Biological Controls MICROCON EXC7 User manual

8/19/2010

MICROCON®

EXC7 and EXC7-UV

User Manual

Read and Save these Instructions

Manufactured by

749 Hope Road, Suite A- Eatontown, NJ 07724 USA

Tel: 800-224-9768, 732-389-8922 Fax: 732-389-8821

www.biologicalcontrols.com

Copyright 2010 Biological Controls 8/19/2010

Copyright 2010 Biological Controls 8/19/2010

SAFETY INSTRUCTIONS

Understand the signal words that are

universally used for overall safety.

•DANGER

•WARNING

•CAUTION

DANGER identifies the most serious

hazards, which will result in severe

personal injury or death.

WARNING signifies hazards, which

could result in personal injury or death.

CAUTION is used to identify unsafe

practices, which would result in minor

personal injury or product and property

damage.

BEFORE

INSTALLATION OR PERFORMING

MAINTENANCE OR SERVICE, TURN

OFF THE MAIN HIGH VOLTAGE

POWER BREAKER TO THE UNIT.

ELECTRICAL SHOCK CAN CAUSE

INJURY OR DEATH. THERE MAY BE

MORE THAN ONE DISCONNECT.

READ INSTRUCTION

MANUAL THOROUGHLY AND

FOLLOW ANY WARNINGS OR

CAUTIONS IN THIS MANUAL AND

ATTACHED TO THE UNIT BEFORE

STARTING INSTALLATION OR

MAINTENANCE ACTIVITIES.

IMPROPER INSTALLATION,

ADJUSTMENT, ALTERATION,

SERVICE, MAINTENANCE, OR USE

CAN CAUSE FIRE, ELECTRICAL

SHOCK, OR OTHER CONDITIONS

THAT MAY CAUSE PERSONAL

INJURY OR PROPERTY DAMAGE.

WEAR SAFETY GLASSES AND WORK

GLOVES AND FOLLOW ALL SAFETY

LOCAL BUILDING AND ELECTRICAL

CODES. CONSULT A QUALIFIED

INSTALLER, SERVICE AGENCY OR

YOUR SUPPLIER FOR INFORMATION

OR ASSISTANCE.

NEVER OPERATE THE

UNIT WITH THE BLOWER EXHAUST

PORT UNCOVERED TO PREVENT

CONTACT WITH THE BLOWER

IMPELLER BLADES. ALWAYS WAIT

UNIT THE BLOWER STOPS SPINNING

BEFORE UNCOVERING THE

IMPELLER.

NEVER EXPOSE EYES

OR SKIN TO ULTRAVIOLET LIGHT

FROM ANY SOURCE. UV LAMPS

MUST BE OFF BEFORE OPENING THE

EXC-UV CHASSIS TO PERFORM

MAINTENANCE OR SERVICE.

PERSONAL INJURY MAY RESULT.

THE UV LAMP

CONTAINS A SMALL QUANTITY OF

MERCURY. IF THE LAMP BREAKS,

CLEAN AND DISPOSE OF WITH CARE.

Copyright 2010 Biological Controls 8/19/2010

Blower Module

Filter

Module Control Panel

Interconnect Cable Assembly

Filter Module

Copyright 2010 Biological Controls 8/19/2010

Table of Contents

Section: Page #

1. INTRODUCTION...........................................................................................................................................................1

2. INSTALLATION MECHANICAL................................................................................................................................2

2.1. System Ducting ................................................................................................................................................................2

2.2. Blower Module-Mechanical............................................................................................................................................2

2.3. Filter Module-Mechanical ..............................................................................................................................................2

2.3.1. Blower Intake collar-plate ..............................................................................................................................................3

2.3.2. Exhaust collar-plate ¼ and ½ HP Blower Modules......................................................................................................3

2.4. Spacing Modules and Components ...............................................................................................................................3

3. INSTALLATION ELECTRICAL..................................................................................................................................3

3.1. Blower Module-Electrical...............................................................................................................................................3

3.1.1. High Voltage Wall Switch (optional) .............................................................................................................................3

3.2. Filter Module-Electrical..................................................................................................................................................3

3.2.1. Blower to Filter Module Interconnect Cable Assembly ...............................................................................................4

3.2.2. Remote Control-Cable (24VDC) ....................................................................................................................................4

3.2.3. 24VDC Remote Controls (optional)...............................................................................................................................4

3.2.4. Switch Plate Control Unit (optional)..............................................................................................................................4

3.2.5. Key-Switch (optional)......................................................................................................................................................5

4. SYSTEM START-UP......................................................................................................................................................5

5. MAINTENANCE INFORMATION..............................................................................................................................6

5.1. Blower Module.................................................................................................................................................................6

5.1.1. Blower Removal...............................................................................................................................................................6

5.2. Filter Module ...................................................................................................................................................................6

5.2.1. Cleaning............................................................................................................................................................................7

5.2.2. Hour Meter ......................................................................................................................................................................7

5.3. Filter Renewal..................................................................................................................................................................7

5.3.1. Pre-Filter..........................................................................................................................................................................7

5.3.2. HEPA Filter .....................................................................................................................................................................7

5.4. UV Lamp Renewal ..........................................................................................................................................................8

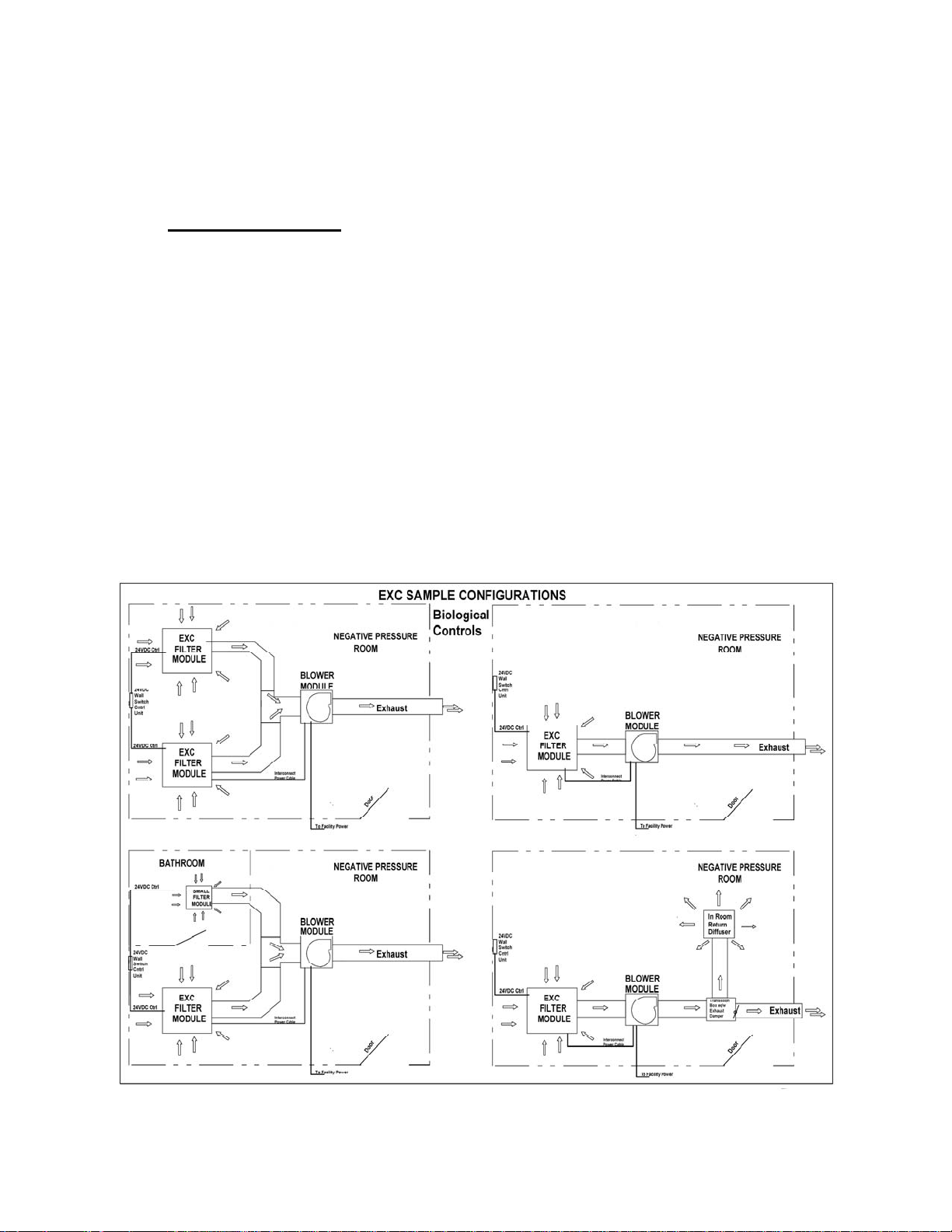

6. System Applications ........................................................................................................................................................9

6.1. Creating A Negative Pressure Room..............................................................................................................................9

6.2. Room Filtration Only....................................................................................................................................................10

7. FACTORY RETURNS (RMA) ....................................................................................................................................10

8. WARRANTY.................................................................................................................................................................10

8.1. Making a Warranty Claim ...........................................................................................................................................10

9. SPECIFICATIONS.......................................................................................................................................................12

9.1. Filter Module .................................................................................................................................................................12

9.2. Blower Modules.............................................................................................................................................................12

10. ASSEMBLY FIGURES & DIMENSIONS..................................................................................................................13

10.1. Filter Module .................................................................................................................................................................13

10.2. Blower Module...............................................................................................................................................................14

11. SCHEMATICS..............................................................................................................................................................15

11.1. Typical System 115V Schematic...................................................................................................................................15

11.2. Typical System 230V Schematic...................................................................................................................................15

11.3. Typical System 1/5 HP 2-Speed Motor Schematic.....................................................................................................16

11.4. Remote Wall Switch Option Schematics......................................................................................................................16

12. EXC7 PARTS LIST.......................................................................................................................................................17

Copyright 2010 Biological Controls 1 8/19/2010

MICROCON®

EXC7 and EXC7-UV

1. INTRODUCTION

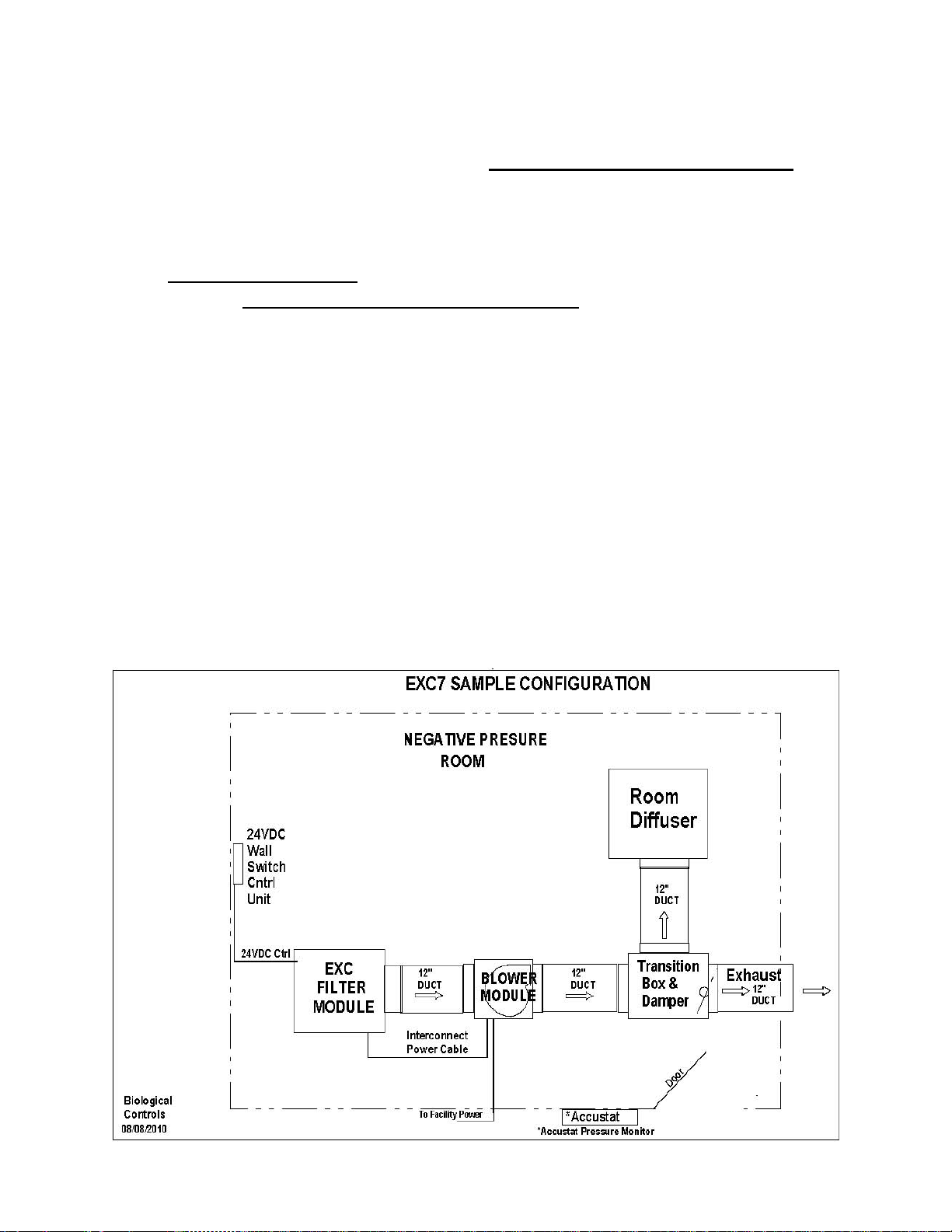

The MICROCON® EXC7 and EXC7-UV are HEPA-Filter based filtration systems that provide

superior room air-purification. The difference between the EXC7 and the EXC7-UV is the addition

of the UVC germicidal light components located in the Filter Module (FM); otherwise, the filter

modules are identical. The Blower Module (BM) portion of the system contains a 1/5hp, ¼ hp

motor, or ½ hp blower motor. All of the configurations are capable of producing either negative or

positive room-pressure environments.

The system is typically equipped with a single Blower Module and one or two Filter Modules. The

components are mounted separately and interconnected with 10” or 12” diameter ducting and with

a provided connectorized Interconnect Cable Assembly.

When a controlled negative room-pressure is required, the system will include a ceiling diffuser

and an exhaust control-duct (transition box with damper). Several low voltage (24V) remote power

control and monitoring options are available.

Copyright 2010 Biological Controls 2 8/19/2010

2. INSTALLATION MECHANICAL

Turn off power at the facility fuse or circuit breaker panel before

proceeding with wiring or installation activities.

The system has more than one electrical-disconnect.

Always Support the Equipment Directly From Building Structure. Obtain an

approved fixture attachment design before proceeding with the installation. The

ceiling support system of the building must be checked to assure that it is

sufficient to carry the weight of the hardware.

2.1. System Ducting

Connect the ducting to the Blower Module, Filter Module(s), room diffusers, and transition boxes

per the system design. Secure the ducting to the inlet and exhaust collars making sure that no air-

leaks exist in the system. Ducts should run in straight lines whenever possible since elbows, bends,

and long runs will decrease the system airflow capacity (cfm).

When maximum CFM is desired, use twelve (12“) ducting wherever possible. Blower and Filter

Modules are typically equipped with 12” duct-collars. The exception is with the smaller 1/5 hp

Blower Module option that use 10” duct-collars. A 10”- 12” adaptor is added to systems that use

the 1/5hp blower module. The same adaptor may be fitted to the Filter Module if it is desired to use

10” ducting between the two components.

Solid-wall ducting is generally preferred over flex-ducting since it provides the lowest air

resistance and best CFM performance. Flex-ducting is used where the speed and ease of installation

is the priority. A combination of duct types and sizes is also an option.

2.2. Blower Module-Mechanical

The Blower Module can be mounted on a platform or suspended. Typically it is mounted above a

suspending ceiling-grid and supported by the four corners of the chassis. The Blower Module is

designed to mount in any position depending upon the height restrictions within the ceiling area.

The unit may be supported using threaded rod, chain or perforated metal straps. All corners and

sides of the larger chassis are equipped with small depression marks in the sheet-metal to mark

standard support locations. Drill out at least four (4) of the chassis depressions to attach the desired

hardware. A set of four (4) eye-bolts eq/w nuts are provided with each Blower Module (1/4 x 20 w/

9/16” ID diameter loop) for a chain support system. The eye-bolts typically extend 15/16 inches off

the mounting surface of the chassis. To prevent air leaks, always calk air-gaps around holes or

mounting hardware attached to the chassis.

The 1/5 hp blower module chassis dimensions are smaller than the ½ and ¼ hp Blower Module

chassis. See the specifications for dimensions. In general, the 1/5 hp system is equipped for 10 inch

ducts and the ¼ and ½ hp systems utilizes 12” ducting. Adaptors may be equipped when required.

2.3. Filter Module-Mechanical

The MICROCON® EXC7 and UV Filter Modules are designed to fit within the standard (nominal

24" x 24") T-bar hardware used to suspend ceiling tiles. Gasket each Filter Module onto the T-'bar

grid surface to provide an air-tight seal between the module and the T-bar channels.

Four (4) small brackets located on the top of the Filter Module chassis must be used to level and support the

weight of the unit using approved cable, wire, or chain hardware.

Copyright 2010 Biological Controls 3 8/19/2010

2.3.1. Blower Intake collar-plate

To avoid freight damage, the duct collar-plate is usually mounted with just four (4) sheet metal

screws with the duct-collar facing into the blower chassis,. The plate must be turned around prior to

installation and reattached using these screws and ten (10) others packaged in a small plastic bag

taped to the Blower Module.

The plate may be attached in one of two (2) positions since the collar is not centered on the blower

chassis. Select the position that best aligns the inlet duct-work with the chassis.

2.3.2. Exhaust collar-plate ¼ and ½ HP Blower Modules

This plate is the same part as the Inlet Collar but has only one correct mounting and is shipped in

the proper position. The collar must align with the blower chassis exhaust port opening.

2.4. Spacing Modules and Components

The distance between a Blower Module and Filter Module cannot exceed nine (9’) feet without a

custom-length Interconnect Cable Assembly. A “slave” Filter Module (a second Filter Module)

requires no Interconnect Cable; therefore, spacing is determined by the duct length restrictions

only.

The distance between the Filter Module intake-grille (door) and any ceiling diffuser should be at

least 6-8 feet to avoid a “short-circuit” of air-circulation. This happens if most of the air-circulation

occurs only between the Filter Module and the ceiling diffuser; as opposed to dispersing the air

more evenly throughout a room.

3. INSTALLATION ELECTRICAL

Turn off power at the facility fuse or circuit breaker panel before proceeding

with wiring or installation activities.

All electrical installation and maintenance must be performed by qualified

individuals and in accordance with the National Electrical Code. ANSI/NFPA

70-1999 and local codes.

3.1. Blower Module-Electrical

The module contains an electrical box to connect to the facility high voltage source (115/230VAC

50/60Hz). The electrical box contains a fuse or breaker to protect the internal wiring. Follow the

appropriate wiring schematic in the appendix depending upon the voltage source available at the

facility power panel. Note that the blower module has been pre-wired for a specific voltage.

Always check the serial number label to confirm the power requirements.

3.1.1. High Voltage Wall Switch (optional)

A high voltage wall switch may be installed to control the input power to the Blower Module.

The switch is provided by the installing electrician.

3.2. Filter Module-Electrical

The Filter Module contains the system power switch, pressure gauge, and optional Hour-Meter. It

also contains some additional components when the remote monitoring and power control options

are provided. Note that the UV lamps for EXCFM-UV units are not installed to protect them

during shipping. The lamps are packaged and taped to the inside of the unit. The lamps should be

installed before adding duct-work to the unit. They can be accessed and installed through the 12”

duct opening in the side of the unit. If not, the bulbs can be accessed by removing the HEPA filter.

Copyright 2010 Biological Controls 4 8/19/2010

Make sure the lamps are clean before installing them into the bi-pin connectors mounted inside the

filter module. The quartz glass may become damaged (etched) when powered with finger grease or

other debris on the lamp surfaces.

3.2.1. Blower to Filter Module Interconnect Cable Assembly

A 10- foot (10’) five (5) conductor wiring-harness is included with each Filter Module. This cable

contains the 120-230VAC circuits necessary to operate the system. It is fitted with insulated

molded-connectors at each end that mate to connectors equipped on the Blower and Filter Module

units. Connect the Filter Module to the Blower Module using the interconnect cable after all

mechanical work is completed.

3.2.2. Remote Control-Cable (24VDC)

When an optional 24VDC remote wall-switch controller is employed an 18-22ga. low voltage cable

is connected between the Filter Module and a wall mounted switch or control unit. Note that the

Filter-Module front panel power-switch will over-ride a remote switch; therefore, the Filter Module

front panel power switch must remain in the "ON" position to activate the remote control function.

The Filter Module power switch will illuminate only when both the Filter Module Power switch

and the remote key-switch are in the "ON" position. Some Filter Modules are equipped with an

internal 24VDC power module. A label near the exit port for the low voltage control cable

indicates the presence of the 24VDC power module.

The internal 24VDC power module is hard-wired to be on 24/7 and there is no

power-off switch. The Blower Module High Voltage must be turned off at the

facility circuit breaker panel or the Interconnect Cable Assembly must be

unplugged from one end to turn off the 24VDC low voltage power.

3.2.3. 24VDC Remote Controls (optional)

Several methods may be used to provide a 24VDC low voltage “on/off” remote-control function

for the system. See the schematic section of this document. Use standard alarm or thermostat-type

wiring to extend the control cable if needed. The control cable is provided on the Filter Module

only when the remote switching option is ordered.

•A standard single-pole light switch (provided by the installing electrician).

•A Key-Switch mounted on a stainless-steel switch-plate (available from Biological

Controls). Part # KSW1 or KSW2 adds a green Power "ON" LED.

•Facility management system capable of providing a “dry-contact” single-pole relay.

•Wall Plate Control Unit (see description below). Part # WPC.

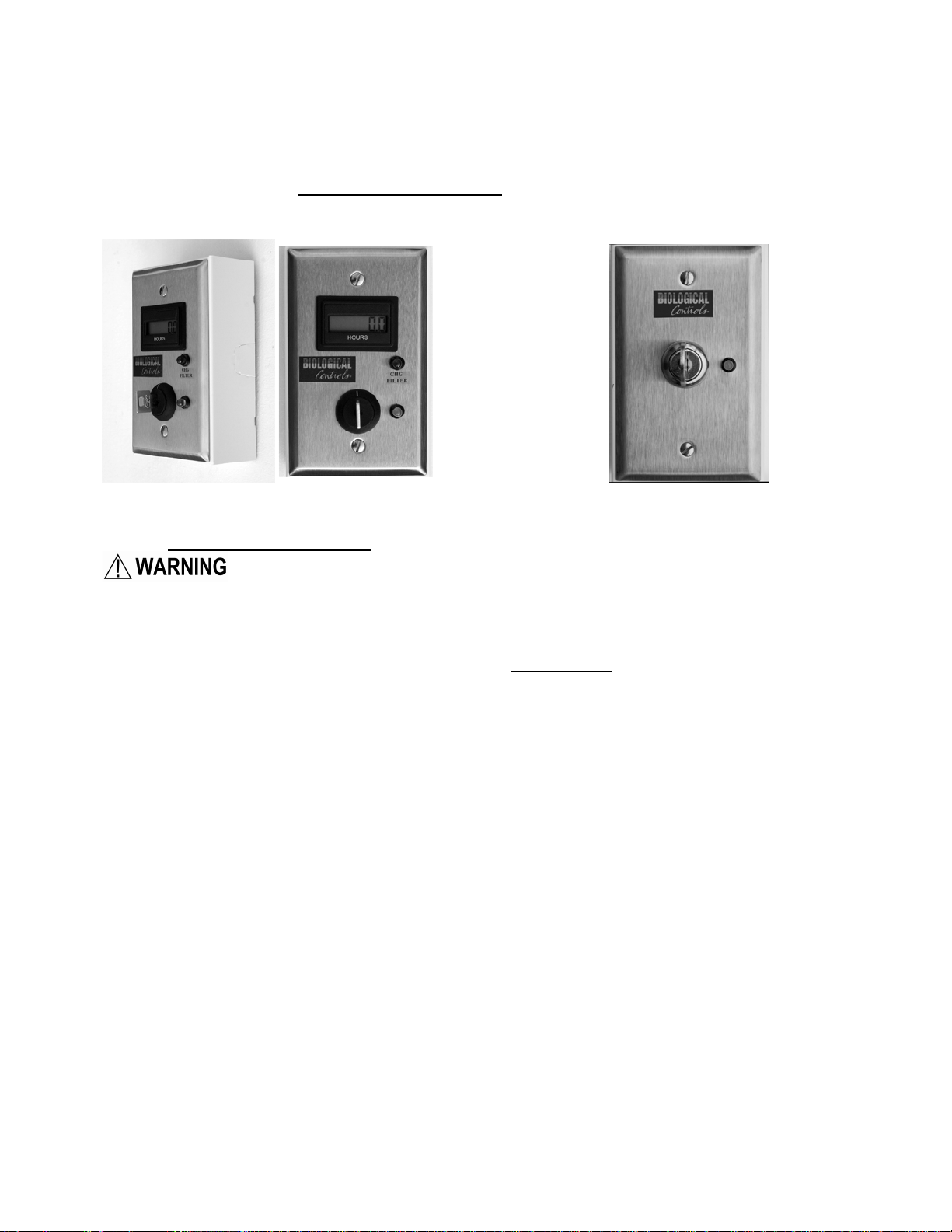

3.2.4. Wall Plate Control Unit (optional)

The Filter-Module is equipped with a 30’foot 3-conductor control cable (4-wire when a pressure

switch option is included). This cable can be lengthened by splicing it to a similar alarm or

thermostat-type (18-22ga.) cable.

A 24VDC universal input power-module is supplied with each Switch Plate Control Unit. The

power-module output can be spliced into the cable at any point in the run. It must be plugged into a

facility AC power source that will not be interrupted during normal activity. Note that the polarity

(+,-) of the power-module 24VDC must be observed as shown in the schematic for proper

operation. The module positive (+) wire is marked with a white-ink dashed line.

Copyright 2010 Biological Controls 5 8/19/2010

Some Filter Modules are equipped with an optional internal 24VDC power module. When

equipped do not use an external unit described above. See the Schematic wiring for each option in

the Appendix.

3.2.5. Key-Switch (optional)

The Key Switch provides only an on/off - key-switch and a LED power indicator.

Switch Plate Controller Key Switch

4. SYSTEM START-UP

After electrical wiring is completed and before applying power to the system, check the

ground (earth) wiring continuity to all of the components per the electrical safety

requirements.

Note: UV units are shipped with the lamps uninstalled and packaged inside the

chassis. The lamps should be installed into their sockets before starting the system

to avoid having to remove the HEPA filter to gain access.

When the system components have been mounted and all of the duct-work and electrical wiring

connections have been completed, the system is ready for operation. Use the on/off switch located

on the Filter Module face-plate or use the optional wall mounted remote switch (note the Filter

Module power-switch must always remain “ON” when used with any remote control switch

option). When powered, the hour-meter will start recording system run-time (the decimal-point

blinks). The mini-helic pressure-gauge will register the filter resistance and the Filter Module

power-switch will illuminate.

Note: When the UV lamps in the EXC7-UV are operating properly a view-port on the faceplate

will glow blue.

For negative-pressure environments (see the System Applications Section), adjust the damper in

the transition-box to achieve the desired room-pressure. (Note: A pressure monitor will be

necessary for this procedure. Wall mount and portable units are available from Biological

Controls.)

Copyright 2010 Biological Controls 8/19/2010

6

5. MAINTENANCE INFORMATION

Remove power from the Blower Module before starting maintenance

routines. Procedures involving electrical wiring should only be performed by

qualified electricians.

5.1. Blower Module

The Blower Module requires no maintenance since it is equipped with permanently lubricated

bearings. The facility power is connected to a circuit-breaker (fuse for 1/5 HP option) mounted in

this module. The breaker/fuse should never open during normal operation. Always consult an

electrician if the breaker/fuse opens since this usually indicates a more serious electrical problem.

5.1.1. Blower Removal

In the unlikely event the blower must be removed from the Blower-Module chassis follow these

steps:

•Remove the intake collar plate from the blower box by removing the screws around the

periphery. Disconnect the internal power cable (three (3) conductors connecting the motor

to the Blower-Module electrical box. This cable will be reused if a new motor is installed.

•Use a ¼” inch hex socket to unfasten the four #6 sheet-metal screws that connect the blower

exhaust-port to the blower chassis.

•Remove the six (6) ¼-20 hex-head bolts holding the blower motor-mounts to the chassis.

The blower along with the motor mounting feet can now be withdrawn from the blower

chassis for repair or replacement.

•Transfer the mounting feet to the new motor using the same hardware. Reinstall in the

reverse order.

5.2. Filter Module

The Filter Module contains the HEPA and Pre-filter media that requires renewal when indicated by

the Air Pressure Gauge or optional Air Switch change-filter LED mounted on the wall mounted

control unit. When the Air Switch option is not provided the Wall Switch Control Plate will not

include the “Chg Fltr” Red LED.

All units are factory tested and meet or exceed both Electrical Hi-Pot and Particle-Count (99.997%

clean exhaust-air @ .3micron particle size) tests per FDA requirements. A ¼ inch diameter probe-

port is accessed by removing a plastic snap-in cover in the center of the rear panel chassis-cover

when field testing is required.

The UV lamps require change-out every 8000 hrs (approximately 1 year) of continued use. Log the

Hour-Meter readings to determine the UV maintenance schedule. The UV view-port mounted on

the control panel will glow blue when the UV bulbs are active.

Copyright 2010 Biological Controls 8/19/2010

7

5.2.1. Cleaning

Wipe the face of the stainless steel Filter Module grille periodically. This is attributable to dust

being attracted by static charge to the grille face before being captured by the pre-filter. A stainless

steel cleaner, mild detergent or alcohol will do the job.

Do not get the filters wet. The filters are not reusable and must be disposed of when loaded.

The UV lamps only require cleaning during the installation process to remove finger oils. Never

attempt to clean the UV lamps when mounted inside the unit. If cleaning is necessary always

remove the lamps from the Filter Module chassis.

5.2.2. Hour Meter

The meter is equipped on the Filter Module and one is also standard on the Switch Plate Control

unit. The meters are activated whenever the blower-fan is operating. The LCD display is always

on to show continuous hours of system run-time. The decimal-point will flash when the system is

running. An internal non-replaceable battery powers the meter for 5-8 years of continuous use. If

the display goes blank when power is turned off it indicates that the meter requires replacement. A

new meter is available from the factory. It is easily replaced by removing the four (4) screws that

secure the control panel, pressing out the old unit and inserting the new one, and finally reinstalling

the panel to the Filter Module chassis. The meter does not have a reset function to prevent

inadvertent resets. Always log the meter readings on the Filter Module label after maintenance

activity.

5.3. Filter Renewal

5.3.1. Pre-Filter

Whenever renewing a pre-filter or when performing any maintenance procedure where

personnel may come into contact with a filter or contaminated surfaces surrounding the

filter-chassis, wear approved face masks, latex gloves, and follow the contamination cleaning

and waste-disposal rules and procedures of the facility.

Filter replacement is necessary when the Minihelic pressure-gauge increases by .1” WC of the

value when the filter was new. This, on average, is every 3-4 months of continuous use.

Open the swing-down stainless steel filter access door by depressing the two ball button-latches.

The door is now free to swing down. Remove the old filter from the door recessed area and replace

it with a new one. Close and secure the door by making sure the two button-latches are engaged.

Log the maintenance activity and hour-meter reading on the door label.

5.3.2. HEPA Filter

Replacement is necessary when the pressure gauge increases by a reading 50-60% greater than

when both filters were new (generally readings above 1.5”WC). The average usage time of the

HEPA is 12-18 months of continuous use.

When handling a new HEPA filter, hold it by its external frame without touching the media.

Temporally place cardboard over the entire room-side face of filter to protect the media

during the procedure. Remove the protective cardboard just before the filter clamps are fully

tightened.

Copyright 2010 Biological Controls 8/19/2010

8

The HEPA filter is replaceable from within the room. Open the swing-down stainless steel door

by depressing the two ball button latches. Once the HEPA filter is exposed, loosen the four (4)

filter clamp-nuts but do not remove them or the clamps from the threaded-rod. Use a 7/16-inch

deep-socket on an extension to loosen the nuts and position them to the end of the threaded-rods

that run through the clamps.

The HEPA filter drops out of Filter Module after twisting the loosened clamps away from the filter

body. Place a plastic bag, large enough to cover the swing down door and the HEPA filter, and

drop the filter into the bag. Seal the bag and dispose of according to facility procedures.

Depending upon the length of time the filter has been in place, it may be necessary to pry it loose

from the framework. Caution must be exercised to prevent damage to the Filter-Module chassis

during the extraction. The HEPA filter is of no value for reuse, so damage to the filter while

handling is inconsequential, although caution should be exhibited to prevent contaminant exposure.

Clean the area where the HEPA gasket makes contact with the Filter Module Chassis surface to

remove debris using alcohol.

Support the new HEPA inside the threaded-rods by twisting the filter clamps to fit around the filter

body. The HEPA gasket should face into the Filter Module. Check the HEPA gasket to make sure it

is compressible and not damaged.

The filter media is very fragile and can be damaged easily. Be careful not to touch or puncture the

HEPA filter face. If the media is ruptured or punctured, it is important to replace or repair it

immediately, by a qualified individual, using approved methods.

Secure the filter in place by tightening the filter clamp nuts. Tighten the nuts until the gasket is

compressed by approximately 50-60%. DO NOT over tighten.

NOTE: HEPA and pre-filters are disposed of after use. They are not washable or cleanable

and cannot be reused. Treat as contaminated.

5.4. UV Lamp Renewal

For EXC7-UV models only

(Replacement Part No. UB-002)

DO NOT EXPOSE EYES OR SKIN TO UVC LIGHT FROM ANY

SOURCE. DO NOT VIEW UV LAMPS WITHOUT USING PROPER EYE AND SKIN

PROTECTION.

Oil and dirt from fingerprints or other sources will permanently etch the

quartz-glass of the lamp and weaken the structure. Always clean lamps outside of the chassis.

Use of incorrect lamps can result in damage to the ballast, LAMP AND

compormise the function of the filtration unit.

A UV lamp contains a small amount of mercury. If the lamp breaks, clean and

dispose of with care according to your facility regulations. Make sure all glass fragments

have been removed from the unit before starting the blowers.

Never attempt to replace lighted UV lamps. When changing UV lamps, use

approved UV eye and skin protection.

UV lamps require renewal every 8000 hours (approx. 1 year) of operation. Check the Hour-Meter

Log to determine a routine maintenance schedule.

Copyright 2010 Biological Controls 8/19/2010

9

To access the UV lamps, open the filter access door and remove the pre-filter and HEPA as

described in the filter renewal process. The lamps are bi-pin type and twist in and out of the

connectors. Replace all lamps at the same time, dispose of properly.

Power the module momentarily to test the lamps. Follow all of the Safety notices above. If all

lamps are working remove power and reinsert the HEPA and pre-filter following the filter renewal

instructions above. Secure the swing down door, log the maintenance activity, and reactivate the

system.

6. System Applications

6.1. Creating A Negative Pressure Room

Negative pressure will be achieved when more air is exhausted from the room than is entering it

(CDC Guidelines state that room exhaust-flow should be either 10% or 50 cfm greater than the

supply to achieve negative pressure). The most recent guidelines call for pressure differential of

negative .010” H2O (W.C.) or minus 2.49 Pascal’s.

The room must be sealed well and leak-free (especially the ceiling) to create a negative

pressure environment. This allows air to only enter the room from the opening under the door,

the corridor or a designated positive pressure area.

When exhausting directly to the outside, it is advisable to place the Blower Module as close to the

exit vent as possible. The longer the total length of the ducts and the more bends and turns in the

ducting, the higher the air flow-resistance and conversely the lower the exhaust air-volume (CFM).

To create negative pressure within a room (the room pressure is less inside the room than in the

surrounding areas) the MICOCON® EXC7 components are placed in any ceiling location that

makes it convenient for attachment to the nearest exhaust duct or outside wall. The length of all

duct-runs should not exceed 12 feet and the total duct-rise should not exceed 10 feet. Since the

exhaust-air has been filtered it is possible to exhaust directly into an air-return area above a sealed

ceiling.

Copyright 2010 Biological Controls 8/19/2010

10

6.2. Room Filtration Only

The system can be used to filter and recirculate air within a room. (The transition-box and exhaust

duct would be removed in the above example and the blower 12”duct is used to connect directly to

the ceiling diffuser.)

In this application, the clean air from the exhaust will be returned to the room through one or more

ceiling diffusers. The best placement for the Filter-Module intake would be above the area

generating the source of contamination. The room diffuser(s) should be placed 6-8 feet away from

the filter-module intake to prevent "short circuiting" the filtered air. This distance will allow

adequate space for the reintroduction of the air back into the room, providing better filtration and

dilution; thereby, increasing the effectiveness of the in-room air changes.

7. FACTORY RETURNS (RMA)

Before shipping any component to the factory, a Return Material Authorization (RMA) Number

must be issued for units under warranty. For units out of warranty, a written purchase order must

be issued to Biological Controls prior to the return. The factory will NOT accept and will refuse

any merchandise returned without proper authorization. The factory is not responsible for any

damage to or loss of merchandise during return shipping. DO NOT RETURN

CONTAMINATED FILTERS TO THE FACTORY.

8. WARRANTY

Limited Warranty:

Biological Controls warrants that the product is free of defects in workmanship and materials

during normal use and service for a period of Twelve (12) months from the date of purchase by the

original end-user.

If at anytime during the warranty period the product is defective or malfunctions, Biological

Controls or its dealer or distributor, from whom the product was purchased, shall at the option of

Biological Controls replace or repair the defective part or component.

This warranty shall not apply if it is shown that the defect or malfunction was caused by damage

due to shipment, improper electrical connections, or improper use or abuse of the product.

The sole responsibility of Biological Controls shall be to repair or replace the product within the

terms stated above. Biological Controls shall not be liable for any loss or damage of any kind,

including any incidental or consequential damages resulting, directly or indirectly, from any breach

of warranty, expressed or implied, or any other failure of this product. (Some areas do not allow the

exclusion or limitation of incidental or consequential damages, so this limitation may not apply to

you.) The warranties set forth are exclusive and Biological Controls expressly disclaims all other

warranties, whether written or oral, implied or statutory, including but not limited to any warranties

of merchantability, workmanship, or fitness for a particular use.

In our continuing effort to produce the highest quality products, we reserve the right to change or

alter product specifications and materials without notice.

This warranty gives you specific legal rights and you may have other rights, which vary, from state

to state or country to country.

8.1. Making a Warranty Claim

To make a warranty claim or if you have questions about the warranty policy, contact the

distributor from whom you purchased the product.

NOTE: Do not return any products or components directly to the factory without a factory issued

“Return Merchandise Authorization (RMA) number” issued by the Biological Controls Customer

Service Department.

Copyright 2010 Biological Controls 8/19/2010

11

Manufacturer: TEL: 800-224-9768

BIOLOGICAL CONTROLS FAX: 732-389-8821

749 Hope Road Suite A WEB SITE: www.biologicalcontrols.com

Eatontown, NJ 07724

Copyright 2010 Biological Controls 8/19/2010

12

9. SPECIFICATIONS

9.1. Filter Module

Feature Description

9.2. Blower Modules

Copyright 2010 Biological Controls 8/19/2010

13

10. ASSEMBLY FIGURES & DIMENSIONS

10.1. Filter Module

Copyright 2010 Biological Controls 8/19/2010

14

10.2. Blower Module

Copyright 2010 Biological Controls 8/19/2010

15

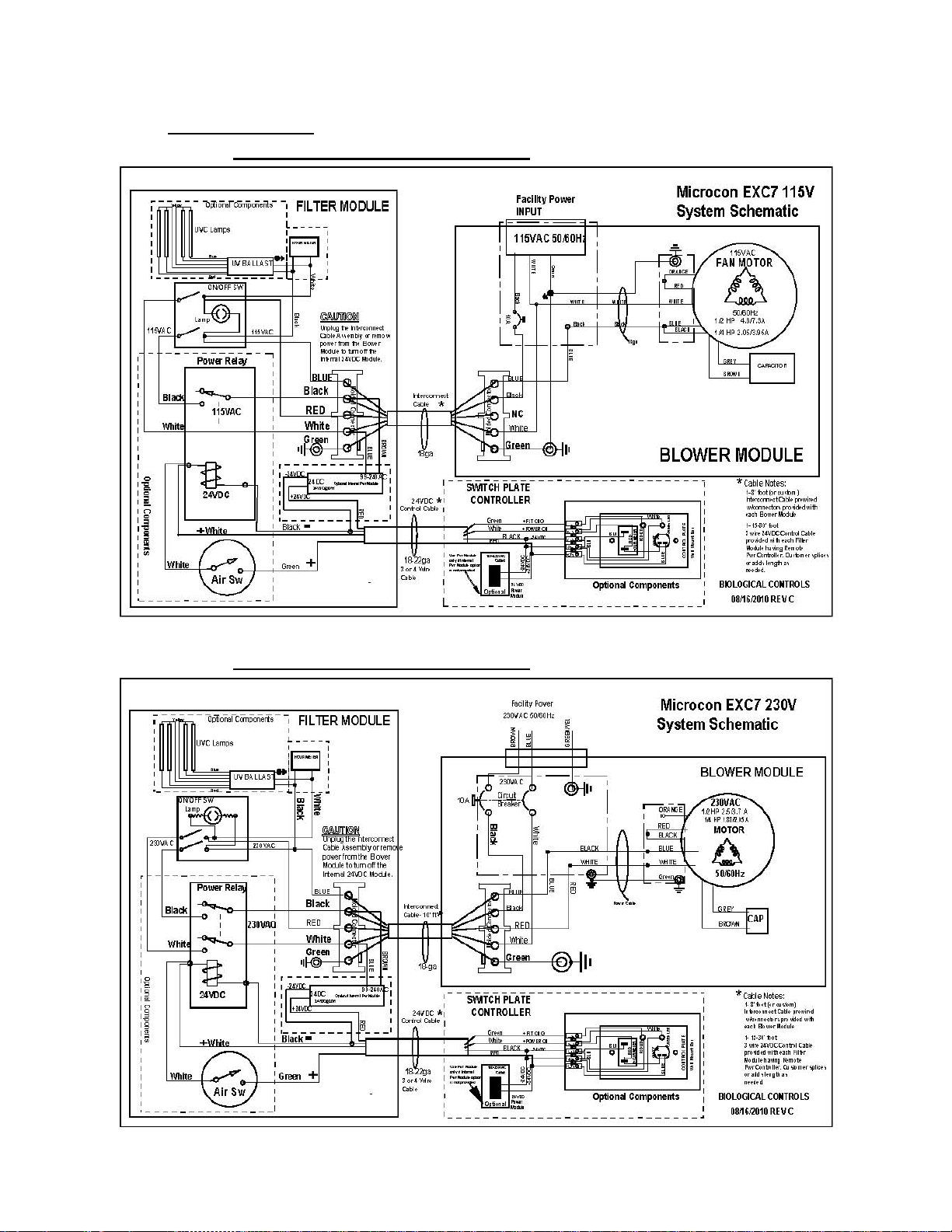

11. SCHEMATICS

11.1. Typical System 115V Schematic

11.2. Typical System 230V Schematic

This manual suits for next models

1

Table of contents