Bison 130 User manual

GASOLINE HIGH PRESSURE WASHER

OWNERS MANUAL

CAUTION Read the instructions before using the machine.

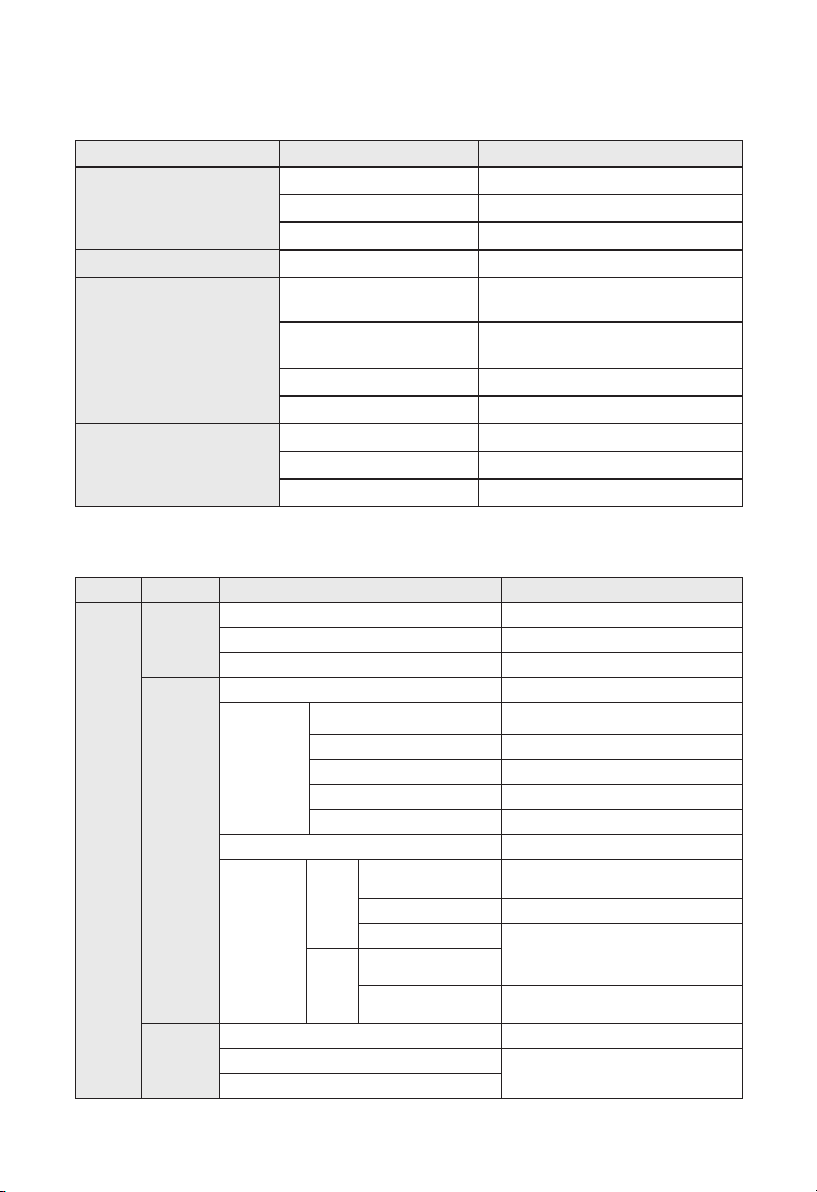

G150

14.5Mpa 19Mpa 20Mpa 17Mpa

11-13Mpa 15-17Mpa 16-18Mpa 13.5-15Mpa

6.5 L/min 9 L/min 9 L/min 12.6 L/min

■Read instructions carefully before operating this product.

■Keep bystanders away.

■This product is for outdoor use only.

■Ensure the engine is stopped before carrying out adjustments,

cleaning or maintenance.

■ Always turn off the engine and water supply when finished.

■Do not use the product if found to be damaged.

■Only use with detergents specified by the manufacturer. Other chemicals may compromise the safety

of the product.

■Do not direct the pressure jet towards mechanical parts containing lubricant grease.

■Clean vehicle tyres from a minimum of 50cm to avoid damage by the high pressure jet.

■Do not point high pressure jets at people, animals, live electrical parts or the product itself.

■Do not use accessories such as hoses and connections that are not advised by the manufacturer.

■Engage the high pressure safety catch located on the gun when not in use.

■Do not step/stand on the high pressure hose.

■Ensure the nozzle is securely attached before using the Product. High pressure can cause it to be fired

from the lance with considerable force, and could cause injury damage.

■Be ready for the kick-back force and the sudden torque on the spray assembly when operating the trigger.

■ A high pressure jet can remove paint and other surface finish. It can also damage tarmac and grouting.

■Switch off completely when not attended.

■The hose is designed specifically for operation with high pressures. Take care to avoid damage that may

prevent correct operation of the product.

■This product is not to be used by children or anyone with reduced capabilities.

■ Always completely unwind the high pressure hose prior to operation.

■Make sure that the machine is switched off before unwinding the high pressure hose, and take care not to

pull the machine over.

■Do not let the high pressure hose contact the hot engine exhaust.

■Do not use this product indoors.

■Keep exhaust emissions away from air intakes.

GENERAL SAFETY INSTRUCTIONS

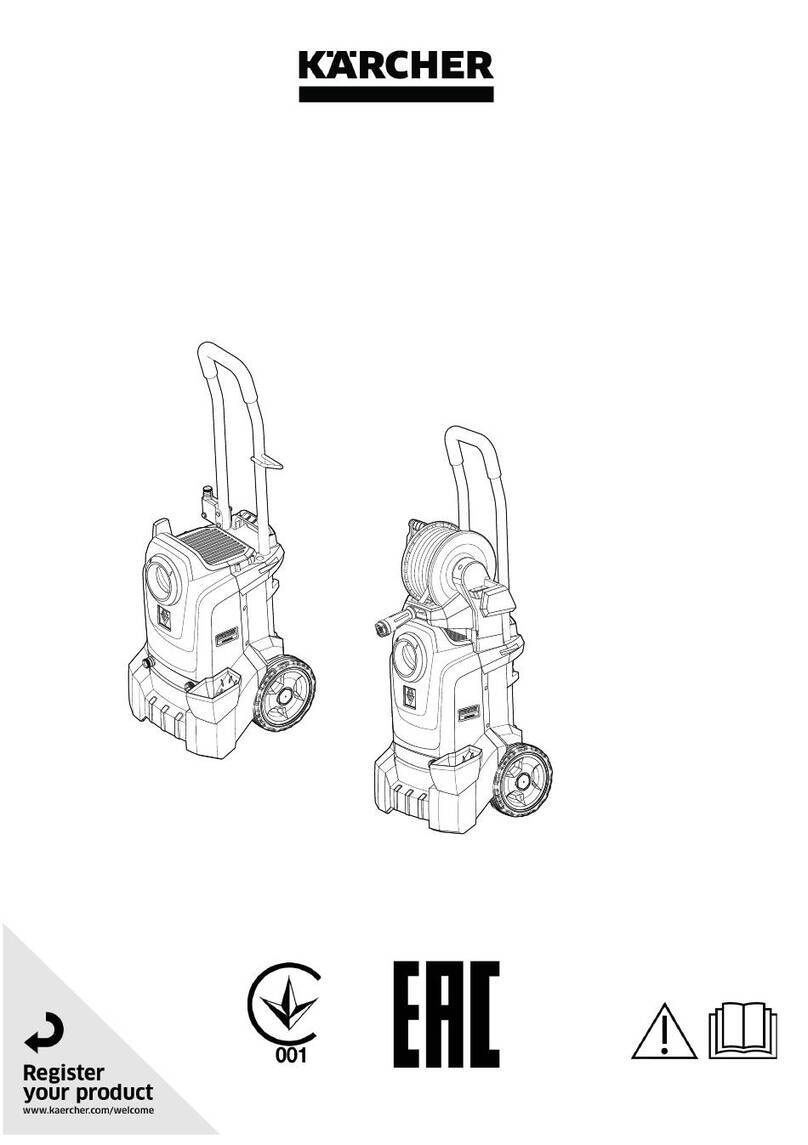

Explanation of the symbols on the appliance!

Warning! Read the operating

instructions before use!

Warning! Do not inhale exhaust fumes!

Attention! Hot surfaces! Risk of burns!

Wear protective gloves!

Wear safety shoes!

Wear hearing protection!

Wear safety goggles!

High-pressure jets can be dangerous if misused. Do not aim at people,

animals, active electrical equipment or at the appliance itself .

Regulate engine speed!

Choke:open/close,petrol:on/off

Machine not suitable for connection to

the potable water mains

Forbidden to adjust

Forbidden to adjust pressure valve

-1-

TECHNICAL PARAMETERS:

■Do not attempt to modify the product in any way.

■To ensure good operating condition arrange regular servicing from an authorising agent.

■Only use replacement parts supplied by the manufacturer

■Only use fresh,clean and good quality fuel in the engine.

■Never operate the engine without oil.

■Never refuel in close proximity to naked flames, sparks or other sources of ignition e.g. cigarettes.

■Do not refuel when the engine is hot.

■Wipe up and correctly dispose of any fuel spillage immediately with a suitable medium.

■Move away from the refuelling areas before restarting the engine. Store fuel for short periods

only in a suitable container away from heat and direct sunlight.

■Clean the pressure washer thoroughly after each use.

■Regularly check external nuts and fixings to ensure vibration caused by normal use has not begun

loosen them. Remove the spark plug ignition lead from the back of the spark plug and position the

lead to avoid accidental reconnection.

■Store the machine in a secure dry location out of reach of children.

■Empty the fuel tank before storage.

MAINTENANCE AND STORAGE

GETTING TO KNOW YOUR PETROL PRESSURE WASHER

1.Engine 2.Pump 3.Lower frame

4.Hand 5.Panel 6.Wheel

7.Lance 8.Hand spray gun 9.Nozzle

10.Hose 11.Soap tank

2

3

5

6

9

10

1

4

7

8

11

-2-

-3-

FIG. 2

ASSEMBLY

FIG. 3

NOTE: Every machine is tested during production,

so there may a few drops of water inside the pump assembly.

FIG. 4

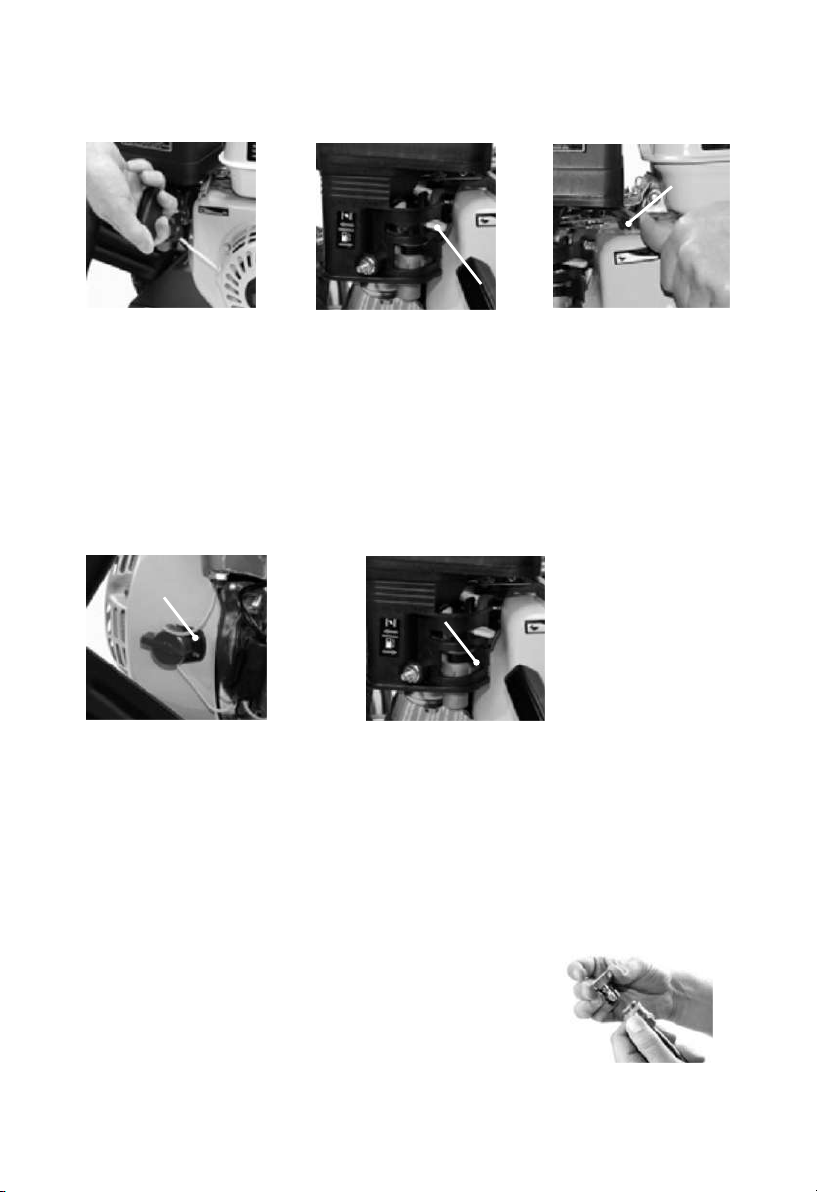

TO ASSEMBLE THE WHEELS

(Figs. 1-2):

FIG. 1

FIG. 5

Insert the axle into the axle tube at

the bottom of the frame, then fix it

with M6 screws.

Assemble the wheel on the axle

and fix it with a nut.

A

Install the hook

for hose

Install the panel on

the upper frame Press the Lock A, install the upper frame

into lower frame

!

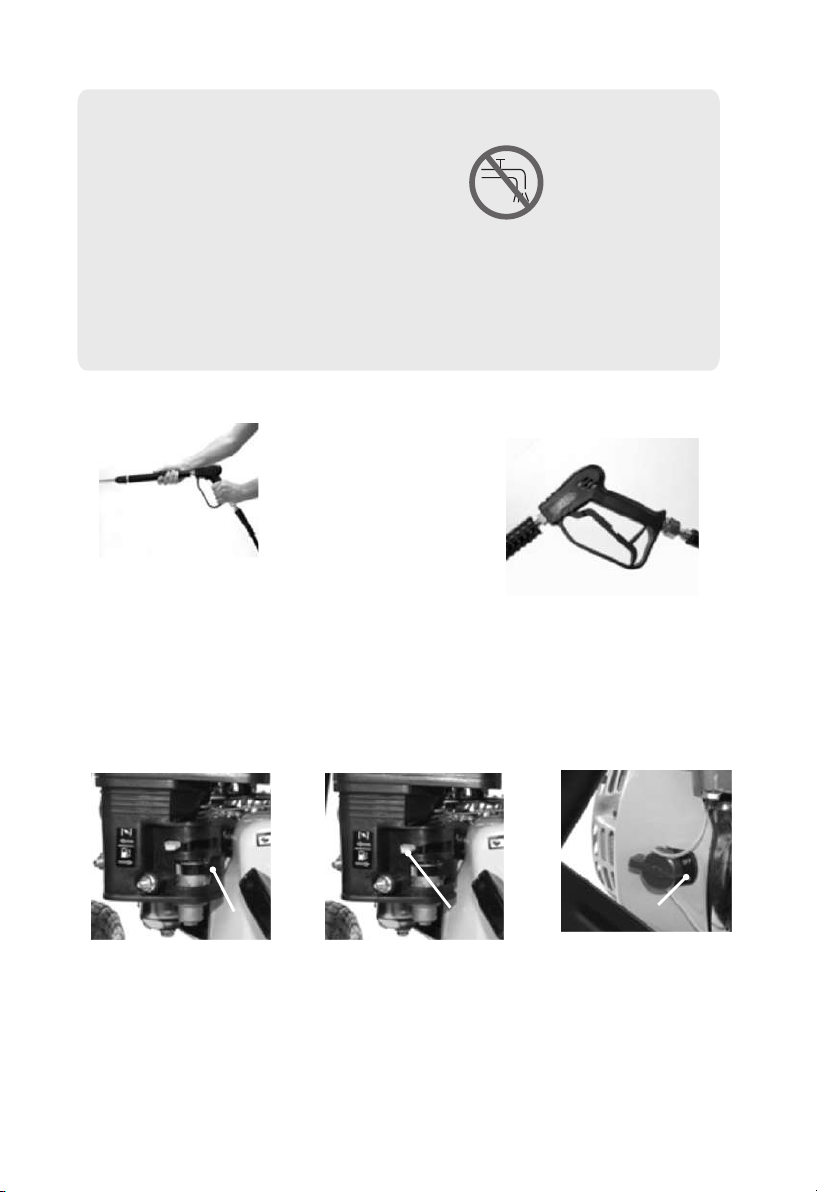

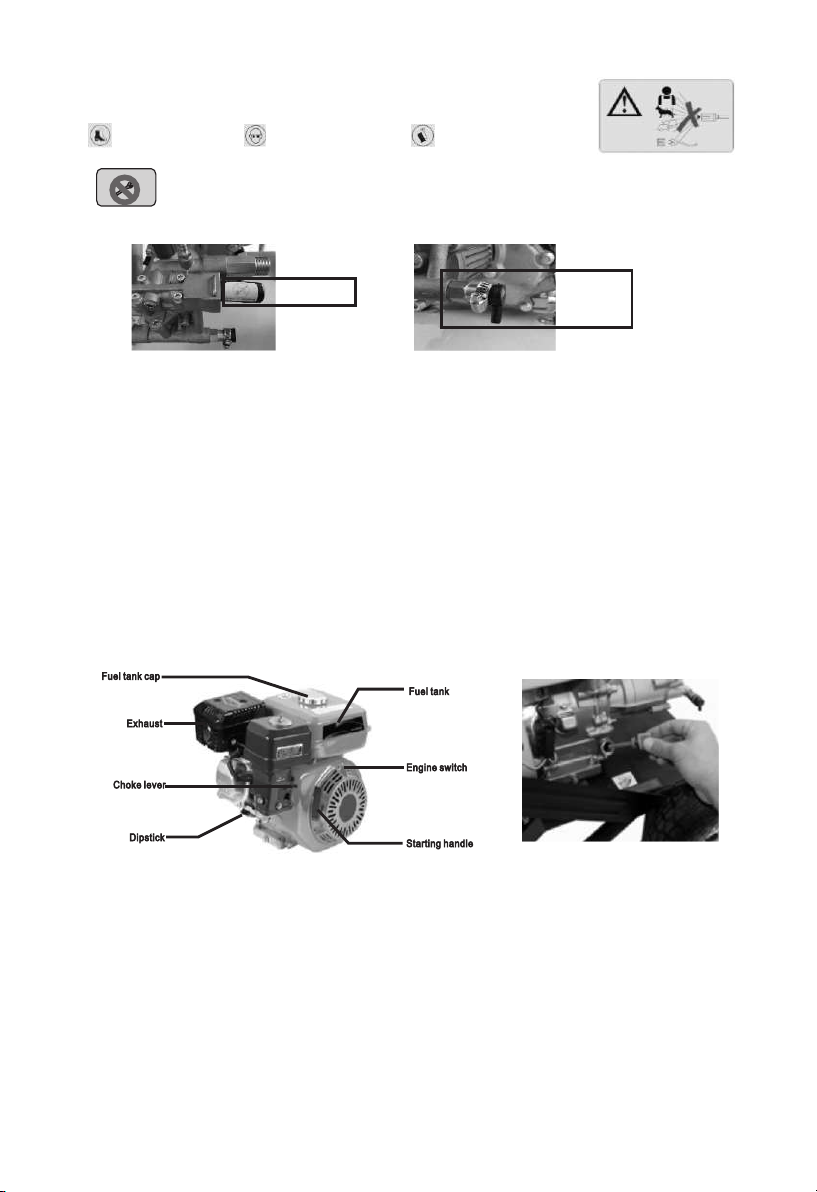

PUMP (FIG8):

WARNING:

If you buy a machine with

a red breathing plug, be

sure to remove the yellow

plastic from the plug before

using it

red breathing plug

yellow plastic

OPERATION AND USE

WARNING: The engine is not filled with oil. It is necessary to fill the unit before starting the

engine. The engine will not produce a spark unless sufficient oil is inside.

CAUTION: Do not run the engine with high or low oil level as this can cause engine damage.

CAUTION: Only use unleaded gasoline.

CAUTION: Avoid damaging your hose by ensuring it does not touch the hot exhaust during

and after use.

CAUTION: Avoid damaging your pump by ensuring the water supply is clean and free of any

foreign objects.

CAUTION: Inlet water temperature must not exceed 40 C and 20PSI .

CAUTION: Never let the appliance operate for more than 2 minutes with the spray gun in the

closed position.

CAUTION: Never operate the pressure washer with repeated and rapid on and off movements

of the trigger

o

-4-

BC

PUMP (FIG9):

If you buy a machine

without a red breathing

plug, please ignore FIG8

FIG. 14

Pull the trigger to eliminate trapped

air and wait for a steady flow of

water to emerge from the spray nozzle.

NOTE:

In order to assist the first startup it is

recommended to press the trigger

during the pulling of the starter handle.

To prevent accidental operation the

trigger is fitted with a locking facility.

FIG. 15

FIG. 16

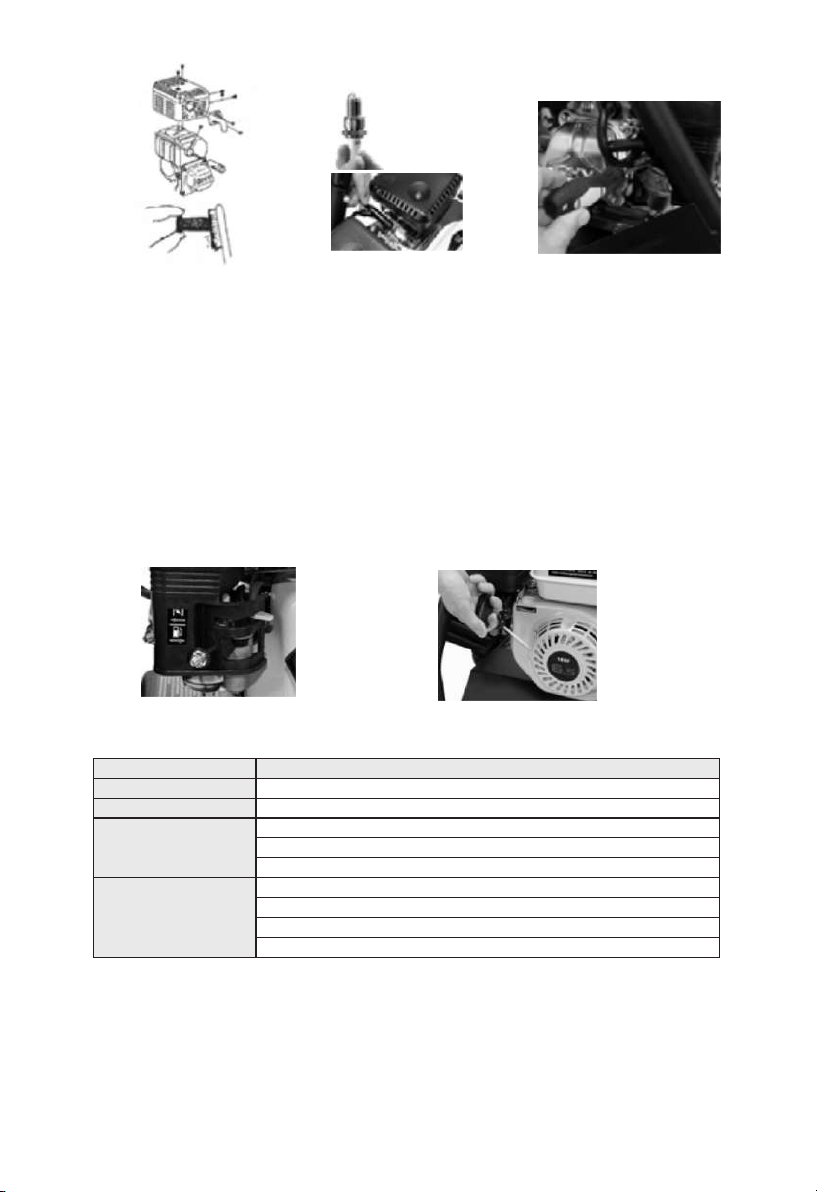

STARTING THE ENGINE

(FIG. 16-19):

Push the fuel lever A to the

right (On position).

A

FIG. 18

Turn the engine switch

clockwise to the ON position.

ON

FIG. 17

Push the choke lever B to the

left; closing the choke for initial

start-up.

NOTE: Do not use the choke

if the engine or air tempreture

is warm.

B

WATER SUPPLY FROM THE WATER MAIN

■Connect a water supply hose (not supplied) to the water inlet connection of the pressure washer.

■Turn on the water supply and pull the trigger until water

is continually flowing out of the nozzle.

WATER SUPPLIER FROM A CONTAINER

■Unscrew the coupling part for the water inlet.

■Screw the suction hose with filter (not included) onto the water connection of the unit.

■Hang the filter in the container.

■Vent the unit before operation.

■Unscrew the high pressure line at the high pressure outlet of the unit.

■Switch on the unit and let it run until water is free of bubbles at the high pressure outlet.

■Switch off the unit and screw on the high pressure hose again.

■Machine not suitable for connection to the potable water mains

-5-

FIG. 23

Turn the engine switch

anticlockwise to the OFF

position. Then slide the fuel

lever E to the right; OFF

position.

CAUTION: When you have

finished working turn off the

engine. When the machine is

switched off, always discharge

the pressure by pressing the

trigger.

E

FIG. 22

STOPPING THE ENGINE

(Fig 22-23):

In an emergency turn the engine switch

anticlockwise to the OFF position to stall

the engine.To stop the appliance normally

use the following sequence.

OFF

FIG. 19

Pull the black starting rope

handle gradually until you

feel resistance; then make a

rapid pull.

NOTE: Return the starting

rope handle gently to prevent

damage to the starter

assembly.

Do not pull the rope all the

way out as this can damage

the starter assembly.

FIG. 20

Let the engine idle for a short

while to preheat before pushing

the choke lever C to the right.

C

FIG. 21

When the appliance is in

operation, the speed can be

adjusted by moving the throttle

D control lever to the high

position (indicated by a hare).

NOTE: There is a stop bracket

on the throttle control lever, do

not force this bracket as it can

damage the engine.

D

ADJUSTING THE SPRAY PATTERN (Fig.24)

You have the choice of 4 different colour coded nozzles giving you different spray patterns to choose from:

0° nozzle (Red):This nozzle delivers a pinpoint stream and is extremely powerful. It covers a very small

area of cleaning. This nozzle should only be used on surface that can withstand this high pressure such as

metal or concrete. Do not use on wood.

15°nozzle (Yellow):This nozzle delivers a powerful 5 degree spray pattern for

intense cleaning of small areas. This nozzle should only be used on areas that

can withstand the high pressure from this nozzle.

40°nozzle (White):This nozzle delivers a 40 degree spray pattern and a less

powerful stream of water. It covers a wide area of cleaning. This nozzle should

be used for most general cleaning jobs.

Low pressure nozzle (Black): This nozzle is used to apply chemicals or

cleaning solutions. It has the least power stream.

FIG. 24

-6-

NOTE:

Before using the pressure washer to clean patio paving slabs it is advisable to test a small area first,

some paving slabs are manufactured from inferior materials and the use of a pressure washer could

damage the surface.

USING THE DETERGENT FACILITY (Fig. 25)

Fill a suitable container with pressure water detergent. Do not use washing up liquid as it contains salt. We

recommend the use of good quality pressure washer detergent for use with this pressure washer. Most

automobile detergents are a combination of a detergent and a wax solution. The viscosity (thickness) of the

detergent will increase in cold weather. It is recommended that this type of detergent is diluted with water before

filling the container. When using combination wash and wax solutions we recommend that they are diluted before

use. As a general guide we would recommend a dilution rate of 50/50. However a trial and error process would

determine the ideal dilution rate for a particular detergent.

NOTES:

A thick viscous detergent would not flow freely from the detergent tank and the residue would cause a blockage

flow system. After using the detergent facility it should be flushed thoroughly using copious amount of water. To

activate detergent delivery, fit the Black LOW PRESSURE nozzle to the and of the lance. Submerge the and of

the detergent pick up pipe into your container of pressure water detergent. Suction and mixing will occur

automatically as the water flows though the pump.

FIG. 25 FIG. 26

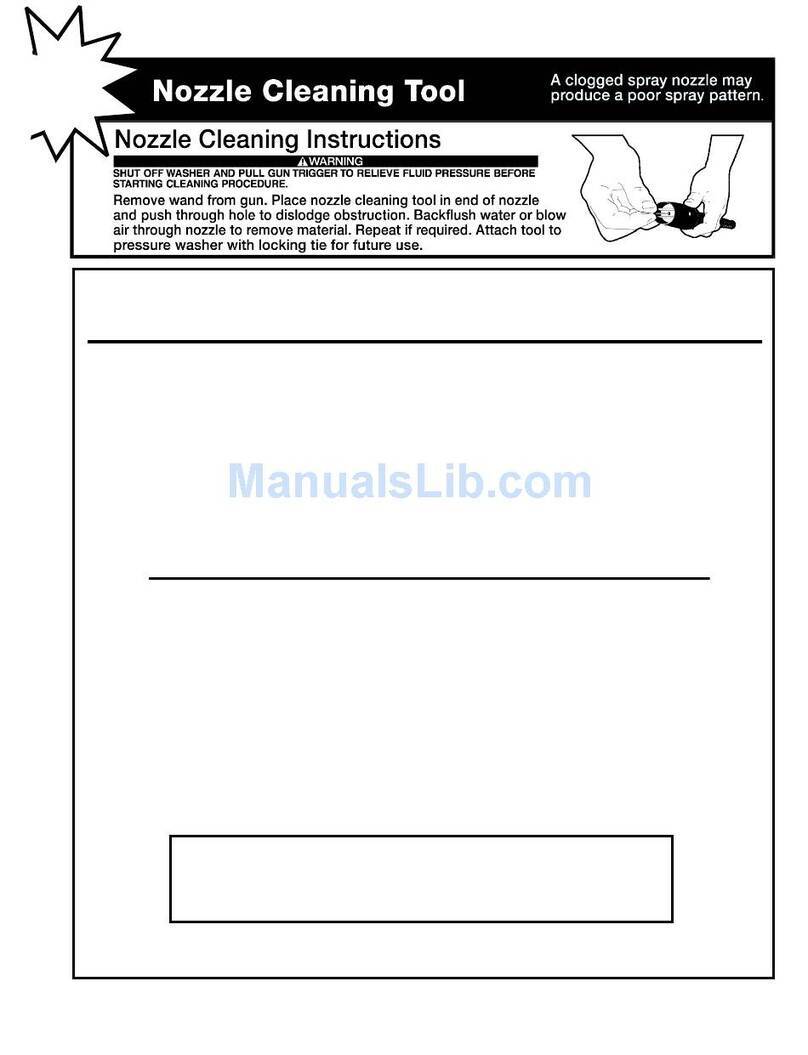

CLEARING A BLOCKAGE (Fig. 26)

If at any time the flow rate stutters or is inconsistent, release the trigger and switch OFF the machine.

Squeeze the trigger to relieve any pressure and check the jet in the end of the lance for any blockage.

If a blockage is suspected use some wire to clean the inside of the nozzle.

SAFETY INSTRUCTIONS FOR THE WASHER

1. Before operating the engine, be sure to read all instructions carefully as injury or permanent damage to

equipment may occur.

2. Run the engine in a well ventilated area.

3.Ensure the appliance is at least one metre away from building walls or other equipment.

4. keep the appliance away from flammable liquids such as petrol.

5.Refuel in a well ventilated area with the engine switched off and avoid sparks or naked flames.

6.When refuelling ensure that you do not overfill the fuel tank.

7.If any fuel is spilled ensure it is deaned up thoroughly before restarting.

8.Ensure the fuel cap Is located securely.

9.

10.Ensure the appliance is cooled before transporting or storing.

11.

wear ear protection to prevent hearing damage!

Not to be used in explosive environment,

The exhaust mufflers, engine case, pump get very hot and will remain hot for sometime after the engine

is switched off.

Sound pressure level:94dB; Sound power level:109dB.

Soap tank

-7-

PRE-OPERATION INSPECTION

CAUTION: Do not use

with additives or 2-stroke gasoline engine oil, as they do not have enough lubricating properties,

which may shorten the engine’s service life.

1 Check the engine is on level ground.

2. 0.6L 15W-30 is recommended for general all temperature use. (FIG. 27)

3.Remove the dipstick and clean it.

4.Reinsert the dipstick into the oil filler without screwing it in and check the oil level.

5.If the oil level is too low add the required amount of engine oil to the oil filler mark.

6.Replace the dipstick securely.

CAUTION: Running with insufficient engine oil may damage the engine severely.

Engine oil is a key factor in deciding the engine’s performance. engine oil

.

FIG. 27

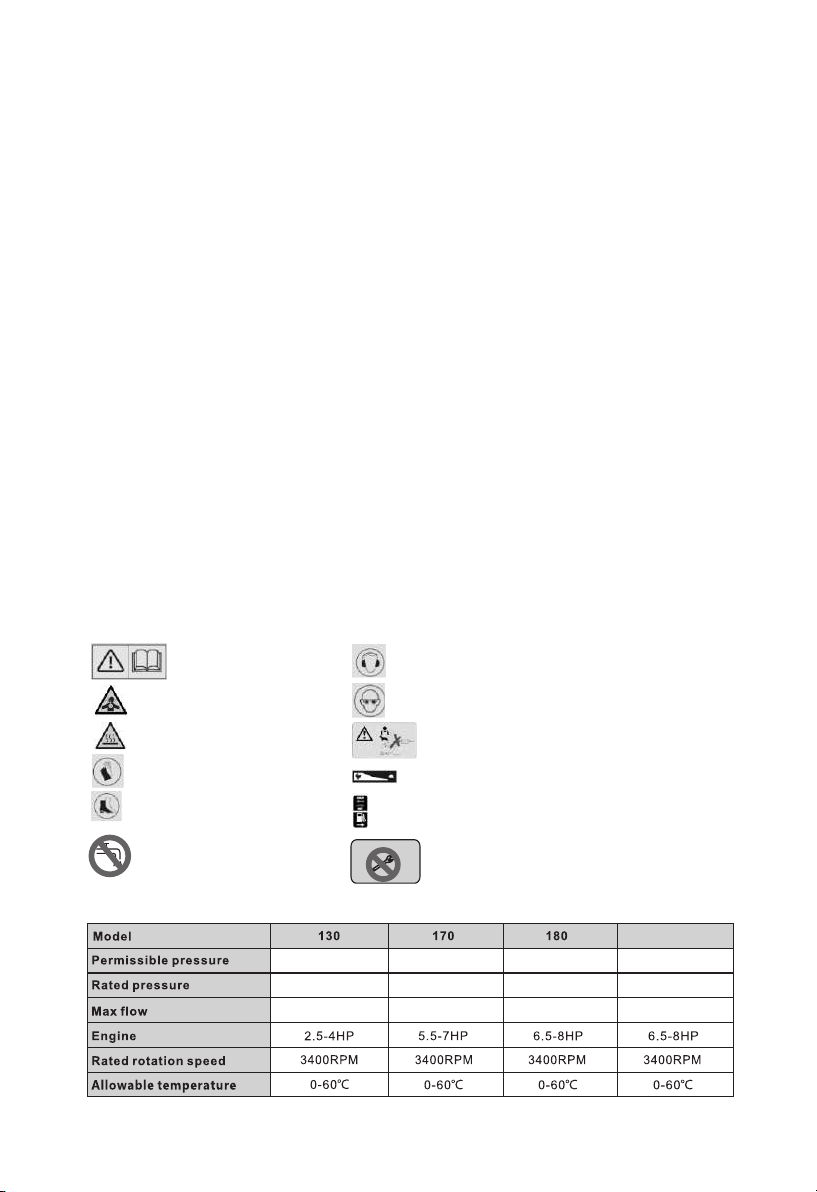

12.High-pressure jets can be dangerous if misused. Do not aim at people, animals,

active electrical equipment or at the appliance itself .

Wear safety shoes! Wear safety goggles! Wear protective gloves!

13.

Forbidden to adjust pressure valve, Otherwise it will cause pump damage。

14. 60 degrees hot water will be ejected from thermal relief valve before water gun closed for

about 1 minute. Careful burns。

pressure valve Thermal

relief valve

15. WARNING Do not use the machine within range of persons unless they wear protective clothing.

16. WARNING Do not direct the jet against yourself or others in order to clean clothes or foot-wear

17. WARNING Risk of explosion – Do not spray flammable liquids.

18. WARNING High pressure hoses, fittings and couplings are important for the safety of the machine.

Use only hoses, fittings and couplings recommended by the nufacturer.

19. WARNING To ensure machine safety, use only original spare parts from the manufacturer or approved

by the manufacturer.

20. WARNING Water that has flowed through backflow preventers is considered to be nonpotable.

Forbi dd en to a dj ust

-8-

FUEL AND FUEL TANK:

Only use unleaded petrol or fuel with an octane number over 86. Using unleaded petrol or fuel will decrease the

possibility of producing carbon deposit and prolong the engines service life. Never use old or polluted petrol or

fuel or a mixture of petrol and engine oil. Make sure the fuel is free of dirt and water.

CAUTION:

Handle fuel with care because it can damage plastic and painted surfaces.Remove the fuel filler cap and check

the fuel level. If the fuel lever is too low, refuel the tank. Remember when adding fuel do not fill over the fuel

filter shoulder.

WARNING:

Petrol is extremely flammable and is explosive under certain conditions. Refuel in a well ventilated area with the

engine stopped. Do not smoke or allow flames and sparks in the area where petrol is stored or where the fuel

tank is refuelled. After refuelling make sure the fuel cap is returned securely.Be careful not to spill fuel when

refuelling. Spilled fuel or fuel vapour may ignite. If any fuel is spilled make sure the area is dry before starting

the engine.

FUEL TANK FILTER (Fig.28):

After every 150 hours of running or every three months the fuel tank filter should be removed and cleaned.

Remove the fuel tank filler cap and the filter, clean the filter thoroughly using environmentally friendly water

based degreasing agent and re-fit.

OIL LEVEL SWITCH:

The engine oil alarm is designed to prevent the operator starting the engine when the oil in the crankcase is

insufficient. Running with insufficient oil will damage the engine. Once the oil level in the crankcase is too

low, the engine oil alarm will stall the engine automatically to avoid damage while the engine switch is still ON.

FIG. 28

AIR FILTER (Fig.29):

After every 100 hours of running or every month, the air filter should be removed and examined for deterioration

and cleaned. Clean the air filter thoroughly using environmentally friendly water based degreasing agent. Allow

to dry fully then replace the air filter. Never run the engine without the air filter fitted.

STORAGE:

If the engine is not to be used or is to be stored for more than one month the following storage procedure should

be carried out.

1. Drain all the fuel from the fuel tank and the carburettor ensure that all the fuel has been removed.

2.Remove the spark plug and pour approximately one tablespoon full of clean engine oil into the spark plug hole.

3.With the ignition turned OFF gently pull on the recoil starter cord several times.

4.Re-fit the spark plug and continue to pull the recoil starter cord until the piston is on the compression stroke

(when resistance is felt) then stop pulling.

5.Store the pressure washer in a dry well ventilated place under a cover to prevent any dust or debris from

accumulating on the pressure washer.

WINTER AND LONG TERM STORAGE:

If the pressure washer is not to be used for more than 3 months or if there is a danger of ice or frost during winter

months the pump unit will require protection to prevent seizing and damage caused by freezing.

FIG. 29

-9-

MAINTENANCE

EXHAUST CONTROL SYSTEM

With the engine running, carbon monoxide, nitrogen oxide and hydrocarbon are produced, and in certain

conditions nitrogen oxide and hydrocarbon will react together to make smoke while carbon monoxide is toxic,

so exhaust control is very important. The manufacturer decreases exhaust emissions by introducing poor-fuel

carburettors and other devices to solve the problem. To keep the exhaust of your engine within the standard

exhaust emission values, pay attention to the following:

MAINTENANCE

Maintain the engine periodically in accordance with the maintenance schedule. The maintenance schedule is

made out on the basis of normal use in normal conditions. If using under heavy load, dusty or wet conditions

or in high temperature, more frequent maintenance will be necessary.

REPLACEMENT OF PARTS

We recommend that you use parts that are supplied by the manufacturer or equivalent quality parts.

Replacement parts of inferior quality may impair the effectiveness of the exhaust control system.

MODIFYING

Modifying the exhaust control system may make exhaust emissions exceed statutory limits. Illegal

modifications are:

Dismantling or modifying any part of the air inlet or outlet system.

Modifying or removing speed adjustment controls or connections which may result in the engine running

outside its set parameters.

PROBLEMS AFFECTING EXHAUST EMISSIONS

1.Difficulty in starting or stopping.

Erratic idling.

Poor ignition spark or no spark.

5.Ignition too advanced. If you have any of these above problems please contact your dealer.

CAUTION:

Before carrying out any maintenance to the machine release any

pressure and remove the water connection.

WATER SUCTION FILTER CHECKING

Check periodically in order to avoid deposits clogging it.

1.

2.

2.

3.

4.

Giving off black smoke or excessive fuel consumption.

SPARK PLUG MAINTENANCE

After every 50 hours clean the spark plug with a brush. If the insulator on the spark plug is damaged replace

it immediately. Check the spark plug gap with a feeler gauge, the gap should be 0.7 - 0.8mm. If adjustment is

necessary bend the side electrode carefully. Check the spark plug gasket is in good condition or replace with

a new one. Screw in the spark plug to the bottom first by hand and then tighten by using a spark plug wrench.

If a new spark plug is used, twist a 1/2 more turn after impacting the gasket. If using the original one twist

1/8 -1/4 more turn.

CAUTION:

The spark plug eliminator should be serviced at least once every 100 hours of operation so as to keep it in

good condition.

WARNING:

The muffler is very hot during running the engine and for a prolonged period after stopping. Only service after

the engine cools down completely.

Unscrew two nuts and remove the exhaust elbow from the engine body.

Unscrew five screws from the muffler guard and take it out.

Unscrew from the spark plug eliminator and separate from the muffler.

Clean the spark eliminator mesh with a wire brush.

Reinstall the spark eliminator in reverse order of removal.

CAUTION:

Be careful not to damage the spark eliminator. Never use a damaged spark eliminator.

CARBURETTOR IDLING ADJUSTMENT:

Start and pre-heat the engine until it reaches normal working temperature. Obtain standard idling by adjusting

the throttle fixing screw under the engine, Standard idling: 3400 300rpm.

+

_

-10-

TRANSPORT

Transport with the fuel switch in the off position. Ensure the engine is cooled so as to avoid the risk of

burns or fire.

CAUTION:

Do not tilt the engine to avoid spilling fuel. Spilled fuel or fuel vapour may ignite.

STORAGE

If the engine is not to be used for a long period of time ensure it is stored correctly. Make sure the storage

area is dry and free of dust.

PREPARE FOR STORAGE

Disconnect the spark plug. Put a spoonful of fresh engine oil into the cylinder and rotate the engine to

distribute the oil evenly. Replace the spark plug. Pull the starting rope until you feel resistance and then

keep pulling so as to align the arrow of the starting sleeve with the hole of the starter: This will close both

the inlet and outlet valves to help prevent the engine rusting inside.Cover the engine to keep it free of dust.

REMOVAL FROM STORAGE

Before re-using, service the engine in accordance with the instructions in the following table.

1 Unscrew the drain plug and drain out the fuel in the carburettor:

2 Turn off the engine switch first, disconnect the deposit cup and empty it.

NOTE:

Do not dump oil containers or discarded engine oil into the ground. For environmental protection take

discarded engine oil in a closed container to a recycling station.

WARNING:

Fuel is extremely flammable and explosive under certain conditions. Keep cigarettes, naked flames and

sparks away from operating site.

No service needed

Drain out original fuel of the fuel tank and refuel

Drain out original fuel of the fuel tank and refuel

Drain out the fuel in the carburettor 1

Empty the deposit cup 2

Drain out original fuel of the fuel tank and refuel

Drain out the fuel in the carburettor 1

Empty the deposit cup 2

Move the engine from the storage place, and start up

SERVICE ITEM

STORAGE TIME

Within one month

One - Two months

Two months - One year

Above One year

-11-

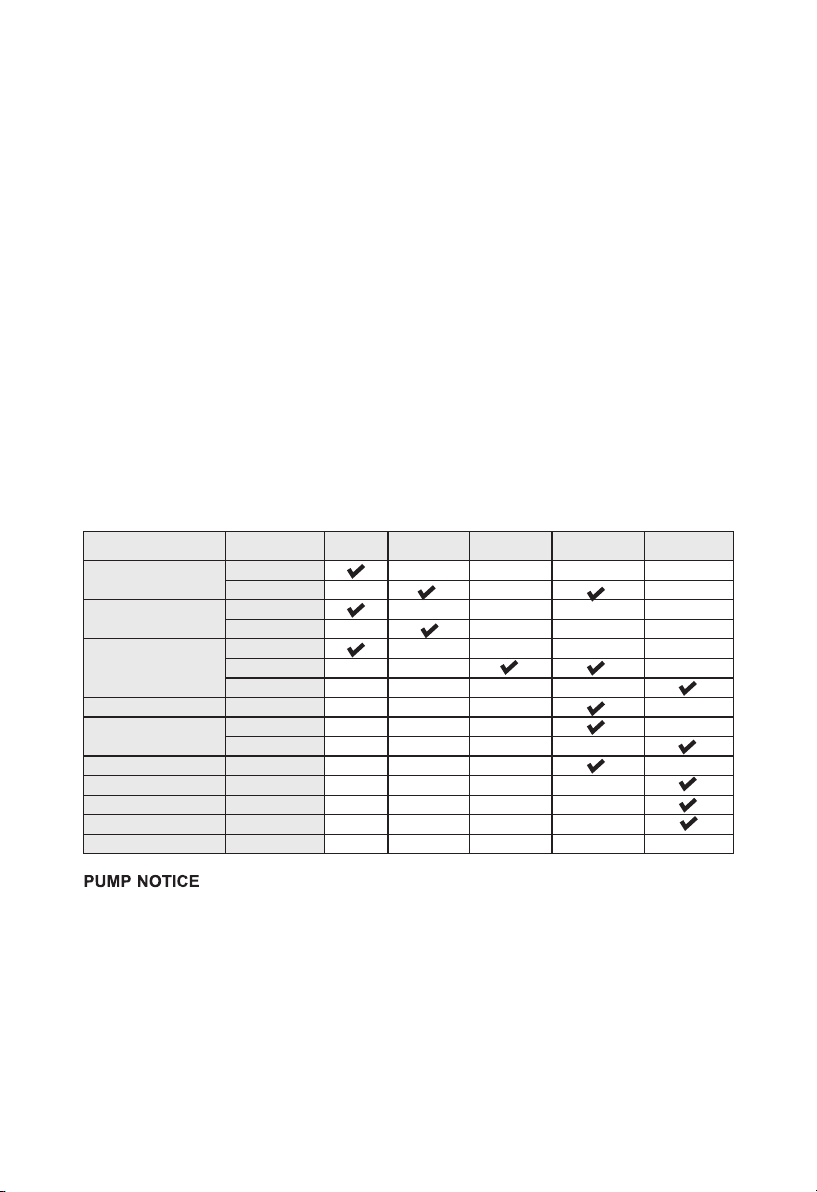

To keep the engine in sound condition, the user should maintain it according to the table below.

CAUTION:

Use parts that are supplied by the manufacturer, otherwise damage to the engine may occur.

WARNING:

Stop the engine before servicing. If servicing is required with the engine running ensure there is good ventilation

in the area. Exhaust emissions contain toxic carbon monoxide which may cause injury or be fatal if inhaled.

ENGINE OIL REPLACEMENT

Place the machine on a level surface and warm up the engine for several minutes. Then stop the engine.

Remove the oil filler cap

Place an oil pan under the engine. Remove the oil drain plug so that the oil can be completely drained. You will

need to use a tube or other similar device to prevent the oil leaking onto the frame of the pressure washer.

Check the oil drain plug, gasket oil filler cap and O-ring and if damaged replace.

Reinstall the oil drain plug.

Add engine oil up to the upper level of the dipstick.

NOTE:

Do not dump oil containers or discard engine oil into rubbish boxes or into the ground. For environmental

protection take discarded engine oil in a closed container to a recycling station.

*

**Only for paper core air cleaners.

Only for inside ventilating double-core carburettors.

1.More often than in schedule if used in dusty conditions

2.Items to be done by dealer unless you are fully trained and equipped to do so.

NOTES:

Item

Engine oil Oil level check

Replace

Reduction gear oil Oil level check

Replace

Air cleaner

Check

Clean

Replace

Deposit cup Clean

Spark plug Clean, adjust

Replace

Spark eliminator Clean

Idling Clean, adjust

Valve clearance Clean, adjust

Fuel tank & fuel filter Clean

Fuel supply line Check

Each time First month

or 20 hours

Each month

or 50 hours

Each 6 months

or 100 hours

Each year or

300 hours

11*

**

2

2

2

-12-

Following operations and maintenance will extend the service life of the pump:

1.After using 20 hours of the new machine, pour out the machine oil,

and add the appropriate amount of kerosene.

Operate the pump without load in 10-15 seconds,

then close the machine and pour out the kerosene, finally add the new oil.

2.Accumulative use after 100 hours,

change the oil in the same way like above.

TROUBLESHOOTING

PUMP TROUBLESHOOTING

TROUBLE PROBABLE CAUSE REMEDY

Fluctuating pressure

Pump sucking in air

Valves dirty, worn out or seized

Blocked jet

Check connection are tight

Contact customer helpline

Remove blockage using jet cleaning tool

Water leakage from pump Seals worn out Contact customer helpline

The pump does not reach the

required pressure

Pump sucking in air from

connections or hose

Check tightness of all connections

Suction/delivery valves are

clogged

Clear or replace valves.

Have machine checked by Service Centre

Unload valves are stuck Loosen and re-tighten regulating screw

Lance or nozzle worn out Check and/or replace

Pump is running but no water

delivery

Kinked inlet and or pressure hose

Blocked inlet filter

Blocked jet

Check, straighten and replace if required

Remove and clean filter

Remove blockage using the jet cleaning tool

ENGINE TROUBLESHOOTING

REPAIR

Tighten plug

Tighten bolt

Replace gasket

Pull rope sharply

Insufficient pulling speed for

starting rope

Clean tank

Clean fuel line with dealers advice

Supply fuel

Open tap

Remove carbon or dry spark plug

Spark plug dirty with

carbon or wet with fuel

Replace spark plug

Consult dealer

Faulty magneto

Pull rope sharply

Insufficient pulling

speed for starting rope

Check grade of fuel

Check the working conditions

Overheating

Overloaded

Wrong grade of fuel used

Improper adjustment of

carburetor

Damaged spark plug

Fuel tap not open

No fuel in tank

Clogged fuel line

Foreign matter in fuel tank

PROBABLE CAUSE

Loose spark plug

Loose cylinder head bolt

Damaged gasket

FUEL SYSTEM PROBLEMS

FUEL SYSTEM PROBLEMS

Poor

spark

Good

spark

Combustion

chamber

supplied with

fuel

No fuel

supplied to

combustion

chamber

Insufficient

compression

Sufficient

compression

Engine

won’t start

Low

engine

output

Engine

runs

erratically

FAULT

-13-

-14-

Other manuals for 130

3

This manual suits for next models

3

Table of contents

Other Bison Pressure Washer manuals

Popular Pressure Washer manuals by other brands

Kärcher

Kärcher K 2.97 M manual

Krüger Technology

Krüger Technology KHL120F instructions

EUROM

EUROM Force 1200 instruction manual

Powr-Flite

Powr-Flite PF1200RT Operator's manual & parts list

DeVilbiss Air Power Company

DeVilbiss Air Power Company MPG-1217 owner's manual

VITO

VITO PRO-POWER POWERWASH 150 HQ instruction manual