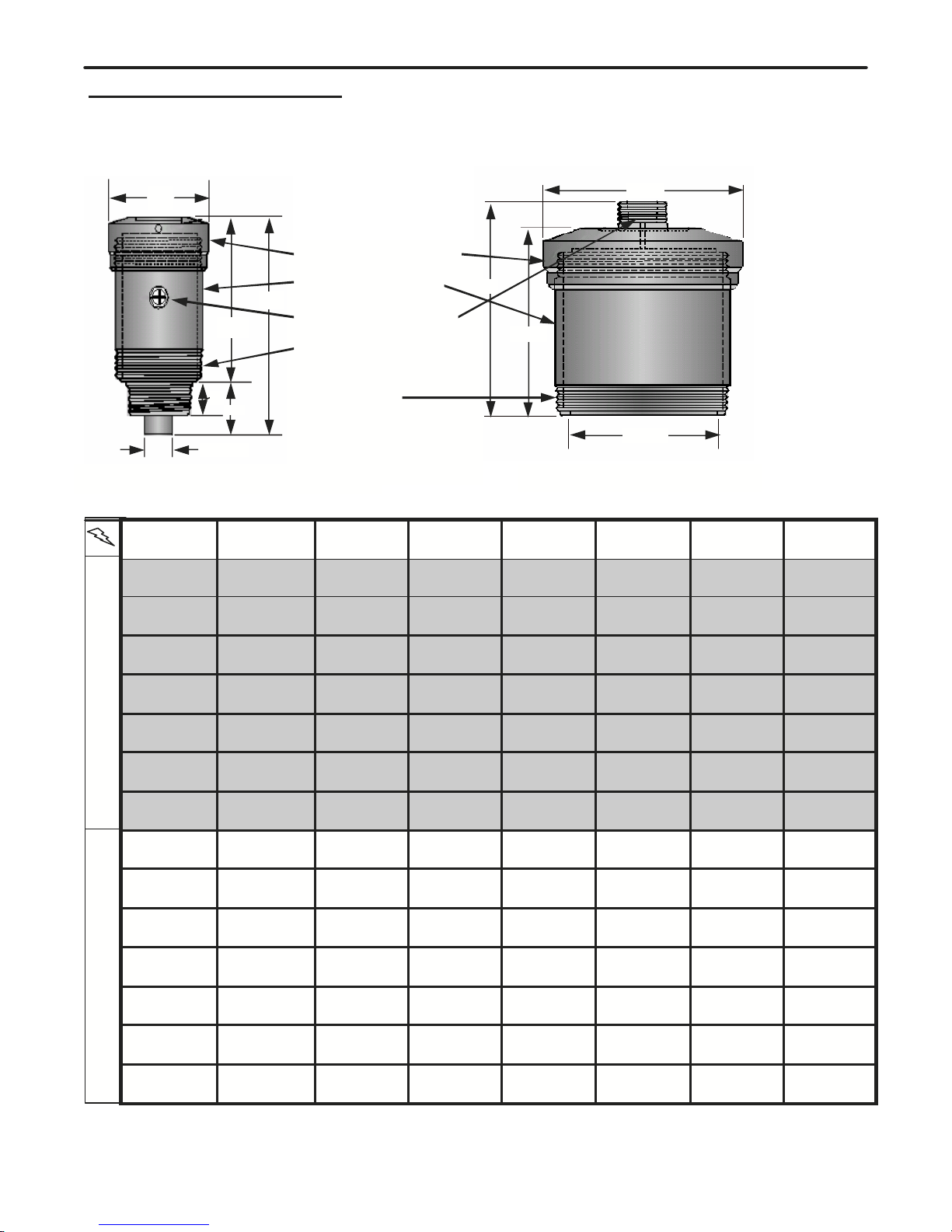

110/230 VAC—4 Wire

4” Ø

6.2”

‘A’

1”

DIA. ‘C’

‘B’

7.3” Ø

‘A’

6.625”

DIA. ‘C’

Threaded Access Cover

Electronic Enclosure

1/2” NPT Conduit Entry

3” NPT Thread Located on

Enclosure

6” NPT Thread

Model SS300/400-25U OnlyModels SS300/400-45U,52U,70U,80U,81U,and 148U

12 to 30 VDC—3 Wire

MODEL RANGE RESOLUTION MOUNTING

SS400-45U 1.0—60ft

0.30—18.2 m 0.19”

5 mm 3.0”

NPT

SS400-52U 0.9—50ft

0.27—15.2 m 0.16”

4 mm 3.0” or 2.0”

NPT

SS400-70U 0.8—30ft

0.24—9.1 m 0.12”

3 mm 3.0” or 2.0”

NPT

SS400-81U 0.6—16ft

0.18—4.9 m 0.08”

2 mm 3.0” or 1.5”

NPT

SS400-148U 0.4—9ft

0.12—2.7 m 0.04”

1 mm 3.0” or 1.0”

NPT

SS300-45U 1.0—60ft

0.30—18.2 m 0.19”

5 mm 3.0”

NPT

SS300-52U 0.9—50ft

0.27—15.2 m 0.19”

5 mm 3.0”

NPT

SS300-70U 0.8—30ft

0.24—9.1 m 0.12”

3 mm 3.0” or 2.0”

NPT

SS300-80U 0.7—20ft

0.21—6.1 m 0.08”

2 mm 3.0” or 2.0”

NPT

SS300-81U 0.6—16ft

0.18—4.9 m 0.08”

2 mm 3.0” or 1.5”

NPT

SS300-148U 0.4—9ft

0.12—2.7 m 0.04”

1 mm 3.0” or 1.0”

NPT

SS400-80U 0.7—20ft

0.21—6.1 m 0.08”

2 mm 3.0” or 2.0”

NPT

SS400-25U 1.4-90ft

0.40-27.4 m 0.41”

10 mm 6.0”/1.0”

NPT

SS300-25U 1.4-90ft

0.40-27.4 m 0.41”

10 mm 6.0”/1.0”

NPT

OPERATING

FREQUENCY

25 KHz

45 KHz

52 KHz

70 KHz

80 KHz

81 KHz

148 KHz

25 KHz

45 KHz

52 KHZ

70 KHZ

80 KHz

81 KHz

148 KHz

DIMENSION

‘A’

7.625”

8.9”

9.3”

8.5”

8.5”

8.4”

8.25”

7.625”

8.9”

9.3”

8.5”

8.5”

8.4”

8.25”

DIMENSION

‘B’

N/A

3.0”

3.05”

2.25”

2.25”

2.1”

2.0”

N/A

3.0”

3.05”

2.25”

2.25”

2.1”

2.0”

DIMENSION

‘C’

5.75”

3.0”

2.2”

1.8”

1.8”

1.5”

1.1”

5.75”

3.0”

2.2”

1.8”

1.8”

1.5”

1.1”

Technical Specifications SmartSonic 9

10

4” Ø

4.75”

‘A’

1”

DIA. ‘C’

‘B’

Threaded Access Cover

Electronic Enclosure

1/2” NPT Conduit Entry

3” NPT Thread Located on

Enclosure

Models SS200-70U,80U,81U,and 148U

2 Wire -4/20mA Loop Powered

MODEL RANGE RESOLUTION OPERATING

FREQUENCY MOUNTING DIMENSION

‘A’ DIMENSION

‘B’ DIMENSION

‘C’

SS200-70U 0.8—30ft

0.24—9.1 m 0.12”

3 mm 70 KHz 3.0” or 2.0”

NPT 7.05” 2.25” 1.8”

SS200-80U 0.7—20ft

0.21—6.1 m 0.08”

2 mm 80 KHz 3.0” or 2.0”

NPT 7.05” 2.25” 1.8”

SS200-81U 0.6—16ft

0.18—4.9 m 0.08”

2 mm 81 KHz 3.0” or 1.5”

NPT 6.95” 2.1” 1.5”

SS200-148U 0.4—9ft

0.12—2.7 m 0.04”

1 mm 148 KHz 3.0” or 1.0”

NPT 6.8” 2.0” 1.1”

Table of contents

Popular Transmitter manuals by other brands

Crestron

Crestron DigitalMedia DM-TX-100F Operation guide

Hallicrafters

Hallicrafters HT-44 Operating and service instructions

Vega

Vega VEGABAR 83 operating instructions

Crestron

Crestron DM-TX1-4K-C-1G Use & care guide

ATI Technologies

ATI Technologies UniSens A12 Series manual

Nortek

Nortek korus Baton Getting started guide