Binsfeld TorqueTrak 9000 User manual

- 1 -

Table of Contents

System Overview......................................................................3

System Components.................................................................4

Features and Controls...............................................................5

RD9000 Receiver ..................................................................5

BT9000 Bridge Transmitter....................................................7

Set Up Procedure......................................................................8

Appendix A: Calibration Verification.........................................12

Appendix B: TorqueTrak 9000 Specifications...........................13

Appendix C: Calibration Calculations.......................................15

C1: Torque on Round Shafts................................................16

C2: Axial Strain on Round Shafts.........................................19

C3: Single Grid (1/4 Bridge).................................................22

Appendix D: RF Channel Configuration...................................25

Appendix E: Transmitter Gain Configuration............................26

Appendix F: Trouble Shooting Guide.......................................27

Appendix G: Strain Gage Application.......................................29

- 2 -

FCC Rules Part 15: Computing Devices

This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to part 15 of the FCC

Rules

The user is cautioned that changes and modifications made to

the equipment without the express approval of the manufacturer

could void the user’s authority to operate this equipment.

Operation is subject to the following two conditions: (1) this

device may not cause interference, and (2) this device must

accept any interference that may cause undesired operation of

the device.

- 3 -

System Overview

The TorqueTrak 9000 is a battery-powered digital radio telemetry

system designed to transmit a single millivolt data signal

(typically from a strain gage or gage-type sensor) 20 feet or

more. Up to 8 individual systems can be operated concurrently

on different frequencies to transmit multiple data signals.

The TorqueTrak 9000 consists of two primary components: the

BT9000 Bridge Transmitter and the RD9000 Receiver.

The TorqueTrak 9000 features:

fully encapsulated rotating electronics

user-selectable input range

user-selectable transmit/receive frequency

AutoZero switch (sets output to zero at no load)

RF signal strength indicator

low battery voltage indicator

switchable low pass filter

reverse polarity switch

excellent accuracy and stability

minimal drift with ambient temperature changes

microprocessor-based digital circuitry from sensor input to

signal output

Ideal for short term diagnostic testing, the TorqueTrak 9000 is

rugged, intelligent, and simple to use.

- 4 -

System Components

BT9000 Transmitter with

-2” screw-mount antenna (reverse polarity SMA connector)

-9V battery connector

RD9000 Receiver

110VAC/12VDC Wall Plug Transformer

(220VAC/12VDC Wall Plug Transformer optional)

RA900 Receiver Antenna (magnetic mount base)

with 25 ft connecting cable

BS900 Bridge Simulator

Screwdriver

9V lithium battery

Rubber sheet

10ft 4-conductor ribbon cable

Desoldering braid

1 roll 1” fiberglass tape

TorqueTrak 9000 Users Manual

- 5 -

Features and Controls

RD9000 Receiver

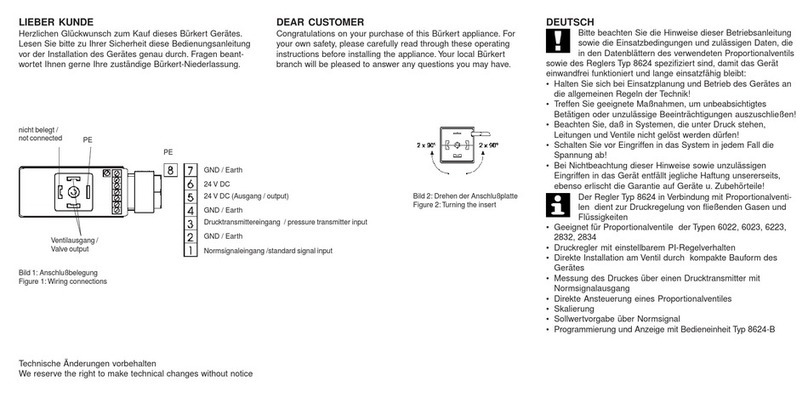

RD9000 Front Panel Controls

Power

Switch

Power Light

On if unit is

powered.

AutoZero

Up position applies an offset to

correct the output to zero volts (set

zero volts out for no-load input). In

down position, no offset is applied.

Low TX Power

Blinking light indicates low

power at transmitter (e.g.

time to change battery).

Full Scale Adjust

Reduces amplitude of

output voltage (for

scaling).

Data Light

On solid indicates successful

data transmission. Blinking or

flickering light indicates data

errors.

Full Scale Switch

In up position, receiver generates positive

full scale voltage signal at Output (can be

attenuated with Full Scale Adjust). In down

position, receiver outputs live data signal

(from transmitter).

Display Output/RF Level Indicator

In the Display Output mode (switch up)

LEDs indicate relative output voltage from

-Full Scale to +Full Scale. In the RF Level

mode (switch down), LEDs indicate relative

RF signal strength.

- 6 -

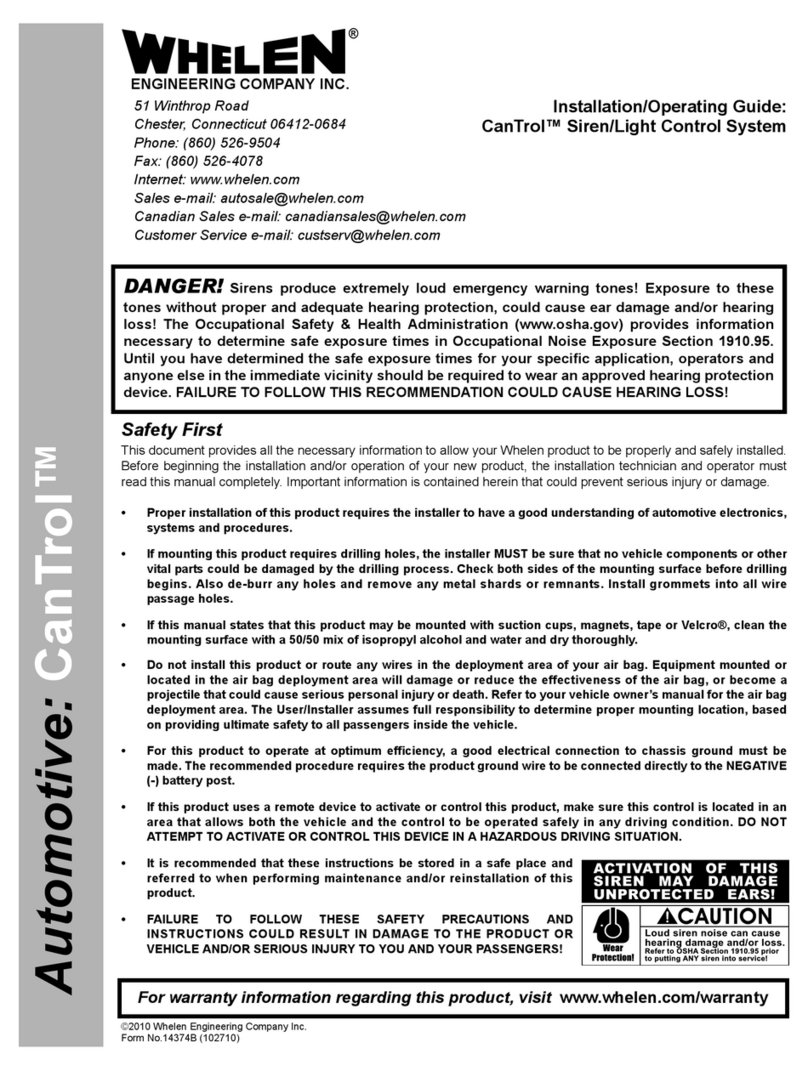

RD9000 Rear Panel Controls

Filter Switch

Switch to up position to

apply 10Hz low-pass filter

to voltage output.

Power Input Jack

Connect to 12VDC

(e.g. wall plug

transformer).

Voltage Output

Connect to chart recorder

or other read-out device.

(±10V Full Scale)

Polarity Switch

Switch to down position

to reverse polarity on

voltage output.

RF Channel Selector

Adjust receiver knob to match RF

transmit frequency of BT9000

transmitter.

Antenna

Connect to RA900

antenna using SMA-

SMA cable.

- 7 -

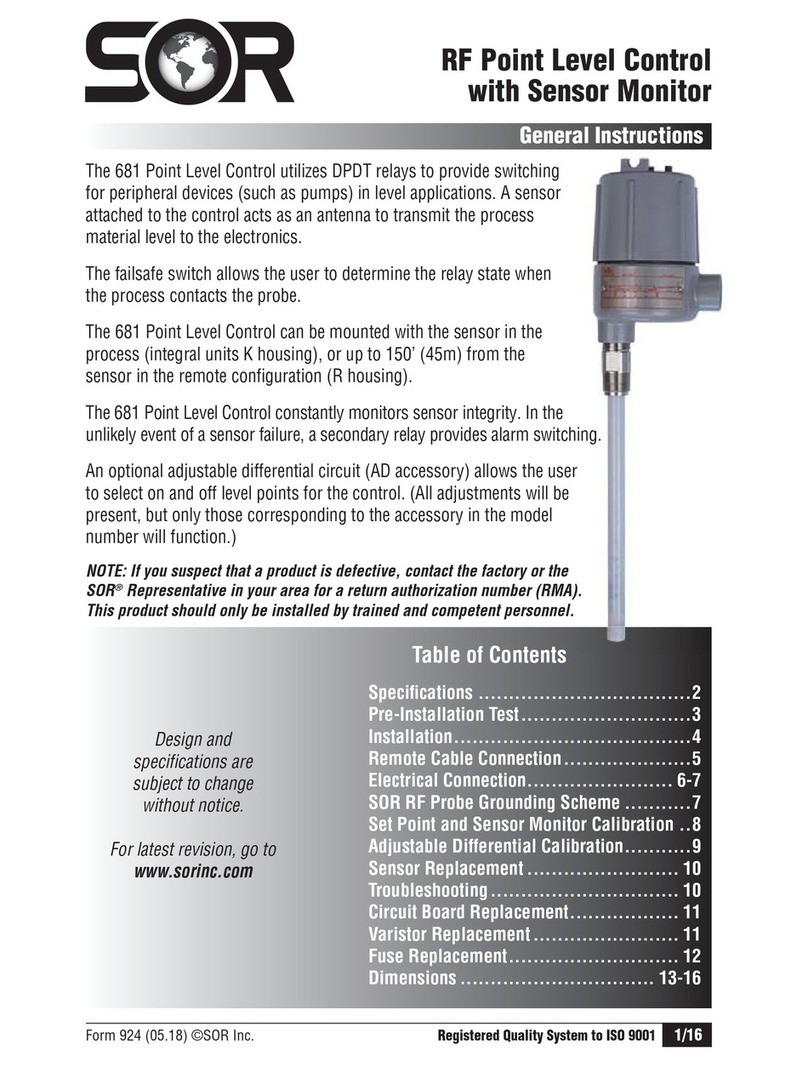

BT9000 Bridge Transmitter

To sensor (gage):

-Exc: Black

-Sen: White

+Sen: Green

+Exc: Red

To 9V battery negative

To 9V battery positive

RF Channel Select

pads

(See Appendix D.)

Gain Select pads

(See Appendix E.)

- 8 -

Set Up Procedure

Before installing the telemetry it is important to verify that the

gain setting of the transmitter is suitable for the expected sensor

load. (The BT9000 transmitter is factory set for a gain of 2000

(Gain Level = 4) which will accommodate most torque

applications.) To determine the appropriate gain setting for a

given application refer to the calculations in Appendix C.

Instructions for changing the transmitter gain setting are in

Appendix E. For instructions about changing the RF channel see

Appendix D.

1. Attach sensor or strain gage(s) to shaft or device being

measured. Be sure shaft and/or sensor is unstrained when

attaching as this is the zero load reference.

2. Secure transmitter and 9 volt battery to shaft or device being

measured using fiberglass strapping tape. Alternatively,

hose clamps, machined collars or other methods or devices

may be used but care should be taken to avoid excessive

compression on the transmitter and battery. CAUTION:

Make sure all components are securely fastened to rotating

equipment. Avoid injury by standing clear of attached items

which may come off during machine operation if improperly

secured!

3. Solder an appropriate length of 4-conductor ribbon cable or

suitable leads to gage or sensor. (Note: Keep ribbon cable

as short as practical (6-8 inches typical). Long cable runs

may pick up unwanted electrical noise.)

4. Connect other end of ribbon cable leads to appropriate

screw terminals on BT9000 transmitter. Secure battery

connector to appropriate screw terminals on BT9000, and

attach to 9 volt battery.

- 9 -

Transmitter, Battery and Sensor Connections

5. Using the provided 25ft coax antenna cable connect the

RA900 receiving antenna to Antenna connection on rear

panel of RD9000 receiver.

6. Position RA900 magnetic-mount receiving antenna near

transmitter, typically within 10 feet.

RD9000 Rear Panel

7. Connect 12VDC AC adapter (Model AC110 or AC220) or

other 12VDC supply to Power Input jack on RD9000 rear

panel. Plug adapter into appropriate power source (wall

outlet). Move RD9000 power switch to On.

Battery Clip

Sensor

(strain gage shown)

- 10 -

RD9000 Front Panel

8. Flip AutoZero switch down to remove the previously stored

reference. Confirm that Full Scale switch is down (used

only for scaling and trouble shooting).

9. Confirm that Data light on front panel of RD9000 is on solid

(indicating successful data transmission). If Data light is not

on solid, see Trouble Shooting Guide in Appendix F.

10. To evaluate radio signal strength, flip Display Output/RF

Level switch down to RF Level. Relative signal strength is

indicated by position of lighted LED with –FS being low end

of scale and +FS being high end. If possible, rotate

transmitter through complete range of motion to verify strong

signal reception in all orientations.

11. Connect recorder or other voltage readout device to Output

terminals on rear panel of RD9000.

12. Flip AutoZero switch up to zero out any initial imbalance

(sensor must be in unloaded state, e.g. no torque on shaft).

Leave switch in up position during test to retain reference.

AutoZero can be reset by flipping switch down and then

back up again. (Sensor must be in unloaded state).

Note: Once the AutoZero feature is activated the initial offset

voltage is subtracted from the full scale output.

Consequently the full scale range of the system will be

reduced by this offset. For example, if the initial offset is

1.6V then the full scale output of the system will be 8.4V

after the AutoZero is set.

If before activating AutoZero there is an initial offset of more

than 50% of full scale, it may be necessary to (1) use a lower

- 11 -

gain setting on the transmitter, (2) apply a shunt resistor to

the gage to bring it closer to balance, or (3) replace the

strain gage. For further assistance, contact technical

support at Binsfeld Engineering.

13. Set Filter switch at rear of RD9000 to desired position, up to

activate 10 Hz low-pass filter (averages dynamic data) or

down to allow full 500 Hz frequency response.

14. Calibrate output voltage based on gain calculations as

demonstrated in Appendix C: Calibration Calculations.

15. System is now ready to record data.

Note: The BS900 Bridge Simulator acts as a Wheatstone bridge

type sensor and can be used to simulate a full bridge strain gage

for bench testing and troubleshooting. The BS900 features a

three-position switch. With the switch in the center position the

device simulates a balanced bridge (zero load) and the

corresponding output from the RD9000 receiver will be

approximately 0 volts. In the “+” and “-” positions the device

simulates a positive and negative sensor load, respectively. The

simulated load is equivalent to 125 microstrain of torque and will

produce approximately 2 volts output at the RD9000 receiver

when the BT9000 transmitter is set at gain level 4 (gain = 2000).

CAUTION: The BS900 is intended to be used as a basic

indicator and is not provided as a calibration reference.

- 12 -

Appendix A: Calibration Verification

The RD9000 is calibrated prior to shipping using instruments

traceable to the United States National Institute of Standards and

Technology (NIST). Calibration can be checked at any time with

a NIST traceable reference such as a calibrated voltmeter.

Check the RD9000 calibration as follows:

1. Turn the unit on and allow a 15 minute warm-up.

2. Turn the Full Scale Adjust screw on the front panel fully

clockwise.

3. Flip the Full Scale switch on the front panel to the down

position.

4. Connect a calibrated voltmeter to the Output on the rear

panel of the RD9000.

5. Without the RD9000 receiving a transmitted signal (e.g.

transmitter not operating or RD9000 channel selector set to

an unused frequency) the Output should read negative full

scale (-10 VDC ± 0.01).

6. Flip the Full Scale switch on the front panel to the up

position.

7. The Output should read positive full scale (+10 VDC ± 0.01).

It is recommended that the RD9000 be checked for calibration

annually. If found to be out of specification, it can be returned to

Binsfeld Engineering Inc. for calibration for a nominal fee

($100.00, price subject to change).

- 13 -

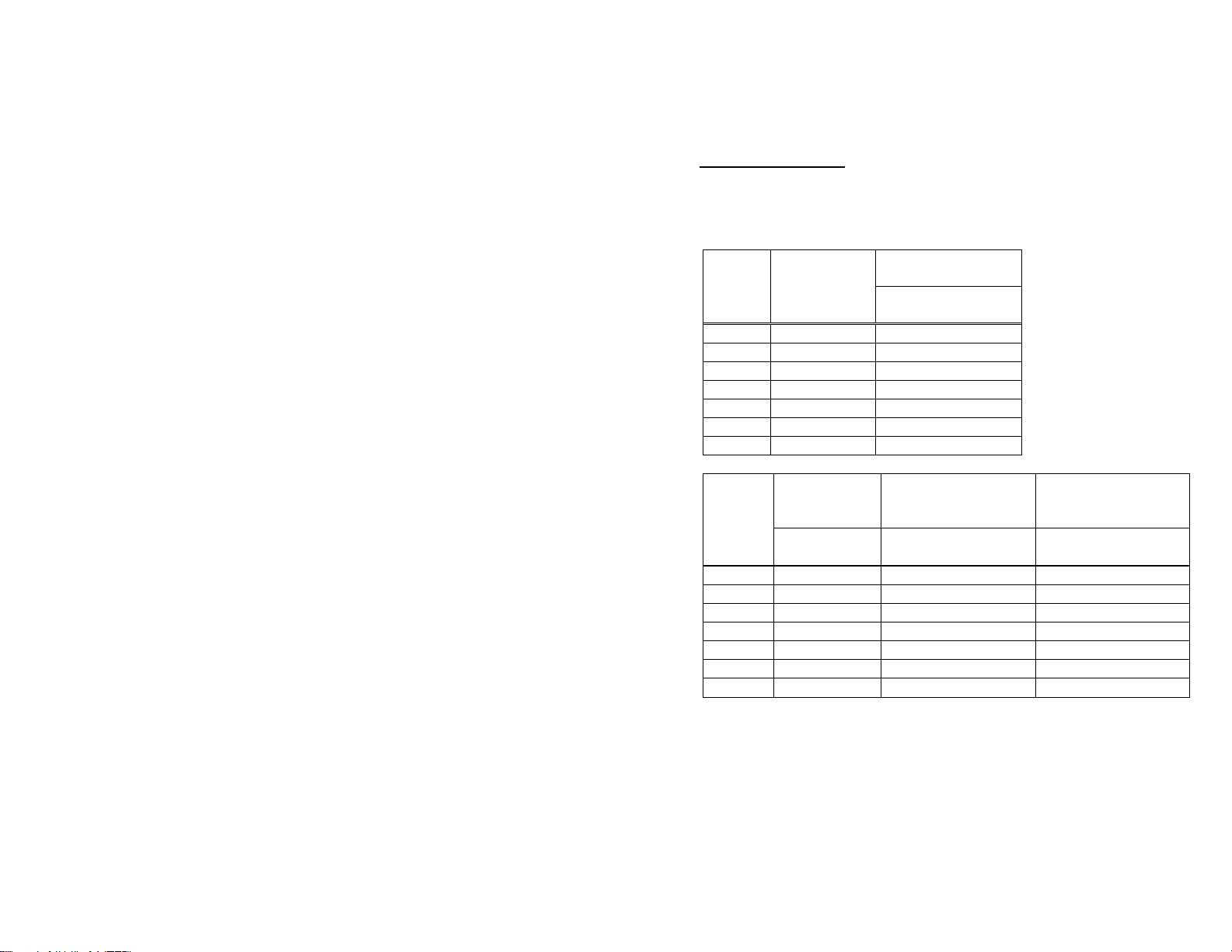

Appendix B: TorqueTrak 9000 Specifications

BT9000 Transmitter

Sensor Input: Full (4-arm) Wheatstone Bridge strain gage

(120-1000 ohms; 350 ohms standard)

Bridge Input: 5.0VDC, regulated

Sensor Range: User selectable. See tables below.

Gain

Level

Transmitter

Gain

(GXMT)

Torque,

Bending

Full Bridge,

4 Active Arms

6

8000

±125 microstrain

5

4000

±250 microstrain

4

2000

±500 microstrain

3

1000

±1000 microstrain

2

500

±2000 microstrain

1

250

±4000 microstrain

0

125

±8000 microstrain

Gain

Level

Transmitter

Gain

(GXMT)

Axial Strain

(Tension,

Compression)

¼ Bridge

Full Bridge,

2.6 Active Arms

Single Gage

(1 Active Arm)

6

8000

±192 microstrain

± 500 microstrain

5

4000

±385 microstrain

±1000 microstrain

4

2000

±769 microstrain

±2000 microstrain

3

1000

±1538 microstrain

±4000 microstrain

2

500

±3077 microstrain

±8000 microstrain

1

250

±6154 microstrain

±16,000 microstrain

0

125

±12,307 microstrain

±32,000 microstrain

(Assumed gage factor = 2.0)

Sensor and Power Connection: Screw terminal block

Transmitter Power Input: 7.5 to 12VDC, 60mA max

(with 350bridge)

Transmitter Battery Life: 12 hours, nominal

(9V lithium, 350bridge, 25°C)

Transmit Distance: 20 feet or more

- 14 -

Transmitter g-force Rating: 3000 g’s (steady state)

Operating Temperature: 0 to 70°C (32 to 158°F)

Size and Weight: 1.05” x 1.95” x 0.70” 2oz

(27mm x 50mm x 18mm) (57g)

RD9000 Receiver

Output Signal: ±10VDC, field adjustable

down to ± 5VDC

Output Connection: 5-way binding posts (banana jacks)

Power Input: 10-18VDC, 250mA max

(110VAC or 220VAC adapter

supplied)

Power Input Connector: 2.1mm jack (for 5.5mm x 2.1mm plug)

Operating Temperature: 0 to 70°C (32 to 158°F)

Size and Weight: 5.5” x 7.5” x 1.5” 3lb

(14cm x 19cm x 3.8cm) (1.4kg)

TT9000 System

Resolution: 14 bits (±full scale = 16384 points)

Gain Error: ±0.1%

(±0.5% before scale calibration)

Gain Drift: ±0.02%FS/°C over operating

temperature range

Zero Error: ±0.1%FS

(±1% typical before AutoZero)

Zero Drift: 0.02%FS/°C over operating

temperature range

Frequency Response: 0 –500Hz (-3dB @ 500Hz, nominal)

(0 - 10Hz with switchable filter)

Delay: 3 msec, typical

Slew Rate: 7.5V/msec, typical

Sample Rate: 1276 samples/sec

- 15 -

Appendix C: Calibration Calculations

The equations in this Appendix define the relationship between

the input signal to the BT9000 transmitter (typically from a strain

gage) and the full scale output voltage of the TorqueTrak 9000

system. The calculations are based on parameters of the device

being measured (e.g. shaft diameter), sensor parameters (e.g.

gage factor) and transmitter gain setting.

Section C1 is specific to torque measurements on round shafts

(full bridge, 4 active arms).

Section C2 applies to axial strain (tension/compression)

measurements on round shafts (full bridge, 2.6 active arms).

Section C3 is for use with a single grid (1/4 bridge).

- 16 -

(VFS)()(E)(4)(Do4-Di4)

= TFS (N-m)

(VEXC)(GF)(N)(16000)(1+)(GXMT)(Do)

C1: Torque on Round Shafts

Step 1: Calculate Full Scale Torque, TFS (ft-lb) that corresponds

to the maximum system output of 10.0V.

For a solid steel shaft, use this simplified equation:

For all other shafts use the more general equation:

Legend of Terms

Di

Shaft Inner Diameter (in) (zero for solid shafts)

Do

Shaft Outer Diameter (in)

E

Modulus of Elasticity (30 x 106PSI steel)

GF

Gage Factor (specified on strain gage package)

GXMT

Telemetry Transmitter Gain (user configurable, typical

is 2000 for ±500 microstrain range; See Appendix E)

N

Number of Active Gages (4 for torque)

TFS

Full Scale Torque (ft-lb)

VEXC

Bridge Excitation Voltage = 5 volts

VFS

Full Scale Output of System = 10 volts

Poisson’s Ratio (0.30 for steel)

For metric applications with Doand Di in millimeters and TFS in

N-m the general equation is:

Where E= 206.8 x 103N/mm2.

(755.17 x 103ft-lb/in3)(Do3)

= TFS (ft-lb)

(GF) (GXMT)

(VFS)()(E)(4)(Do4-Di4)

= TFS (ft-lb)

(VEXC)(GF)(N)(16)(1+)(GXMT)(Do)(12)

- 17 -

Example: Given a solid steel shaft with

Do (shaft diameter, measured) = 2.5 inches

GF (gage factor from gage package) = 2.045

GXMT (BT9000 gain based on jumpers) = 2000

(755.17 x 103ft-lb/in3)(2.50 in)3

TFS = = 2,885 ft-lb

(2.045) (2000)

so 10.0 V output at the RD9000 indicates 2,885 ft-lb of torque or

288.5 ft-lb/volt.

Step 2: Trim the Full Scale Output: If desired, the full scale

output voltage of the RD9000 can be trimmed so that the

voltage output corresponds to an even round number

torque level, e.g. 100 ft-lb/volt. First, calculate the

trimmed voltage value (VTRIM) that corresponds to the

round number (trimmed) torque level (TTRIM). Note: TTRIM

must be greater than TFS calculated above.

Legend of Terms

TFS

Full Scale Torque (ft-lb)

TTRIM

Trimmed Torque (ft-lb)

VFS

Full Scale Output of System = 10 volts

VTRIM

Trimmed Output of System

(TFS)(VFS)

VTRIM = TTRIM

- 18 -

Example: The full scale torque (TFS) has been calculated to

be 2,885 ft-lb, for 10 volts. However the user would

like to scale the system output to an adjusted

torque (TTRIM) of 4,000 ft-lb for 10 volts. (Note that

TTRIM = 4,000 is greater than TFS = 2,885.)

(2,885 ft-lb)(10 volts)

= VTRIM = 7.21 volts

(4,000 ft-lb)

Step 3: Adjust the Full Scale Output to equal VTRIM on the

RD9000.

a) Flip the Full Scale switch up on the front of the

RD9000. (This produces a full scale positive voltage

output.)

b) Connect a voltmeter to the Output terminals on the

rear panel of the RD9000 to read the full scale

output voltage.

c) Turn the Full Scale Adjust screw on the front of the

RD9000 until the voltmeter reads 7.21 volts.

The system is now calibrated so that 4,000 ft-lb equals 10 volts

(i.e. the gain of the system is 400 ft-lb/volt).

In summary:

Before adjusting full scale output:

2,885 ft-lb = 10 volts (288.5 ft-lb/volt)

After adjusting full scale output:

4,000 ft-lb = 10 volts (400 ft-lb/volt)

- 19 -

C2: Axial Strain on Round Shafts

Step 1: Calculate Full Scale Forces PFS (lb) that corresponds to

the maximum system output of 10.0V.

For a solid steel shaft, use this simplified equation:

For all other shafts use the more general equation:

Legend of Terms

Di

Shaft Inner Diameter (in) (zero for solid shafts)

Do

Shaft Outer Diameter (in)

E

Modulus of Elasticity (30 x 106PSI steel)

GF

Gage Factor (specified on strain gage package)

GXMT

Telemetry Transmitter Gain (user configurable, typical is

2000 for ±770 microstrain range; See Appendix E)

PFS

Full Scale Force (tension or compression) (lb)

VEXC

Bridge Excitation Voltage = 5 volts

VFS

Full Scale Output of System = 10 volts

Poisson’s Ratio (0.30 for steel)

(VFS)()(E)(Do2-Di2)

= PFS

(VEXC)(GF)(2)(1+)(GXMT)

(72.50 x 106 lb/in2)(Do2)

= PFS

(GF) (GXMT)

Table of contents

Other Binsfeld Control System manuals

Popular Control System manuals by other brands

Bruker

Bruker B-ACS 60 installation manual

Crestron

Crestron 4 Series quick start

Roger

Roger MCT62E installation manual

SPINOGY

SPINOGY Xcontrol-E operating manual

Idex

Idex Knight Ultra Micro-Pro UMP 100 Series instruction manual

Shenzhen Guanhong Automation

Shenzhen Guanhong Automation SZGH-CNC990TDb series user manual