• 1 x operating instructions

• 1 x dehumidifying controller

• 2 x temperature/dampness sensors

• 2 x sensor cables 10 m

• 4 x expansion anchors 6 mm (sensor)

• 4 x assembly screws (sensor)

• 4 x expansion anchors 6 mm (housings)

• 4 x assembly screws (housings)

• 1 x plug

• optional: 1 x interior sensor

• optional: 1 x sensor cable 10 m

• optional: 1 x coupler module

4

• 1 x operating instructions

• 1 x dehumidifying controller

• 2 x temperature/dampness sensors

• 2 x sensor cables 10 m

• 4 x expansion anchors 6 mm (sensor)

• 4 x assembly screws (sensor)

• 4 x expansion anchors 6 mm (housings)

• 4 x assembly screws (housings)

• 1 x power supply (in-wall)

• optional: 1 x interior sensor

• optional: 1 x sensor cable 10 mste

• optional: 1 x coupler module

Electrical connection 220 -240 ~ (power supply unit)

Power consumption (ESG + mains adaptor) <10 W

External connection (oating contact) Max. 1800 W

Protection class Protection class 2

Frost protection (adjustable) ON/OFF (standard ON)

Frost protection temperature (adjustable) 0 – 15 °C (standard 5 °C)

Active period (adjustable) 0 – 60 minutes (standard 10 minutes)

Inactive period (adjustable) 0 – 60 minutes (standard 10 minutes)

Switching dierence (indoors/outdoors) 0.5 g/m³

Operation hours from (adjustable) 0:00 - 23:30 hours

Operation hours to (adjustable) 0:00 - 23:30 hours

Minimum air humidity (adjustable) 0 – 100%

Maximum temperature (adjustable) 0 - 40°C

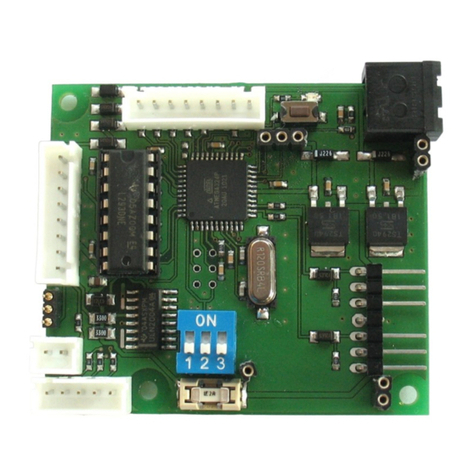

Temperature/Humidity Sensor bx-ESG-TF

Response time 8 seconds

Energy consumption 3.2µW (at 8 bit, 1 metering / s)

Measuring range: relative humidity 0 - 100%

Measuring range: temperature - 40 to 125 °C

Humidity tolerance 2%

Temperature tolerance 0.3 °C

Dimensions (H x L x W) 40 x 64 x 24 mm

Distance between drilled holes 18 mm