114JS50E4.00 ·EVJS 500 Split

CONTENTS

04/2022

| 3 |

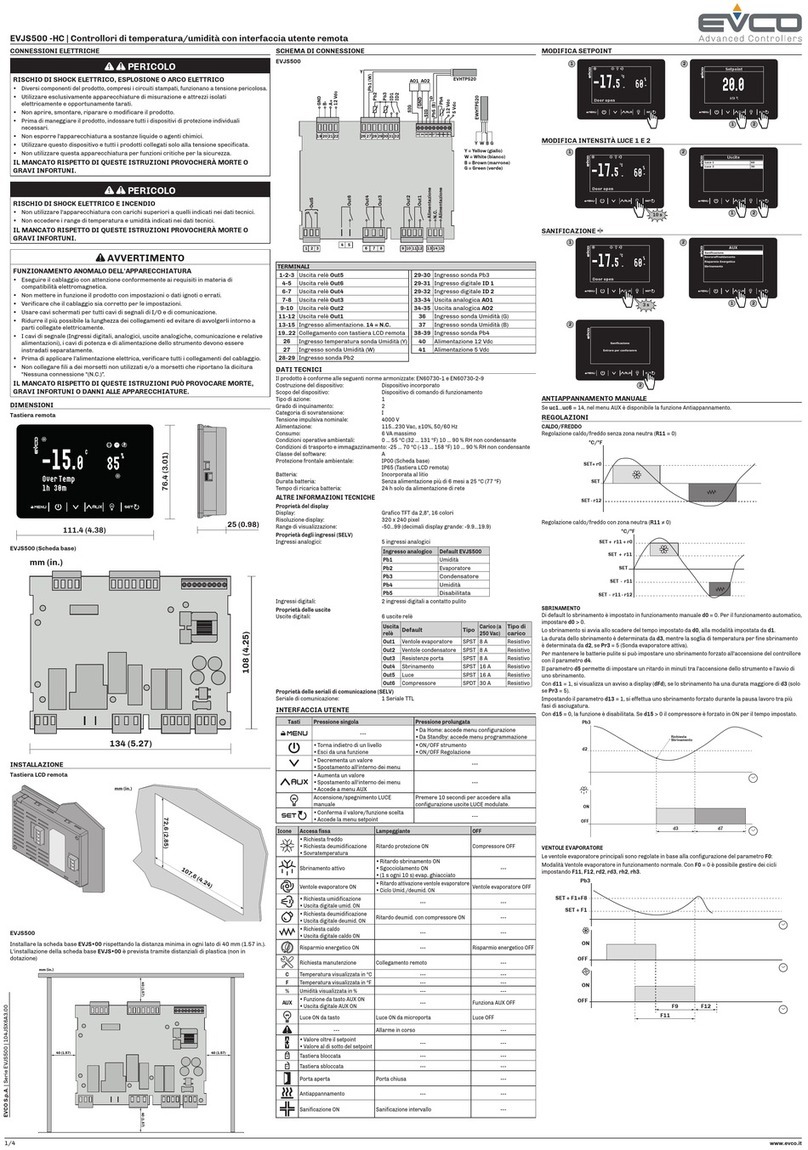

5.4.4 Changing the intensity of light 1 and 2 ....................................................................................................20

5.4.5 Setting the clock ........................................................................................................................................21

5.4.6 Accessing the parameters .......................................................................................................................22

5.4.7 Programming menu...................................................................................................................................23

6. DEFROSTING.................................................................................................................................. 24

6.1 Introduction .........................................................................................................................................24

6.1.1 Operating conditions.................................................................................................................................24

6.1.2 Dripping interval........................................................................................................................................24

6.1.3 Defrost types .............................................................................................................................................25

6.2 Modular defrost: RTC ..........................................................................................................................25

6.3 Standard defrost..................................................................................................................................25

6.3.1 Electric heater defrost .............................................................................................................................25

6.3.2 Cycle inversion (hot gas) defrost.............................................................................................................27

6.3.3 Defrost on compressor stoppage............................................................................................................29

7. REGULATORS ................................................................................................................................. 30

7.1 Hot/cold temperature ......................................................................................................................... 30

7.1.1 Operation ...................................................................................................................................................30

7.2 Hot/Cold temperature with neutral zone ..........................................................................................30

7.2.1 Operation ...................................................................................................................................................30

7.3 Temperature and dehumidication with compressor .....................................................................31

7.3.1 Operation ...................................................................................................................................................31

7.3.2 Temperature priority over dehumidication .........................................................................................31

7.4 Humidity ................................................................................................................................................31

7.4.1 Operation ...................................................................................................................................................31

7.5 Humidity with neutral zone..................................................................................................................32

7.5.1 Operation ...................................................................................................................................................32

7.6 Compressor ..........................................................................................................................................32

7.6.1 Operating diagrams ..................................................................................................................................33

7.7 Dual Compressor .................................................................................................................................34

7.7.1 Operating diagram ....................................................................................................................................34

7.8 Evaporator fans....................................................................................................................................35

7.8.1 Operation ...................................................................................................................................................35

7.8.2 Operating modes .......................................................................................................................................35

7.8.3 Operation during a defrost.......................................................................................................................35

7.8.4 Evaporator fan operation during dripping .............................................................................................35

7.9 Condenser fans ....................................................................................................................................36

7.9.1 Operation ...................................................................................................................................................36

7.10 Energy Saving.....................................................................................................................................36

7.10.1 Operation .................................................................................................................................................36