Biomarine BioPak 240 REVOLUTION User manual

BioPak 240R Benchman Manual

A47D135 Revision J

A47D135, Revision N

B5-06-6000-15-0

ECO 9891, February 2014

BioPak 240R-NIOSH

Closed-Circuit, Self-Contained Breathing Apparatus

Benchman Manual

BioPak 240R Benchman Manual

A47D135 Revision N

Page 2 of 45

CERTIFICATION APPROVALS 4

Respirator NIOSH Approval Label 4

ExtendAir®CO2Scrubber NIOSH Approval Label 5

OrbSorb®CO2Scrubber NIOSH Approval Label 5

RMS MSHA Electrical Approval 6

CAUTIONS AND LIMITATIONS 7

S-SPECIAL OR CRITICAL USER’S INSTRUCTIONS 7

1. TURN AROUND MAINTENANCE PROCEDURE 10

1.1 Maintenance Tag 10

1.2 Disassembly 10

1.3 Cleaning/Disinfection 10

1.4 Coolant Canister 11

1.5 Oxygen Cylinder 11

1.6 Facemask 11

1.7 Assembly 11

1.8 Constant Flow Test 12

1.9 Low Pressure Leak Test 13

1.10 Alarm Test 13

1.11 Upper Housing 14

1.12 Carbon Dioxide Scrubber Pre-Packing Procedure 14

2. LONG TERM MAINTENANCE PROCEDURE 15

2.1 Visual Inspection 15

2.2 Demand Valve Functional Test 15

2.3 Constant Flow Test 15

2.4 Vent Valve Functional Test 15

2.5 Low Pressure Leak Test 15

2.6 High Pressure Leak Test 15

2.7 Emergency Bypass Valve Functional Test 16

2.8 Alarm Test 16

2.9 Maintenance Tag Validation 16

3. GENERAL SERVICE PROCEDURES 17

3.1 Scheduled Component Inspection 17

3.2 System Lubrication 17

3.3 Oxygen Cylinder 17

3.4 Alarm Battery Replacement Procedure 18

3.5 Flow Restrictor Replacement Procedure 18

3.6 Factory Service and Training 19

4. STORAGE GUIDELINES 19

5. PARTS LISTS 20

5.1 Top Assembly 20

5.2 AV3000 Facemask Assembly 22

5.3 AV3500 Facemask Assembly 23

5.4 AV3500 Breathing Hose 24

5.5 AV3000 Breathing Hose 25

5.6 Center Section Lid Assembly 26

5.7 Center Section Assembly 27

5.8 Diaphragm Assembly 29

5.9 Pneumatic Assembly 30

5.10 Manifold Assembly 32

5.11 RMS Alarm Monitor 33

5.12 Oxygen Cylinder Assembly 34

5.13 Lower Housing Assembly 35

5.14 Service Kit Assembly 37

5.15 Coolant Canister Freeze Form 39

5.16 Miscellaneous Supplies 40

5.17 Optional Attachments 41

6. APPARATUS SPECIFICATIONS 42

BioPak 240R Benchman Manual

A47D135 Revision N

Page 3 of 45

7. MAINTENANCE LOG SHEET 43

8. WARRANTY 44

BioPak 240R Benchman Manual

A47D135 Revision N

Page 4 of 45

CERTIFICATION APPROVALS

Respirator NIOSH Approval Label:

BioPak 240R Benchman Manual

A47D135 Revision N

Page 5 of 45

ExtendAir® Carbon Dioxide Chemical Scrubber NIOSH Approval Label:

BIOMARINE INCORPORATED

456 CREAMERY WAY, EXTON, PA 19341-2532 USA

PHONE: (610) 524-8800

CLEAN AIR SCRUBBER

CHEMICAL SCRUBBER CANISTER

TC-13F-541 and TC-13F-684

CAUTIONS AND LIMITATIONS

1. Approved for use only in replacing or refilling chemical scrubber part number C47C010.

2. Not approved for use after indicated expiration date.

3. Do not re-use scrubber materials.

A47C024DLd

REV. D [12/07/2011]

OrbSorb®Carbon Dioxide Chemical Scrubber NIOSH Approval Label:

BIOMARINE INCORPORATED

456 CREAMERY WAY, EXTON, PA 19341-2532 USA

PHONE: (610) 524-8800

CLEAN AIR SCRUBBER

CHEMICAL SCRUBBER CANISTER

TC-13F-541 and TC-13F-684

CAUTIONS AND LIMITATIONS

1. Approved for use only in replacing or refilling chemical scrubber part number D47C055.

2. Not approved for use after indicated expiration date.

3. Do not re-use scrubber materials.

A47C077DLb

REV. B [12/07/2011]

BioPak 240R Benchman Manual

A47D135 Revision N

Page 6 of 45

Remote Monitoring System (RMS) MSHA Electrical Approval:

Eveready, Inc. Energizer #522

or Duracell, Inc. # MN1604

following 9-Volt batteries only:

MSHA approved for use with one of the

to Biomarine BP240R Breathing

The connectors can only be connected

Rayovac Corp. # A1604

Panasonic Industrial Co. # 6AM6

MSHA Approval No: 18-A060028-0

BIOMARINE - NTRON, INC.

Tested for intrinsic safety in methane-air

456 Creamery Way, Exton, PA19341 USA

Permissible Pressure and Temperature

Mine Safety and Health Adminstration

United States Department of Labor

The battery is to be changed in

Apparatus.

Warnings:

fresh air only.

mixtures only.

Monitoring Device

Model: RMS

BioPak 240R Benchman Manual

A47D135 Revision N

Page 7 of 45

CAUTIONS AND LIMITATIONS

J - Failure to properly use and maintain this product could result in injury or death.

M - All approved respirators shall be selected, fitted, and maintained in accordance with NIOSH,

MSHA, OSHA, and other applicable regulations.

N - Never substitute, modify, add, or omit parts. Use only exact replacement parts in the

configuration as specified by Biomarine.

O - Refer to User’s instructions, and/or maintenance manuals for information on use and

maintenance of these respirators.

S - Special or Critical User’s Instructions and/or specific use limitations apply. Refer to User’s

instructions before donning.

S-SPECIAL OR CRITICAL USER’S INSTRUCTIONS

Please Read Carefully and Fully Understand

All users of the Self-Contained Breathing Apparatus (SCBA) must be trained by Biomarine

Qualified Instructors in the donning, operation, inspection and emergency use procedures of

the BioPak 240R.

Biomarine, or a qualified Biomarine representative, must perform all repairs beyond the

scope of this or the BioPak 240R Benchman manual.

Prior to using the BioPak 240R it must be determined that the user is medically fit. The

following lists some, but not all, medical and psychological conditions that could limit or

prevent the use of the BioPak 240R.

Emphysema Chronic Obstructive Pulmonary Disease

Bronchial Asthma X-Ray evidence of Pneumonia

Evidence of reduce pulmonary function Coronary Artery Disease

Severe or progressive hypertension Epilepsy-Grand Mal or Petit Mal

Pernicious Anemia Diabetes-Insidious or Mellitus

Breathing difficulties when wearing a SCBA Abnormal or ruptured ear drum

Claustrophobia or anxiety when wearing a SCBA Pacemaker or other Cardiac Conditions

Compressed Oxygen Hazard: Always handle oxygen cylinders with care to prevent

damage. Do not allow oil, grease or other foreign materials to come in contact with cylinder,

cylinder valve or cylinder pressure regulator to prevent possible ignition. Do not open the

cylinder valve in the presence of open flame, sparks or high radiant heat. Failure to follow

these recommendations could result in personal injury or death.

Oxidizing Agent Hazard: Oxygen will enhance the combustion of other materials so that

materials that normally will not burn in air may burn in oxygen-rich atmospheres; and,

materials that do burn in air will burn more vigorously and at a higher temperature in oxygen-

rich atmospheres. Oxygen will not cause materials to ignite without the presence of an

ignition source.

Work Load Stress Factors: The use of a SCBA will add to the work load and stress of the

user. The user must be capable of determining when excessive ambient temperatures and

high workloads will lead to physical exhaustion and/or collapse.

Low Temperature Operation: The BioPak 240R is suitable for respiratory protection during

entry into and escape from oxygen deficient atmospheres in temperature as low as -5oF

(-20oC) providing: 1) If the BioPak is stored in low temperatures it must be fully dry and

NOT have the carbon dioxide scrubber pre-packed into the breathing chamber; and 2) the

carbon dioxide scrubber is stored at temperatures above 32oF (0oC) and is only installed into

BioPak 240R Benchman Manual

A47D135 Revision N

Page 8 of 45

the BioPak just prior to use. Prior to donning a cold BioPak, verify that the cylinder is securely

connected to the pressure regulator.

The BioPak 240R is approved only with the oxygen cylinder is fully charged with compressed

medical or aviation grade oxygen with moisture content less than 50 mg/m3at 3000 psi (207

bar). Allow the oxygen cylinder to cool after filling to determine the correct pressure. Do not

substitute any other gas type for the specified oxygen. The user bears full

responsibility for the purity of oxygen contained in the BioPak 240R oxygen cylinder.

The use of non-approved gasses can result in injury or death. If the oxygen cylinder is

improperly filled with any gas other than oxygen, the cylinder must be replaced. A

foreign gas may cause cylinder corrosion.

Always check the BioPak 240R oxygen cylinder for a current hydrostatic test date. DOT

requires carbon fiber wrapped, aluminum cylinders be tested by an approved facility on a 5-

year cycle from the date of manufacture. Cylinder inspections by the user as outlined in CGA

6.2 must be done on a regular basis.

Prior to each use of the BioPak 240R, a fully charged oxygen cylinder, a fresh charge of

carbon dioxide absorbent, frozen ice canisters, moisture control sponges and the phase

change module (PCM) must be installed.

After each use of the BioPak 240R, a thorough cleaning and disinfection of the facemask,

breathing hoses and breathing loop must be completed in accordance with procedures

provided in the BioPak 240R Benchman manual.

Use with adequate skin protection when worn in atmospheres that contain gases or vapors

that poison by skin absorption (for example hydrocyanic acid gas).

Do not use an unapproved facemask. Use only the facemasks approved for the BioPak

240R. An unapproved facemask will compromise the protection provided to the user by the

BioPak 240R. A good facemask seal is important to achieving full protection and duration.

Users should conform to MSHA/NIOSH guidelines concerning facial hair and use of the

facemasks. A clean-shaven user will significantly increase the chances of achieving an

adequate face seal.

The on-going effectiveness and reliability of any protective breathing equipment is dependent

upon the user/owner’s standard of care in maintaining the equipment and the user’s expertise

in using the equipment.

Personnel who intend to use protective breathing equipment in a dangerous atmosphere

must have the proper training, temperament and experience to be able to function safely.

The user shall periodically inspect the TRIM display as described in this manual to determine

the status of the respirator oxygen supply.

Intrinsic Safety Consideration for Model/Type RMS permissible Pressure and

temperature Monitoring Device:

Read manual before use.

The connectors of the monitoring device may only be connected to a Biomarine

BioPak 240R Breathing Apparatus oxygen regulator, manifold block and breathing

chamber. The fiber optic cable may only be connected to the BioPak 240R remote

gauge assembly.

Tested for intrinsic safety in methane-air mixtures only.

The battery is to be changed in fresh air only. Do not change battery in hazardous

areas. Approved for use only with the battery types specified in this manual.

BioPak 240R Benchman Manual

A47D135 Revision N

Page 9 of 45

The use of the OrbSorb®carbon dioxide chemical scrubbers must always include the

installation of the moisture pad provided with the scrubber. Failure to install the moisture pad

as described in this manual can lead to scrubber flooding and elevated inhalation

concentrations of carbon dioxide that may lead to injury or death.

Carbon Dioxide Chemical Scrubber: Users ARE NOT permitted to mix versions of the

OrbSorb®within a BioPak. Scrubber canisters installed into the BioPak for use must be of

exactly the same shape and type.

DISCLAIMER

This manual presents the minimum recommended procedures for maintaining the BioPak

240R. End users are free to implement additional procedures and tests above and beyond

the scope of this manual as they see fit or as may be required for specific locations or

applications, provided these procedures meet all criteria presented in the manual.

Failure to follow the minimum procedures presented in this manual may violate

government or agency approvals as well as void the manufacturer’s warranty.

Contact Biomarine with any questions pertaining to customized procedures or questions

concerning the procedures stipulated in this manual.

BioPak 240R Benchman Manual

A47D135 Revision N

Page 10 of 45

1. TURN AROUND

MAINTENANCE PROCEDURE

1.1 Maintenance Tag

Obtain a maintenance tag supplied with

replacement carbon dioxide scrubbers.

The maintenance tag shall be completed as

directed in this procedure and then attached

to the apparatus in a prominent location to

show completion of all maintenance steps.

Record the apparatus identification onto the

tag.

1.2 Disassembly

Immediately after completion of BioPak

use, remove the used CO2 scrubber

canisters, scrubber moisture pad and

disconnect the demand and constant add

lines to the center section to prevent

migration of moisture into the manifold

assembly.

Disassemble the apparatus to prepare for

cleaning and disinfection. Identify any

apparatus damage and repair as needed.

Repairs beyond the scope of the Benchman

should be referred to Biomarine.

1. Remove the upper housing.

2. Remove the coolant lids and coolant ice.

3. Remove the oxygen cylinder, making

sure the seal washer remains in place,

and install the regulator wash cover

supplied with the service kit.

It is acceptable to leave the oxygen

cylinder in place until after washing and

disinfecting has been completed to

prevent ingress of contaminates into the

high pressure plumbing of the BioPak.

4. Remove the facemask from the

breathing hoses.

5. Remove the breathing hoses from the

breathing chamber.

6. Remove the center section lid.

7. Remove and discard the two carbon

dioxide scrubber components and the

scrubber moisture pad.

8. Remove the moisture sponges and the

PCM.

9. Disconnect the electrical line and both

pneumatic connections to the center

section. Use care when handling the

center section. Avoid sharp objects and

rough surfaces that could damage the

rubber diaphragm.

10. Remove the four quarter-turn fasteners

and remove the center section.

1.3 Cleaning/Disinfection

Use only cleaners and disinfectants that are

approved by Biomarine.

The apparatus must be cleaned and

disinfected as soon as possible after each

use. If cleaning is not immediately possible

after use, at a minimum remove and discard

the carbon dioxide scrubber and moisture

pad, remove the moisture control foam pads

and temporarily store the BioPak with the

center section lid open to prevent the growth

of mold or mildew.

DO NOT submerge the electronic monitor

housing.

DO NOT allow any fluids to contact the

input port of the pressure regulator.

1. Clean the upper and lower housings, ice

canisters and coolant lids and all

connected components with a mild soap

and water mixture if necessary.

2. Mix the disinfectant with clean water as

directed on the package.

3. Submerge the facemask, hoses with

facemask connector, center section lid,

center section, PCM and moisture

sponges into the disinfectant solution.

Allow the components to be wetted on

all surfaces for a minimum of 10-

minutes.

BioPak 240R Benchman Manual

A47D135 Revision N

Page 11 of 45

Install a Demand Port Wash Plug,

supplied with the service kit, to the

demand port of the center section to

keep water from migrating into the

demand housing.

Do NOT allow the mask to soak in

cleaning solutions for extended periods.

Extended soaking can cause

delamination of the anti-fog film.

4. Thoroughly rinse all components in

clean water to remove all disinfection

solution. It is extremely important to

fully rinse the facemask of all

cleaning solution.

5. Allow all components to dry either by

air-drying, heated drying or through the

use a dryer system. Heat assisted

drying temperatures shall not exceed

120oF (50oC).

6. Date and initial the maintenance tag

under Washed/Disinfected.

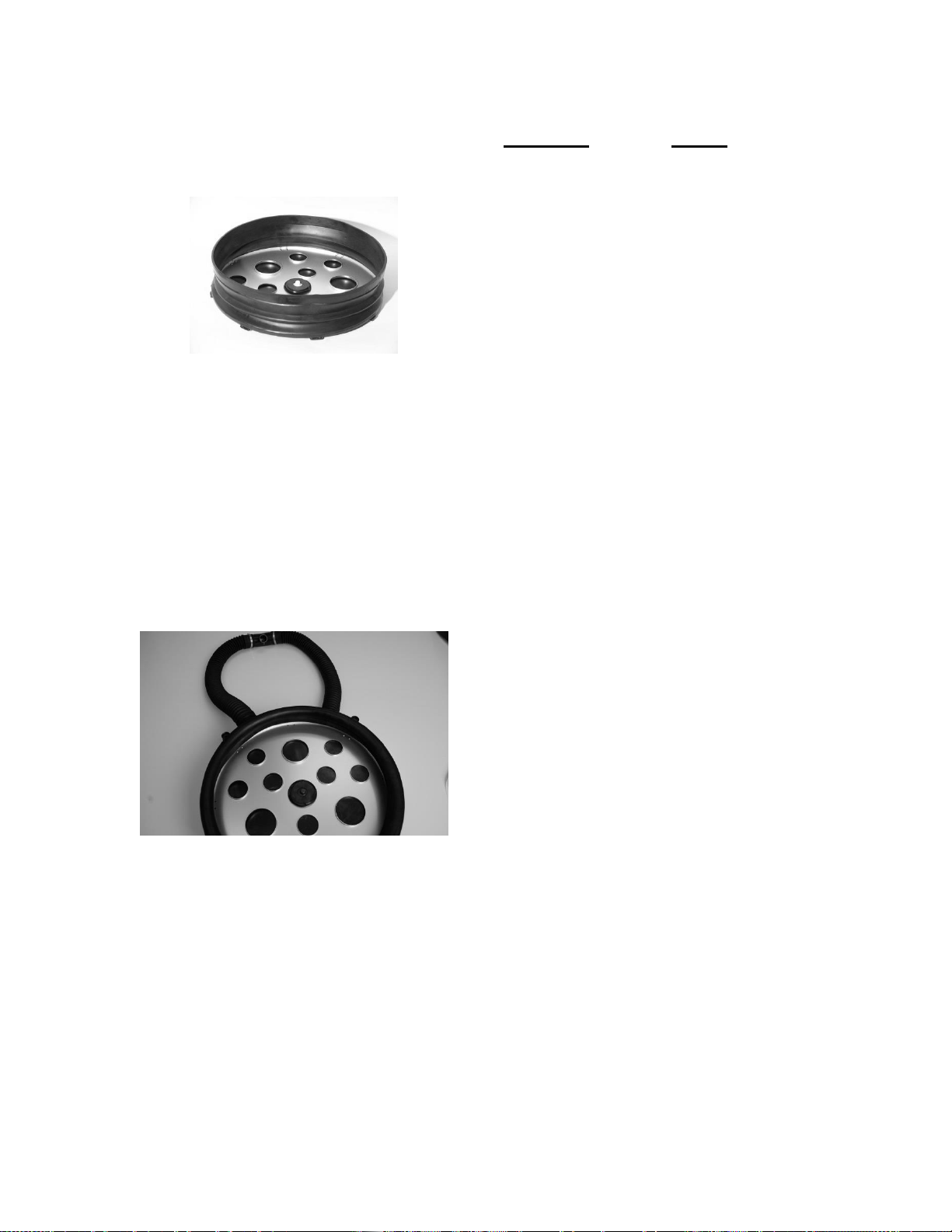

1.4 Coolant Canister

The coolant canisters must be frozen before

use.

1. Place the cleaned and dried canisters

into the freeze form and tighten the nuts

securely.

2. Place the freeze forms onto a level

surface in a freezer for a minimum 8-

hour period at a temperature of 10oF

(-12oC) or less.

3. Date and initial the maintenance tag

under Ice Placed in Freezer.

1.5 Oxygen Cylinder

The oxygen cylinder must be fully charged

to 3000 psi (207 bar) with oxygen before

use.

Oxygen used to supply or charge the

breathing apparatus must be medical or

aviation grade oxygen with moisture content

less than 50 mg/m3at 3000 psi (207 bar).

The composition of suitable oxygen is given

below.

Oxygen: 99.5% minimum mole

Carbon Dioxide: 300 ppm maximum

Carbon Monoxide: 10 ppm maximum

The purity/quality of oxygen used to supply

and charge breathing apparatus should be

tested periodically in accordance with

national regulations.

National regulations must be observed.

Oxygen will enhance the combustion of

other materials. Personnel dealing with

compressed oxygen and compressed

oxygen cylinders must be fully trained in the

use and handling of compressed oxygen.

1. Obtain the proper cylinder fill adapter

needed to connect the oxygen cylinder

to the booster pump.

2. Connect the cylinder to the booster

pump and charge to 3000 psi (207 bar)

pressure with medical or aviation grade

oxygen, according to pump

manufacturer’s instructions.

1.6 Facemask

1. Inspect the components of the facemask

and replace as required.

2. Do not apply anti-fog solutions of any

kind to the lens of the facemask.

3. Date and initial the maintenance tag

under Mask Inspection.

1.7 Assembly

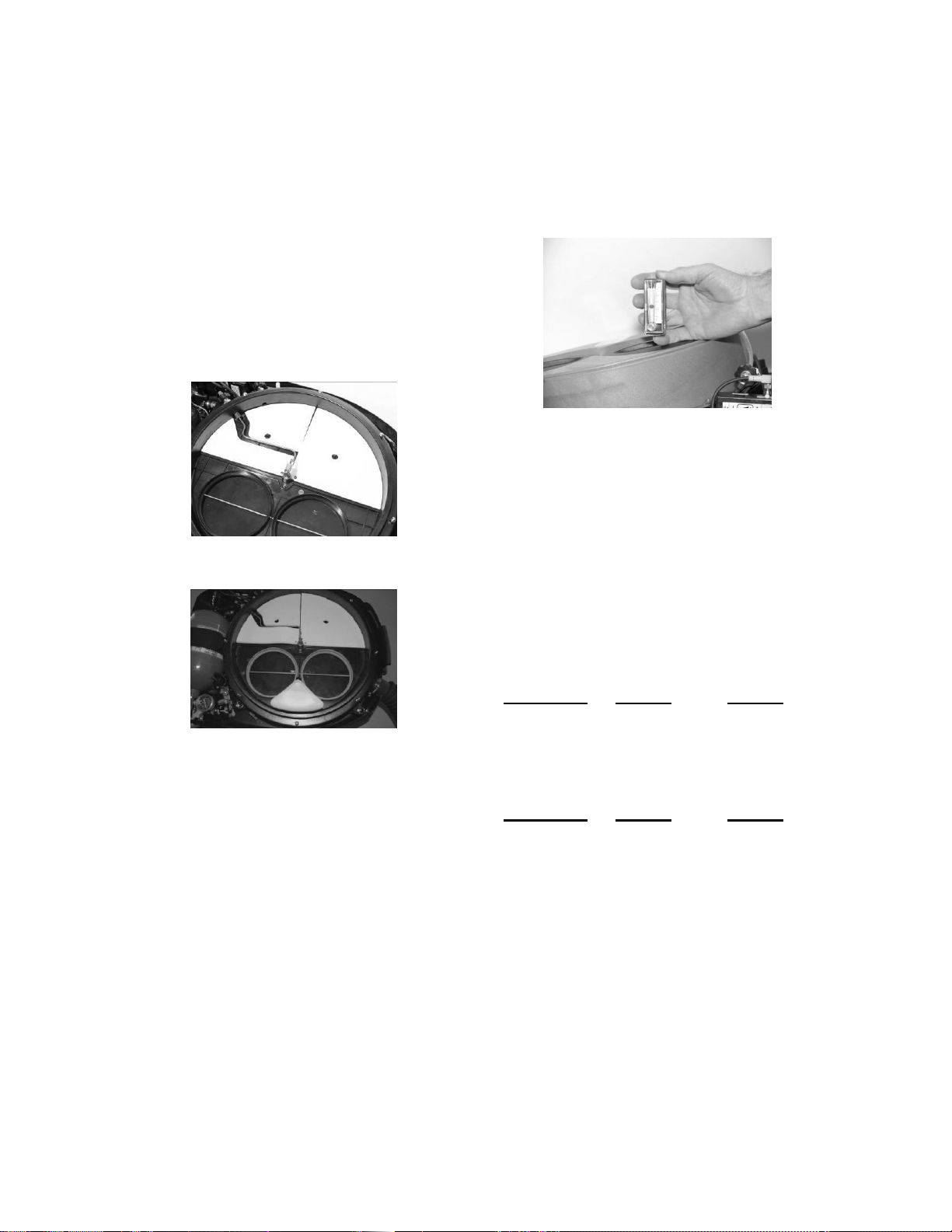

1. Position the BioPak in a level position,

as depicted above, by propping up the

handle end of the lower housing.

BioPak 240R Benchman Manual

A47D135 Revision N

Page 12 of 45

2. Install the center section making sure to

properly seat the three springs onto the

diaphragm.

3. Lock the center section into position

using the four quarter-turn fasteners.

4. Connect the electrical and pneumatic

lines to the center section. Verify the

presence of an o-ring seal on each

pneumatic line connection.

5. Position the fully dry moisture sponges

into the center section. The sponges

must be fully dry to prevent the growth

of mold within the apparatus.

6. Install the PCM into the breathing

chamber.

7. Install the center section lid and latch to

secure. If pre-packing the carbon

dioxide scrubbers complete section 1.12

then return to step 7 of this section.

8. Install the breathing hoses to the

breathing chamber and secure with

clamps making sure mask connector is

sitting flat and the flow direction arrows

of the connector are facing up.

9. Install the storage plug into the

facemask connector.

10. Install the oxygen cylinder and secure

with the hold down strap.

1.8 Constant Flow Test

1. Disconnect the constant add feed line to

the center section (smaller of the two

pneumatic connections) and connect the

test flowmeter from the service kit to the

open end of the feed line.

2. Open the oxygen cylinder valve and

observe flowmeter while holding it in a

vertical and level position. The

flowmeter shall indicate a flow as per

the table below when reading the center

of the flowmeter ball. The table

provides flow readings for elevations of

sea level to 5280 feet (1600 meters) and

above 5280 feet (1600 meters).

If the flow does not meet the requirements of

the table below, the flow restrictor will need

replacement.

Cylinder Flow Flow

Pressure, 0-5280 ft, + 5280 ft,

psi lpm lpm

1500-2000 1.8-2.4 1.9-2.6

2000-3000 1.9-2.5 2.0-2.8

Cylinder Flow Flow

Pressure, 0-1600m, + 1600m,

bar lpm lpm

100-150 1.8-2.4 1.9-2.6

150-207 1.9-2.5 2.0-2.8

3. Enter the measured flow rate, date and

initial the maintenance tag under Flow

Test____ lpm.

4. Close the oxygen cylinder valve, remove

the test flowmeter and reconnect the

constant add feed line to the center

section.

BioPak 240R Benchman Manual

A47D135 Revision N

Page 13 of 45

1.9 Low Pressure Leak Test

1. Remove the storage plug from the

breathing hoses and install the leak test

adapter from the service kit.

2. Attach rubber tubing from the service kit

between the leak test adapter and the

input port of the service kit.

3. Insert two test keys from the service kit

in the keyholes in the back of the lower

housing.

4. Open the oxygen cylinder valve and

depress the bypass valve until the test

kit displays a pressure of 3.0” water

column, then immediately close the

oxygen cylinder valve.

5. Activate the emergency bypass valve to

empty all gas into the breathing

chamber and raise the pressure reading

to between 6 and 8” water column. DO

NOT over pressurize.

6. After the test gauge stabilizes, note the

exact pressure reading of the service kit

and allow the apparatus to sit

undisturbed for 60-seconds. The

apparatus pressure shall not drop more

than 0.2” water column in the 60-second

period.

If the oxygen cylinder is not closed the

pressure reading will continue to rise and

potentially damage the breathing

chamber.

If the apparatus pressure drops more

than 0.2” in the 60-second there is a leak

that must be located and repaired.

7. Open the service kit bleed valve.

8. Remove the leak test adapter to vent

the apparatus.

9. Replace the storage plug.

10. Remove the two test keys from the

rear of the lower housing.

11. Date and initial the maintenance tag

under Low Pressure Leak Test.

1.10 Alarm Test

1. While observing the pressure gauge and

TRIM indicator, open the oxygen

cylinder valve. The cylinder must be

filled with a minimum of 1500 psi (100

bar) pressure for this test.

2. When the oxygen cylinder is opened the

TRIM indicator shall cycle Red, GREEN,

BLUE with the horn sounding. The

TRIM will then flash GREEN and the

horn will be silent.

3. The pressure gauge will reach full

reading in approximately 60-seconds.

4. Close the oxygen cylinder and allow the

BioPak to slowly reduce pressure while

observing the pressure gauge and LED

indications. The LED indication should

turn to a flashing red with a horn

sounding when the pressure gauge

reads between 650-1000 psi (45-69

bar). The LED indication will cease

when the pressure gauge reads less

than 25 psi (1.7 bar).

5. Verify that the oxygen cylinder is fully

charged to 3000 psi (207 bar) and top

off if necessary.

6. Date and initial the maintenance tag

under O2 Cylinder Replaced/Filled.

BioPak 240R Benchman Manual

A47D135 Revision N

Page 14 of 45

1.11 Upper Housing

1. Replace the upper housing onto the

apparatus.

2. If the carbon dioxide scrubbers have not

been installed into the apparatus then

leave the maintenance tag CO2

Cartridges Replaced field blank.

See section 1.12 concerning procedures

for pre-packing the carbon dioxide

scrubber into the apparatus during turn

around maintenance.

3. Tie the completed maintenance tag to

the BioPak in a conspicuous and

consistent location.

1.12 Carbon Dioxide Scrubber Pre-

Packing Procedure

Pre-packing the BioPak 240R with the

carbon dioxide scrubbers is only

permitted when utilizing OrbSorb®

carbon dioxide scrubber.

The OrbSorb®carbon dioxide scrubbers can

be pre-packed into the apparatus during turn

around maintenance if so desired.

Pre-packed carbon dioxide scrubbers

may only be stored in the apparatus for a

maximum period of 1-year.

Moisture sponges must be installed dry

when pre-packing the BioPak.

DO NOT pre-pack any BioPak that will be

stored at temperatures at or below

freezing (32oF/0oC).

Apparatus that are pre-packed with the

carbon dioxide scrubber shall be stored

within the specified storage temperature

and humidity levels and must be sealed

air-tight in the apparatus.

1. Inspect the expiration date of the carbon

dioxide scrubber to ensure that it is not

expired. Record the carbon dioxide

scrubber serial number and expiration

date onto the maintenance tag or affix

the scrubber label to the back of the tag.

2. Verify that each carbon dioxide scrubber

canister has an o-ring installed.

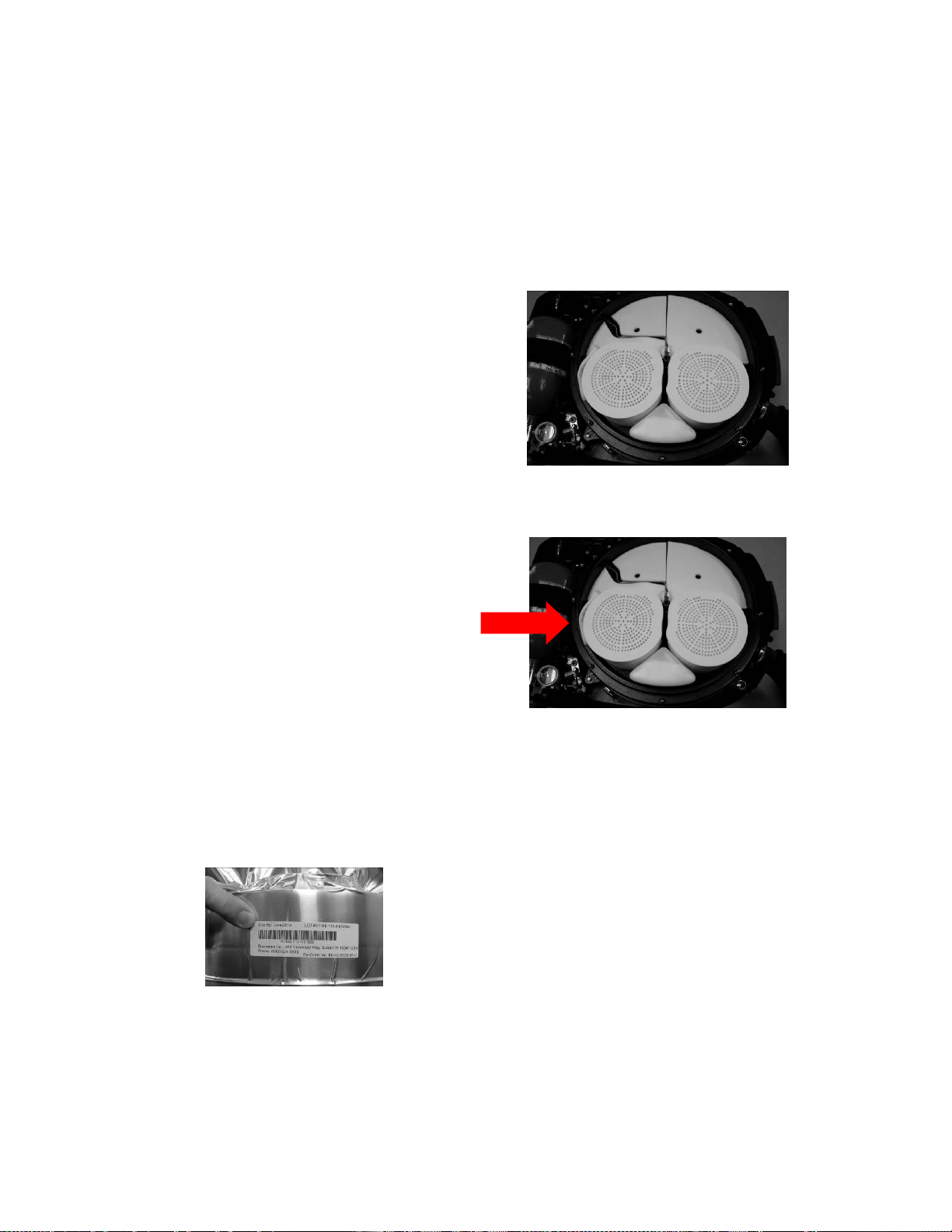

3. Install two carbon dioxide scrubber

canisters into the breathing chamber

making sure that they are proper aligned

and fully seated into position. Proper

alignment of the scrubbers will have the

canister arrows directed at the center

point of the center section.

4. Install the moisture pad supplied with

the canister into the center section as

depicted below.

WARNING: Failure to install the moisture

pad will result in scrubber flooding and

caused elevated carbon dioxide levels in

the inhalation gas that could lead to

injury or death.

WARNING: Users ARE NOT permitted to

mix versions of the OrbSorb®within a

BioPak. Scrubber canisters installed into

the BioPak for use must be of exactly the

same shape and type.

5. Install and secure the breathing

chamber lid.

BioPak 240R Benchman Manual

A47D135 Revision N

Page 15 of 45

6. Date and initial the maintenance tag

under CO2 Cartridges Replaced.

Record the expiration date of the

scrubber onto the maintenance tag.

The expiration date of pre-packed carbon

dioxide scrubbers will be the shorter time

period between the following two factors:

1-year from date of scrubber installation

into BioPak, or,

“Use By” date provided on packaging of

carbon dioxide scrubber.

2 Long Term Maintenance

Procedure

In addition to normal turn around

maintenance, the apparatus shall be visually

inspected and pressure tested on a monthly

basis, if the apparatus is being used at least

once per month; or, quarterly, if the

apparatus is used less than once per month

or is in long term storage.

BioPaks that have been placed in long term

storage should have the Long Term

Maintenance Procedure conducted every 6-

months.

A Maintenance Log Sheet is provided in this

manual to assist in tracking long-term

maintenance procedures.

2.1 Visual Inspection

Remove the upper housing and visually

inspect the apparatus for signs of wear,

abuse, loose connections or other damage.

Repair as necessary.

Verify that the apparatus is properly sealed

against the ambient environment by the

presence of the storage plug.

2.2 Demand Valve Functional Test

1. Vent the BioPak of all internal pressure.

2. Open the oxygen cylinder and listen for

the sound of gas escaping into the

breathing chamber. The sound will last

approximately 1-3 seconds. This

signals that the demand has properly

opened.

3. After 1-3 seconds the sound of gas

escaping into the breathing chamber

must cease. This signals that the

demand valve has properly closed.

2.3 Constant Flow Test

1. Perform the test as described in Section

1.8.

2.4 Vent Valve Functional Test

1. Replace the seal plug from the

facepiece adapter with the leak test

adapter from the test kit and connect the

barb of the adapter to the barb of the

service kit using rubbing tubing.

2. Fill the apparatus by depressing the

emergency bypass valve in several

short burst. Observe the pressure

reading on the service kit. The

apparatus pressure should remain at or

below 2” water column pressure after

releasing the emergency bypass valve.

2.5 Low Pressure Leak Test

1. Perform the test as described in Section

1.9.

2.6 High Pressure Leak Test

1. Place the apparatus on a flat surface.

Ensure that the test keys of the Low

Pressure Leak Test have been

removed. The oxygen cylinder must

be fully charged to above 1500 psi

(103 bar).

2. Open the oxygen cylinder valve and wait

until the apparatus pressure gauge has

reached its final reading.

3. Inspect each plumbing connection with

oxygen safe leak detection fluid by

wetting each joint, waiting 60-seconds,

then inspecting each joint for the sign of

bubble formation. The presence of

bubbles will indicate a leak.

4. Repair any leaking joint or replace the

leaking components. Repairs must be

performed with the BioPak fully

vented of all internal pressure.

BioPak 240R Benchman Manual

A47D135 Revision N

Page 16 of 45

5. Close the oxygen cylinder valve and

depress the emergency vent valve to

depressurize the apparatus.

2.7 Emergency Bypass Valve

Functional Test

1. Open the oxygen cylinder and depress

the emergency bypass valve for 1-2

seconds. The sound of gas escaping

into the breathing shall be heard

whenever the valve is depressed and

shall cease whenever the valve is

released.

2. Close the oxygen cylinder.

2.8 Alarm Test

1. Perform the test as described in Section

1.10.

2.9 Maintenance Tag Validation

1. Inspect the maintenance tag that should

be attached to the apparatus in a

conspicuous and consistent location.

Verify that all portions of the tag are

properly completed.

2. Verify that the apparatus oxygen

cylinder is fully charged to 3000 psi (207

bar) and top off if necessary.

3. Replace the upper housing.

BioPak 240R Benchman Manual

A47D135 Revision N

Page 17 of 45

3. General Service Procedures

3.1 Scheduled Component Inspection

Breathing Diaphragm:

Annually, remove the center section and

disconnect the diaphragm from the center

section by loosening the clamp. Inspect the

diaphragm for signs of wear, cracking or rot.

Disassemble the vent valve, clean and

inspect all components and lubricate as

needed. Reference the parts list for proper

diaphragm alignment.

Diaphragm Alignment: Proper diaphragm

alignment is depicted below. Note the

positioning of the three large holes in the

diaphragm plate in relation to the breathing

chamber mounting feet and the breathing

hoses. Reference diagram in Section 5.8.

Facemask: Inspect all rubber components

for signs of wear, tears, rips, cracking or rot.

Breathing Hoses: Inspect for signs of

wear, tears, rips, cracking or rot.

O-ring Seals: If the apparatus has passed

the high and low pressure leak tests the o-

ring integrity is acceptable. It is

recommended to perform full system

lubrication on an annual basis. Otherwise

inspect o-rings at intervals of:

O-Ring Uses or

Description Age

Center Section 25 uses

annually

Vent Valve 50 uses

annually

Other annually

3.2 System Lubrication

Leaks discovered during high and low

pressure testing are often caused by

damaged or improperly lubricated o-rings.

Replace faulty o-rings and follow the guides

below for o-ring handling and lubrication.

Never pry o-rings from glands with a

screwdriver. Remove o-rings by

hand or using the pick tool provided

in the service kit.

Unless otherwise directed, do not

lubricate o-rings while they are still

seated within their gland.

Do not use heavy coats of

lubrication. Proper o-ring lubrication

will result in a shiny surface without

lumps.

Do not stretch or deform o-rings

during handling.

Visually inspect under bright lighting

and inspect by feel, o-rings for signs

of damage such as nicks, cuts, tears

or abrasion.

Christo-Lube™ and Dow 111™ are

the only lubricants approved for use

in the apparatus.

NEVER lubricate the sealing washer

that sits between the oxygen

cylinder and the pressure regulator.

3.3 Oxygen Cylinder

The cylinder should be inspected regularly

for signs of damage to the outer wrapping.

Cylinders that are cracked, flaking or show

exposed fibres should be immediately

retired from service.

Cylinders will require periodic hydro-static

testing per national requirements. Typical

intervals are every 5-years from the date of

BioPak 240R Benchman Manual

A47D135 Revision N

Page 18 of 45

manufacture. Cylinder testing should be

conducted by an authorized testing facility.

Cylinders that have been hydro-static tested

shall be cleaned for high-pressure oxygen

service as per national standards.

Cylinders are to be retired from service 15-

years after the date of manufacture.

3.4. Alarm Battery Replacement

Procedure

The alarm system battery shall be replaced

after 200-hours of use, after 6-months or

after the alarm system low battery alarm

(RED, GREEN, BLUE flashes with

corresponding horn sounding), whichever

occurs first.

1. Remove the upper cover.

2. Disconnect the electrical line to the

center section.

3. Use two 7/16” wrenches from the

service kit to remove the light guide from

the alarm monitor housing. DO NOT

allow the fitting anchored to the alarm

housing to rotate.

4. Remove the alarm housing from the

apparatus. Inspect the housing for

cracks or damage. Dust-tight and

water-tight integrity are required for use

in potentially explosive atmospheres.

The alarm module will require

replacement if any damage to the

housing is discovered.

5. Remove the battery cover. Inspect the

cover and gasket for cracks or damage.

The battery cover door will need to

be replaced if any damage is found.

6. Remove the battery from the alarm

housing and replace with a fresh

battery. Inspect the interior of the

battery compartment for the presence of

corrosion, liquid or dust. Clean if

necessary or replace the alarm module.

Use only battery types as specified for

replacement.

7. Replace the battery cover making sure

that the gasket is properly positioned

and that the gasket is not damaged in

any way. The battery door will only fit in

one orientation on the module.

8. Install the alarm housing into the

apparatus.

9. Use two 7/16” wrenches from the

service kit to install the light guide from

the alarm monitor housing. DO NOT

allow the fitting anchored to the alarm

housing to rotate. The light guide shall

be positioned so that it is directed

straight down towards the lower

housing.

10. Connect the electrical line from the

center section to the alarm housing.

11. Conduct the Alarm Test as described in

section 3.10.

12. Install the upper housing.

3.5 Flow Restrictor Replacement

Procedure

1. Remove the upper housing and vent the

BioPak of all internal pressure.

2. Use the ¼” hex driver from the service

kit to the remove the flow restrictor. Be

sure to remove and discard the

existing head gasket of the existing

flow restrictor.

3. Use the ¼” hex driver from the service

kit to the install a replacement flow

restrictor.

Use caution when installing the flow

restrictor to insure that o-ring does not

roll out of its gland.

4. Perform the high-pressure leak test as

directed in long term maintenance.

5. Perform the constant add test as

directed in turn around maintenance.

6. Replace the upper housing.

BioPak 240R Benchman Manual

A47D135 Revision N

Page 19 of 45

3.6 Factory Service and Training

Factory service and personnel User and/or

Benchman Training can be provided by

contacting the location listed below or by

contacting your local Biomarine Dealer or

Distributor.

The BioPak 240R-NIOSH User and

Benchman manuals can be supplied in

electronic format upon request.

Biomarine, Inc.

ATTN: Service Department

456 Creamery Way

Exton, PA 19341-2532

USA

Tel: (610) 524-8800

Extensions 146 or 163

Fax: (610) 524-8807

Web: www.BioPak240r.com

Contact Biomarine prior to returning any

equipment.

To better serve your needs, please provide

the following information when contacting

Biomarine.

Apparatus Model Number

(240R, 240S, 240 LW, etc.)

Apparatus Serial Number

(Located internal to the BioPak,

beneath the oxygen cylinder)

Date of purchase

Approximate number of uses

Description of problem

Actions taken to correct problem

Contact name, address and phone

number with area or country code

and email address

Please provide your current email

address with all service

correspondence.

4. STORAGE GUIDELINES

Follow the guidelines below for proper

storage of the apparatus.

Storage plug shall be installed.

Never store a wet apparatus. The

apparatus shall be fully dry before

storage.

Never store an apparatus that has

not been fully cleaned and

disinfected.

Store in a location free from impact

that could cause damage to the

apparatus.

Store in the stated conditions of

ambient temperature, relative

humidity and air pressure.

Store in a location that will not

submerge the apparatus.

Do not store the apparatus pre-

packed with the ExtendAir® carbon

dioxide scrubber canisters.

Long Term Storage (storage of

BioPak for periods exceeding 6-

months without use): Follow all of

the above guidelines. The BioPak

should not be placed back into

service until all the procedures

associated with Turn Around and

Long Term maintenance have been

performed and passed.

BioPak 240R Benchman Manual

A47D135 Revision N

Page 20 of 45

5. PARTS LIST

5.1 Top Assembly

ITEM # QTY. PART NUMBER DESCRIPTION

1a 1 --- AV3000 Facemask Assembly-See Section 5.2

1b 1 --- AV3500 Facemask Assembly-See Section 5.3

2 1 B6-02-5002-18-0 Upper Housing Assembly

3 2 B2-02-4000-39-0 Coolant Lid

4 2 B6-02-5002-37-0 Ice Canister

5 2 B2-02-7001-09-0 Breathing Hose-See Section 5.4 or Section 5.5

6 1 B6-02-5002-04-3 Center Section Lid Assembly-See Section 5.6

7 1 B6-02-5003-69-0 OrbSorb®CO2Scrubber Canister2

8 1 B6-02-5003-34-0 Scrubber Moisture Pad3

9 1 B6-02-5002-07-5 Center Section Assembly-See Section 5.7

10 1 --- Pneumatic Assembly-See Section 5.9

11 1 B6-01-5000-05-0 Alarm Monitor-See Section 5.11

12a 1 B6-02-5001-98-0 Green Oxygen Cylinder, Empty-See Section 5.12

12b 1 B6-02-5001-98-1 Green Oxygen Cylinder, Full-See Section 5.12

13 1 B6-02-5002-28-0 Lower Housing Assembly-See Section 5.13

14 1 B2-02-7001-24-0 Harness Assembly-Flame Rated

15 2 B6-02-5002-40-0 Ice Canister Freeze Form-See Section 5.15

16 1 B5-06-6000-22-0 User Manual-ENGLISH3

17 1 B5-06-6000-23-0 Benchman Manual-ENGLISH3

18a opt. B6-02-5002-63-0 Hard Transit Case (not depicted)

18b opt. B2-02-7000-39-0 Soft Transit Case (not depicted)

19a 1 B2-02-4001-50-0 AV3500 Storage Plug

19b 1 B2-02-4000-90-0 AV3000 Storage Plug

20a 1 B6-02-5002-54-0 Cylinder Fill Adapter, CGA 540 Male

20b 1 B6-02-5002-55-0 Cylinder Fill Adapter, CGA 540 Female

20c 1 B6-02-5002-53-0 Cylinder Fill Adapter, G ¾-A Male

20d 1 B6-02-5002-66-0 Cylinder Fill Adapter, fits Drager Booster Pump

21 1 B6-02-5002-41-0 Phase Change Heat Exchanger (PCM)

22 1 B2-02-7001-07-0 Moisture Absorbent Pad Set

Note:

1. The BioPak 240R respirator is supplied with a cardboard/foam shipping box. Hard or soft transit cases are to be

ordered separately.

2. CO2Scrubber Canister, part number B6-02-5003-69-0, will supply four sets of canisters, four sets of moisture

pads, and maintenance tags for four separate single uses.

3. Alternate language manuals are available. Contact Biomarine Representative for details.

Other manuals for BioPak 240 REVOLUTION

2

This manual suits for next models

1

Table of contents

Other Biomarine Diving Instrument manuals

Popular Diving Instrument manuals by other brands

Dräger

Dräger LAR 7000 manual

Scubatech

Scubatech Tecline Donut 15 User instruction manual

odoland

odoland SP0810 instruction manual

Aqua Lung

Aqua Lung 63093 owner's manual

AIR SYSTEMS INTERNATIONAL

AIR SYSTEMS INTERNATIONAL PAK-3 OPERATING INSTRUCTIONS AND REPLACEMENT PARTS

Oceanic

Oceanic VEO 100 operating manual