2

INTRODUCTION AND PRECAUTIONS

Intended Use

AAF Flanders AstroHood™Ducted HEPA Terminal Hoods ensure the delivery of cleanroom-quality

air to critical process applications, such as Pharmaceutical Manufacturing, Life Sciences, Biosafety,

Healthcare, and all other applications where clean supply air is a requirement.

User Responsibility

This document contains the information necessary to properly receive, assemble, install, operate,

and maintain the AAF Flanders AstroHood Ducted HEPA Terminal Hood equipment. The purchaser,

installer, and operator of the filter system MUST read and comply with this document in its entirety.

Failure to comply with the requirements of this manual may result in serious injury and void the

product warranty.

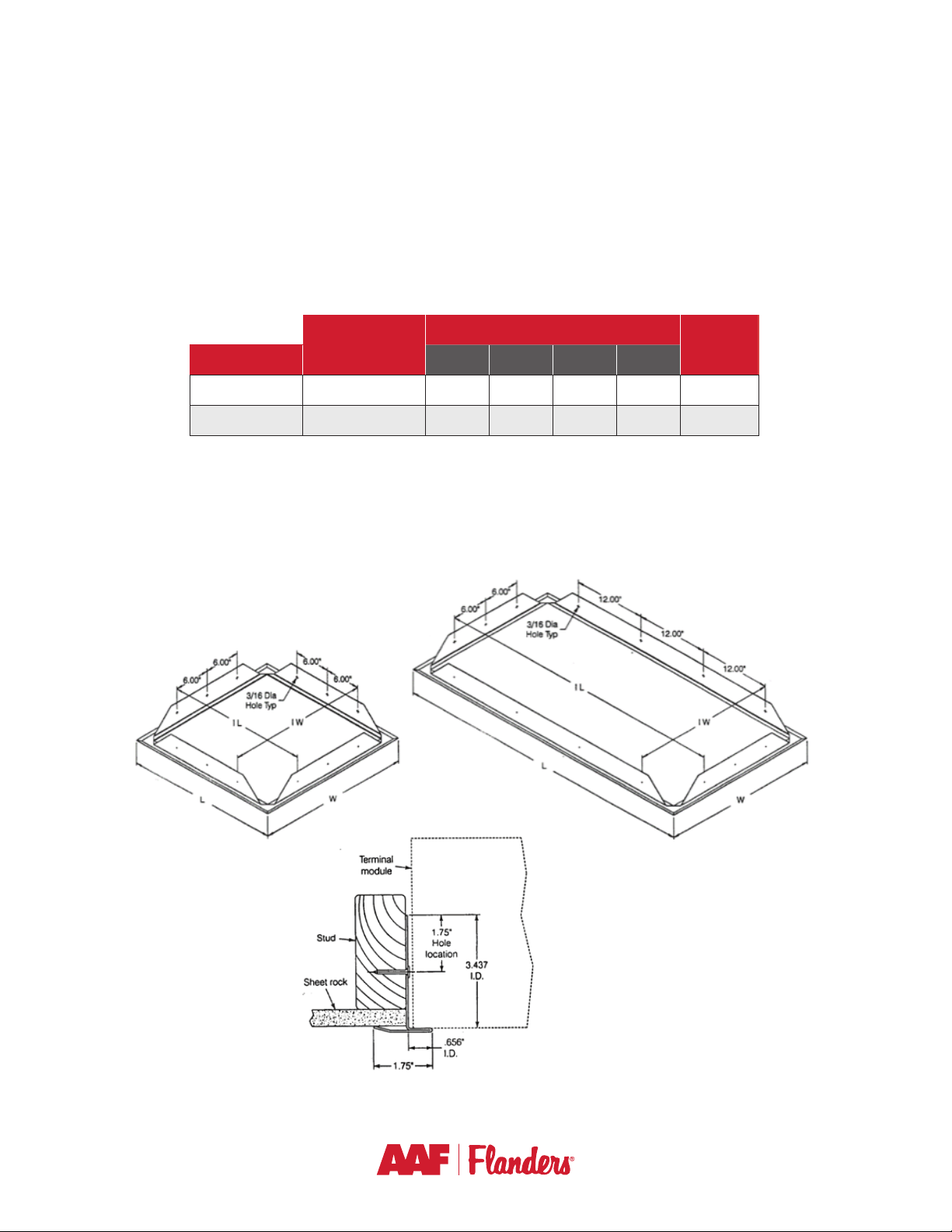

These instructions are specific to the AAF Flanders AstroHood S-l and S-ll units and incorporated

filters. All ancillary tasks including, but not limited to, electrical and mechanical work, equipment

handling, and safety procedures must be performed in accordance with industry-accepted practice

and all relevant local, state, and federal government codes, laws, and policies.

Before proceeding with installation, operation, or maintenance, review this Installation, Operation, and

Maintenance Manual in its entirety and all safety procedures with your company’s safety personnel.

Precautions

• Units must be properly transported and handled, since improper transport and/or handling can

result in damage , blemishes, or other imperfections.

• Deliveries are to be immediately inspected in the presence of the freight carrier to ensure

equipment is delivered in full and free from damage.

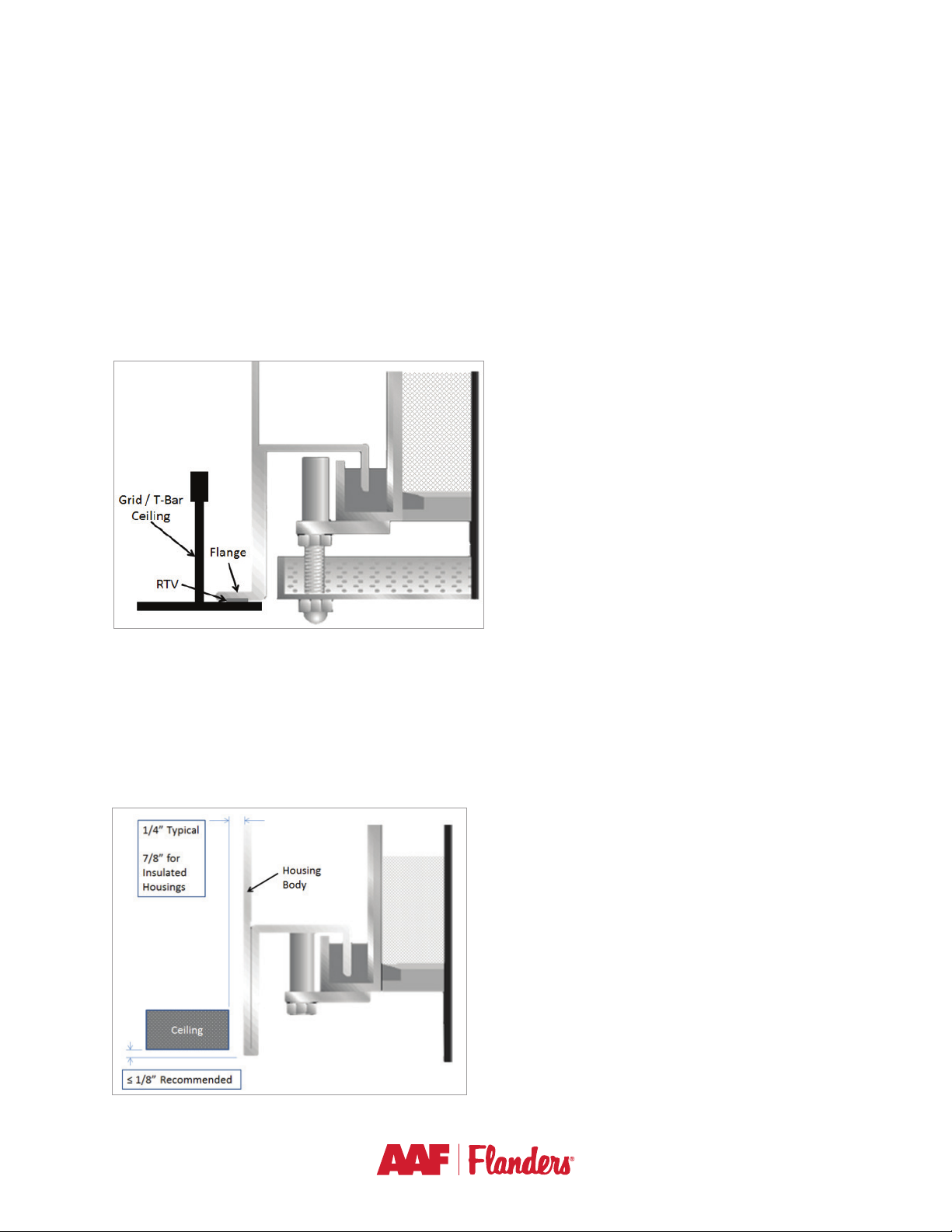

• The installation site must be suitable for unit installation.

• The supporting construction must be level, and the structure must have sufficient load strength to

support all equipment supplied.

• Mounting must be carried out by qualified and trained personnel in accordance with all local, state,

and national codes and regulations.

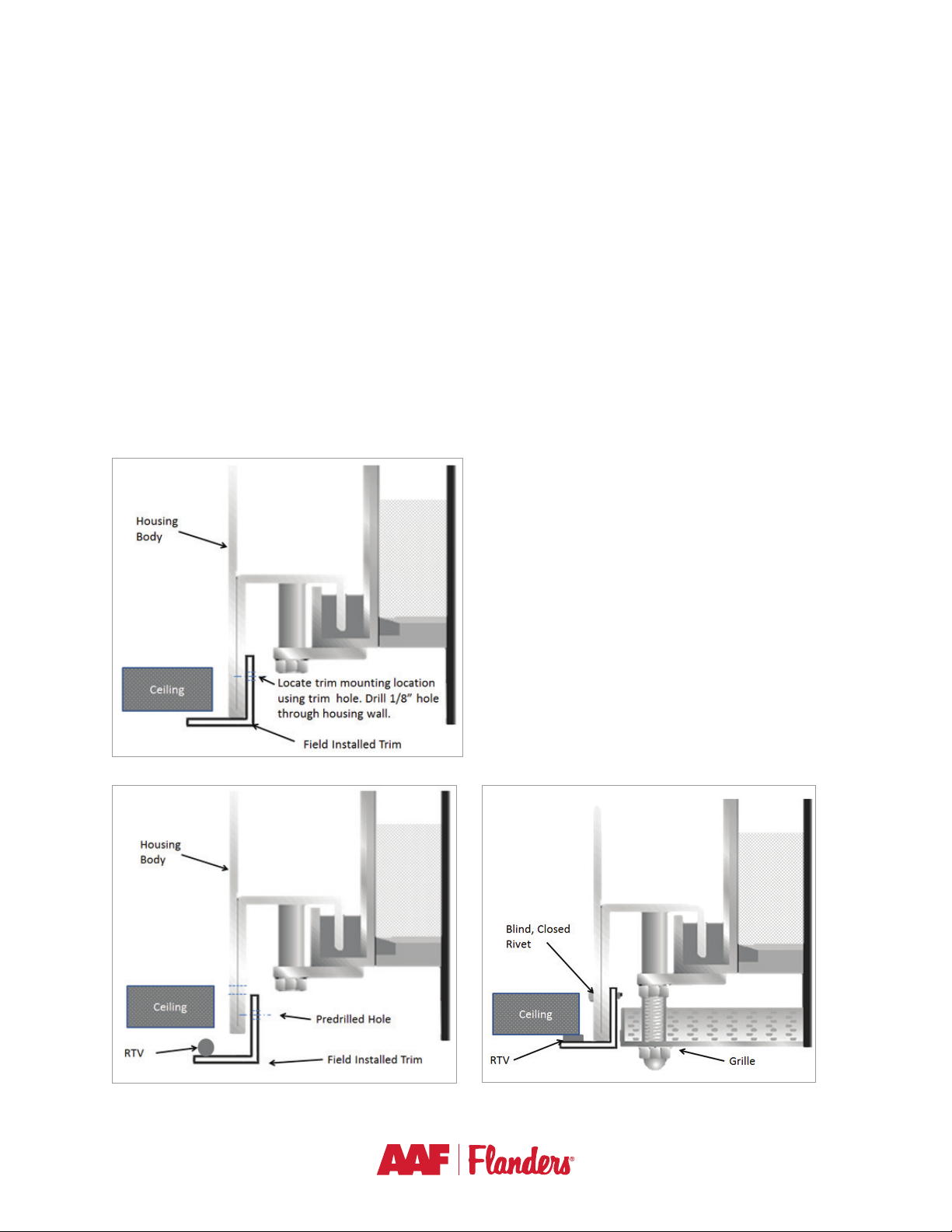

• Drilling through the unit and/or the use of fasteners, such as sheet metal screws, rivets, etc., to

secure the hood, as well as installation of field-installed trim, can compromise the integrity of the

supply hood by creating leak paths through the pressure boundary. Utilize only factory-approved

methods for suspending the hood from structural members located above the ceiling and

attaching field-installed trim.