2

1 General Safety Notes

1.1 Symbol

The following symbols are used throughout these instruc-

tions and must be adhered to

DANGER of possibly serious personal injury

WARNING against material damage

NOTE as additional information

1.2 Norms and Regulations

The standards and regulations applicable at the installa-

tion location must be adhered to.

●Make sure to observe country and territory regulations

related to roof works and roof sealing standards as well

as professional codes for plumbing work. The installa-

tion process must reflect the on-site conditions as well

as applicable rules, regulations and accident preven-

tion procedures. Appropriate work safety measures

must be observed (ropes, hooks, lines, scaffolding,

protection nets).

●Safety barriers to protect pedestrians against falling

parts must be set up.

●The dimensioning of the mounting system (number of

roof brackets etc.) should be specifically carried out for

each individual project, following the specified struc-

tural engineering standards and regulations.

●Prerequisite for the proper application always is a solid

mounting base that can accommodate the occurring

forces (weight, wind and snow loads).

●Especially the pipes in the lower parts of the building

must be connected electrically conductive, conforming

to standards. The collector installation must be profes-

sionally integrated with an existing or new lightning

protection system.

1.3 Qualification of the Installer

Setup, installation and proper commissioning of the solar

installation must be carried out by authorized profession-

als. Non-compliance renders the warranty void.

1.4 Intended Use and Application

Scope and Limitations of Application

The collector is intended for the application in solar ther-

mal installations for hot water preparation and space

heating support. As operating mediums water (attention

– risk of freezing!) or an appropriate water-glycol mixture

can be used in a closed circuit. Operational conditions

underrunning the dew point within the collector for pro-

longed periods are not permitted! This can occur for ex-

ample, when collectors are integrated in the brine circuit

of a heat pump.

Maintenance

For maintenance notes and additional information about

setup and operation of the collector field, please refer to

the technical information “Solar Thermal Systems”.

1.5 Notes on Proper Collector Storage

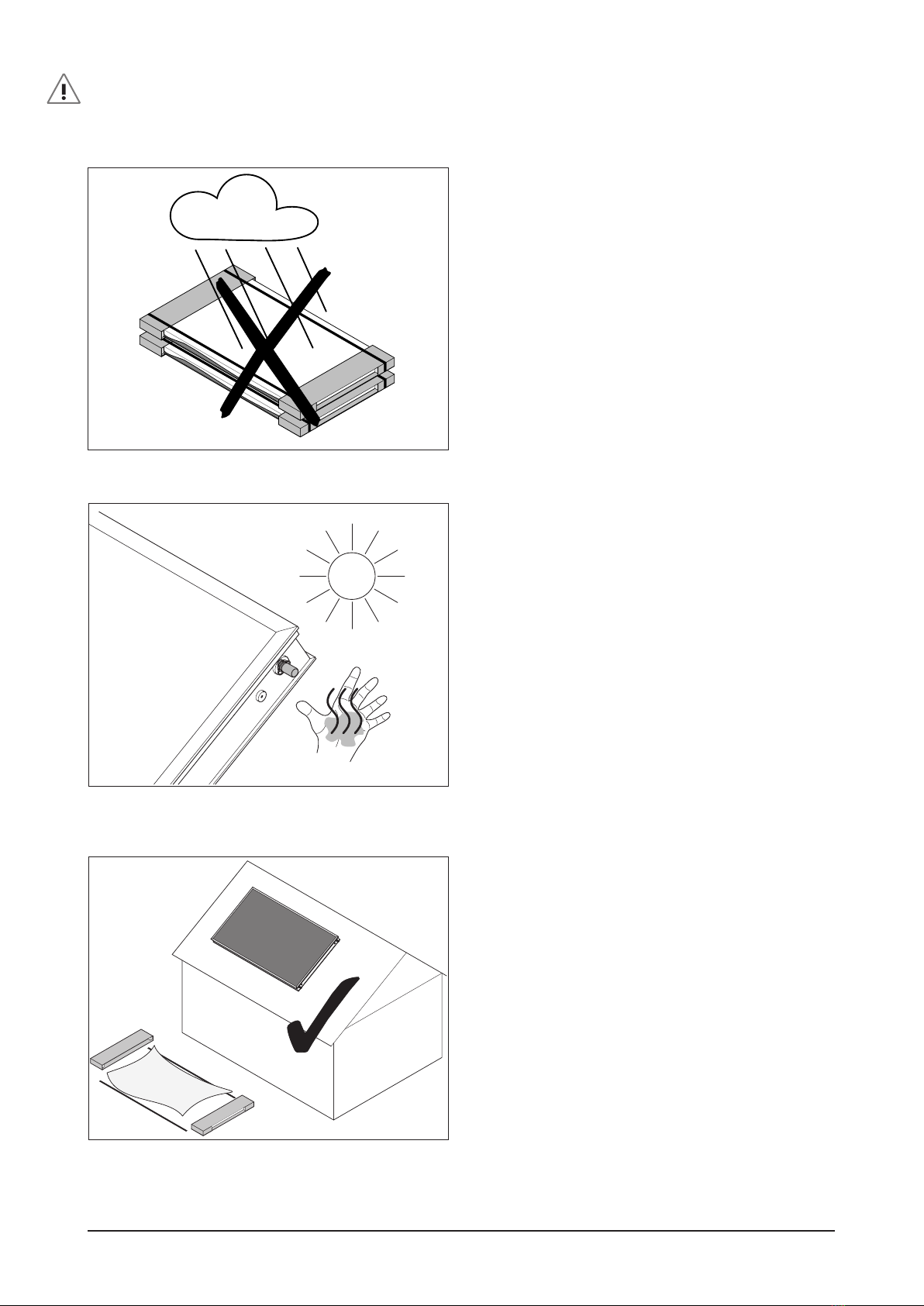

1.5.1 Proper Outdoor Storage of Collectors

●Remove protective film and lay down collectors with

glass pane up. Avoid direct ground contact (e.g. un-

derlay square timber). Avoid scratches on glass panes

by using spacers between collectors (e.g. wooden bat-

tens).

●When leaning collectors against walls or similar, use a

minimum inclination of 15° and apply spacers. Do not

use cardboard as under liner. If incorrectly stored, hu-

midity can enter the collectors through the air vents.

●Storing collectors in foil package may damage the

glass surface (see figure 2).

1.6 Pre-Installation Notes

Ensure technically correct roof structure

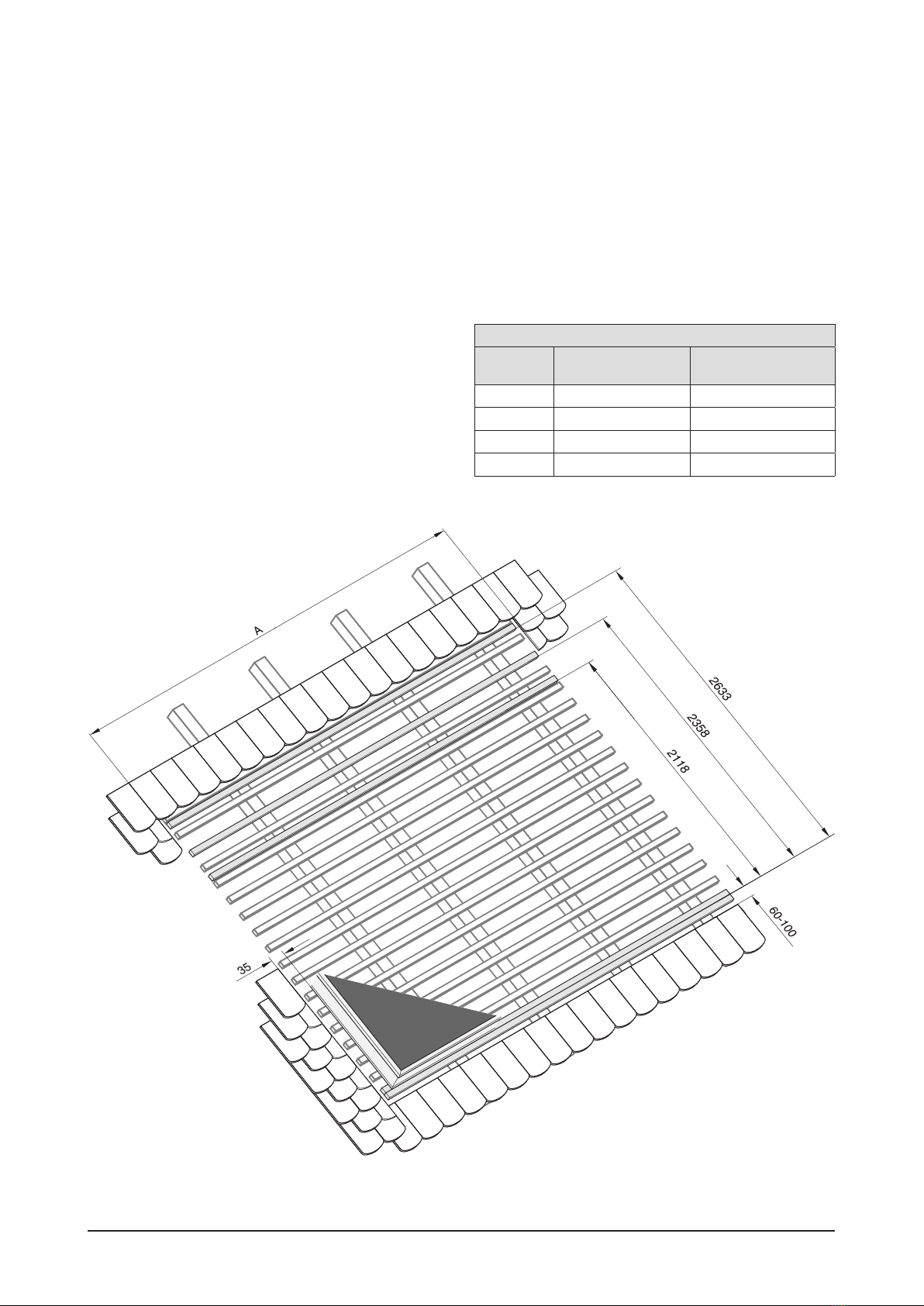

For roof integrated installation the space behind the col-

lector field has to be protected against uprising and ac-

cumulating humidity. Ensure that the roof is sufficiently

ventilated in the area of the in-roof collector field (see

“Installation Field” on page 6)

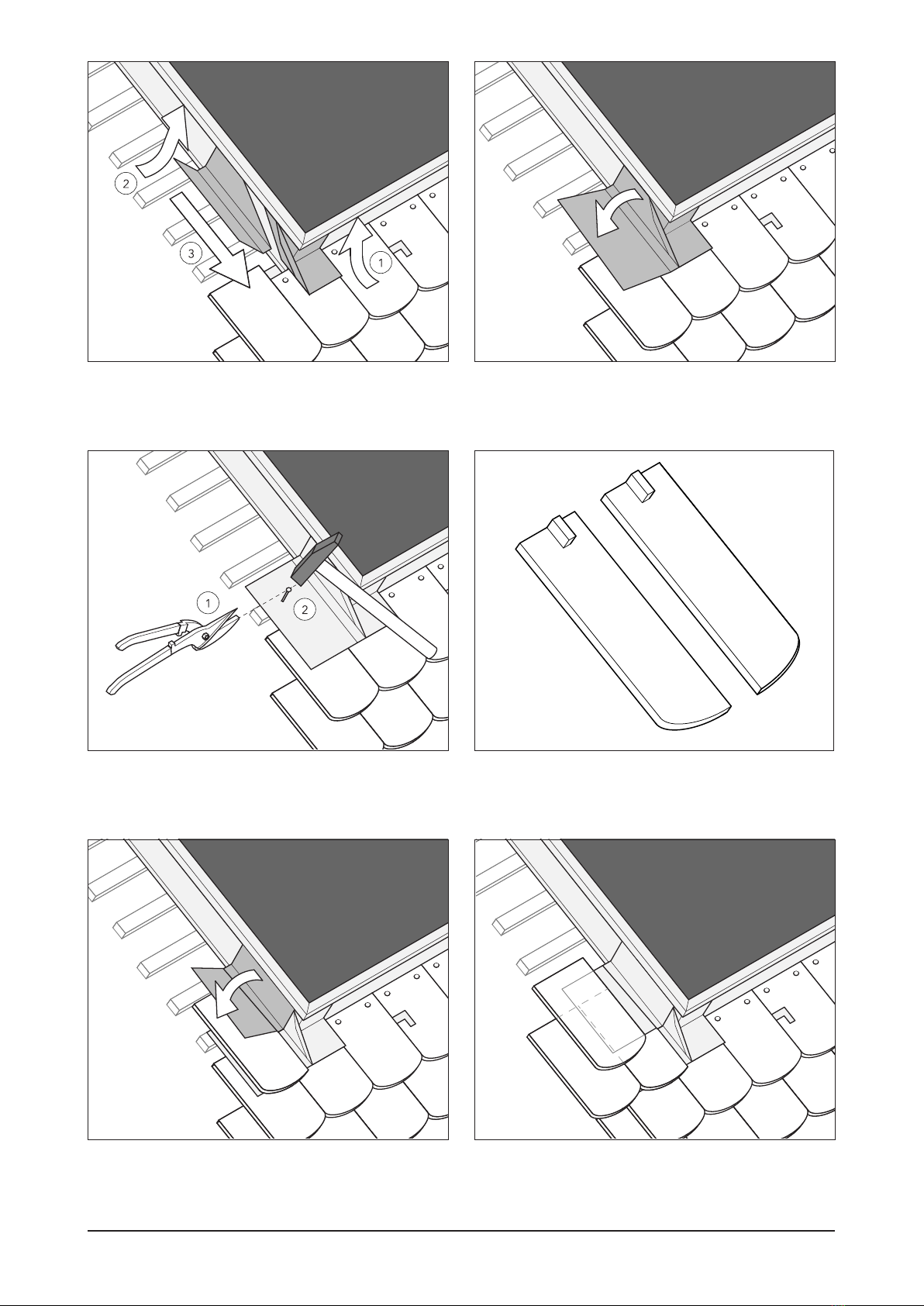

●Danger of open injuries when working with sharp

edged metal sheets and components!

●Risk of burns at collector connections as soon as uncov-

ered collector is exposed to the sun.

●Remove glass protection PE-LD film before commenc-

ing installation work!

●Do not subject the coollector connections to mechani-

cal loads or use as transportation handles. Specially de-

signed collector handles are available for this purpose.

●Keep a minimum distance between collectors and roof

structures such as chimneys, air vents, sky lights that

may release moist air. Otherwise there is a n increased

risk of excess humidity entering through the air vents

of the collector encasing.

Overheat Protection

For roof heating centrals and when 4 or more EURO col-

lectors with anti reflective glass are installed vertically, the

“Technical Information Solar Thermal Systems – Setup,

Commissioning and Maintenance” must be followed to

avoid damage to the solar circuit.

Ensure technically correct roof structure

For roof integrated installation the space behind the col-

lector field has to be protected against uprising and ac-

cumulating humidity. Ensure that the roof is sufficiently

ventilated in the area of the in-roof collector field (see

“Installation Field” on page 6)