Seac Sub Diamond User manual

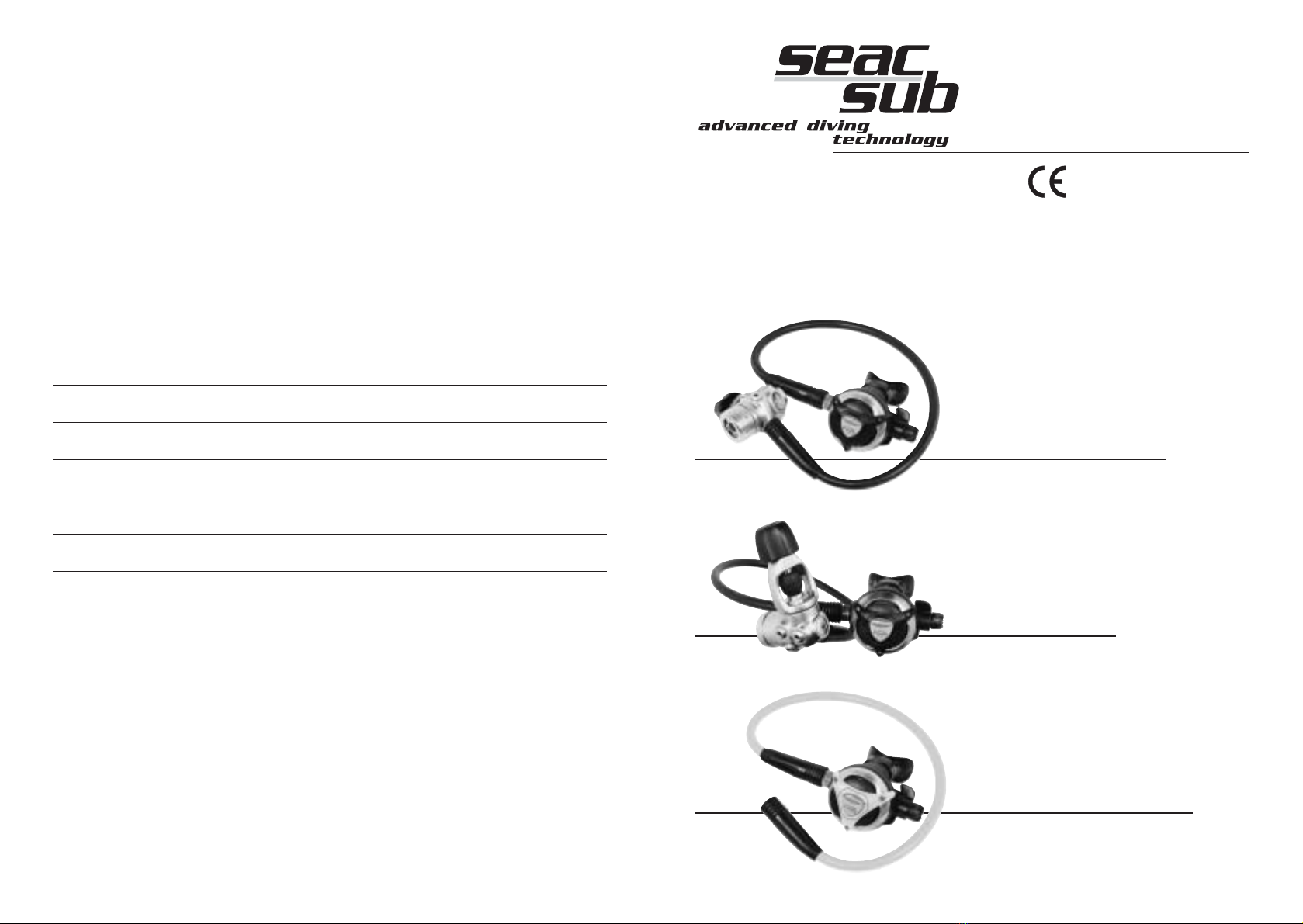

Diamond Ice

Diamond

Diamond Octo

Diamond Ice

Diamond

Diamond Octo

ISTRUZIONI

INSTRUCTIONS

INSTRUCTIONS

INSTRUCCIONES

ANWEISUNGEN

I

I

UK

F

E

D

ISTRUZIONI

INSTRUCTIONS

INSTRUCTIONS

INSTRUCCIONES

ANWEISUNGEN

EROGATORI

REGULATORS

DETENDEUR

REGULADOR

ATEMREGLER

Diamond Ice

Diamond

Diamond Octo

SEAC DIVING PRO srl

Via D. Norero, 29

16040 San Colombano Certenoli (GE), Italy

Tel. +39 (0185) 356301

Fax. +39 (0185) 356300

Info: [email protected]

Web Page: www.seacsub.com

0474 - EN 250 : 2000

INDEX

ITALIANO pag. 5

ENGLISH pag. 13

FRANÇAIS pag. 21

ESPANOL pag. 29

DEUTSCH pag. 37

SEAC SUB ENGLISH

15

SEAC SUB ENGLISH

14

PURPOSE - DEFINITIONS - LIMITS

The purpose of the requirements and tests

specified by standard EN 250: 2000 is to en-

sure a minimum safety level for the operation

of Self-Contained Underwater Breathing Ap-

paratus (SCUBA) at a maximum depth of 50

meters.

SCUBA Definition:

Compressed-air open-circuit underwater breath-

ing apparatus contained in a cylinder.

SCUBA - MINIMUM EQUIPMENT REQUIRED

(EN 250 : 2000)

1. Cylinder body and valve assembly (cylinder

assembly)

2. Regulator

3. Pressure gauge or pressure control, reserve

or alarm device

4. System for cylinder support, transport and

connection to the diver (back-piece and/or

straps)

5. Head equipment (mouthpiece or complete

mask or diving helmet)

6. Instructions for use

SCUBA - Component assemblies (EN 250 : 2000)

The Scuba may consist of separate compo-

nent assemblies, such as:

Cylinder assembly, Regulator, Pressure

gauge, Support-transport system.

Cylinder assembly defines the assembly of

cylinder body, valve and tank boot, if any.

The Seac Diving Pro regulators described

in this handbook are to be used in the

SCUBA assembly and are certified in com-

pliance with European Directive 89/686/EC

and standard EN 250 : 2000.

The compressed air contained in the cylin-

der assembly shall comply with the requi-

rements for breathable air defined in EN

12021 : 1998

Warning!

The following instructions shall be integrated

with the ones relevant to the other compo-

nents of your SCUBA. Before using your SEAC

SUB regulator, read carefully all the instruc-

tions for use contained in the relevant hand-

books.

Congratulations for choosing the

quality and reliability of a Seac Diving

Pro product. The equipment you bought

was produced using selected and tested

materials. Our constant evolution

results from continuous research and

development. Innovative production

processes, constant testing and actual

functionality tests developed at our

research centre guarantees the

reliability characterizing all Seac Diving

Pro products.

Warning!

This booklet is not a diving manual!

Read the whole instruction

handbook before using this

equipment!

This manual for use must be

preserved for the whole life of the

product!

General Instructions

Before using the regulator or any other

products for underwater diving, you

should attend a course held by qualified

instructors and obtain the relevant diving

certificate. The use of diving equipment by

non certified divers is dangerous and can

lead to serious accidents, or even death, to

the diver and his/her diving mates.

During the assembly and regulation of the

regulator, every step was taken to ensure

high reliability of the product in time.

These steps however may become ineffec-

tive if the regulator is not used correctly and

if adequate maintenance is not provided.

Seac Diving Pro s.r.l declines any liability

for any problem arising from non-compli-

ance with the instructions contained in

this handbook.

For any other problem, please contact your

dealer or directly Seac Diving Pro. Only la-

boratories authorized by Seac Diving Pro

may carry out repairs or maintenance.

Seac Diving Pro diving regulators are the

result of a research carried out in close co-

operation with many professional divers.

Their innovative features ensure a reliabi-

lity which remains unchanged even after a

long series of dives. At the same time, their

easy mechanics and operation allow an ex-

tremely simple maintenance.

If you are not experienced in the use of

this equipment, we strongly advise you to

get familiar with its operation during test

diving in shallow waters and under favora-

ble conditions; if needed, contact a quali-

fied instructor for a refresher course.

This diving regulator has been certified ac-

cording to standard EN 250: 2000 which

provides a long series of functional tests

up to a maximum depth of 50 meters and

at a temperature of 4 degrees centigrade

(test tolerance range -2°C/ +0°C).

Warning!

This diving regulator has been designed to be

used with normal atmospheric air complying

with the specifications of standard EN 12001.

Danger!

Do not use this or any other product of the

Seac Diving Pro line with other gases or oxy-

gen enriched air mixtures (usually known as

NITROX). Failure to follow this recommenda-

tion could cause serious accidents or even

death, due to fire or explosions, or seriously

damage your equipment.

Introduction Reference to European Standard EN 250: 2000

The Seac Diving Pro regulators described in

this handbook were tested and certified by

the notified testing body 0474 RINA, Genoa

office (Italy) in compliance with Directive

89/686/EEC of 21 December 1989.

Tests were carried out in compliance with stan-

dard EN 250: 2000, implementing the above Di-

rective, which defines the conditions of sale

and the essential safety requirements of Third-

Category Individual Protection devices (DPI).

CE marking means compliance with the essen-

tial health and safety requirements (Ann. II DE

89/686/EEC). Number 0474 near “CE“ identifies

the notified testing Body RINA in charge of pro-

duction control under Art. 11B DE 89/686/EEC.

The certification obtained for the DIAMOND,

DIAMOND ICE, and DIAMOND OCTO provides

possible use in both of the following categories:

Regulators for non-cold waters, having a

water temperature equal to or exceeding

+10° C

Regulators for cold waters, having a water

temperature lower than +10° C

In compliance with standard EN 250 : 2000,

waters are considered cold when their tem-

perature is lower than + 10° C.

CE Certification

MARK ON EACH REGULATOR: 0474

SEAC SUB ENGLISH

17

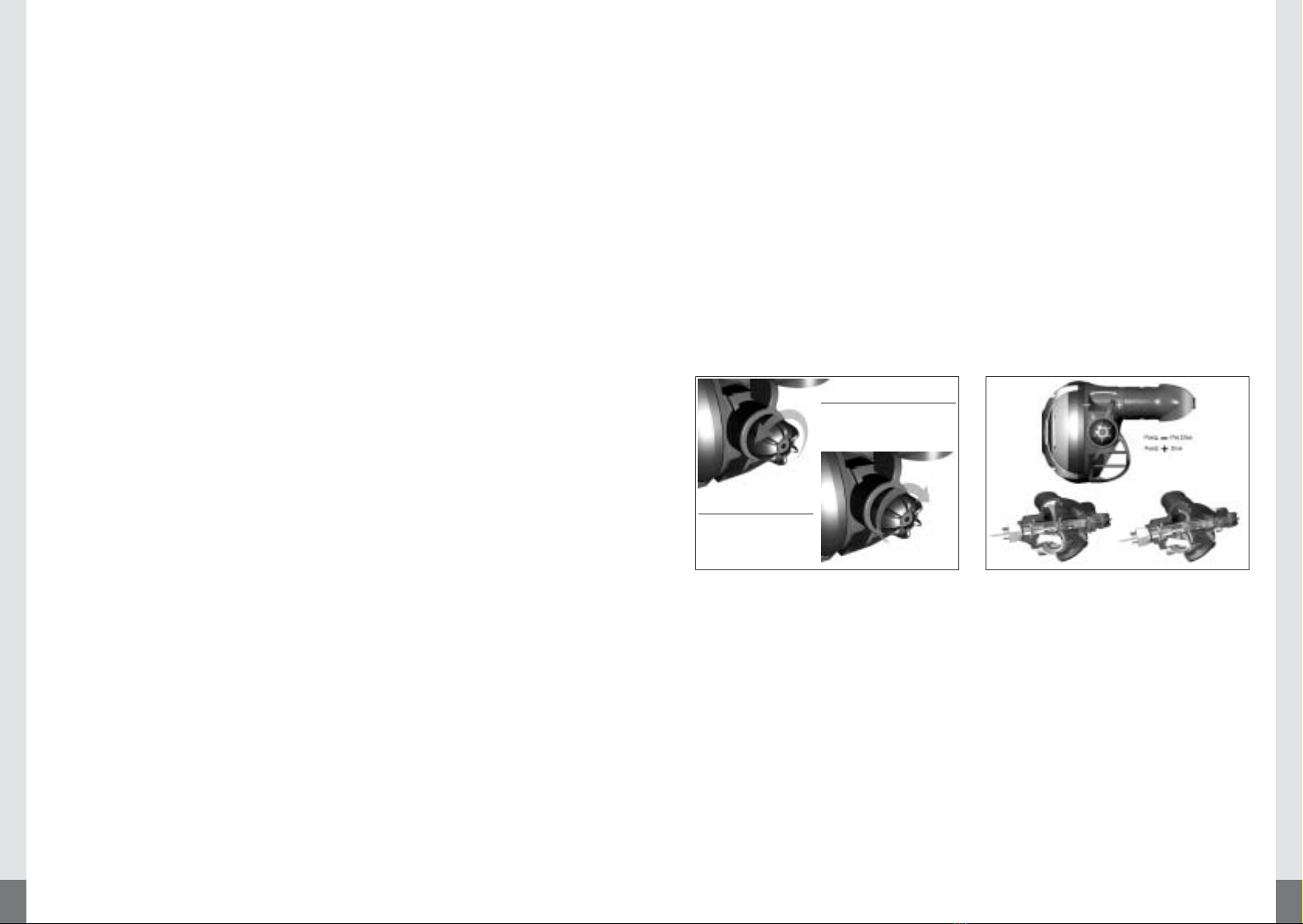

DIAMOND /DIAMOND ICE REGULATORS

SECOND STAGE

Second stage with air balancing system which

reduces the initial breathing effort while pro-

viding a linear and constantly smooth breath-

ing. The system operation is based on a pneu-

matic piston working in close contact with the

spring, enabling the latter to work with a

lower load force (consequent light breathing)

ensuring a perfect seal of the air flow during

the breathing out phase.

By actuating the knob located on the left of the

regulator (see Figure A-B) you can regulate the

breathing softness according to your breathing

demand and to the diving conditions.

By rotating it anticlockwise you will get the

maximum breathing softness and by rotating

it clockwise you will gradually reach a stan-

dard breathing flow. This second stage conse-

quently allows individualizing the breathing

demand as a function of the dive require-

ments and type.

The operation is of the “Downstream” type.

This system allows for low air consumption by

reducing air waste, as it perfectly meets the

breathing demand.

This means that the air flow delivery is per-

fectly controlled by the diver’s breathing ac-

tion: a normal breathing action produces a

light air flow, while heavy breathing due to

fatigue or deep diving produces a free air

flow, also increased by the Venturi effect.

In addition, this system also provides safety

margins in case of first stage overpressure:

should the intermediate pressure supplied by

the first stage suddenly increase, the second

stage would continue to work, thus releasing

excess pressure and enabling the diver to

breathe.

The control of the DIVE and PRE-DIVE mecha-

nism allows to insert the Venturi effect. This

system is placed around the knob regulating

the breathing effort reduction system.

By actuating this mechanism placed to the

left of the second stage you can insert the

Venturi effect and consequently increase air

delivery.

By turning the lever towards the outside you

reach the “PRE-DIVE” position, while by turn-

ing the lever towards the diver you reach the

“DIVE” position. (see Figure C)

The “PRE-DIVE” position is recommended to

prevent accidental delivery when the regula-

tor is under pressure but not used, while the

“DIVE” position is recommended during the

dive.

Warning! Move the lever to “PRE-DIVE” only

when the regulator is not used, and rotate it

to “DIVE” before dive start.

The main body is made of synthetic resin,

which is highly resistant to impacts, abrasions,

ultraviolet rays and chemical agents. Di-

aphragms are made of medical grade silicone,

while nitrile rubber O-rings are of different

hardness (Shore) as a function of their appli-

cations. Chrome-plated brass and stainless

steel internal components. Black anallergic

silicone mouthpiece.

The nut placed on the hose end was especial-

ly designed with slightly marked lines for cos-

metic purposes, so as to give the Diamond

regulator a professional and captivating look.

The hose is of the standard type (770 mm

length and 3/8” thread).

SEAC SUB ENGLISH

16

This first stage combines very high performance

with an extremely compact and round shape.

Operation is ensured by a balanced di-

aphragm system which keeps a constant in-

termediate pressure with reference to both

tank pressure and depth. In addition, the di-

aphragm completely separates the regulator

core from the external environment, ensuring

total reliability over a long series of dives.

It is cast as a single block of copper-plated

brass, subsequently nickel- and chrome-plat-

ed. Internal components are in chrome-plated

brass with music-wire springs and nitrile-rub-

ber seals. Particular care was given to the sep-

arating diaphragm, made of a special rubber

which remains unchanged and is resistant to

low temperatures.

Four low-pressure ports, provided with 3/8”

thread, supply a constant pressure of 9.8 bars;

all ports are considered preferential, as they

are implemented on the same axis; in addi-

tion, two of them are positioned at 30° with

regard to the first stage body, so as to make

the correct bending of the valves inserted

easier; the most important components, such

as the main regulator (on the right) and the

jacket or dry diving suit hose (on the left),

shall be connected to these two ports.

In decentralized position there are two high-

pressure ports (one to the right and the other

to the left) with 7/16” thread and inner hole

having a 0.20 mm. diameter; a diving pres-

sure-gauge may be connected to these high-

pressure ports, to check the internal pressure

of the cylinder used, by means of a hose with

7/16” thread male connection.

Warning!

Use only CE certified pressure gauges provid-

ed with standard thread. Do not use any type

of adapter between the first stage and the

high pressure hose connection.

The DIAMOND first stage has been designed

to operate with cylinder working pressures up

to 300 bar. For pressure exceeding 230 bar it

is advisable to use the version provided with

the 300 bar thread connection (THREAD CON-

NECTION ISO 12209-2/3.2; 300 BAR) imple-

mented in our model DIAMOND ICE

The DIAMOND first stage is implemented in

the following versions:

International YOKE connection

(ISO 12209-1 230 BAR)

THREAD connection

(ISO 12209-2/3.5; 230 BAR)

DIAMOND ICE REGULATOR

FIRST STAGE

First stage has the same characteristics as the

DIAMOND version, but with the addition of

the innovative ANTIFREEZE DRY SYSTEM.

This system enables diving under extreme

temperature conditions, while keeping oper-

ating characteristics unchanged.

An antifreeze silicone separating diaphragm,

placed at the end of the first stage insulates

the regulator mechanics from the outside,

while transmitting through a simple and

functional mechanism, the water external

pressure needed for proper and constant bal-

ancing of the first stage under any pressure

and diving conditions.

This version is recommended for dives in cold

waters or mountain lakes where the water

may reach temperatures nearing zero.

The DIAMOND ICE version First stage is imple-

mented in the following versions:

International Yoke connection

(ISO 12209-1 230 BAR)

Thread connection

(ISO 12209-2/3.5; 230 BAR)

Thread connection

(ISO 12209-2/3.2; 300 BAR)

Warning!

To use the YOKE connection (ISO 12209-1 230

bar) or the THREAD connection (ISO 12209-

2/3.5; 230 bar), you must use a cylinder having

valves fitted with the relevant connections.

We recommend you to keep a common 8 mm

Allen wrench within reach, so that you may

operate on the valves, if needed, to obtain

the right connection. Please note that (the

300 bar THREAD connection) (ISO 12209-

2/3.2; 300 bar), only valves with the relevant

connection should be used.

EROGATORI DIAMOND, DIAMOND ICE, DIAMOND OCTO.

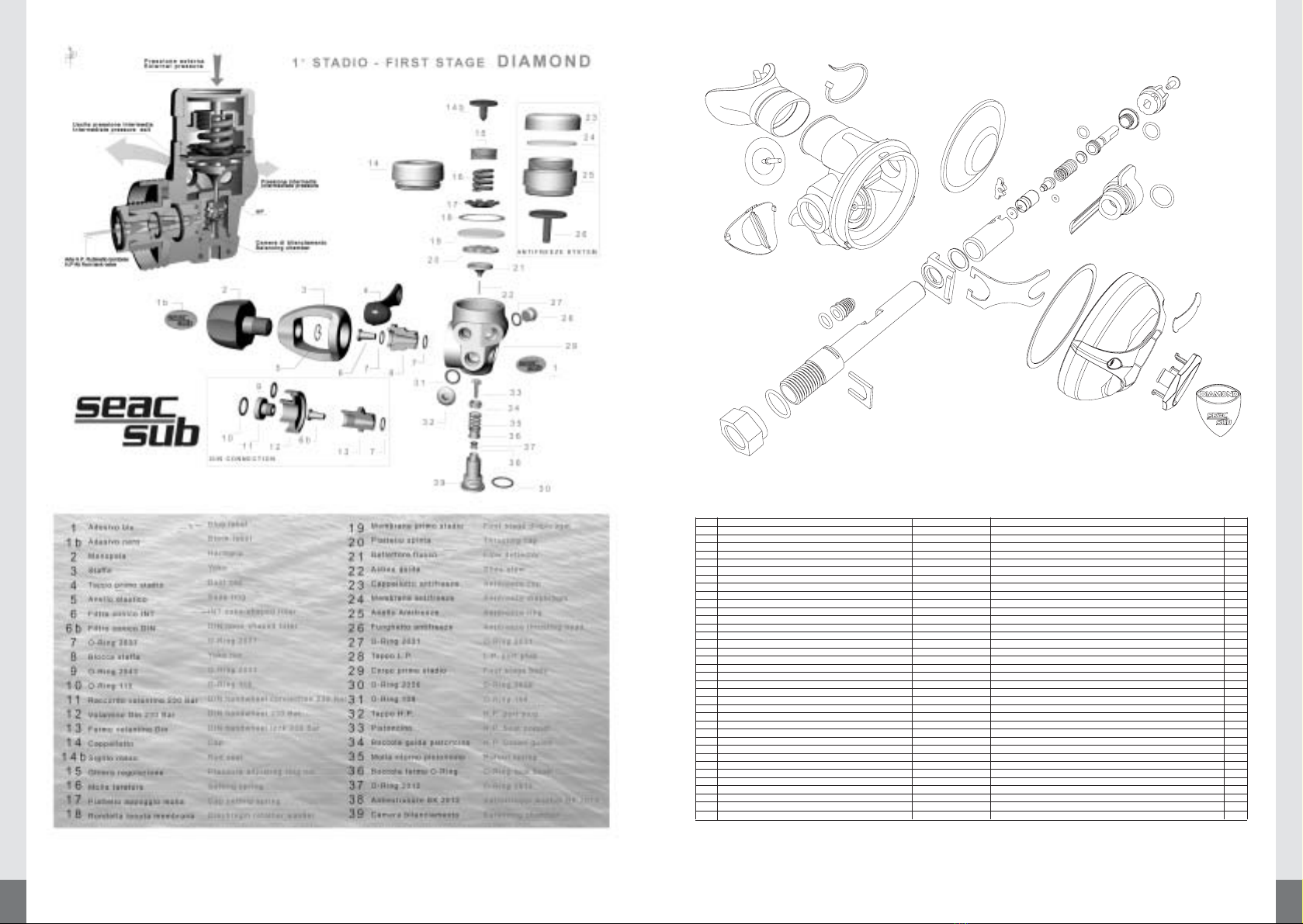

DIAMOND REGULATOR - FIRST STAGE

Figure A-B Figure C

DIVE PRE-DIVE

A

MANOPOLINA SVITATA

(SENSO ANTIORARIO)

RIDUZIONE SFORZO

INSPIRATORIO

B

MANOPOLINA AVVITATA

(SENSO ORARIO)

SFORZO INSPIRATORIO

NORMALE

SEAC SUB ENGLISH

19

BEFORE EACH DIVE

The regulator must always be transported

separately so as to prevent it from being in

contact with the other components of the

equipment or with other heavy or pointed

objects.

To assemble the regulator properly onto the

valves, proceed as follows:

When assembling a first stage with YOKE

connection, check the O-Ring embedded

in the valve; in case of THREAD connec-

tion, the O-ring is housed in the first stage.

The O-ring must be in perfect condition,

free from cuts or porosity; it is advisable to

have some spare ones, so that it may be re-

placed at once in case the above signs of

damage are detected.

Check that all the hoses are properly con-

nected to the first stage and that they do

not show apparent signs of wear or damage.

Open the valve let out a small quantity of

compressed air, thus clearing the nozzle

from any foreign matter.

Remove the filter protection cap inserted

on the relevant connections.

Check for filter integrity and proper cleaning.

Position the first stage on the valve and

start screwing it up using the knob, in case

of yoke connection, or the swivel screw, in

case of thread connection.

Slowly open the cylinder valve counter-

clockwise taking care to avoid violent and

sudden air flow through the regulator; at

the same time, it is recommended to let

out a breath of air from the second stage

by keeping the latter slightly depressed

warning!

do not carry out this operation if ambient

temperature is lower than +10°C.

Depress twice or three times the purge

button of the second stage to discharge

dust or foreign matter. Finally, breathe

from the second stage to make sure that

everything works properly.

warning!

Do not carry out this operation if ambient

temperature is lower than +10°C.

Check the cylinder internal pressure by

means of the appropriate pressure gauge.

In order to optimize the positioning of the

different valves, it is recommended to pla-

ce the main and secondary regulators on

the right hand side and the service valves

(pressure gauge hose, jacket hose, and dry

diving suit hose) on the left.

The valve must be fully open before dive

start.

When the regulator is not held in your

mouth at the time of plunging into the

water, it is advisable to submerge it com-

pletely to prevent air discharge due to its

high sensitivity.

The Octopus or the second safety regula-

tor should be used in PRE-DIVE position

and with the appropriate cap fitted on the

mouthpiece to prevent the entrance of fo-

reign matters or accidental air delivery.

Warning!

Do not rotate the first stage connected

with the cylinder with the system under

pressure.

DURING THE DIVE

When the regulator is not held in your

mouth, air self-delivery may occur. This in-

convenience may be easily eliminated by

rotating the regulator upside down while

checking that the same has been previou-

sly filled with water.

The use of suitable containers for mouth-

piece protection will prevent such inconve-

nience and will also provide a cover for the

passage inside the second stage, thus re-

moving the risks of sand and dirt introduc-

tion into it.

Check that the regulations placed on the

Diamond second stage are set in such a

way as to fully exploit the advantages pro-

vided.

AFTER EACH DIVE

AND PERIODIC MAINTENANCE

Your regulator is made of very high-quality

materials and has undergone exhaustive sea-

water testing. However, every precaution

shall be taken in order to protect the equip-

ment from the corrosive action of salt.

Below is the procedure to be followed after

surfacing or on board at the end of the dive.

The first operation to be carried out after the

dive is to disassemble the equipment used.

Close the valve by turning it clockwise; di-

scharge all the residual air remaining in

the regulator system by actuating the se-

cond stage pushbutton.

This operation may require several se-

conds, as the air leaving the pressure gau-

SEAC SUB ENGLISH

18

DIAMOND OCTO

The technical specifications and the materials

used for the DIAMOND OCTO are the same as

for the second stage version assembled on

the above described DIAMOND and DIA-

MOND ICE regulators.

The only differences are in the color of the

shield which is yellow, especially designed for

easier identification in case of quick use, and in

the hose which is also yellow. The latter was es-

pecially made with a length of 1000 mm (3/8”

thread) for easier use in emergency conditions.

We recommend correct positioning of the DI-

AMOND OCTO to PRE-DIVE and with the air

flow regulation knob fully screwed up if it is

used as an auxiliary or emergency regulator.

The DIAMOND OCTO first stage assembly

shall be carried out by qualified or experi-

enced persons in order to optimize and en-

sure the functionality and safety require-

ments needed.

Use a common 4 mm Allen wrench to remove

the low pressure port closing cap (3/8” pitch)

then make sure that the O-ring is present, in-

serted and positioned in the hose over the rel-

evant thread. Screw up the hose with your fin-

gers until end stop, and then tighten the nut

with a 14 wrench without using excessive force.

Check for proper operation by putting the as-

sembled regulator under pressure before the

dive.

Warning!

For safety reasons you are recommended to

use the DIAMOND OCTO only on the DIA-

MOND, DIAMOND ICE and SORIUS first stages

having an intermediate pressure of 9.8 bar.

The use of the DIAMOND OCTO connected to

other first stages automatically makes the CE

Certification null and void, as the latter was

obtained with tests carried out with connec-

tion of the DIAMOND OCTO to Seac Diving

Pro First stages.

Failure to comply with this recommendation

may also cause malfunctioning of the second

stage and serious accidents may result.

Warning!

Do not use adapters for any reason with the

purpose of connecting the low pressure hose

and relevant second stage to the high pres-

sure port identified by letters HP. Low pres-

sure components were designed and imple-

mented to operate with pressures not

exceeding 20 bar. Failure to comply with this

warning may cause serious damage to per-

sons and equipment.

Be extremely careful when handling compo-

nents that are under pressure.

SPECIFICATION DESCRIPTION DIAMOND DIAMOND ICE DIAMOND OCTO

CE Certification Cold Water < 10 c° Cold Water < 10 c° Cold Water < 10 c°

Mark and Certifying Body CE 0474 CE 0474 CE 0474

Mark Position On the first stage On the first stage On the hose

First Stage System H.F. Balanced Diaphragm H.F. Balanced Diaphragm -

Antifreeze Dry System No Present -

Low Pressure ports No. 4 3/8” UNP No. 4 3/8” UNP -

High Pressure ports No. 2 7/16 UNP No. 2 7/16 UNP -

Intermediate Pressure 9,8 bar 9,8 bar -

First Stage weight

Yoke 230 bar 950 gr 980 gr -

Thread 230 bar 730 gr 750 gr -

Thread 300 bar - 780 gr -

Hose Length 770 mm 770 mm 1000 mm

Second Stage System Balanced Pneumatic Balanced Pneumatic Balanced Pneumatic

Second Stage Weight with hose 350 gr 350 gr 400 gr

SEAC SUB FRANÇAIS

21

Certificat de Garantie

Seac Diving Pro s.r.l. garantit le bon fonctionnement du produit auquel ce certificat est joint.

Cette garantie a une durée de 2 (deux) ans, conformément à la réglementation européenne en

vigueur.

La garantie en question ne s’applique qu’aux conditions et dans les limites spécifiées ci-dessous:

1. La garantie a une durée de 2 (deux) ans à partir de la date d’achat du produit chez un re-

vendeur agréé Seac Diving Pro et ne nécessite aucune formalité préalable ou validation suc-

cessive.

2. La garantie n’est reconnue qu’au premier acheteur du produit chez un revendeur agréé Seac

Diving Pro.

La garantie étant strictement nominative, elle ne peut pas être cédée à un Tiers sans préa-

lable autorisation explicite de la part de Seac Diving Pro.

3. La garantie couvre uniquement tous les défauts de fonctionnement dus à:

Vices intrinsèques dérivant d’un matériel jugé inadéquat

Erreurs évidentes de conception, fabrication ou assemblage du produits ou de ses compo-

sants

Instructions et avertissements d’utilisation incorrects ou impropres

4. La garantie déchoit automatiquement, et avec effet immédiat, à la suite de toute réparation,

modification, transformation, adaptation ou violation en général du produit fini ou de ses

composants qui n’a pas été préalablement autorisée par Seac Diving Pro ou en tout cas ef-

fectuée par du personnel non agréé.

5. La garantie donne droit à l’intervention et à la réparation gratuite dans les plus brefs délais

ou bien au remplacement sans frais du produit (au choix sans appel de Seac Diving Pro) ou

de quelques uns de ses composants si Seac Diving Pro a reconnu que ces vices de fonctionne-

ment sont formellement cités à l’alinéa 3 ci-dessus.

6. La garantie peut être exercée par l’envoi du produit jugé défectueux à Seac Diving Pro. L’in-

termédiaire autorisé à cette opération doit être le revendeur agréé Seac Diving Pro où le pro-

duit a été acheté. Dans le cas où cela ne serait pas effectivement possible, n’importe quel re-

vendeur Seac Diving Pro. peut expédier le produit défectueux, après avoir obtenu

l’autorisation du fabricant. La condition nécessaire pour que la garantie puisse être exercée

est que le produit soit accompagné de la copie du ticket de caisse ou de la facture (ou d’autre

document d’enregistrement fiscal où figure le nom du revendeur agréé Seac Diving Pro chez

lequel le produit a été acheté, ainsi que la date de l’achat.

Pour le cas où Seac Diving Pro. recevrait un produit qui:

n’est pas accompagné du document d’enregistrement fiscal ayant les caractéristiques ci-

dessus

que les circonstances sont telles qu’elles déterminent la déchéance de la garantie, comme

spécifié à l’alinéa 4 ci-dessus

qu’il présente des défauts dérivant de causes externes ou diverses de celles formellement

spécifiées à l’alinéa 3

qu’il a été utilisé d’une façon impropre et/ou pour un emploi divers de celui pour lequel il

a été conçu

elle s’abstiendra de toute intervention sur le produit et en fera parvenir la communication im-

médiate à l’expéditeur ou au revendeur agréé.

Si l’expéditeur désire quand même faire effectuer la réparation, il devra faire parvenir à Seac Di-

ving Pro, dans les quinze jours ouvrables successifs, une demande dans ce sens en déclarant qu’il

se chargera de tous les coûts relatifs à l’intervention en question (main d’œuvre, pièces de re-

change éventuelles, frais d’expédition).

Dans le cas contraire, Seac Diving prendra soin de retourner le produit aux frais et aux soins du

destinataire.

SEAC SUB ENGLISH

20

ge through the first stage shall pass throu-

gh a 0.20 dia. hole.

Unscrew the knob positioned on the yoke

or, in case of Thread connection system,

unscrew the threaded ring nut.

Lay the cylinder down to prevent it from

falling, positioning it in such a way that it

cannot roll in any direction.

Thoroughly clean and dry the first stage

filter and housing with a cloth or with a

soft compressed-air jet.

Repeat the same operation on the protec-

tion cap covering the filter.

Place the protection cap onto the filter

and fasten it by tightening the knob screw

or, in case of thread connection, screw up

the swivel-screw cap.

Rinse but do not immerse the regulator in

running fresh water taking care of all its

parts.

In this phase do not for any reason remo-

ve the first stage filter protection cap. Du-

ring this operation be extremely careful

not to press on the diaphragm, to avoid

water leaks into the first and second stage.

If you think you are not going to use the reg-

ulator for some weeks, again connect the reg-

ulator to a cylinder and, by depressing the

second stage pushbutton, cause continuous

delivery for about ten seconds. In this way all

the water is discharged and there is no risk of

scale deposits or evil taste.

The regulator shall be put to dry in a place

sheltered from the sun and dust, hanging

from the first stage yoke, so that the hose is

not bent.

At the end of a particularly intensive diving

season or, in any case, after a long period of in-

activity, it is advisable to give the equipment to

an authorized service centre for a complete

overhaul. Consequently, we advise you to con-

tact your dealer who will give you the best in-

formation on the quickest and safest ways for

carrying out the annual overhaul.

DIVING IN COLD WATER

Incorrect preparation for cold water diving

(less than +10 degrees centigrade) might

cause serious damage.

Before diving in cold water, you should follow

specific training under the supervision of spe-

cialized and qualified trainers in cold water

diving.

You must use specific regulators certified for

such conditions and closely follow the instruc-

tions contained in the relevant handbooks.

Though the risks of freezing are limited as far

as possible by continuous research, it is not

possible to prevent second stage freezing in

the most extreme conditions.

This could be the case when the water tem-

perature is below +4 degrees centigrade and

with external air temperatures is below zero).

Consequently, in order to prevent or reduce

any possible risks, adequate training is need-

ed to prevent the regulator from freezing.

In extreme conditions you should strictly ob-

serve the following guidelines:

1. Do not use the regulator out of the water

particularly when the external surface tem-

perature is below zero.

2. Never actuate the second stage discharge

pushbutton unless under water.

3. Try to limit as far as possible the time of rest

on the surface before diving.

For further information you may contact our

technical office at the following e-mail

SEAC SUB

45

SEAC SUB DEUTCH

44

Werfen wir also einen Blick auf die Regeln,

die zu beachten sind, nachdem der Tauch-

gang beendet ist und wir wieder an der Ober-

fläche oder auf dem Boot sind.

Als erstes ist nach einem Tauchgang das ge-

brauchte Gerät zu demontieren.

Schließen Sie das Ventil, indem Sie das

Handrad im Uhrzeigersinn drehen und las-

sen Sie die gesamte restliche Luft heraus,

die sich noch im System des Atemreglers

befindet, indem Sie auf den Duschknopf

der zweiten Stufe drücken.

Dieser Vorgang kann einige Sekunden

dauern, da die Luft, die aus dem Manome-

ter durch die erste Stufe austritt, durch ei-

ne Öffnung vom Durchmesser 0,20 entwei-

chen muß.

Die Bügelschraube am Bügel abschrauben,

oder im Fall des Gewindeanschlusses

(Thread Connection), den Schraubenring

abschrauben.

Legen Sie die Flasche hin, damit sie nicht

umfällt und achten Sie darauf, dass die Fla-

sche nach keiner Richtung wegrollen kann.

Den Filter der ersten Stufe und sein

Gehäuse sorgfältig säubern und abtrock-

nen, entweder mit einem Lappen oder mit

einem schwachen Strahl Pressluft.

Verfahren Sie ebenso mit dem Schutzver-

schluss, mit dem der Filter abgedeckt wer-

den muss.

Die Staubschutzkappe auf den Filter setzen

und mit der Bügelschraube blockieren,

bzw. im Falle des Gewindeanschlusses den

betreffenden Schraubdeckel aufschrauben.

Sorgfältig alle Teile des Atemreglers mit

Süßwasser abspülen, ohne das Gerät ganz

einzutauchen.

In dieser Phase darf auf keinen Fall die

Staubschutzkappe des Filters auf der er-

sten Stufe entfernt werden. Es ist sorgfäl-

tig darauf zu achten, dass kein Druck auf

die Membrane ausgeübt wird, um zu ver-

meiden, dass Wasser ins Innere der ersten

und der zweiten Stufe eindringt.

Wenn Sie, den Atemregler für einige Wochen

nicht benutzen, verbinden Sie ihn wieder mit

einer Flasche und, während Sie den Dusch-

knopf der zweiten Stufe drücken, führen Sie

für einige Sekunden einen Luft-Zufluß herbei.

Auf diese Weise werden alle Wasserreste aus-

geblasen und man vermeidet Kalkablagerun-

gen oder eine Geschmacksverschlechterung.

Der Atemregler wird zum Trocknen an einem

sonnen- und staubgeschützten Platz am Bü-

gel der ersten Stufe aufgehängt wobei der

Schlauch nicht geknickt werden soll.

Nach einer besonders intensiven Saison oder

auch nach einer langen Zeit, in dem das Gerät

nicht benutzt wurde, sollte das Gerät einer au-

torisierten Werkstatt zu einer kompletten Über-

holung, übergeben werden. Ihr Fachhändler

kann Ihnen kompetent Auskunft geben über

die schnellsten und sichersten Möglichkeiten,

die jährliche Überholung durchführen zu lassen.

TAUCHGÄNGE IN KALTEN GEWÄSSERN

Eine ungenügende technische Vorbereitung

auf Tauchgänge in kalten Gewässern (unter

+10°C ) kann schwerwiegende Folgen haben.

Vor Tauchgängen in kalten Gewässern ist eine

besondere Vorbereitung ratsam, die unter

Aufsicht von spezialisierten und qualifizierten

Tauchlehrern erfolgen sollte. Bei Tauchgän-

gen in kalten Gewässern sind weiterhin be-

sondere Atemregler und Zertifikationen not-

wendig. Außerdem sollten die Anweisungen

in den jeweiligen Bedienungsanleitungen ge-

nauestens befolgt werden.

Zwar wird durch andauernde Forschungsarbeit

in unseren Labors die Gefahr des Einfrierens

begrenzt, aber es ist nicht möglich, das Einfrie-

ren der zweiten Stufe in jeder Lage zu vermei-

den. Das gilt insbesondere, wenn der Tempera-

turunterschied zwischen der Oberfläche und

dem Wasser beträchtlich ist (wir sprechen hier

von Tauchgängen in kalten Gewässern mit

+2°C/ +4°C und Außentemperaturen weit unter

null Grad) . Auch der Atemregler DIAMOND

ICE könnte in besonders extremen Situationen

Symptome eines „Einfrierens» zeigen. In einer

solchen Situation könnte es sein, dass der

Atemregler nicht korrekt funktioniert. Das

kann auch schwere Schäden zur Folge haben.

Zur Vermeidung oder Verminderung potentiel-

ler Risiken ist deshalb eine entsprechende Vor-

bereitung notwendig, damit eventuelle Proble-

me , die durch einen Atemregler mit Anzeichen

des „Einfrierens» entstehen, vorab vermieden

oder beseitigt werden können.

In derartigen Situationen sollten folgende Re-

geln genauestens befolgt werden:

Die Benutzung des Atemreglers außerhalb

des Wassers ist zu vermeiden, besonders

wenn die Außentemperatur unter null

Grad liegt.

Den Duschknopf der zweiten Stufe nur

während des Tauchgangs verwenden.

Halten Sie sich vor dem Eintauchen nur so

kurz wie möglich an der Oberfläche auf.

Für jede weitere Information können Sie sich

an unsere technische Abteilung unter folgen-

der E-Mail Adresse wenden:

1

1b

2

3

4

5

6

6b

7

8

9

10

11

11b

12

12b

13

13b

14

14b

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

ADESIVO BLU

ADESIVO NERO

MANOPOLA

STAFFA

TA PPO 1°STADIO

ANELLO ELASTICO

FILTRO CONICO INT

FILTRO CONICO DIN

O-RING 2037

BLOCCA STAFFA

O-RING 2043

O-RING 115

RACCORDO VOLANTINO 230 BAR

RACCORDO VOLANTINO 300 BAR

VOLANTINO DIN 230 BAR

VOLANTINO DIN 300 BAR

FERMO VOLANTINO DIN 230 BAR

FERMO VOLANTINO DIN 300 BAT

CAPPELLOTTO

SIGILLO ROSSO

GHIERA REGOLAZIONE

MOLLA TARATURA

PIATTELLO APPOGGIO MOLLA

RONDELLA TENUTA MEMBRANA

MEMBRANA 1°STADIO

PIATTELLO SPINTA

DEFLETTORE FLUSSO PRIMO STADIO

ASTINA GUIDA

CAPPELLOTTO ANTIFREEZE

MEMBRANA ANTIFREEZE

ANELLO ANTIFREEZE INTERMEDIO

FUNGHETTO ANTIFREEZE

O-RING 2031

TA PPO L.P.

CORPO 1°STADIO

O-RING 2056

O-RING 108

TA PPO H.P.

PISTONCINO

BOCCOLA GUIDA PISTONCINO

MOLLA RITORNO PISTONCINO

BOCCOLA FERMO O-RING

O-RING 2012

ANTIESTRUSORE BK 2012

CAMERA BILANCIAMENTO

S810002

S500027

S500025

S810005

S500024

S500029

S500030

S500051

S510021

S810006

S101030

S101023

S810007

S810008

S810009

S810010

S810011

S810012

S810013

S720004

S500046

S500044

S810014

S500040

S500039

S810015

S810016

S500038/B

S810017

S810003

S810018

S810019

S101017

S810020

S810021

S101024

S510022

S810022

S500037

S500037/B

S500037

S500035

S150004

S500034

S810023

BLUE LABEL

BLACK LABEL

HANDGRIP

YOKE

DUST CAP

SNAP RING

INT CONE-SHAPED FILTER

DIN CONE SHAPED FILTER

O-RING 2037

YOKE NUT

O-RING 2043

O-RING 115

DIN HANDWHEEL CONNECTION 230 BAR

DIN HANDWHEEL CONNECTION 300 BAR

DIN HANDWHEEL 230 BAR

DIN HANDWHEEL 300 BAR

DIN HANDWHEEL LOCK 230 BAR

DIN HANDWHEEL LOCK 300 BAR

CAP

RED SEAL

PRESSURE ADJUSTING RING NUT

SETTING SPRING

CAP SETTING SPRING

DIAPHRAGM RETAINER WASHER

FIRST STAGE DIAPHRAGM

THRUSTING CAP

FIRST STAGE FLOW DEFLECTOR

SLIDE STEM

ANTIFREEZE CAP

ANTIFREEZE DIAPHRAGM

INTERMEDIATE ANTIFREEZE RING

ANTIFREEZE THRUSTING HEAD

O-RING 2031

L.P. PORT PLUG

FIRST STAGE BODY

O-RING 2056

O-RING 108

H.P.PORT PLUG

H.P. SEAT/POPPET

H.P. CROWN GUIDE

RETURN SPRING

O-RING LOCK BUSH

O-RING 2012

ANTIEXTRUDER WASHER BK 2012

BALANCING CHAMBER

1

1b

2

3

4

5

6

6b

7

8

9

10

11

11b

12

12b

13

13b

14

14b

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

PRIMO STADIO DIAMOND - DIAMOND ICE DIAMOND - DIAMOND ICE FIRST STAGE

DIAMOND ICE INT 230 SEAC REF. 8210

DIAMOND ICE DIN 230 SEAC REF. 8211

DIAMOND ICE DIN 300 SEAC REF. 8215

DIAMOND INT 230 SEAC REF. 8110

DIAMOND DIN 230 SEAC REF. 8111

3

4

1b

2

5

67

87

32

31 33

34

35

36

37

38

30

39

1

29

27 28

22

21

14

15

16

17

18

19

20

23

24

25

26

7

10

11 9

12

6b

13

12b

11b

13b

14b

SEAC SUB

47

SEAC SUB

46

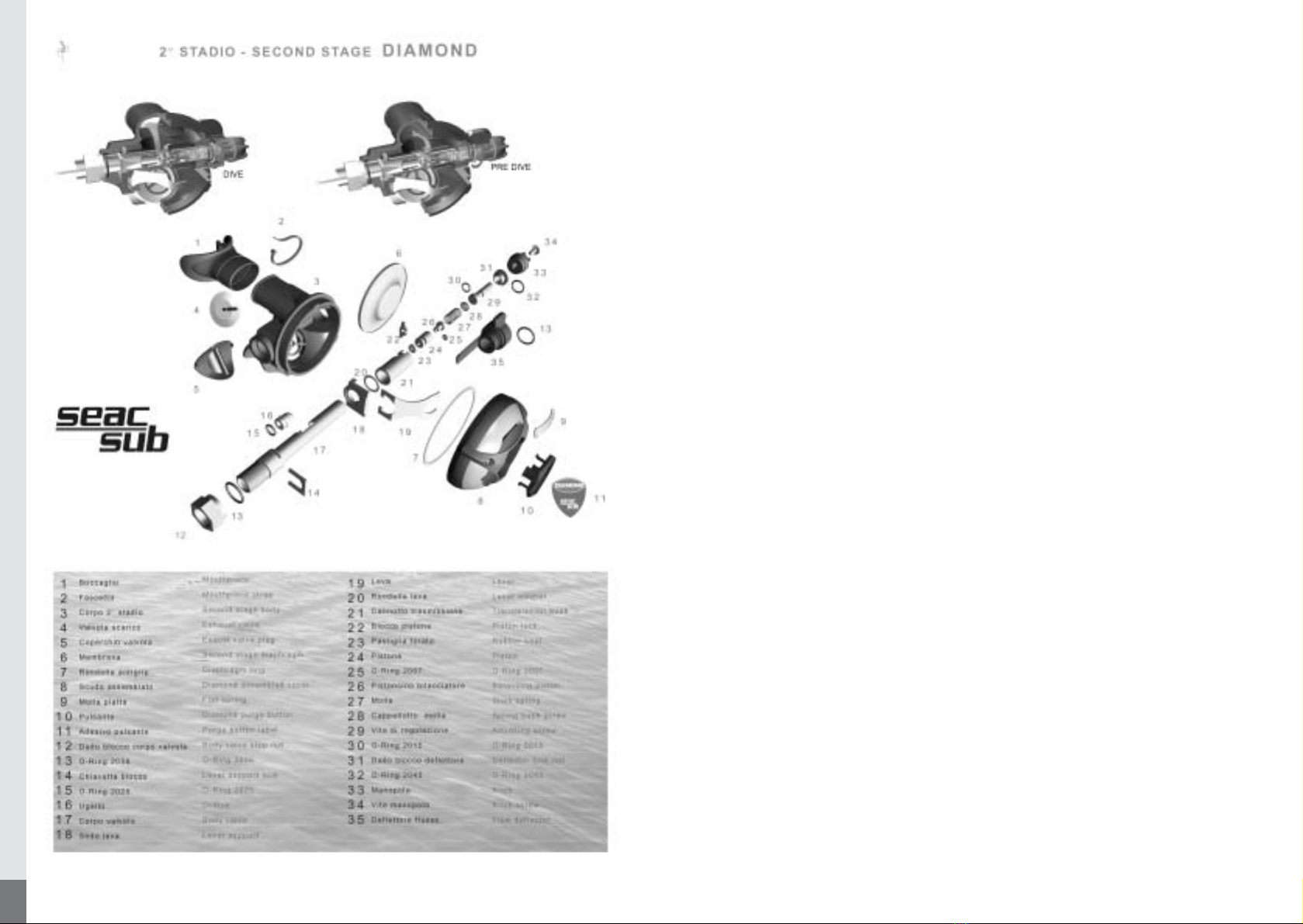

SECONDO STADIO DIAMOND

SECONDO STADIO DIAMOND OCTO

BOCCAGLIO

FA SCETTA

CORPO SECONDO STADIO DIAMOND

VA LVOLA DI SCARICO

COPERCHIO VALVOLA

MEMBRANA

RONDELLA ANTI GRIP

SCUDO ASSEMBLATO DIAMOND

SCUDO ASSEMBLATO DIAMOND OCTO

MOLLA PIATTA

PULSANTE DIAMOND

PULSANTE DIAMOND OCTO

ADESIVO PULSANTE

DADO BLOCCO CORPO VALVOLA

O-RING 2056

CHIAVETTA BLOCCO

O-RING 2025

UGELLO

CORPO VALVOLA

SEDE LEVA

LEVA

RONDELLA LEVA

CANNOTTO TRASMISSIONE

BLOCCO PISTONE

PA S T IGLIA FORATA

PISTONE

O-RING 2007

PISTONCINO BILANCIATORE

MOLLA

BOCCOLA GUIDA MOLLA

VITE DI REGOLAZIONE

O-RING 2015

DADO BLOCCO DEFLETTORE

O-RING 2043

MANOPOLA

VITE MANOPOLA

DEFLETTORE FLUSSO

1

2

3

4

5

6

7

8

8b

9

10

10b

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

1

2

3

4

5

6

7

8

8b

9

10

10b

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

MOUTHPIECE

MOUTHPIECE STRAP

DIAMOND SECOND STAGE BODY

EXHAUST VALVE

EXHAUST VALVE PLUG

SECOND STAGE DIAPHRAGM

DIAPHRAGM RING

DIAMOND ASSEMBLED COVER

DIAMOND OCTO ASSEMBLED COVER

FLAT SPRING

DIAMOND PURGE BUTTON

DIAMOND OCTO PURGE BUTTON

PURGE BUTTON LABEL

BODY VALVE STOP NUT

O-RING 2056

LEVER SUPPORT LOCK

O-RING 2025

ORIFICE

BODY VALVE

LEVER SUPPORT

LEVER

LEVER WASHER

TRANSMISSION BUSH

PISTON LOCK

RUBBER SEAT

PISTON

O-RING 2007

BALANCING PISTON

STEM SPRING

SPRING BUSH GUIDE

ADJUSTING SCREW

O-RING 2015

DEFLECTOR LOCK NUT

O-RING 2043

KNOB

KNOB SCREW

FLOW DEFLECTOR

236

S500023

S812004

S812003

S812005

S770003

S812024

S812060

S812061

S770005

S812028N

S812028G

S812029

S812006

S101024

S812008

S500021

S500016

S812007

S812009

S812010

S812011

S812012

S812013

S812014

S812015

S812017

S812016

S500018

S812018

S812019

23602

S812020

S101030

S812021

S175008

S812023

DIAMOND SECOND STAGE

DIAMOND OCTO SECOND STAGE

1

2

3

4

5

6

7

8

8b

9

10

10b

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

13

SEAC REF. 8120

SEAC REF. 8320

SEAC REF. 8120

SEAC REF. 8320

SEAC SUB

48

S810030

SEAC DIVING PRO srl

Via D. Norero, 29

16040 San Colombano Certenoli (GE), Italy

Tel. +39 (0185) 356301

Fax. +39 (0185) 356300

Info: [email protected]

Web Page: www.seacsub.com

This manual suits for next models

2

Table of contents

Other Seac Sub Diving Instrument manuals