Bindicator TDR-1000 User manual

Table of contents

Other Bindicator Radar manuals

Popular Radar manuals by other brands

Endress+Hauser

Endress+Hauser Micropilot FMR53 Brief operating instructions

Siemens

Siemens SITRANS LG260 operating instructions

Image Sensing Systems

Image Sensing Systems RTMS Echo user guide

Kustom Signals

Kustom Signals Raptor RP-1 Operator's manual

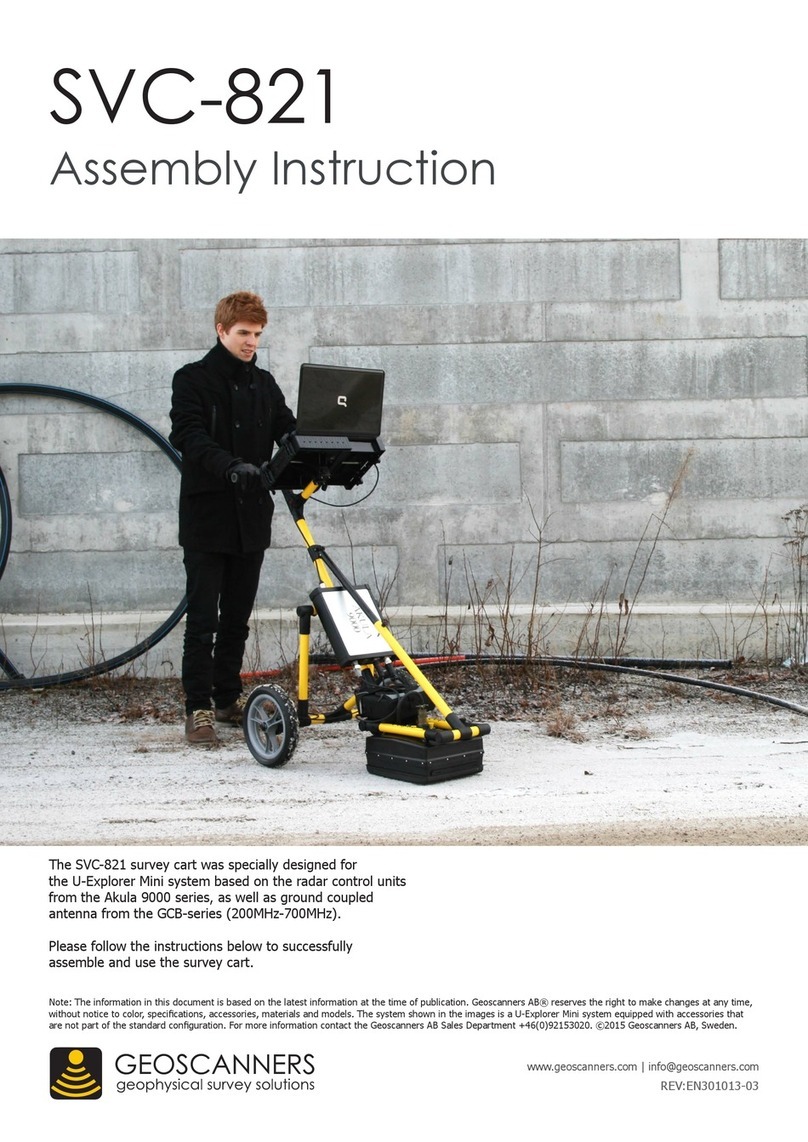

Geoscanners AB

Geoscanners AB SVC-821 Assembly instruction

Endress+Hauser

Endress+Hauser Hart Micropilot FMR60B operating instructions

Vega

Vega VEGAPULS 6X operating instructions

Decatur Electronics

Decatur Electronics Surface Velocity Radar SVR2-01 user manual

Endress+Hauser

Endress+Hauser Micropilot FMR66B PROFINET with Ethernet-APL Brief operating instructions

Koden

Koden MDC-1041 Operation manual

Decatur Electronics

Decatur Electronics Railmaster user manual

Radarsign

Radarsign TC-800 installation manual