BISOL BIPV User manual

The sunny side of life!

EN

General Information

Installation Manual

BISOL BIPV MODULES

AND MOUNTING STRUCTURE

2Installation Manual: BIPV Modules

We want to congratulate you for purchasing BISOL BIPV solar modules and express our most sincere gratitude for using products that

are high energy ecient and designed for long-term high-performance use. It is our pleasure and delight to know that we have been

able to full your expectations with our high-quality materials processed on state-of-the-art automated production line.

We are proud of our products, and we are proud of you as our BISOL ambassador.

BISOL Team

Before starting the installation of BISOL BIPV solar modules, carefully read this entire installation manual.

This manual contains important information about safety, installation, wiring, operating, maintenance and

similar.

If any further information is necessary, please consult your module dealer or the manufacturer directly.

Failure to follow these instructions may result in material damage and can in worst case jeopardize life

safety and health.

Store this manual in an easy reachable place.

THANK YOU!

!

4

Installation Manual: BIPV Modules

3Installation Manual: BIPV Modules

5 INSTALLATION ..................................................................................................................................................... 29

5.1 Checking the Requirements ........................................................................................................................... 29

5.1.1 Roof Plan and String Plan .............................................................................................................................. 29

5.1.2 Limit of Application....................................................................................................................................... 29

5.1.3 Safety at Work .............................................................................................................................................. 29

5.1.4 Checking the Content of the Shipment............................................................................................................ 30

5.2 Tools .................................................................................................................................................................. 30

5.3 Mounting .......................................................................................................................................................... 30

5.3.1 Preparing the Roof........................................................................................................................................ 30

5.3.2 Calibrating and Placing the Substructure........................................................................................................ 32

5.3.2.1 Mounting the Solrif ® Battens....................................................................................................................... 33

5.3.3 Determining the Reference Point and Perpendicularity of the PV Array ............................................................ 35

5.3.4 Mounting the Lead Flashing........................................................................................................................... 36

5.3.5 Laying Cable Conduits, Connection Cables and Cable Strings ............................................................................ 37

5.3.6 Marking the Horizontal Positions of the Mounting Clamps Prole..................................................................... 38

5.3.7 Laying the Bottom Row of Modules ................................................................................................................ 39

5.3.8 Laying the Remaining PV Array ...................................................................................................................... 44

5.3.9 Top of the Array............................................................................................................................................. 50

5.3.10 Finishing Process......................................................................................................................................... 53

6 MAINTENANCE....................................................................................................................................................... 56

6.1 Maintenance Plan............................................................................................................................................ 56

6.2 Replacing Modules........................................................................................................................................... 57

7 DEINSTALLATION AND DISPOSAL...................................................................................................................... 57

8 ADDITIONAL INSTRUCTIONS.............................................................................................................................. 58

8.1 Rules for Mounting Battens............................................................................................................................ 58

9 FURTHER INFORMATION..................................................................................................................................... 59

TABLE OF CONTENTS

1 GENERAL INFORMATION .......................................................................................................................................6

1.1 Information on this Manual..............................................................................................................................6

1.2 Exclusion of Liability..........................................................................................................................................7

1.3 Guarantee Conditions........................................................................................................................................8

1.4 Customer Service and Product Monitoring .....................................................................................................8

2 SAFETY REQUIREMENTS........................................................................................................................................8

2.1 Introduction .......................................................................................................................................................8

2.2 Responsibility.....................................................................................................................................................8

3 INSTALLATION MANUAL........................................................................................................................................9

DESCRIPTION OF THE BISOL BIPV MODULES WITH SOLRIF® INROOF MOUNTING SYSTEM................................9

3.1 BISOL BIPV Modules with Solrif® In-roof Mounting System Overview.........................................................9

3.2 Components....................................................................................................................................................... 10

3.2.1 BISOL BIPV Module with Solrif® Frame............................................................................................................ 11

3.2.2 Dimension of PV Array and Module Mounting Pitches...................................................................................... 12

3.2.3 Substructure................................................................................................................................................. 15

3.2.4 Mounting Clamps.......................................................................................................................................... 16

3.2. Flashing Proles ............................................................................................................................................. 18

3.2.6 Side Flashings ............................................................................................................................................... 18

3.2.7 Bottom of PV-Array: Lead Flashing, Wedge Plank, Sealing Tape Strip ................................................................ 20

3.2.7.1 Lead Flashing............................................................................................................................................. 21

3.2.7.2 Wedge Plank .............................................................................................................................................. 21

3.2.7.3 Sealing Tape Strip ...................................................................................................................................... 23

3.2.8 Connection Cables, Cable Strings .................................................................................................................... 23

3.2.9 Grounding and Lightning Protection .............................................................................................................. 24

3.2.10 Mounting Screws for Battens........................................................................................................................ 25

3.2.11 Other Accessories......................................................................................................................................... 25

3.2.11.1 Fixing for Flashing.................................................................................................................................... 25

3.2.11.2 Protective Proles .................................................................................................................................... 26

3.2.11.3 L-Section to Support the Bottom Row of Mounting Clamps................................................................................ 26

3.3 Technical Data/Limit of Application............................................................................................................... 27

4 TRANSPORTATION................................................................................................................................................. 28

4.1 Transportation in Packaging .......................................................................................................................... 28

4.2 Transportation of Individual Modules........................................................................................................... 28

6

Installation Manual: BIPV Modules

5Installation Manual: BIPV Modules

1 GENERAL INFORMATION

Notice

BISOL BIPV INSTALLATION MANUAL is the summary of installation manual with title:

Solar Energy Systems by Schweizer: Installation Manual – Photovoltaic In-Roof Mounting

System Solrif®.

All information provided (including pictorial material) is owned by the Ernst Schweizer AG.

BISOL BIPV INSTALLATION MANUAL is specically modied for BISOL BIPV modules and

mounting structures owners only.

1.1 Information on this Manual

This manual describes the procedure for the in-roof mounting of BISOL BIPV modules as well as for replacing BISOL BIPV modules

with Solrif® in-roof mounting system. With in-roof mounting, the PV array substitutes any existing tile roong. However, tile

roong remains around the PV array. In addition, this manual provides instructions on the maintenance of BISOL BIPV modules

with Solrif® in-roof mounting system and their disposal.

Supplementary Documents

Delivery note with article numbers and description of all components delivered.

Limit

• The installation of full-roof PV systems (the roof is covered completely with photovoltaic modules or dum my modules, no

tiles are left on the roof) is possible, but is not the subject of this installation manual.

• For connection of the PV array to the inverter, please refer to the inverter supplier’s documentation.

This manual is intended for craftspeople who have completed their vocational training in the roong trade. Furthermore, the

craftsman must also have acquired either an additional qualication for the installation of photovoltaic systems or have many

years of experience in the installation of photovoltaic systems. With regard to adhering to maintenance procedures, this manual

is also directed at the operator of the photo voltaic system.

Before carrying out any work, the implementing or supervising person must:

• Read this manual carefully and understand it, or clarify any ambiguity with the system’s planners.

• Instruct assisting personnel according to this manual and supervise them during the entire work process.

The installation company must:

• Keep this manual to hand during the entire work procedure on the building site.

• After the installation work has been completed: hand over this manual to the system operator.

The system operator must:

• Store this manual and the delivery note with the rest of the system documentation.

• Observe the instructions on system maintenance.

• Make this manual and any further relevant documentation available to the specialist personnel who have been commissioned

to carry out the maintenance, repair or deinstallation work and enclose them with the documentation for the photovoltaic

system again after the work has been completed.

The seller of the system or of the building on which it is installed must:

• Pass on this manual to the new operator as part of the system documentation.

Further applicable documents, regulations and provisions

• Apart from this manual, please observe the module pitch plan and the string plan, the relevant safety regu lations, particularly

those for working on a roof and for handling electrical currents, as well as the documentation for the other components in

the photovoltaic system.

• In the event of discrepancies or other ambiguity, clarify these through the system’s planners.

Diagrams in this manual are intended to aid fundamental understanding and show the example of a 3x3-array. The

implementation for the actual design must be analogous to this example portrayed here.

1.2 Exclusion of Liability

BISOL Production Ltd. as a manufacturer of BISOL BIPV photovoltaic modules takes no responsibility for the design solutions of

individual designers nor for Solrif® system solutions, which as such are a product of Ernst Schweizer AG, all in connection to the

installation of photovoltaic modules with Solrif® system.

The information and safety instructions in this manual have been compiled taking into account the currently applicable norms,

guidelines and regulations, the latest technology and the long years of experience gathered by BISOL Production Ltd. and Ernst

Schweizer AG.

The shipment contents, or the design of the system, can deviate from the descriptions and diagrams specied in this manual

because of optional items ordered, manufacture of customised designs or the latest technological changes.

This manual’s publication date shall apply. BISOL Production Ltd. reserves the right to update this manual in the light of technical

changes to the system as part of further development to improve performance characteristics and safety. The most recent

version of this manual is published on ocial website www.bisol.com.

BISOL Production Ltd. accepts no liability for damages and accidents that may arise in particular from the following causes:

• Inappropriate use of the mounting system

• Non-observance of the information and instructions in this manual

• Work carried out on or with the system by non-qualied or unauthorised personnel

• Mounting of non-original spare parts

• Unauthorised modications

8

Installation Manual: BIPV Modules

7Installation Manual: BIPV Modules

1.4 Customer Service and Product Monitoring

For problems and questions that cannot be solved with the aid of this manual and/or on consultation with the planner, as well

as for technical information:

• Please contact the customer service of the BISOL Production Ltd or of Ernst Schweizer AG. Above and beyond customer

service, BISOL Production Ltd is interested in experiences that arise from dealing with the system with the objective of

constantly improving the system.

• In the event of problems when dealing with the system, interruptions in operation and any errors that occur, please contact

BISOL Production Ltd using the contact data in the footer.

2 SAFETY REQUIREMENTS

2.1 Introduction

Installation of the device may only be carried out by authorized personnel and industry experts who are familiar with all the latest

international and local guidelines for the installation of PV products. Non-observance of the safety requirements instructions

and safety and warning notices specied in local legislation and guidelines can lead to considerable dangers.

2.2 Responsibility

As customer/operator:

Only commission specialist rms which oer guarantees for the professional and safety-oriented work execution with the

planning of the system and the execution of the installation, maintenance, repair and deinstallation work.

As employer of the rm executing the work:

Ensure that all work is carried out or supervised by suciently qualied specialist personnel, roong jobs by roofers, AC/DC

cabling by electricians. Ensure that at least two persons are present on the construction site at all times while work is being

conducted.

Ensure that instructed personnel/assistant personnel were instructed suciently on safety-oriented work on the roof and is

supervised during the entire work process. Also observe the country-specic accident prevention regulations of the respective

trade associations (in Germany: BGV A1 – Principles of Prevention BGV A3 – Electrical Plant and Equipment, BGV C22 –

Construction Work).

Ensure collective protection (scaoldings, roof guard rails) in accordance with the current regulations (installation of photovoltaic

systems on roofs is only permissible with collective protection).

Ensure that all personnel that carries out work on the photovoltaic system or supervises such work has read and understood this

manual, that assistant personnel were instructed suciently and is supervised during the entire work process.

1.3 Guarantee Conditions

BISOL BIPV photovoltaic modules are subject to the Standard Limited Guarantee (SLG) terms and conditions, which are published

on the ocial website www.bisol.com.

Supply your personnel with personal protective equipment (PPE) in accordance with the current regulations for roof work and

enforce the correct use of PPE. Before installing the system, ensure that the roof substructure (rafters, roof battens) corresponds

to national regulations in terms of both quality and load-bearing capacity.

As the person executing or supervising the work:

Only tread onto the roof if the conditions for working safely are fullled. Instruct assisting personnel on all safety-relevant

aspects and supervise them during the entire work process.

The employer in the rm executing the work must ensure that the requisite safety measures have been taken to prevent falls.

The system operator must:

Observe the maintenance intervals stipulated in this manual.

For other information on safety regulations, you can also see:

Installation Manual – General Information at www.ernstschweizer.ch.

3 INSTALLATION MANUAL

DESCRIPTION OF THE BISOL BIPV MODULES WITH SOLRIF® INROOF MOUNTING SYSTEM

3.1 BISOL BIPV Modules with Solrif®

In-roof Mounting System Overview

Figure 1: BISOL BIPV modules with Solrif® in-roof mounting system overview

10

Installation Manual: BIPV Modules

9Installation Manual: BIPV Modules

General Components Overview

1Lead flashing, wedge plank, sealing tape strip

2Fixing for flashing

3Mounting Clamp (Profile/Glass)

4Wood screws with pan head 4.5 × 35

5Flashing side left

6Flashing profile left

7Solrif® batten 120×30 mm²

8Tiling battens

9Flashing side top left

10 Flashing top left

11 BISOL BIPV with Solrif® frame

12 Protective profile

13 Flashing top middle

Notice

Measurements that are taken from the left-hand edge of the PV array towards the right, meaning

horizontally, parallel to the eaves or to the roof ridge, will henceforth be referred to as “width.”

Measurements that are taken from the eaves towards the roof ridge, parallel to the verge, will henceforth

be referred to as“height.”Measurements that are taken perpendicular to the roof surface will be referred

to as “thickness.” The largest measurement of a component before installation will be referred to as

“length” irrespective of its orientation after installation. These descriptions can deviate from those in

your supplier’s data sheet, for example, the measurement of the longer side of the module can be

described as “length” and that of the shorter side as “width,” irrespective of the module’s orientation

after installation.

3.2 Components

3.2.1 BISOL BIPV Module with Solrif® Frame

Figure 2: BISOL BIPV module with Solrif® frame overview

BISL BIPV Components Overview

1BISOL BIPV laminate

2Solrif® frame profiles

3Backsheet or glass

4Connection cables with connectors

5Junction box

The frames of modules placed side by side interlock. The modules that are installed above overlap the modules below them

(like roof tiles). A rubber lip in the upper prole seals between the two modules. Thus the photovoltaic modules form the water-

proong layer on the roof. Hence for roof slopes > 10°, rainproof integration into the roong is possible in accordance to ZVDH

regulations (Central German Roong Industry Association).

• Only use a BISOL BIPV module within one PV array.

12

Installation Manual: BIPV Modules

11 Installation Manual: BIPV Modules

3.2.2 Dimension of PV Array and Module Mounting Pitches

Figure 3: Layout of the module pitch (3 modules BISOL BIPV’s inserted)

Figure 4: Details

Figure 5: Horizontal cross-section

Figure 6: Vertical cross-section

14

Installation Manual: BIPV Modules

13 Installation Manual: BIPV Modules

General Components Overview

1Fkashing side left

2Flashing profile left

3BISOL BIPV module

4Flashing profile right

5Flashing side right

6Wedge plank

7Mounting Clamp Profile

8Flashing top

LBWidth of the laminate

LHHeight of the laminate

MBWidth of a single framed module = L_B + 50

MHHeight of a single framed module = L_H + 32

Rhor

Rhor Horizontal module mounting pitch (distance of any reference point on the module to the same point on the module

mounted beside it to the right or left) = MB– 18

Rver

Rver Vertical module mounting pitch (distance of any reference point on the module to the same point on the module

mounted above or below it) = MH– 32

Nhor Nhor Number of modules laid out side by side in the PV array

Nver Nver Number of modules laid out above each other in the PV array

BGR Width of the PV array between the ashing sides = (Nhor × Rhor) + 42

BGL BGL Width of the PV array including the ashing sides = (Nhor × Rhor) + 284

HG

HG Height of the PV array between the lower edge of the bottom mounting clamp and the upper edge of the top mounting

clamp = (Nver × Rver) + 104

HGB

HGB Height of the PV array between the lower edge of the bottom mounting clamp and the upper edge of the ashing tops

= (Nver × Rver) + 283

3.2.3 Substructure

Solrif® battens measuring 120 mm × 30 mm are used as a substructure, which are screwed onto the existing roof construction

instead of or in-between the roof battens to which the tiles were attached. Minimum requirements for wood quality: Strength

category C24.

Notice

Plan an extra 10 % for cutting losses compared to the batten plan. In addition, keep some spare wood to

hand to equalize out any unevenness in the roof construction or to be able to implement connections

or linings. A wedge plank is necessary for the bottom gutter of the PV array, see Chapter „Wedge Plank“.

The bottom row of Solrif® battens must extend beyond the ashing sides by at least 150 mm respectively as an overlay for the

lead ashing, i. e. the length of the bottom row of Solrif® battens must be at least BGL + 300 mm.

All other rows of Solrif® battens must extend beyond the ashing sides by at least 50 mm respectively, i. e. the length of the

other rows of Solrif® battens must be at least BGL + 100 mm respectively.

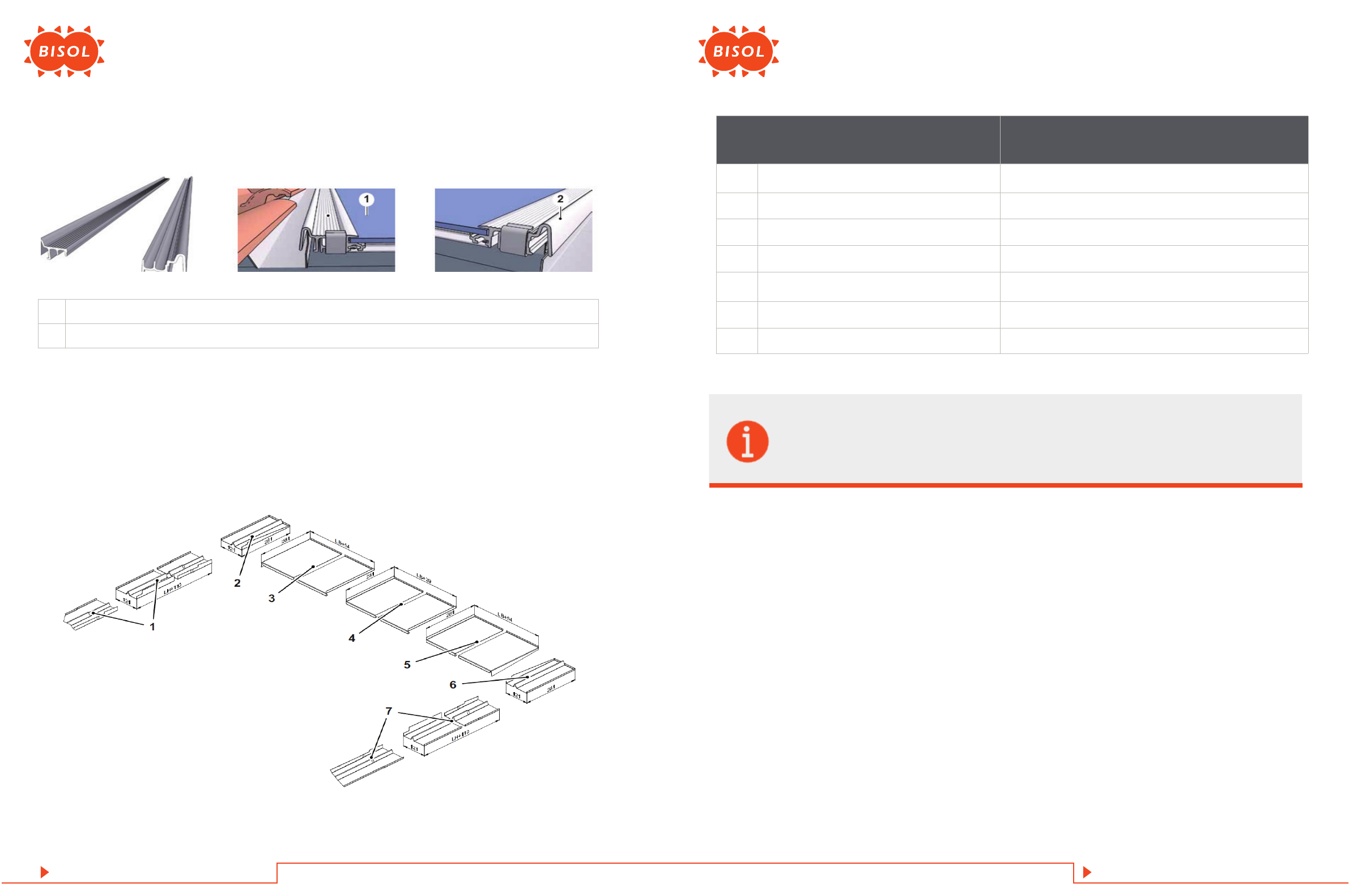

Figure 7: Substructure

16

Installation Manual: BIPV Modules

15 Installation Manual: BIPV Modules

3.2.4 Mounting Clamps

BISOL BIPV module with Solrif® frame are attached to the substructure with mounting clamps. There are three dierent types

of clamps:

Figure 8: Mounting clamps

Art. No. Application

1

Mounting Clamp Profile

- raw, 1.4310

- black/browned, 1.4310

- raw seawater-resistant, 1.4404

13318

06497

13995

Fastens overlapping modules in the area of the profiles

left/right or flash ing tops; always required

2

Mounting Clamp Glass with protective shrink tubing

- raw, 1.4310

- black/browned, 1.4310

- raw seawater-resistant, 1.4404

13319

06500

13996

Fastens overlapping modules in the area of the open

glass edge; number according to structural analysis

requirements

3

Mounting Clamp Top

- raw, 1.4310

- raw seawater-resistant, 1.4404

33954

13997 For fastening the top row of modules when not using

regular flashings top

4

Wood screw with pan head 4.5×35 SST, with general

building inspectorate approval ETA/DIBt

(countersunk bolts may not be used)

61831

Notice

Danger of confusion!

Please be aware that the dierent types of clamps must be used positioned and in quantities as required

according to the roof plan.

Roof plan design needs to be done with PV planning software SPT (proSOLRIF design software SPT at

www.ernstschweizer.ch for calculating the number of mounting clamps required per module.)

Figure 9: Mounting clamps mounted

1Mounting clamp prole mounted with the ashing tops

2Mounting clamp prole for securing the module overlap or the overlap with ashing proles

3Mounting clamp glass for securing the bottom module edge

18

Installation Manual: BIPV Modules

17 Installation Manual: BIPV Modules

3.2. Flashing Proles

Figure 10: Flashing proles

1Flashing prole left

2Flashing prole right

3.2.6 Side Flashings

The ashing sides create a link between ashing proles and roof tiles. The ashing tops ensure a transition between the top

module edge and the row of tiles that lies above it. They are designed in such a way that they are suitable for many conventional

types of roof tiles. In the event of other requirements (e. g. tiling bat tens and Solrif® battens at dierent levels, special types of

tiles, like slate, etc.) please contact BISOL Production Ltd and Ernst Schweizer AG.

Figure 11: Side ashings

Measurements height × width

LH= laminate height, LB= laminate width

1Flashing side left (LH+110) × 121

2Flashing side top left 281 × 121

3Flashing top left 281 × (LB + 54)

4Flashing top middle 281 × (LB + 32)

5Flashing top right 281 × (LB + 54)

6Flashing side top right 281 × 121

7Flashing side right (LH+110) × 121

Notice

When using side ashings other than the original Solrif® side ashings, it must be checked whether

galvanic separation is necessary.

20

Installation Manual: BIPV Modules

19 Installation Manual: BIPV Modules

1Roof tile

2Lead flashing

3Wedge plank

4Mounting clamps

5Sealing tape strip

6BISOL BIPV module with Solrif® frame

7Solrif® batten

DKu Thickness of the wedge plank at the bottom

HKHeight of the wedge plank

3.2.7 Bottom of PV-Array: Lead Flashing, Wedge Plank, Sealing Tape Strip

Figure 12: Bottom gutter

The BISOL BIPV module with Solrif® frame can be mounted either down to the eaves or with tile roong between PV array and

eaves. Observe the tech note about the application limits (snow loads) in the instruction sheet under customer login at www.

ernstschweizer.ch.

When tile roong is used between PV array and eaves, the transition should be executed using lead ashing and wedge plank.

3.2.7.1 Lead Flashing

For the transition from the bottom edge of the array to the tiles, lead ashing is used as is customary for other roof inserts, for

example skylights (lead foil roll 300 mm or black aluminium Mage Flex ashing tape.

280 mm or 450 mm available as accessories, roll length 5 m or 7.5 m). The required height of the lead ash ing depends on the

roof slope and the tile arch and must be determined in combination with the height of the wedge plank, see Chapter „Wedge

Plank“.

Notice

If the lead ashing is to be comprised of several sections of Mage Flex ashing tape, the sections must

overlap by at least 100 mm.

3.2.7.2 Wedge Plank

The wedge plank is mounted underneath the bottom Solrif® batten. It supports the lead ashing, ensuring that no trough forms

in the lead ashing and thus no water can remain there.

Minimum requirements for wood quality: Strength category C24

Figure 13: Excess height

22

Installation Manual: BIPV Modules

21 Installation Manual: BIPV Modules

3.2.7.3 Sealing Tape Strip

Roof slope Excess height ~20 mm Excess height ~40 mm

HKDKu HKDKu

10° 145 mm 50 mm 300 mm 70 mm

15° 75 mm 45 mm 170 mm 65 mm

20° 45 mm 45 mm 110 mm 65 mm

25° 30 mm 40 mm 80 mm 60 mm

30° 20 mm 40 mm 60 mm 60 mm

35° 10 mm 40 mm 45 mm 60 mm

40° 10 mm 35 mm 30 mm 55 mm

Figure 14: Measurements of the wedge plank

The length of the wedge plank corresponds to the width of the PV array including the ashing sides (BGL).

The sealing tape strip is mounted onto the lead ashing to close the gap underneath the bottom row of clamps against small

animals.

Figure 15: Sealing tape strip

3.2.8 Connection Cables, Cable Strings

Use connection cables and cable strings which full the following requirements:

• Made of exible copper wire.

• Double insulation, suitable for in-roof installation, meets protection class II (SCII) and IEC 61730.

• Heat resistant up to at least 90 °C.

• Has dimensions in accordance with the regulations at the place of installation.

• Follow the directions for the division of the PV array into strings and the resulting position of connection cables and cable

strings in the module pitch plan or string plan which was drawn up by the system planner.

• When the modules are arranged in a series connection, ensure that the maximum permissible system voltage is not exceeded.

• When the modules are arranged in a parallel connection, ensure that every row is fused with its own fuse.

• Observe the instructions of the module manufacturer and of the system planner.

1Sealing tape strip

24

Installation Manual: BIPV Modules

23 Installation Manual: BIPV Modules

3.2.10 Mounting Screws for Battens

To mount the Solrif® battens to the counter battens, 2 wood screws with general building inspectorate approval in accordance

with roong standards are required for each intersection of a Solrif® batten and counter batten:

3.2.9 Grounding and Lightning Protection

Notice

The national and local requirements regarding grounding and lightning protection must be observed.

A photovoltaic system does not aect whether lightning protection is necessary or not, i. e. a roof without a photovoltaic system

which does not have to be tted with lightning protection does not need lightning protec tion even with a photovoltaic system.

If lightning protection exists, the photovoltaic system must be integrated into the lightning protection pursuant to the local

regulations. You will nd further details in the tech note under your customer login at www.ernstschweizer.ch.

Figure 16: Drilling work for grounding

1Flashing top

2Module

3Cable strings

4Grounding cables within a grounding string

5Grounding cables between array and household fuse box

6Holes (Φ 3.3 mm) for grounding (view onto top module edge)

Diameter Length 5 mm

Permissible shape of head Thickness of the counter batten + 60 mm Countersunk

3.2.11 Other Accessories

Fixing for ashing is used to mount the side ashing onto the Solrif® battens or tiling battens.

3.2.11.1 Fixing for Flashing

Figure 17: Fixing for ashing on ashing sidesgrounding

1Fixing for flashing

2Clout nail 2.5 × 25 mm

26

Installation Manual: BIPV Modules

25 Installation Manual: BIPV Modules

Roof plan design needs to be done with PV planning software SPT (proSOLRIF design software SPT at www.ernstschweizer.ch

for calculating the number of mounting clamps required per module).

3.2.11.2 Protective Proles

Protective proles are used to connect ashing tops, see Chapter „Side Flashings“.

Figure 18: Protective prole (view onto top edge of array)

1Protective profile

3.2.11.3 L-Section to Support the Bottom Row of Mounting Clamps

Figure 19: L-section

1L-section

In elevated snow load conditions (> 2,400 Pa) the bottom row of mounting clamps must be supported (to be provided by the

customer: e. g. using a 16 mm aluminium L-section, a piece of wood or similar).

3.3 Technical Data/Limit of Application

Measurements/Weight of the Modules see the module manufacturer's data sheet

Max. snow load

5,400 N/m² **, structural design must be observed

(proSOLRIF design software at www.ernstschweizer.ch for

calculating the number of mounting clamps required per

module.)

Max. wind load (suction)

2,400 N/m² **, structural design must be observed

(proSOLRIF design software at www.ernstschweizer.ch for

calculating the number of mounting clamps required per

module.)

Substructure

Requirements according to the effects (wind and snow loads)

on the supporting structures and taking into account the

planned implementation of the PV array (Germany: DIN 1055-

4 Wind loads, DIN 1055-5 – Snow and ice loads, EN 1991-

1-3 – Snow loads (Eurocode 1), EN 1991-1-4 – Wind loads

(Eurocode 1))

Acceptable deviation from the flatness of the substructure 0.5 % (5 mm per meter)

Acceptable roof slope where there is a rainproof roof underlay 22 … 65°*

Acceptable roof slope where there is a watertight roof underlay 10 … 65°*

Min. permissible distance to the coast when using non-salt-wa-

ter-resistant mounting clamps 3 km**

Min. permissible distance to the coast when using salt-water-resis-

tant mounting clamps 50 m**

* With roof slopes below 32°, drainage of the roof underlay into the rain gutter must be ensured.

**Please also observe the limit of application stipulated by the module manufacturer or the system planner.

In the case of renovation, the characteristics of the roof underlay foil on roof slopes < 32° must be checked for conformity with the above-men-

tioned requirements and replaced if necessary.

28

Installation Manual: BIPV Modules

27 Installation Manual: BIPV Modules

4.1 Transportation in Packaging

• Please observe the personnel requirements pursuant to Chapter „Responsibility“.

• Please observe the handling instructions on the packaging.

4.2 Transportation of Individual Modules

Unprotected glass rim on the lower edge of the module.

Risk of damage to module!

• Do not set the module down on its glass rim.

• Leave the module in its original packaging until immediately prior to insertion into the PV array.

• Never hold or carry the module under any circumstances by its connection cables or junction box.

5.1 Checking the Requirements

5.1.1 Roof Plan and String Plan

Ensure that a roof plan and a string plan are supplied which contain at least the following information:

• Description of the system as well as of the snow and wind load assumed for the system

• Positioning of the PV array within the roof area

• Positioning, number and type of mounting clamps

• Specication of all module mounting pitches measured from a reference point

• Division of the PV array into strings

• Grounding and lightning protection cables

5.1.2 Limit of Application

Deviation of actual conditions from the values used in the design. Deadly danger!

Check whether the limit of use the parameters stated in the project documentation (location, roof pitch, building height, wind

and snow load area) correspond to the current buildings, see also section “Technical data / Limit of application”.

• Make sure that the roof lining meets the requirements of protection against rain or waterproofness, depending on the slope

of the roof.

• Observe local roong regulations or country-specic ventilation regulations.

5.1.3 Safety at Work

• Ensure that the roof is protected by collective protection (scaolding, roof railings) in accordance with local regulations.

• Ensure that all personnel are equipped with personal protective equipment (PPE) in accordance with legal regulations and

use it correctly.

• Ensure that support sta are properly trained and supervised throughout the work process.

4 TRANSPORTATION 5 INSTALLATION

30

Installation Manual: BIPV Modules

29 Installation Manual: BIPV Modules

5.1.4 Checking the Content of the Shipment

Combining connectors from dierent manufacturers. Danger of failure!

• Make sure that all BISOL BIPV modules have the same type of connector and are produced by the same manufacturer.

• Ensure that connectors of the same type as the BISOL BIPV modules are used for the connecting cables and cable sets.

• Do not make any connections using components from dierent manufacturers or types, even if they seem compatible.

• Check that the supplied material is in perfect condition and fully delivered.

• Make sure that the slats have a cross-section of 120 mm × 30 mm and that all types of coniferous wood meet at least strength

category C24.

• Make sure that two wood screws approved by the General Building Inspectorate (ETA) type 5 × 120/6 are used to mount each

batten.

• Be sure to use 4.5 × 35 SST at-head wood screws to secure the mounting brackets. The use of countersunk screws is not

permitted.

5.2 Tools

• Cordless screwdriver with T25 bit

• Disk grinder

• Screwdrivers of various sizes

• Carpenter’s hammer

• Wood saw

• Twine, e. g. chalk line

• Tape measure

• Folding yardstick

• Aiming stake

• Carpenter’s pencil

• Mandatory to use:When installing BISOL BIPV module with Solrif® frame, mounting gauge is mandatory to use (gauge for

easy and correct positioning of the mounting clamps, matching the BISOL BIPV module.)

5.3 Mounting

5.3.1 Preparing the Roof

Figure 20: Tile transition

1. Remove the tiles according to the roof plan (PV planning software SPT) and calculated size of the PV array plus one or two

rows of tiles at the bottom (depending on the roof slope and the height of the tile) and one tile column on each side, to the

left and right of the PV array.

Figure 21: Removed tiles

Figure 22: Removed tiling battens

To avoid collision with junction boxes:

2. Remove the tiling battens in the area of the PV array, but not from the ashing sides.

32

Installation Manual: BIPV Modules

31 Installation Manual: BIPV Modules

Figure 23: Cross section of rafters and counter battens

Notice

In the following diagrams, the lead ashing is blanked out (the lead ashing has to be placed before the

mounting clamps are mounted!) for better understanding.

Figure 24: Calibration

1Bottom Solrif® batten

2Wedge plank

3Flashing side left

4Flashing side right

Nhor Number of modules side by side in the PV array

Rhor Horizontal module mounting pitch

Nhor × Rhor Distance between the centre lines of the outermost mounting clamps

HKHeight of the wedge plank (depends on the roof slope and the shape of the tile, see„Wedge Plank“).

EIReference point bottom left

EBReference point bottom right

1. Mount the bottom Solrif® batten at a distance of the height of the wedge plank plus 30 mm from the upper edge of the

bottom row of tiles, observing Chapter „Rules for Mounting Solrif® Battens“.

5.3.2.1 Mounting the Solrif ® Battens

Figure 25: Mounting the bottom batten

5.3.2 Calibrating and Placing the Substructure

“Calibrating” is the tting and alignment of the PV array within the remaining roong. For denitions of the in- dividual

measurements, see Chapter „Dimension of PV Array and Module Mounting Pitches“ on page 12, for the placement of the

reference points, see also Chapter„Preparing the Roof”.

3. As shown on the picture below. The evenness of the roof needs to be checked and corrected, if necessary. Respecting the

stated conditions below is mandatory.

4. Check whether the roof fulls the following requirements across the entire PV array:

A ≤ 1 cm

A / (2 × B_S) ≤ 0.5 %

If the requirements are not fullled:

5. Even out the troughs by nailing on pieces of wood (shifts).

34

Installation Manual: BIPV Modules

33 Installation Manual: BIPV Modules

5.3.3 Determining the Reference Point and Perpendicularity of the PV Array

Notice

The perpendicularity of the PV array is a basic prerequisite for trouble-free and successful installation.

Figure 26: Mounting further battens

Figure 27: Mounting the wedge plank

Figure 28: Rectangular and “warped” PV array

1. In the left-hand bottom corner of the PV array, determine reference point EL (1), see Chapter „Preparing the Roof“.

Notice

Do NOT fully screw in the screws that subsequently must be placed: tension lines or tape measures must

be tied to them!

Figure 29: Calibration

2. Mount the other rows of battens at intervals of x × R_Ver (measured from the bottom row of battens) respectively and

mount them with two mounting screws each to each rafter/each counter batten.

3. Mount the wedge plank at a distance of ca. 10 mm from the bottom edge of the bottom row of battens, observing Chapter

„Rules for Mounting Battens“.

36

Installation Manual: BIPV Modules

35 Installation Manual: BIPV Modules

5.3.4 Mounting the Lead Flashing

1. Roll the lead ashing out over the bottom row of battens and the wedge plank and place it in such a way that the lead

ashing extends past the wedge plank on both sides by at least 150 mm respectively.

If the lead ashing comprises several strips:

2. Ensure the strips overlap by at least 100 mm.

For roof slopes <22°:

3. Place the lead ashing in such a way that the top edge of the lead ashing extends past the top edge of the bottom batten

by 20 mm.

For roof slopes >22°:

4. Place the lead ashing in such a way that the top edge of the lead ashing is ush with the top edge of the bottom batten.

Figure 30: Lead ashing on roof slopes < 22°

5.3.5 Laying Cable Conduits, Connection Cables and Cable Strings

1. Lay cable conduits for connection cables and cable strings according to local and national regulations.

2. Lay connection cables and cable strings according to the string plan.

2. Place a screw in the position of the left-hand reference point EL(1).

3. Place a screw in the position of the right-hand reference point ER(2) (distance to left-hand reference point = BGR).

4. Stretch a tension line tightly between the two reference points EL (1) and ER(2).

5. Measure along the line from ER(2) to EL (1) a distance of 4“units”(e. g. meters) and mark the point (3) with a screwed-in wood

screw.

6. Attach the tape measure to right-hand reference point ER (2) and draw a “compass circle” with the radius of 3 “units” in the

right-hand top corner of the PV array.

7. Attach the tape measure to point (3) and draw a “compass circle”with the radius of 5 “units” in the right- hand top corner of

the PV array.

- The intersection of the two compass circles is point (4).

8. Extend the line from the right-hand reference point ER (2) to (4) at the height of HGon the PV array; this gives you the

preliminary right-hand top reference point RR(5).

9. Mark the right-hand top reference point RR (5) with a screwed-in wood screw.

10. Attach the tape measure to the wood screw (5) and draw a “compass circle” with the radius of BGR in the left-hand upper

corner of the PV array.

11. Attach the tape measure to the left-hand bottom reference point EL(1) and draw a “compass circle” with the radius of HGin

the left-hand upper corner of the PV array.

- The intersection of the two compass circles is point (6), the preliminary left-hand top reference point RL.

12. Measure the diagonal of the PV array from point (1) to point (5).

13. Measure the diagonal of the PV array from point (2) to point (6).

- The diagonals must be the same length within the limits of measurement accuracy.

14. Check that the reference point in the left-hand top of the PV array RL. is at a distance of ca. 30 mm from the vertical tile edge.

If this is conrmed:

15. Mark the right-hand PV array edge (2) to (5) across all battens, e. g. with a tension line.

5. Feel out the positions of the two screws that mark the bottom reference points ELand ER, pierce the lead ashing at these

points or make 2 short crossed cuts.

6. Press the screw heads through the lead ashing.

7. Remove the two screws, put sealing washers on them and screw them back in so far that the screws are still protruding

about 20 mm from the lead ashing.

8. Flange out the top edge of the lead ashing about 20 mm wide.

38

Installation Manual: BIPV Modules

37 Installation Manual: BIPV Modules

5.3.6 Marking the Horizontal Positions of the Mounting Clamps Prole

1. Stretch a line between the two bottom left reference points EL and bottom right ER (see Diag. “Calibration”).

2. Stretch a line between the right-hand reference point ER and the top right reference point RR (see Diag.“Calibration”).

Notice

Measuring the clamp positions from one clamp to the next will lead to measurement chain errors.

Determine the position of each Mounting Clamp Prole from the right-hand reference line (= tension line

on the right-hand edge of the PV array).

Figure 31: Mounting clamps horizontal positions

5.3.7 Laying the Bottom Row of Modules

1. On the bottom batten, mount the Mounting Clamps Prole with 2 screws each, horizontal position at the marked points,

vertical position such that the top edge of the mounting clamps is at the same height as the tension line (the mounting

clamps should NOT push away the tension line!).

Figure 32: Mounting clamps bottom row

Figure 33: Fitting the mounting gauge

3. On each batten, mark the horizontal positions of the Mounting Clamps Prole at the following positions starting from the

tension line on the right-hand edge of the PV array:

18 mm

18 mm + Rhor

18 mm + 2×Rhor

…

18 mm + Nhor × Rhor

If you are using a mounting gauge:

2. Remove the tension line at the bottom end of the PV array and screw in the screws at positions ELand ERtightly.

Table of contents