Bio SB TintoRetriever User manual

www.biosb.com | email: info@biosb.com | phone: +1-805-692-2768

Bio SB

BIOSCIENCE FOR THE WORLD

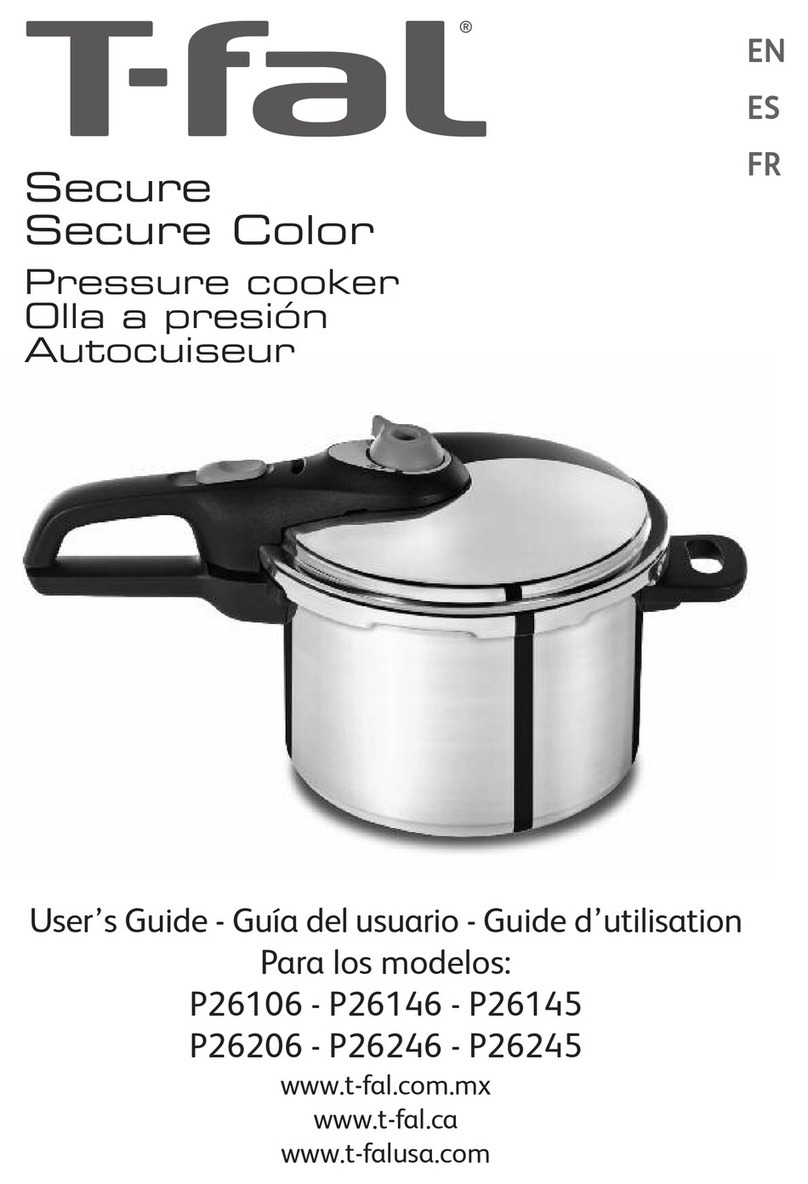

Bio SB TintoRetriever Pressure Cooker

Nucleic Acid & Epitope Retrieval System

Instruction Manual

Bio SB Inc, 69 Santa Felicia Drive, Santa Barbara, CA 93117, USA

Tel: +1-805-692-2768 | Fax: 1-805-692-2769

Immunohistochemistry

Fluorescent In-Situ Hybridization

Chromogenic In-Situ Hybridization

V5 05/18/17

www.biosb.com | email: info@biosb.com | phone: +1-805-692-2768 2

1. DESCRIPTION & FEATURES

Most formalin-xed paran embedded tissues require an epitope retrieval step prior to any immunochemical staining. The epitope

retrieval step breaks some of the methylene bridges that cross-link proteins in formalin-xed tissue and allows antibodies to bind to

unmasked epitopes.

Heat induced epitope retrieval (HEIR) and nucleic acid retrieval steps are most often performed using a conventional pressure cooker or a

microwave oven. The Bio SB TintoRetriever is a precision-controlled heat source capable of maintaining a constant and reliable tempera-

ture while minimizing the potential for evaporation of the working solution under HIER procedure conditions.

TheTintoRetriever Pressure cooker is recommended for use in both Immunohistochemistry (IHC) and In-Situ Hybridization (ISH) protocols,

and can be easily integrated into a clinical or research laboratory.

Topic Page

Description & Features Page 2

Main Technical Parameters Page 3

Safety Requirements Page 4

Parts & Features Page 5

Installation Page 6

Operating Procedures Page 7

Cleaning & Storage Page 9

Temperature Settings Page 10

Applications for IHC Page 11

Troubleshooting & Contact info Page 12

Qality Control Certicate Page 13

Index

Rapid Heat Retrieval

Multiple Temperature Settings

Use in IHC & ISH Applications

Low Reagent Use

Holds 96 Slides Per Run

Cost Eective HIER Solution

√

√

√

√

√

√

Figure 1 - TintoRetriever system with slide racks and

reagent holders.

IHC

p40 RMab

BSB 2072

CISH

HER2/CEN 17

3022-40

FISH

ALK/EML4 TriCheck

Z-2117-200

TintoRetriever Applications (Pictured on Cover)

www.biosb.com | email: info@biosb.com | phone: +1-805-692-2768

V5 05/18/17

www.biosb.com | email: info@biosb.com | phone: +1-805-692-2768 3

2. MAIN TECHNICAL PARAMETERS

• Power Requirements: AC110V, 60Hz, 1000W

• Dimensions: 320mm x 320mm x 340mm (W x D x H)

• Packaged Dimensions: (330mm x 330mm x 360mm) (W x D x H)

• Weight: 12.6 lb (5.7 Kg)

• OperationalTemperature: 10 °C - 35 °C

• Operational Humidity: 85%

• Chamber Working Temperature: 100 °C - 121 °C (+/- 1- °C )

• Chamber Working Pressure: 10 - 15 PSI (103 kPA, 1.03 bar, 1 kg/cm2)

NOTE:

TintoRetriever Pressure Cooker is intended to be run with AC110V, 60Hz,1000W.

If there is a need to operate this instrument at AC 220V, Bio SB recommends using a transformer with the following specications.

Output: 110Volts and a minimum of 1000Watts

Figure 2 - Recommended transformer for use in countries with 220V standard electricity.

V5 05/18/17

www.biosb.com | email: info@biosb.com | phone: +1-805-692-2768 4

3. SAFETY REQUIREMENTS:

CAUTION: Read the user manual fully before use and pay particular attention to sections containing this symbol. Please care-

fully read user manual before installation, operation, maintenance and repairing to avoid personal injury and damage to the

Instrument.

3.1 Do not immerse electrical cord, plugs or main cooker body into water or other liquids to avoid electrical shock and/or re hazard.

3.2. Do not touch hot surfaces of the pressure cooker. Use handles only.

3.3. Operate the pressure cooker only with properly closed lid.

3.4. Do not ll working chamber with more than recommended volume of water.

3.5. Never attempt to open the lid while the unit is operating. Wait until the unit is switched o and pressure has been completely

released. If the lid is dicult to rotate, this indicates that the working chamber still has excess pressure.

3.6. Never move the pressure cooker while operating it.

3.7. Exercise care when releasing excess pressure from the cooker; improper technique may result in scalding or injury.

3.8. Unplug from outlet when not in use or when cleaning/servicing.

3.9. Do not use under hanging shelves, cabinets etc or damage may occur.

3.10. Always check the pressure limit valve for possible clogging before each run.

www.biosb.com | email: info@biosb.com | phone: +1-805-692-2768

V5 05/18/17

www.biosb.com | email: info@biosb.com | phone: +1-805-692-2768 5

TintoRetriever Components

Figure 3 - TintoRetriever Parts

Number Component

1Pressure Limit Valve

2 Red Pressure Indicator

3 Push Rod

4 Sealing Ring

5 Working Chamber

6 Condensation Collector

7 Handle

8 Main Body

9 Heating Plate

10 Base

11 Power Cord

12 Lid Handle

13 Lid

14 Sealing Ring Supporting

Cover

15 Rubber Grommet

16 Upper Ring

17 Control Panel

18 Trivet

V5 05/18/17

www.biosb.com | email: info@biosb.com | phone: +1-805-692-2768 6

5. INSTALLATION:

5.1. RemoveTintoRetriever Pressure Cooker from packaging material and inspect for any damage. Please follow important unpacking

instructions provided with the shipment and be sure all parts have been included before discarding any packaging material. If any signs

of mechanical damage to the Digital Pressure Cooker have been observed, do not use it and contact Bio SB (see page 12 for contact

details).

5.2. Thoroughly clean all parts with a towel/rug and place the Digital Pressure Cooker on a clean, at surface.

5.3. Place the condensation collector in the rear of the main cooker body until it clicks into place as shown below:

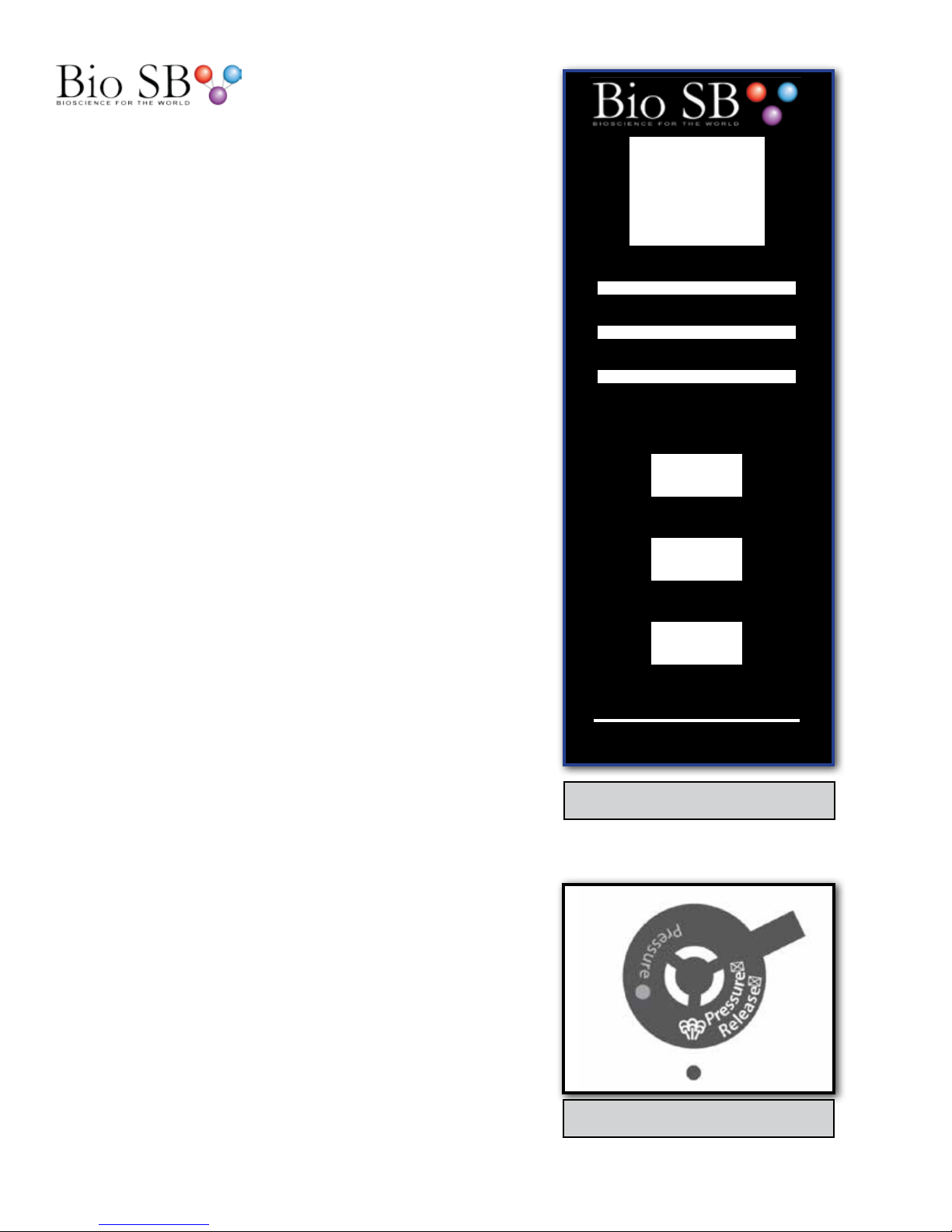

Place the pressure limit valve on the lid as shown below:

NOTE: Even though pressure limit valve will have a loose t, it is safely secured.

Figure 4 - Condensation Collector Placement

Figure 5 - Setting Instrument to Pressure setting

www.biosb.com | email: info@biosb.com | phone: +1-805-692-2768

V5 05/18/17

www.biosb.com | email: info@biosb.com | phone: +1-805-692-2768 7

6. OPERATION PROCEDURES:

6.1. Place clean and dry working chamber and dry the main body. Make sure that no water or any other liquid is present inside the main

body. Any liquid inside the main body may cause a malfunction with permanent damage, as well as cause a SERIOUS HEALTH AND/OR

FIRE HAZARD .

6.2. Position the trivet the inside working chamber (legs down) and pour approximately 500 ml to 1000 ml of water into the working

chamber to barely cover the trivet’s surface.

6.3. Prepare the reagent holder (BSB 7009) with slides in slide rack (BSB 7010) and gently ll the container with working concentration

of HIER solution. We recommend Bio SB ImmunoDNA Retriever with Citrate (BSB0023, BSB0020, BSB0021, BSB0022) or with

ImmunoDNARetriever EDTA (BSB 0033, BSB 0030, BSB 0031, BSB 0032).

6.4. Place the prepared container inside the working chamber on top of the trivet. Make sure that the bottom of the container makes

good contact with water in the working chamber.

6.5. Place and secure the lid onto the cooker’s main body. This is done by putting the lid into place atop the cooking chamber with the

red pressure valve on the left and turning the lid counter clockwise to secure in place.

6.6. Position the pressure limit valve into the“pressure”position (see below gure).

Figure 6 - Pressure cooker in

pressure mode

Figure 7 - Pressure cooker in

pressure release mode

V5 05/18/17

www.biosb.com | email: info@biosb.com | phone: +1-805-692-2768 8

TintoRetriever

Heat Retrieval System

100° C 100-112° C

Low Pressure High Pressure

80-86° C 58-62° C

Time

106°-110° C 114°-121° C

6. OPERATION PROCEDURES (Continued):

6.7. Plug the power cord into an outlet.

6.8. Press the MENU button on the control panel until the desired indicator

light is lit. For recommended settings for proper epitope or nucleic acid

retrieval refer to page 11.

6.9. Press theTIME button until the desired time is lit. Bio SB recommends

a 15 minute time setting for proper epitope or nucleic acid retrieval (see

page 11).

If needed, press the START/CANCEL button twice to reset timer and then

set new desired time.

NOTE: Timer will count time accurately only if used with 60 Hz electrical

supply.

6.10. Press the START/CANCEL button to start the procedure. The red

pressure light will ash. As the pressure and temperature increases, the red

pressure valve on top of the lid will rise and stay in place until the pressure

is eventually released. Conrm that the red pressure valver has risen to

the top a few minutes after starting the unit, typically 5 to 10 minutes fter

cycle start (see note 2).

NOTE 1: If the red pressure valve does not rise to the top it will prevent

sucient pressure build-up within the chamber and could cause

overcooking of the samples.

NOTE 2:The timer will start counting down only after unit reaches the

preset temperature and pressure.

6.11. At the end of the set time, the unit will beep and automatically

switch to the“keep warm”setting until the START/CANCEL button is

pressed again (see 6.8).

NOTE: Do not keep slides under“keep warm”conditions for an extended

amount of time as it will aect performance of your nucleic acid/epitope

retrieval procedure.

6.12. Position the pressure limit valve into the“release”position.

Figure 9 - Valve in“Pressure Release”position

Figure 8 - Front Panel of TintoRetriever

MENU

TIME

START/CANCEL

www.biosb.com | email: info@biosb.com | phone: +1-805-692-2768

V5 05/18/17

www.biosb.com | email: info@biosb.com | phone: +1-805-692-2768 9

CAUTION!: Steam coming out of pressure limit valve can cause a SERIOUS HEALTH HAZARD. Avoid scalding by wearing suitable

protective clothing and exercising extra caution.

6.13. Conrm that the red pressure valve dropped and remove the lid by turning it clockwise. Open and Lift the working chamber.

6.14. Remove the container with the slides from the working chamber. Allow slides to cool for 15-20 minutes. Proceed with slide

treatment as recommended by your protocol.

CAUTION!: Be aware that container and inner parts of cooker will be extremely hot. Avoid SERIOUS HEALTH HAZARD (scalding

or burns) by wearing suitable protective clothing and exercising extra care.

7. CLEANING AND STORAGE

7.1. Unplug from outlet when not in use or when cleaning/servicing.

7.2. Wait until the working chamber, the water inside chamber and the trivet have been cooled to room temperature.

7.3. Remove the working chamber from cooker and remove the trivet from the working chamber.

7.4. Inspect the main body and remove any water/residue from inside or outside with a clean dry paper towel/rug. Do not immerse the

main body in water or pour water onto it.

7.5. Dispose the water from the working chamber and dry the working chamber and trivet with clean paper towel/rug. Never use harsh

chemicals or scouring pads.

7.6. If needed, disconnect the condensation collector, remove any water, and dry it with clean paper towel/rug.

7.7. If needed, dry the lid and the gaskets with a clean towel/rug. Never use harsh chemicals or scouring pads.

7.8. Connect the condensation collector back to the main body, place the working chamber back inside the main body, place the trivet

inside the instrument and place lid on top of the main body. Protect from heat, water, snow, mechanical and electromagnetic shock.

NOTE: Do not lock the lid to allow any residual moisture to escape internal parts of cooker.

V5 05/18/17

www.biosb.com | email: info@biosb.com | phone: +1-805-692-2768 10

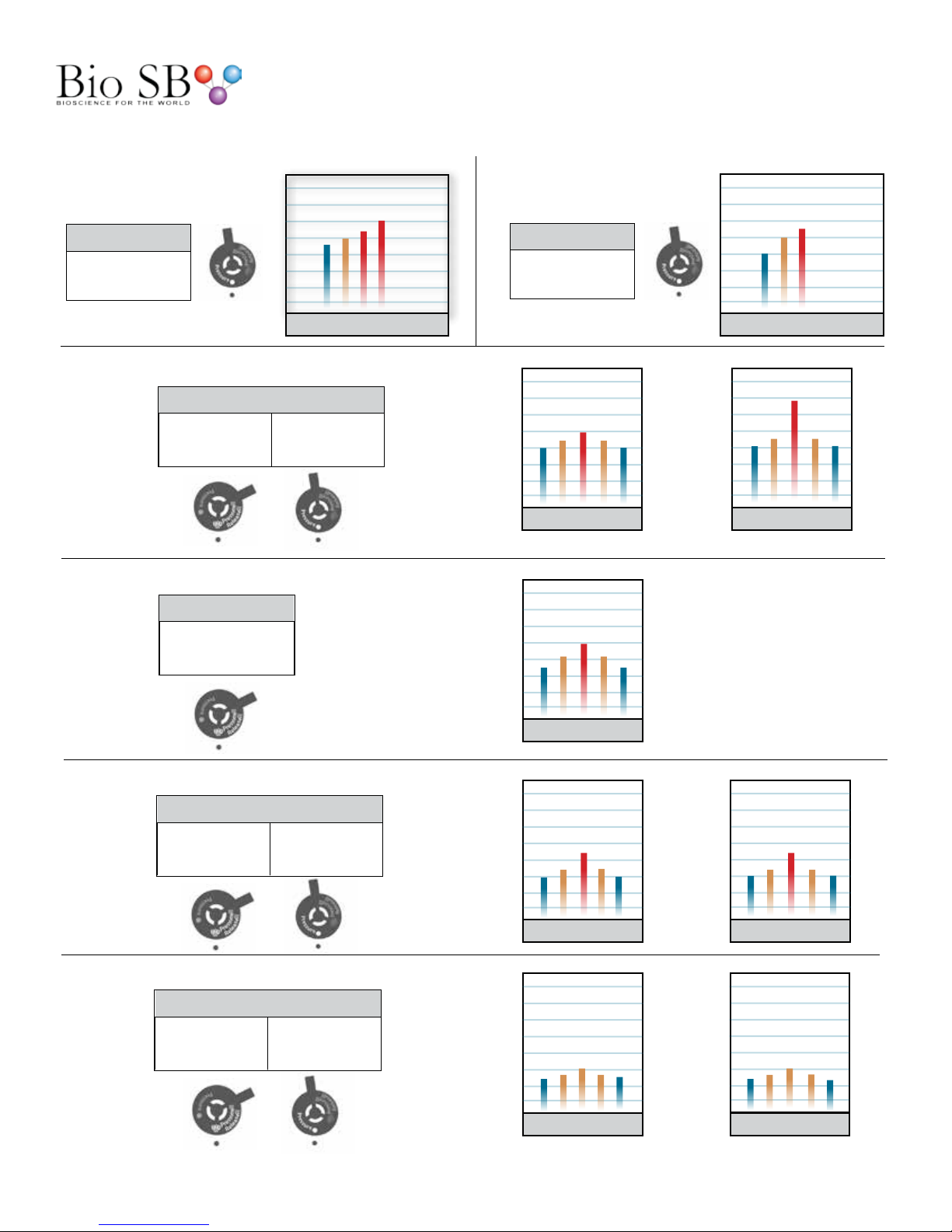

High Pressure

8. TINTORETRIEVER TEMPERATURE SETTINGS

Temperature (°C)

Pressure

114°-121°C

106°C-110°C

114°-121°C

Pressure

100-112°C

Temperature (°C)

Pressure Release Pressure

100°C 106°-112°C

100°C

106-112°C

Pressure

Pressure Release Pressure

100°C

Temperature (°C)

Pressure Release

100°C

100°C

Pressure Release

80-86°C

Temperature (°C)

Pressure Release Pressure

80-86°C 80-86°C

80-86°C 80-86°C

Pressure Release Pressure

Low Pressure

Temperature (°C)

Pressure

106°-110°C

58-62°C

Temperature (°C)

Pressure Release Pressure

58-62°C 58°-62°C

Pressure Release Pressure

58-62°C 58-62°C

www.biosb.com | email: info@biosb.com | phone: +1-805-692-2768

V5 05/18/17

www.biosb.com | email: info@biosb.com | phone: +1-805-692-2768 11

9. TINTORETRIEVER IN THE LABORATORY

TintoRetriever

Heat Retrieval System

100° C 100-112° C

Low Pressure High Pressure

80-86° C 58-62° C

Time

106°-110° C 114°-121° C

TheTintoRetriever is a rapid epitope and nucleic acid retrieval system which can

be used in a variety of applications in the modern pathology lab.

The Bio SBTintoRetriever comes pre-programmed with 6 temperature settings

that can be used for deparanization, epitope retrieval, or nucleic acid retrieval

(ISH).

This section will focus on tips and recommended settings for theTintoRetriever

in a clinical or research setting.

IHC Epitope Retrieval & ISH Nucleic Acid Retrieval

For formalin-xed paran-embedded (FFPE) tissue sections, the High

Pressure setting with a time of 15 minutes is recommended for thorough heat

permeabilization of tissue.We recommend using Bio SB Immuno/DNA Retriever

with Citrate (BSB 0020 - BSB 0023) or Immuno/DNA Retriever with EDTA (BSB

0030 - BSB 0033) for IHC/ISH protocols.

Tissues prone to detachment

Should tissues detach after using the“High Pressure”setting, it is recommended

that tissues are mounted using Bio SB Hydrophilic Plus Slides (BSB 7028).

Hydrophilic Plus Slides prevent tissue detachment while promoting reagent

dispersion.

Tissue Microarrays

Tissue Microarrays (or TMA’s) typically need gentler epitope retrieval methods

than those used with whole tissue sections. At Bio SB, our Normal, Cancer and

Cell Line Microarrays undergo heat-induced epitope or nucleic acid retrieval

using the Low Pressure (106 C-110 C) or High Pressure (114 C-121 C) options.

Additionally, the Bio SB TintoRetriever PT module has gentler epitope retrieval

settings (BSB 7030), and may be ideal for labs that utilizeTMA’s.

TintoDeparanator Citrate and EDTA

TheTintoDeparanator Citrate and TintoDeparanator EDTA (BSB 0175

- BSB 0178) are safe, ecient and economical alternatives to traditional

deparanization.These solvent-free products reduce exposure to toxic solvents

like xylenes, toluene and alcohols when handling FFPE tissues for molecular

pathology. These solutions are recommended to be used at Low Pressure (106

C - 110C) or High Pressure (114 C- 121 C) for 15 min.

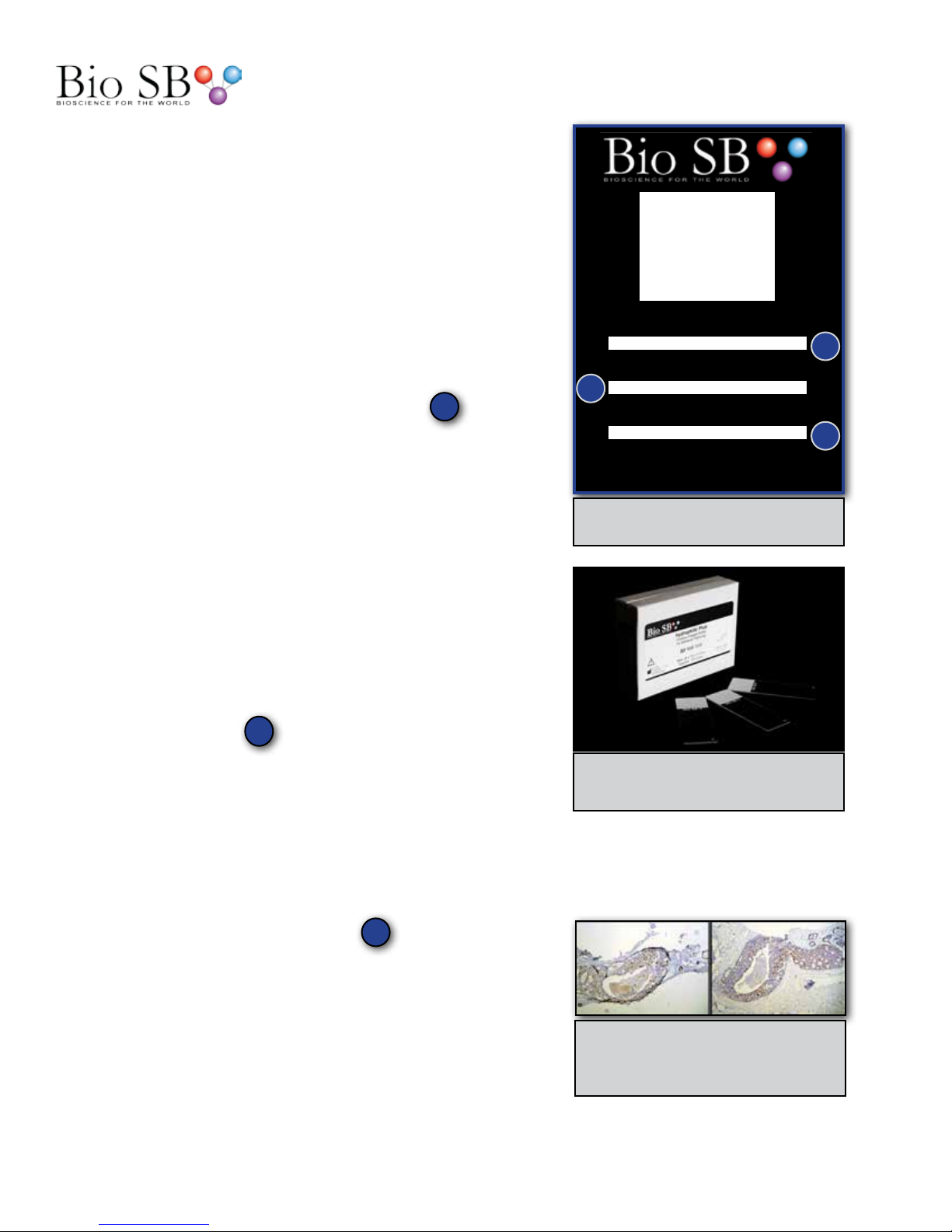

Figure 10 - Pre-programmed temperature

settings

1

1

2

2

3

3

Figure 11 - Hydrophilic Plus Slides

BSB 7028

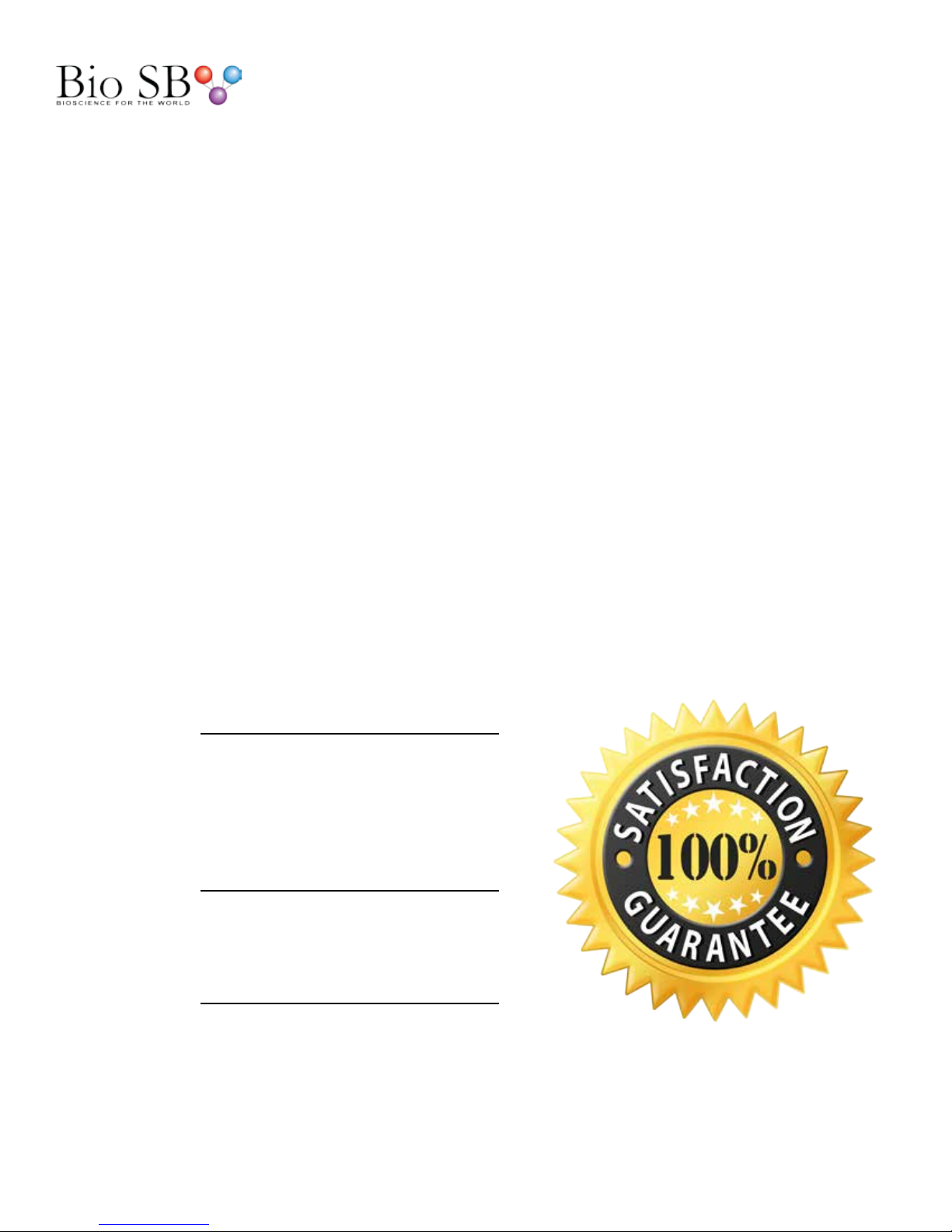

Figure 12 -Tissue Detachment on a

Hydrophobic Slide (Left) vs. Hydrophilic Slide

(Right)

V5 05/18/17

www.biosb.com | email: info@biosb.com | phone: +1-805-692-2768 12

8. TROUBLESHOOTING

Problem Cause Solution

Lid does not lock The ring is not properly installed Reinstall ring

Red pressure valve is seized by push rod Push rod down

Can’t open lid after steam exhaust Red pressure valve is up Press red valve down or wait for

temperature to drop

Steam escapes from the rim of lid No sealing ring was installed Install the sealing ring

Sealing ring worn out/dirty Clean/replace ring

Lid is not locked Rotate and lock lid

Steam escapes from red pressure valve Sealing ring on valve is worn out Replace sealing ring

Dirty red pressure valve Clean valve

Red pressure valve will not rise Pressure limit valve is not placed properly Set the pressure limit valve to“Pressure”

setting

Not enough water in the working chamber Add sucient amount of water to cover

trivet

Steam escaping from rim of lid while

pressure limit valve is in“Pressure”

position

Lid not secured and in lock position Re secure lid and twist until locked

Serious malfunction Unknown Stop operation of unit and call customer

support

To contact Bio SB customer support

Phone: 1-800-561-1145

Email: info@biosb.com

Hours of Operation: 9am - 5pm PST, Monday - Friday

www.biosb.com | email: info@biosb.com | phone: +1-805-692-2768

V5 05/18/17

www.biosb.com | email: info@biosb.com | phone: +1-805-692-2768 13

Guarantee and Warranty

When used in laboratory conditions and according to these working instructions, this product is guaranteed for ONE YEAR from shipping

date against faulty materials or workmanship. For service or technical help, please contact our Technical Support (technical@biosb.com)

or your local distributor.

This product is warranted to the original purchaser only to conform to the quantity and contents stated in this manual and outer labels.

Bio SB Inc.’s obligation and the purchaser’s exclusive remedy under this warranty is limited to replacement, at Bio SB Inc.’s expense, of

any product which shall be defective in manufacture, and which shall be returned to Bio SB Inc., transportation prepaid, or at Bio SB Inc.

option, refund of the purchase price. Claims for merchandise damaged in transit must be submitted to the carrier.

This warranty shall not apply to any products which have been altered outside Bio SB Inc., nor shall it apply to any products which have

been subjected to misuse or mishandling.

ALL OTHER WARRANTIES EXPRESSED, IMPLIED OR STATUTORY ARE HEREBY SPECIFICALLY EXCLUDED, INCLUDING BUT NOT LIMITED TO

WARRANTIES OF MERCHANT ABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Bio SB Inc.’s maximum liability is limited in all events to

the price of the products sold by Bio SB Inc. IN NO EVENT SHALL BIO SB INC. BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES.

Product Name: Bio SB TintoRetriever Pressure Cooker

Product Catalog Number: BSB 7008

Serial No.:

This product is tested and qualied for delivery.

Checked by:

Date:

Other manuals for TintoRetriever

1

Table of contents

Other Bio SB Electric Pressure Cooker manuals

Popular Electric Pressure Cooker manuals by other brands

Elo TouchSystems

Elo TouchSystems Praktika Plus XS instructions

Farberware

Farberware FPC400 use instructions

Westfalia

Westfalia 24 33 78 instruction manual

Drew & Cole

Drew & Cole Clever Chef Pro user manual

PRINCESS HOUSE

PRINCESS HOUSE Heritage Care & use manual

Morphy Richards

Morphy Richards Equip 46640 user manual