Bison 1800 User manual

ELECTRIC HIGH PRESSURE WASHER

INSTRUCTION MANUAL

Please read this book carefully before operating.

2

APPLICATION

High pressure washer mainly used for cleaning and maintaining

motor vehicle, project vehicle, project mechanism and agricultural

mechanism, such as cleaning car, bulldozer, concrete stirrer and so on,

also can be used to clean hotel, showplace, station, dock and so on.

ITEM DESCRIPTION

WORKING THEORY

Motor connect to crank directly, driving piston pump working, water

enter into pump through inlet hose, high pressure stream pass by outlet

connector, high pressure hose enter into trigger valve, press high

pressure , water sprayed by nozzle of spray pole.

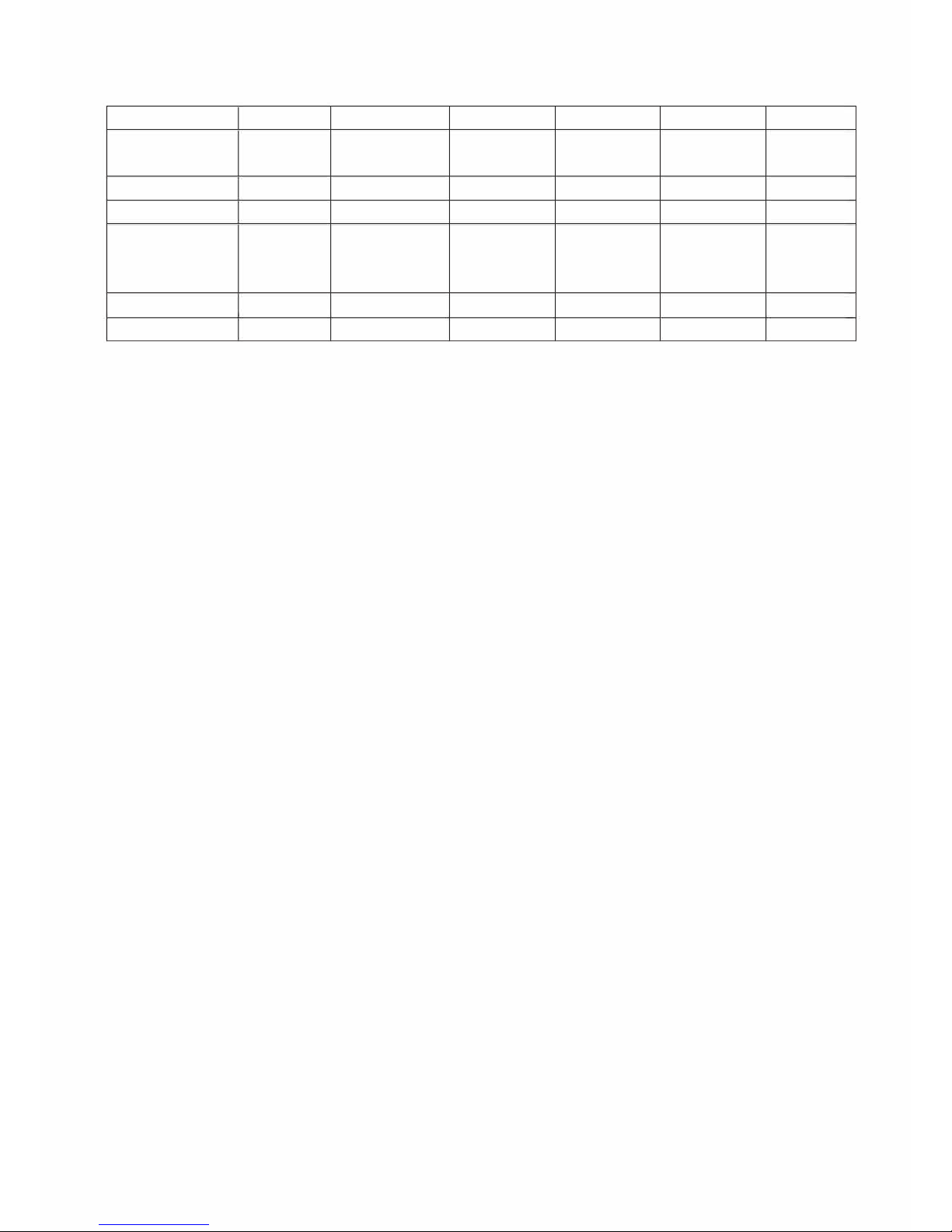

MAIN TECHNICAL DATA

1800 2500 2600 2900 3600H 3600

Never

Never

Never

Never

Never

Never

Never

Never

SAFETY RULE

3

4

itself.

• To reduce the risk of injury, do not operate the machine near children.

• Learn how to stop the machine and release pressure quickly. Be

thoroughly familiar with the controls.

• Stay alert — watch what you are doing.

• Wear safety goggles.

• Do not use acids, solvents, or any flammable material in this product.

These products can cause physical injuries to the operator and

irreversible damage to the machine.

• Do not operate the product when fatigued or under the influence of

alcohol or drugs.

• Keep operating area clear of all persons.

• Do not stand on unstable surfaces. Stand with both feet balanced at

all times.

• To reduce the risk of electrocution, keep all connections dry and off

the ground. Do not touch plug with wet hands.

• The Trigger Gun Safety Lock PREVENTS the trigger from accidentally

being engaged. This safety feature DOES NOT lock trigger in the on

position.

Water Supply (Cold Water Only)

• Water hose must be at least 1/2 inch in diameter.

5

• Flow rate of water supply must not fall below 4 GPM (gallons per

minute).

• Flow rate can be determined by running the water for one minute into

an empty 5-gallon container.

• The water supply temperature must not exceed 104°F/40°C.

• Never use the pressure washer to draw in water contaminated with

solvents, e.g. paint thinner, gasoline, oil, etc.

• Always prevent debris from being drawn into the unit by using a clean

water source.

ASSEMBLY INSTRUCTIONS

To prepare your pressure washer for operation, you will

need to perform these tasks:

1. Attach handle, wheel, hook

2. Add oil to pump.

3. Connect high pressure hose to spray gun and pump.

4. Connect water supply to pump.

5. Attach nozzle extension to spray gun.

6. Connect power.

Attach Handle and wheel

1. Place handle (A) onto handle supports (B) connected to main unit.

Make sure holes (C) in handle align with holes (C) on handle supports.

6

NOTE: It may be necessary to move the handle supports from side to

side in order to align the handle so it will slide over the handle supports.

Hold the location pin in the wheel set backward in horizontal level and

press the locating pin into supporting tube until the click is heard, which

indicates the pin clutches at the supporting tube.(P1)

Until the pin is higher than the thickness of supporting wall.(P2)

P1 P2

Add pump Oil

• Place pressure washer on a level surface.

• For the convenience of transport, Pump without machine oil, and

Breather plug is not installed. Please add 15W/40 machine oil before

7

using. Machine oil quantity is subject to slightly not too oil lens center

line, then install the breather plug.

Connect Hose and Water Supply to Pump

1. Attach high pressure hose to gun. Tighten securely.

2. Connect spray wand to gun. Tighten securely.

3. Assemble grommet kit and quick-connect nozzles as described in

the instructions supplied.

4. Attach other end of high pressure hose to high pressure outlet on

pump. Tighten by hand.

8

5. Run water through your garden hose for 30 seconds to clean out any

debris. IMPORTANT: DO NOT siphon standing water for the water

supply. Use ONLY cold water (less than 104°F (40°C)).

6. Before connecting water inlet hose to water inlet, inspect inlet screen

(A). Clean screen if it contains debris or have it replaced if damaged.

DO NOT run pressure washer if inlet screen is damaged.

7. Connect the water inlet hose (not to exceed 50 feet in length) to the

water inlet. Tighten by hand.

CONNECT POWER

1. Choose right power supply nearly

2. Turn off power switch

3. Connect the power wire of high pressure washer.

4. Turn on power switch

9

GROUNDING Instructions

This product must be grounded. If it should malfunction or break down,

grounding provides a path of least resistance for electric current to

reduce the risk of electric shock. This product is equipped with a cord

having an equipment-grounding conductor and a grounding plug. The

plug must be plugged into an appropriate outlet that is properly installed

and grounded in accordance with all local codes and ordinances.

DANGER- Improper connection of the equipment-grounding conductor

can result in a risk of electrocution. Check with a qualified electrician or

service personnel if you are in doubt as to whether the outlet is properly

grounded. Do not modify the plug provided with the product - if it will not

fit the outlet, have a proper outlet installed by a qualified electrician. Do

not use any type of adapter with this product.

10

HOW TO USE

Turn on the pressure washer (I). The motor starts only if the trigger

of the gun is pulled and shuts off when the trigger is released.

Read instruction manual carefully before operating this machine, check

whether screw, nut loose, oil in crank tank dry. If no oil, shall inject to

half, exchange oil-cork with hole. Not allowed to be working without oil.

Connect one side of high pressure hose to pump body, the other side

connected to spray gun, then connect the inlet hose to inlet connector,

ensure not leakage, open water source, press spray gun, waiting for

drain all air inside then turn on switch, can be use.

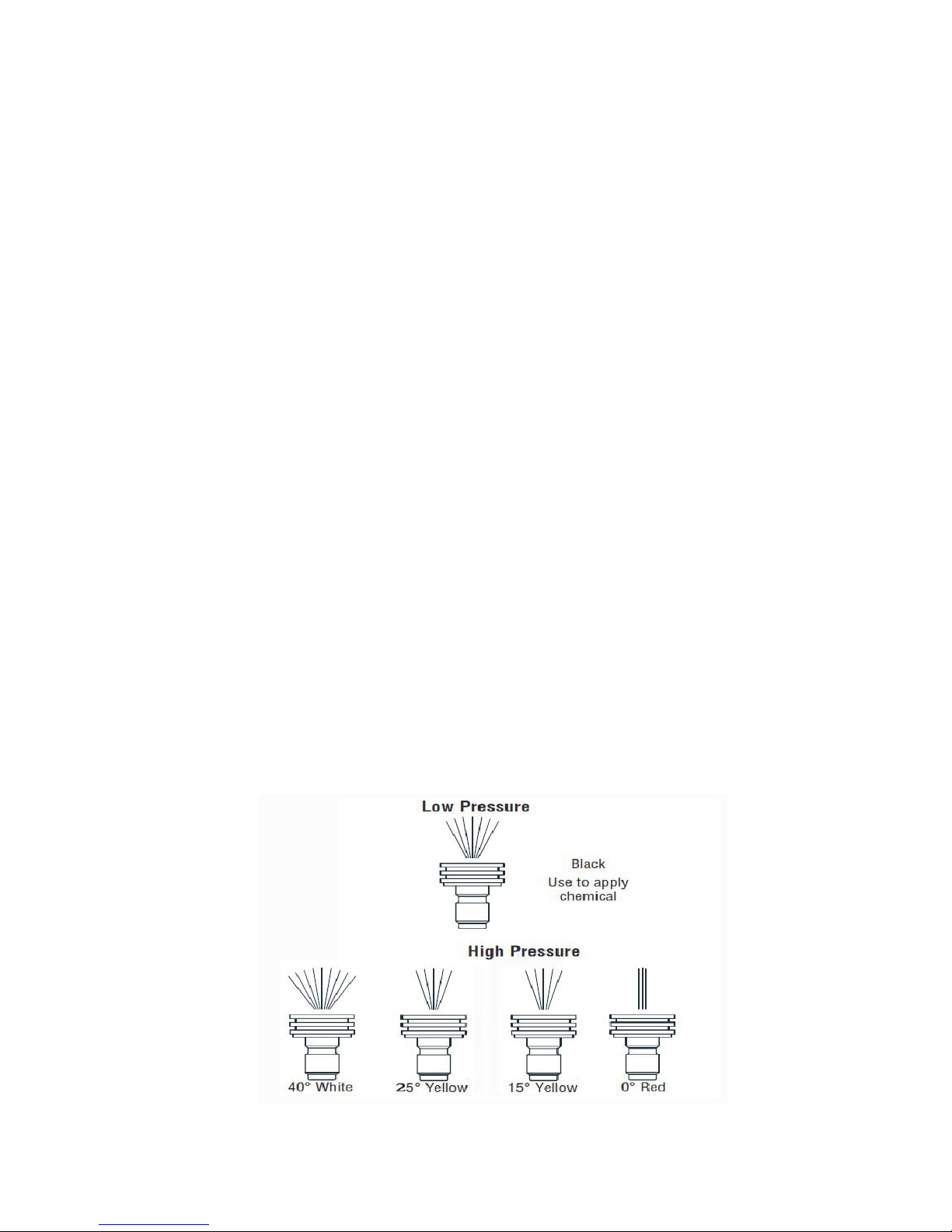

How to Use Spray Tips

The quick–connect on the nozzle extension allows you to switch

between four different quick connect spray tips. Spray tips can be

changed while pressure washer is running once spray gun trigger lock

is engaged. The spray tips vary the spray pattern as shown below.

11

1. Pull back collar on quick–connect and pull current spray tip

off. Store spray tips in holder provided on the nozzle extension.

2. Select desired spray tip:

•For gentle rinse, select white 40°spray tip.

•To scour surface, select yellow 15°or red 0°spray tip.

•To apply detergent, select black spray tip.

3. Pull back on collar, insert new spray tip and release collar. Tug

on spray tip to make sure it is securely in place.

Usage Tips

•For most effective cleaning, keep spray tip from 8 to 24 inches (20 to

61 cm) away from cleaning surface.

•If you get spray tip too close, especially using a high pressure Spray

tip, you may damage surface being cleaned.

•DO NOT get closer than 6 inches (15 cm) when cleaning tires.

OPERATING AND MAINTENANCE

When cleaning, the distance between spray nozzle to surface not too

far, shall be 10cm, because the pressure of the spray nozzle will be

reduce if too far.

The pressure not over working pressure, pressure shall be adjusted

under jet situation.

When operating, the bottom of pump if have few drips, not effect using.

It is normal.

12

When finished cleaning, release trigger valve, turn off motor (within 3

minutes), because after release trigger valve the will do bypass working,

water flowed in the pump body, if too long, will be very hot, broken seal

or other parts.

Spray pole is made of iron paint chrome, keep carefully when operating,

when not using, put the spray gun hung on the pothook, drain out the

balance water inside.

If Long-term stock, drain out all water in pump, separate inlet hose from

water source, running motor about 1 minutes without water source, take

inlet hose and high pressure hose drain all water in hose, when high

pressure hose drain shall press trigger valve.

13

TROUBLE SHOOTING

Trouble

Cause

Remedy

The motor fails to start

or when running

automatic stop

1. No power or socket

is not good enough

2. Switch is broken

3. No oil in crank tank

4. Voltage too low

5. Motor burn out

1. Check power, repair

socket

2. Change switch

3. Inject oil

4. Check voltage

5. Change motor

No jet from nozzle or

pressure not stabile.

1. Nozzle blocked

2. Inlet hose broken

3. air in the pipe

4. filter blockage

1. Dredge nozzle

2. Check connector of inlet

hose, drain air of hose or

change inlet hose.

3. First check whether the

connection of screw

thread end of water inlet

hose is tight, and then fill

the inlet hose with water,

next trigger the gun, and

start the motor.

4. clean the filter.

Spray gun and

connector leakage

1. Screw of connector

loosen or seal

broken

2. Quick connector

not in proper

position or O-ring

broken

1. Tighten screw or

change seal.

2. Re-insert quick

connector or change

seal.

Crankcase heats

1. Too much oil

2. The friction between

the connecting rod

and the crankshaft

caused by too little

oil.

1. let out the extra oil.

2. dismantle the pump to

remove friction marks ob

the connecting rod and

crankshaft.

No water or too little

water from the gun

1. the new pump can

not suck water

2. debris in the pump

3. water inlet and outlet

check valve

damaged

1. start the motor and fill

the water inlet hose with

the water to drain up the

air in the hose

2. dismantle and repair the

pump

3. change the check valve

14

This manual suits for next models

5

Table of contents

Other Bison Pressure Washer manuals

Popular Pressure Washer manuals by other brands

A-iPower

A-iPower PWE1801 Owner's Manual and Operating Instructions

Alto

Alto Triton 730 operating instructions

Craftsman

Craftsman 580.752722 Operator's manual

Kärcher

Kärcher 750mx manual

Landa

Landa VLP3-1100 Operator's manaul

DeVilbiss Air Power Company

DeVilbiss Air Power Company EXCELL VR2400 Operation manual