Bircher Swissdoor RFGate 3.2 User manual

1

12

ON

12

ON

ON

1 2

ON

1 2

ON

1 2

RFGate 3.2

7544

121

24

106

50

121

23

106

22

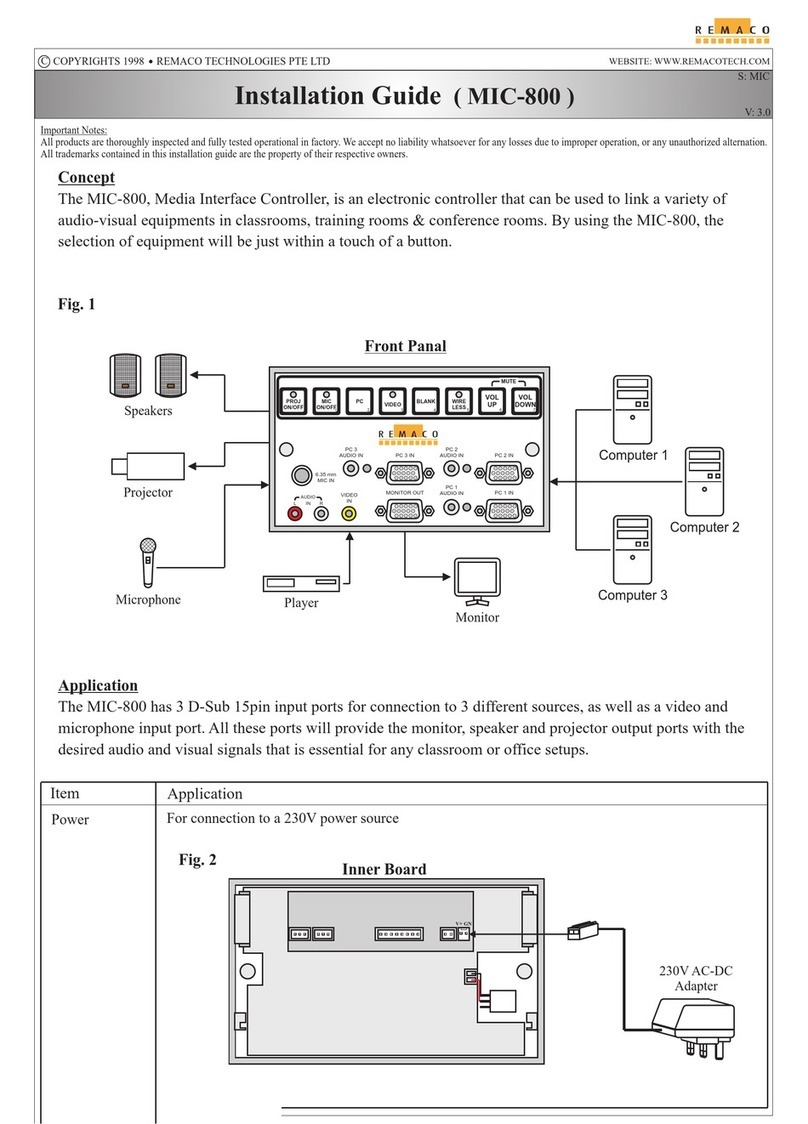

Wireless dual channel signal transmission system for safety edges

Original operating instructions

General

1Safety instructions

2Common application

2.2 Industrial door

ENGLISH

370052A

05/18

TransmitterReceiver

Warning: Switch off the operating voltage before working on the

system. Only trained, qualied personnel may perform installation

and startup. The unit may only be repaired by the manufacturer. The

switching unit may only be used to protect against dangers on

crushing and shearing points and on automatic industrial doors and

gates (intended use). National and international regulations on

industrial door and gate safety must be complied with. Always

Transmitter

Contact

Receiver

Safety edge

Mobile safety edges

Receiver

TransmitterTransmitter 1 Transmitter 2

DIP switch 2 OFF

Transmitter 2 Transmitter 1

Safety edge

8.2 kOhm

Contact

(e.g.wicket door)

consider the safety functions of your application as a whole, never just in

relation to one individual section of the system. The installer is responsible

for carrying out a risk assessment and installing the industrial door system

correctly.

i

Battery life up to 2 years, but it is recommended

batteries are changed every 12 months.

Receiver Receiver

Safety edge

8.2 kOhm

not used not used

Safety edge

8.2 kOhm

DIP switch 2 ON

2.1 Sliding gate

Transmitter input 1 corresponds to receiver output 1

Transmitter input 2 corresponds to receiver output 2

i

Transmitter 1 (input 1) corresponds to receiver output 1

Transmitter 2 (input 1) corresponds to receiver output 2

i

Further transmitters with separate manuals

Batteries

CR2032

Push

button

Push

button

2

i

i

1 2

ON

1 2

ON

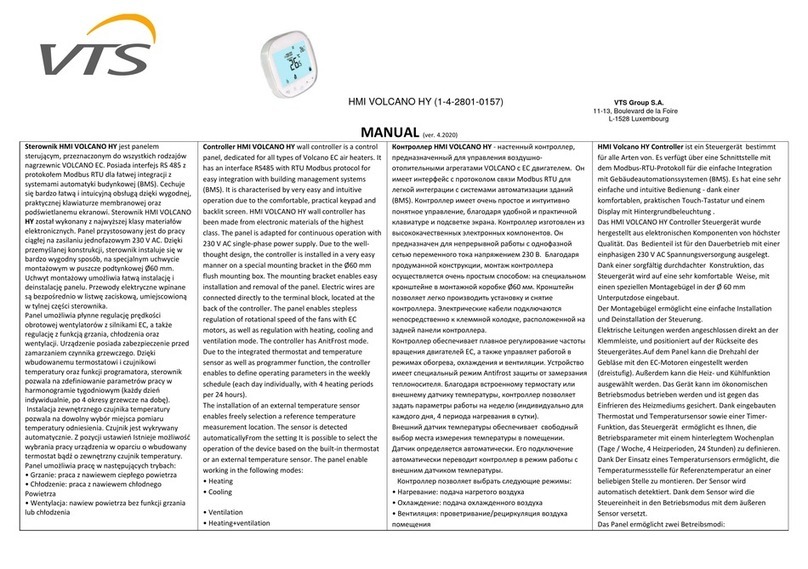

IN1

IN2

8k2

IN1

IN2

34 5 6

(7) (8) (9) (10)

8k2

12 3 456

(7) (8) (9) (10)

J1F1

1k2

3 456

(7) (8) (9) (10)

J1F1

1k2

4.2 DIP switches

4.3 Cable routing, strain relief

3.1 DIP switch setting according to sensor (safety edge, switch contact)

4Receiver

3Transmitter

1 2

ON *Transmission frequency

869.525 MHz

1 2

ON 868.15 MHz

*= factory setting

12

ON *Programming at 1-ch transmitters

Transmitter 1 corresponds to output 1

Transmitter 2 corresponds to output 2

12

ON Programming at 2-ch transmitters

Input 1 corresponds to output 1

Input 2 corresponds to output 2

*= factory setting

Power supply Outputs: Relay contacts are shown unpowered Conductor cross section 0.25 – 0.75 mm2

4.1 Wiring: Power supply and outputs with control

Control unit with

NC input

Control unit with

1.2 kOhm NC input

12–36V

AC/DC

+/~ –/~

Control unit with

8.2 kOhm input

Example: RFGate 3.2.T

Sensor connection DIP switch Sensor connection DIP switch

Further instructions see separate transmitter manuals.

Determine the cable routing

Break out the corresponding part of the cover if necessary

Punch hole into the grommet

Thread cable

Fix cable with the clamp (➔strain relief)

Cable Ø: 3.1 – 5.2 mm

… or use holes

in the base plate

Break out …

Hint:

Remove J1!

3

1 2

ON

1 2

ON

i

ON

OK?

2x

12

ON

2x

2x

12

ON

*

*

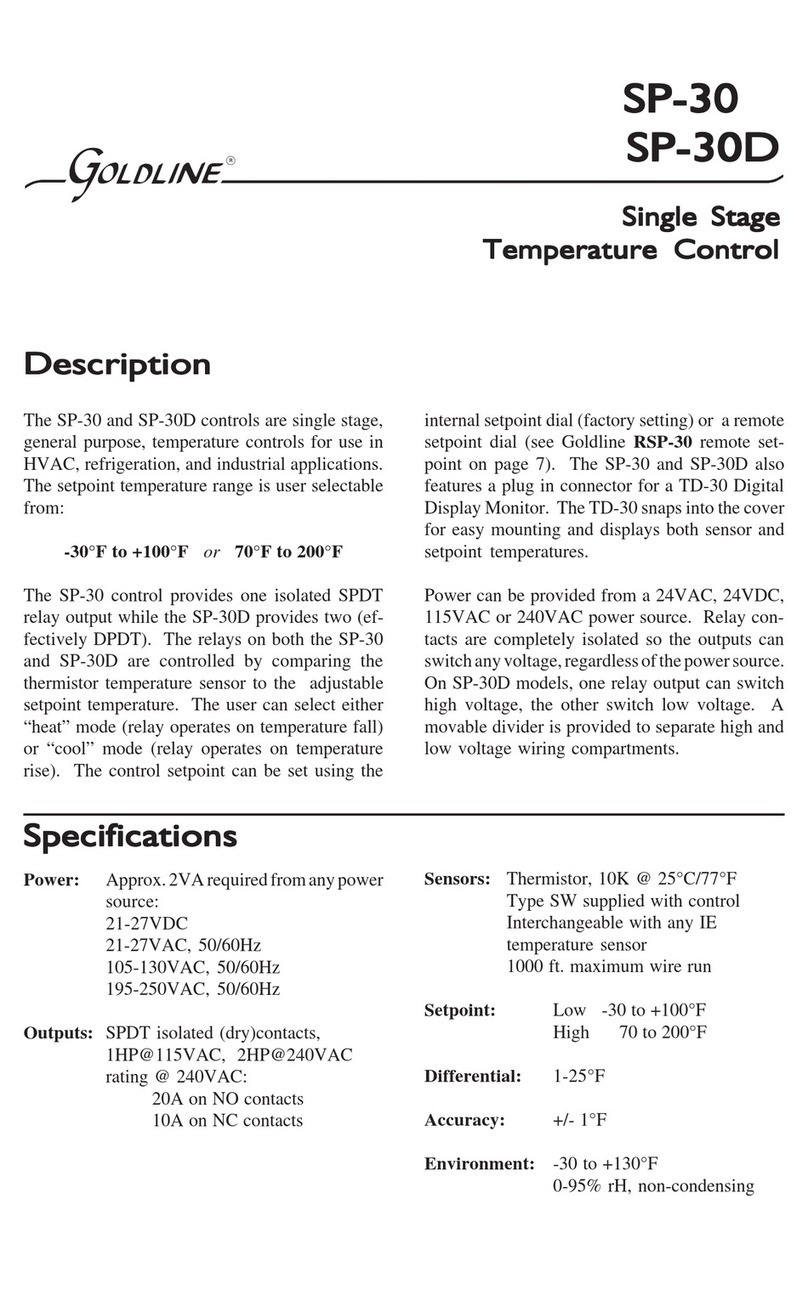

6.1 Pairing transmitter with receiver (using the rst channel of dierent transmitters) according to application 2.1

5Installation sequence set-up

6Programming

2.

On the

transmitter

Press and release button Beep Wait 2 beeps

10 sec.

1.

On the receiver

Press

button

Beep LED

lights up

6.

Transmitter:

install

Release

button

4.

Transmitter:

insert

batteries

1.

Check DIP

switch settings

5.

Pairing (Chapter 6):

transmitter with receiver

Transmitter and receiver and

further transmitters must be at

least 0.5 m apart

Code saved

LED goes out

7.

Transmitter:

wire

3.

Turn on power

supply

2.

Install and wire

receiver

8.

System test: press

safety edge on gate or

door

6.2 Pairing transmitter with receiver (using both channels of the transmitter) according to application 2.2

2.

On the trans-

mitter for

channel 1

On the

receiver

On the

receiver

On the

receiver

Press and release button Beep Wait 2 beeps

10 sec.

4.

On the trans-

mitter for

channel 2

Press and release button Beep Wait

10 sec.

3.

On the receiver

Beep BeepRelease

button

Release

button

LED orange

lights up

LED orange

lights up

Press

button

Press

button

1.

On the receiver

Press

button

Beep

LED 1 LED 2

LED 1

LED orange

lights up

Release

button

2 beeps

Code saved

Code saved

Beep

Beep

Beep Beep

Beep

Beep Beep

Beep

BeepBeep

* Quality of

the radio connection

1 beep: strong signal

2 beeps: good signal

3 beeps: medium signal

* Quality of

the radio connection

1 beep: strong signal

2 beeps: good signal

3 beeps: medium signal

*

4

2x

3x

OK?

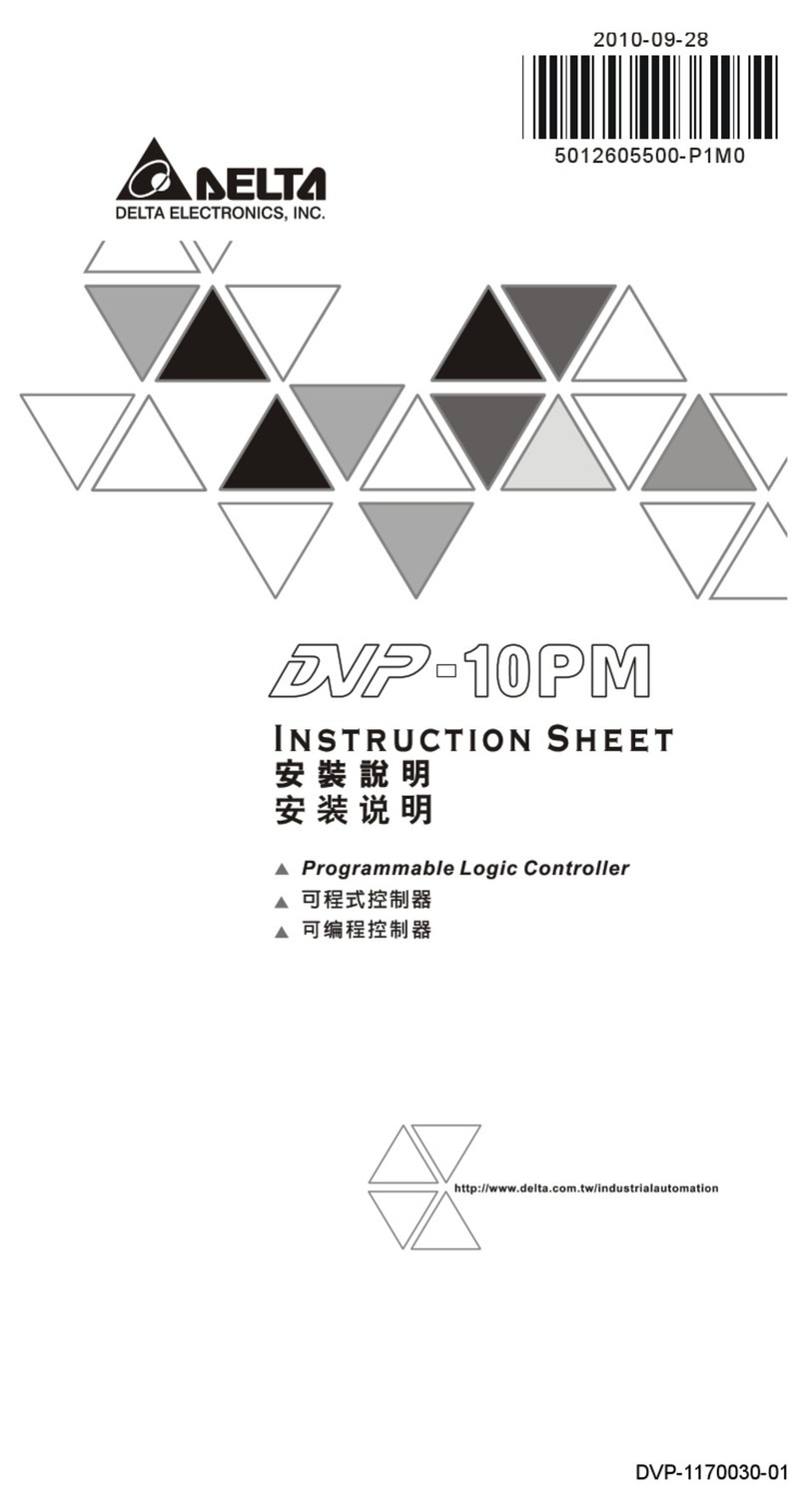

7Standard operation

9Technical data

8Optional cover xation (against vandalism)

10 EU Declaration of Conformity

12 Contact

7.1 Receiver LED indicators 7.2 Warning indicator for low battery voltage

Input

actuated

LED red

LED 2LED 1

Receiver: 3 beeps every minute

To nd out which transmitter has low

battery voltage:

Press each edge. A beep indicates the low

battery.

Safety

OK

LED green

Battery voltage

low

6.3 Clear pairings

6.4 Memory full

Press button

and keep pressed

Short beepsBeep WaitRelease

button

10 sec.

2 beeps

Beep 10 sec.

Receiver

Supply voltage 12–36 V ACDC

Transmitter memory 7 per channel

Outputs 2x 2 relays 24 V, 0.5 A

Power consumption 0.5 W @ 12 V; 1.2 W @ 24 V

Standard transmitter

Battery power 2x Lithium 3 V Type CR2032

Power consumption Transmitting: 17 mA standby: 16 µA

System

Frequency bands 869.525 MHz & 868.15 MHz

Range Under optimum conditions up to 100 m

Protection class

IEC 60529

IP65

Working temperature –20 °C to +55 °C

On the receiver All pairings

deleted

Beep

Beep

Beep Beep Beep

Beep Beep

Beep

See attachment

Drill a hole (Ø 3.5 mm) at the marked

position

Close the cover

Tighten the screw (3.5 mm x 8 mm

self-tapping,T15) enclosed

To avoid the cover removal without tools:

Use screw to attach the cover.

11 WEEE

Devices with this symbol must be treated separately during disposal. This must be done in accordance with the laws of

the respective countries for environmentally sound disposal, processing and recycling of electrical and electronic equipment.

At power on,

or when program

button is pressed

Bircher Reglomat AG, Wiesengasse 20, CH-8222 Beringen, www.bircher-reglomat.com | Swissdoor ApS, Stenhuggervej 2, 5471 Søndersø, www.swissdoor.dk