Bircher UniScan User manual

1

Testable surface sensor for moving

operation on automatic door systems

Always consider the safety functions of your application as a whole, never

just in relation to one individual section of the system.

The sensor may only be operated in the aluminium profile provided for this purpose.

Parts of the sensor may become hot during operation.

The installer is responsible for carrying out a risk assessment and installing the

sensor and the door system correctly.

Start-up

2.1 Mounting the aluminium profile

Aluminium profile

Sensor (US beam)

nd cap 2x

Front cover

Bearing clamp 2x

Screw terminal

(not visible in figure)

Tran lation of the original in truction

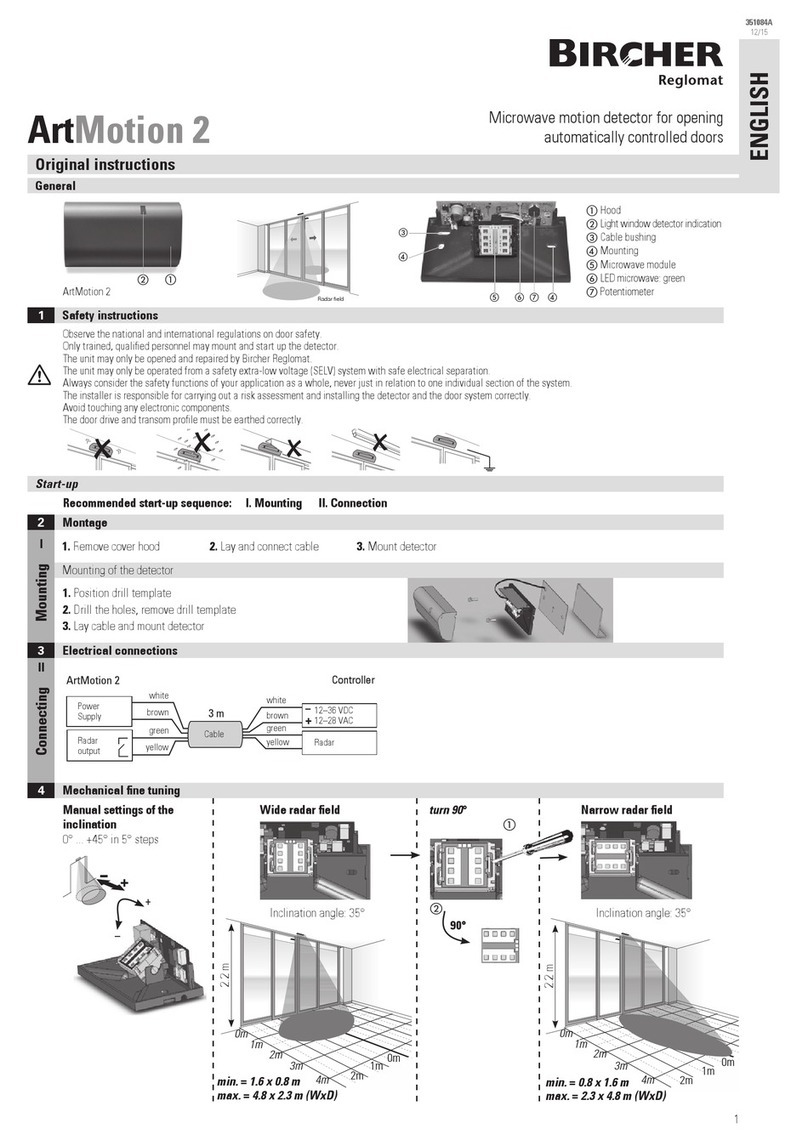

Recommended start-up sequence: I.Mounting the aluminium profile, II. Connect, III. Mounting sensor/cables, IV. Adjusting the angle, V. Initialisation

Safety instructions

1

General

Connect

2.2

2.

Mounting sensor/cables

The start-up procedure below covers virtually all applications. However, you may have need of a particular setting not described here. In this case, please refer to your application

documents and to the table found in chapter 3 of these instructions; alternatively, you can contact our product specialists.

Electrical connection

I

II

III

Observe the national and international regulations on door safety.

Never touch any electronic or optical components of the sensor.

Only trained, qualified personnel may mount and start up the sensor.

The unit may only be opened and repaired by your supplier.

The unit may only be operated from a safety extra-low voltage (S LV)

system with safe electrical isolation.

If the front cover breaks, there is a risk it may shatter.

Mounting the profile

ENGLISH

1

2

3

4

5

6

common

nc

no

Test input

2

2.3 Mounting the optical unit

1. If the profile does not have any mounting holes, make

some in the rear of the profile and mount it so that it is hori-

zontal (use a spirit level). Important: The aluminium profile

must lay flat against the mounting surface.

2. If the front cover has been supplied by metre

and needs to be cut to size, lay it on a flat, clean

surface and cut it using a fine tooth hacksaw,

a metal cutter or a rotary tool (with an appro-

priate attachment), without applying any pressure.

To attach the cover following start-up: 1. remove

protective foil 2. Insert the cover , 3. Click the

cover into place.

1.

3. Affix the end caps after attaching the cover.

Affix the end caps with alignment pins

on the profile side. Optional: Affix the end

caps with screws for reinforced fixation.

Therefore pierce through the drill-hole.

Sensor b must be rotated by 180° and

mounted.

ABCD

2°

2°

14°

2°

14°

2°

2°

14°

2°

14°

b

Rotate by 180°

To do this, rotate the mounting clips on the sensor

(in the sequence A, B, C, D).

2°

2°

14°

2°

14°

2°

2°

14°

2°

14°

b

The buttons red and green on the optical unit must be

mounted onto the corresponding door edge.

Check the function of your entire door system in relation to the applicable safety standards (e.g. N 16005) and U regulations.

Cable to door controller

Notes on wiring:

Wiring according to the requirement of the door system

1. Pull screw terminal out of the sensor to be connected to the door controller

(= master sensor).

2. Perform wiring in accordance with the door controller specifications.

3. Once the plug terminal has been wired, re-insert it into the sensor.

Connection diagram for individual sensors

Attention! Connection scheme is illustrated powered off

In standard relay is powered (passive)

NC = Use connection 5 (NO)

If AC voltage is supplied, only single sensor operation is possible and it is

not allowed to cascade the sensors by ribbon cable. Always use ferrules

when wiring (recommended core cross-section 0.25 mm2).

For a both-sided protection of the door, it is recommended to us the optional

Y-Adapter (288879).

Master/slave wiring

Master/slave wiring using enclosed ribbon cable. A maximum of 3 additional

slave modules can be added in this way.

buttons

256283W

01/17

UniScan

Setting options for parameters and values

2

Example of a sensitivity setting

Notes on setting options:

Adjusting the angle

Initialisation

1. Click sensors and b onto the aluminium profile . Insert the

upper lug of the mounting clips into the upper groove of the profile ,

then click into place.

2. There is space for the cables between the mounting clip

and the profile .

3. Use the ribbon cable to connect the individual sensors

and b (note the narrow and wide grooves, do not use force

to insert the cable).

Setting the inclination angle

2.4

Initialisation of a sensor

2.5

3

To ensure correct functioning, the same angle must be set on the left and

right sides of a sensor.

The position of the detection field 10 is determined by the position of the

US beam in the aluminium profile.

Push the sensor as far as possible to the left or right end of the profile in

order to protect the closing edges.

The inclination angle of each sensor must be selected such that the door stops

BEFORE it comes into contact with an obstacle.

The inclination angle values specified cover 90% of all applications. For special

applications, refer to your application documents.

2–14°

Adjustable

inclination anglel

2° – 14° (3° angle)

5°

5°

5°

8°

2°

2°

14°

2°

14°

A sensor must always be initialised on the master module on each start-up (first initialisation).

Notes on initialisation for special backgrounds:

In the case of special backgrounds (such as a metal grating), place a cardboard on the background in order to ensure faultless initialisation (see the table in chapter 5

relating to background composition parameters).

Nature of the background:

• One of 3 setting options must be selected, depending on the composition of

the ground being used. If the red L D blinks twice and there is no object in the

sensorfield, a special background has to be set:

– Standard

– Very dark and/or reflecting ground

– Metal grating -> A base must be placed over the grating during initialisation

(the sensitivity is then fixed at >= 50 cm). This setting will switch off the

background test and –tracking function.

Synchronisation:

• Synchronisation is active in standard mode and ensures that the sensors will

continue to work faultlessly even if fields overlap.

– Caution: If a US beam (green label) or a R3 (yellow label) is used

together with an older release, synchronisation must be switched off and

overlapping prevented manually (various levels, switch off beams).

Master-initialisation using the «green» key:

«green» key

«green» L D

«red» key

«red» L D

Master-initialisation using the remote control

(RegloBeam 2):

After initialisation, the sensor is ready for operation. Please check the sensor’s detection responses. If they do not meet your

requirements, you can use the sensor’s keys or the remote control to set various detailed configurations and optimise your door

system's functionality (see next chapter).

1. Both the red and green L Ds flash to show that the

initialisation procedure has been triggered. You now

have 6 seconds to leave the detection field.

2. The red L D flashes to show that initialisation is

being performed. Do not enter the detection field.

3. If the L Ds continue to flash as before, please refer

to chapter 4, Troubleshooting.

4. Once both L Ds cease to flash, initialisation

is complete.

Press the «green» key for 5 seconds to trigger the

master-initialisation procedure. Trigger the master-

initialisation only on the sensor which is connected

with the door controller.

Initialisation:

1. Press key «G»

2. Press keys F + 3 + 6 to trigger the

initialisation procedure

3. lock the remote control: F + 3 + 8

The remote control is available as an

optional accessory.

1.Press the «red» and «green» keys for 1 second, -> device located

at parameter 1, «test input».

2.Press the «red» key 3 times -> device moves to parameter 4, «sensitivity»

and indicates a value of 3 (20 cm) by flashing green 3 times

3.Press the «green» key twice -> device indicates a value of 5 (40 cm) by

flashing green 5 times.

4.Optional: xit setting mode by pressing the “red” and “green” keys

for 1 second.

1. Press key «G» on the remote control («3» lights up for the device with address 3, for

example).

2. Press key «D»; key «3» lights up, i.e. the previous value was 3 (20 cm).

3. Press key «5»; a value of 5 (40 cm) is set (key «5» lights up).

Note:

The parameterisation by remote control will be locked after 30 min without operation.

Reactivation: briefly press the green key, switch the supply on/off or enter an actication

code.

Setting using the «red» and «green» keys: Setting using the remote control:

Sensitivity:

• The sensitivity value must be selected on-site in accordance with requirements

(e.g. N 16005).

– The values specified are guide values and relate to the height of the object to be detected.

This will vary depending on the composition of the background and must be checked on-site.

Initialisation:

• The mounting height of the sensors is memorised during initialisation.

– The corresponding specified height is saved in parameter 8 using values 1 – 4 (1 = 1.4 – 1.7 m

approx., 2 = 1.7 – 2 m approx., 3 = 2.0 – 2.4 m approx., 4 = 2.4 – 3.0 m approx.).

Restoring the factory default setting:

•Press both the “red” and “green” keys for 5 seconds until the red ED flashes

rapidly, then release them.

Enhanced levels

Standard mode sets all values to their factory default settings and switches all light beams on.

Power saving mode sets all values to their factory default settings and switches light beams 2, 4

and 6 off.

Narrow groove

IV

V

2°

14°

1.

2. 3.

Wide groove

Upper groove

Sensor clicked into place

door leaf

Remote control Value 1 Value 2 Value 3 Value 4 Value 5 Value 6 Value 7 Value 8 Value 9 Factory default setting

B + Nr.: beam

Displayed and

selected as «on»

or «off» using

keys 1 and 2

B + 1: beam 1

B + 2: beam 2

B + 3: beam 3

B + 4: beam 4

B + 5: beam 5

B + 6: beam6

B + 7: beam 7

B + 8: beam 8

B + 9:

all beams on

Power saving mode

3

Setting options using keys & remote control:

Parameter 2, light points:

Legend for sensor keys and L Ds:

4= Red L D = Red key

%= Green L D = Green key

Value 1: Value 2: Value 3: Value 4: Value 5: Value 6: Value 7: Value 8: Value 9: Notes:

Remote

control 123456789

Sensor

keys

%flashes1x %flashes 2x %flashes 3x %flashes 4x %flashes 5x %flashes 6x %flashes 7x %flashes 8x %flashes9x A number is assigned to

each value

Press 1x Press 1x Press 1x Press 1x Press 1x Press 1x Press 1x Press 1x After value 9, returns to

value 1

Remote cont. Sensor keys

A4Flash 1x High aktive

pull up High aktive

pull down Low aktive

pull up Low aktive

pull down *off – – – –

press 1x

4flashes 2x See tables below for all settings

Cpress 1x

4flashes 3x

Relay active

circuit

*Relay

passive circuit – – – – reboot SW-version –

Dpress 1x

4flashes 4x 10 cm 15 cm 20 cm 30 cm *40 cm 50 cm 70 cm – –

press 1x

4flashes 5x 0 ms 50 ms 200 ms *500 ms 1 s 3 s 6 s 10 s – Relay drop-out delay

F + 1 press 1x

4flashes 6x 12*34567 – – Device address after initi.:

master=3 slave= 4 - 7

F + 2 press 1x

4flashes 7x standard

* Floor:

dark/

reflecting

Floor:

Metal grating

(use a base

when making

settings)

––––––

When making set-

tings for a metal gra-

ting, the sensitivity is

fixed at >= 50 cm

– attend to safety

requirements

F + 3 press 1x

4flashes 8x

Mount. height

1.4 – 1.7 m

approx.

Mount. height

1.7 – 2 m

approx.

Mount. height

2 – 2.4 m

approx.

Mount. height

2.4 – 3.0 m

approx.

Teach-in height

or press the

«red» key for 1 s

Master

initialisation

or press the

«green»key for 5 s

L D-test RegloBeam 2

off

Value 1 – 4 for display

purposes only

F + 4 press 1x

4flashes 9x *synch No synch standby &

synch – –––––Off if release 3 or US

beam is combined with

older devices

F + 8 –Standard

mode

*Power

saving mode ––––––Select enhanced level =

parameters set to factory

default settings

3

6

4

5

StartStart

The setting options available via the remote control and sensor keys differ for parameter 2. Individual beams can be switched off and on using the remote control, whilst light beam patterns can be set using the «red»

and «green» keys. If light beams are switched on or off, the «height teach-in» function must be executed. With sensitivity levels 6 and 7, the sensor only has access to 7 light beams; beam 8 is deactivated.

2Light beams

Sensor keys Value 1: Value 2: Value 3: Value 4: Value 5: Value 6: Value 7: Value 8: Value 9:

After parameter 1,

press 1x Press 1x Press 1x Press 1x Press 1x Press 1x Press 1x Press 1x Press 1x

4flashes2x %flashes1x %flashes 2x %flashes 3x %flashes 4x %flashes 5x %flashes 6x» %flashes7x %flashes 8x %flashes 9x Factory default

setting

Display of

special pattern

Power saving mode

2Light beams

Parameter 2 using the remote control

Parameter 2 using the «red» and «green» keys

Setting mode using keys:

Press the red and green keys for at least 1 s.

xit by pressing red and green again for 1 s.

Setting mode using remote control:

Press key G

Set

value

Select

parameter

1.

2.

1Test input

2Light beams

3Output

4Sensitivity

5Relay hold

interval

6Device

address

7Nature of the

background

(ground)

8Initialisation

9Synchronisa-

tion mode

nhanced levels

(via remote

control only)

Factory default setting *As-delivered condition

Key 1 = on

Key 2 = o

Key 1 = on

Key 2 = o

Key 1 = on

Key 2 = o

Key 1 = on

Key 2 = o

Key 1 = on

Key 2 = o

Key 1 = on

Key 2 = o

Key 1 = on

Key 2 = o

Key 1 = on

Key 2 = o

Note: If parameters are changed, an initialisation procedure must always be performed on the corresponding sensor module.

DIN 18650 DIN 18650 DIN 18650 DIN 18650

DIN 18650 DIN 18650 DIN 18650 DIN 18650 DIN 18650 DIN 18650

DIN 18650 DIN 18650

= Fulfills DIN 18650 installed moving

DIN 18650

Symptom Possible cause Remedy

The red L D flashes 8 times after

initialisation

- The detection field was not empty during initialisation

- The bearing clamps are not mounted correctly in the profile

- The bearing clamps are set to different angles on the same sensor

- Reflecting background or metal grating

- Carry out the initialisation again

- Click the bearing clamps into the profile correctly

- Set the bearing clamps to the same angle

- Select a different background

The red L D flashes continuously - Faulty ribbon cable - Replace the ribbon cable

The red L D flashes twice - Dark or reflecting ground

- Object in the detection field (no fault) - Set parameter 7 to «dark / reflecting»

The door does not open or close

although nothing has been detected

- The test input has not been activated or an incorrect version has been

activated

- Make sure that the test input has been activated

- Set the correct relay output in accordance with the door

controller (see page 3, test input))

Master initialisation does not work, the

red L D flashes 4 times - Use of AC voltage - Convert the sensors to a DC supply

Not all sensors react when carrying out

the master initialisation

- Use of AC voltage

- Connection interrupted along the ribbon cable

- Convert the sensors to a DC supply

- Insert the ribbon cable correctly or replace it

No reaction from the doors, although

detection is taking place

- Initialisation has been carried out on a sensor that is not directly

connected to the door controller or to the Y adapter

- Carry out initialisation on the sensor that is directly

connected to the door controller

The sensor functions without the cover

but not with it

- The angle of the bearing clamps has changed

- The cover is of poor quality (has coarse grooves)

- Sensitivity too low

- Check the angle of the bearing clamps

- Replace the cover

- Increase the sensitivity

The red L D flashes 4, 5, 6 or 7 times

- Use of AC voltage

- Configuration error (sensors have been swapped following master

initialisation)

- Sensors have been incorrectly initialised or not initialised at all

- Self-test failed, triggered unexpectedly

- Convert the sensors to a DC supply

- Carry out the initialisation again

- Carry out initialisation on the master (sensor on the door

controller)

- Carry out the initialisation again

Both L DS (red and green) are lit

permanently

- Supply voltage is not stable enough

- Supply voltage is too low

- Voltage break

- Isolate the sensor from the supply

- Check the power supply

- Switch the supply on again

Detection sometimes takes place whilst

the door panels are moving

- If the floor is very uneven and the door moves, this may lead to

detection

- Incorrect background parameters have been selected

- Reduce the sensitivity

- Select the correct background parameters

- Set a different angle (ensure safety requirements are met)

Incomprehensible response to a

cascade of several devices, red L D

flashes once

- Various sensor releases have been used

(release 2, release 3 and US beam sensors)

- Only use US beam and/or release 3 sensors

- For US beam or release 3 sensors, switch synchronisa-

tion off and manually prevent any overlap

The red L D flashes 10 times - Loss of power during parameterisation (memory error) - Carry out initialisation on the master (sensor on the door

controller)

The green L D on the slave module

lights up permanently - The master is in standby mode and the slave is not. Only the slave

was reactivated.

- Reactivate master using door activation

- Carry out initialisation on master

(sensor on door controller)

- Check test input (parameter 1)

- Activate synchr. on all sensors (parameter 9)

- Replace ribbon cable if necessary

Troubleshooting

4

Technical data

5

Declaration of conformity, identification of the year of manufacture by means of the serial number

6

7Contact

Bircher Reglomat AG

Wie enga e 20

CH-8222 Beringen

www.bircher-reglomat.com

Technology Active infrared (triangulation)

Wavelength 880 nm

Number of IR beams 8, can be switched separately, synchronized

Dimensions of an IR beam 30 mm x 60 mm at 2.2 m mounting height

Detection zone, dimensions 471 mm x 60 mm at 2.2 m mounting height

Response time < 50 ms

Mounting height 1.7 – 3.0 m, depending on the background

Angle setting 2° – 14°, set in increments of 3°

Installation length in the profile 300 mm incl. mounting clips

Power supply 15 – 37 VDC/ 15 – 26 VAC, AC independently

Power consumption Max. 3.3 W, 0.17 W per beam

Making current < 500 mA

Test input 4 versions (high/low active, pull up/down

Output Change-over relay, max. 40 VDC/40 VAC, 1 A

Hold intervals 0 – 10 s (adjustable)

Operating temperature -20 °C bis 60 °C

Type of protection IP54 suitable

Remote control range 5 m

Number of devices that can be in-

terconnected 4 units, synchronized

Application Stationary/moving presence detection

Functional safety level SIL2

4

Identification of the year of manufacture by means of the serial number

6.2

Green label:

Position of the green label on the US beam sensor:

Year of

manufacture Week

Note: Carrying out master initialisation or switching the operating voltage off/on will reset an error.

Bircher Reglomat AG, Wiesengasse 20, CH-8222 Beringen

MD 2006/42/ G, RoHS 2011/65/ U, MC 2014/30/ U

44/205/12/413806-001

TÜV NORD C RT, NB 0044

6.1 EC-Declaration of conformity

Manufacturer:

Following directives have been observed:

C type-examination certificate:

Notified inspection centre:

Product variant: Usbeam, UniScan

Danish seller

Swissdoor ApS

Stenhuggervej 2

DK-5471 Soendersoe

www.swissdoor.dk

Tlf.: +45 86 28 00 00

Table of contents

Other Bircher Accessories manuals