BJB Enterprises Centerpointe CPE-325 User manual

by BJB Enterprises, Inc.

CPE-325

Meter-Mix Dispense System

Operations Manual

2 CPE-325 Operation Manual

www.centerpointe-equipment.com

Centerpointe

by BJB Enterprises, Inc.

14791 Franklin Avenue

Tustin, California 92780

PH: 714-734-8450

Fx: 714-734-8929

www.centerpointe-equipment.com

CPE-325 Operation Manual 3

714.734.8450

CPE-325

Table of Contents

Section: Page

1) System Requirements............................................................................... 4

2) Initial Start-up.............................................................................................. 4

3) Loading Material......................................................................................... 6

4) Heater Controls........................................................................................... 8

5) De-Airing Material...................................................................................... 8

6) Setting Speed and Ratio.......................................................................... 10

7) Dispensing Material.................................................................................. 12

8) Solvent Flush System (Optional)........................................................... 12

9) Daily Shut Down........................................................................................ 14

10) Weekly Maintenance.............................................................................. 16

11) Long Term Storage.................................................................................. 17

Trouble Shooting............................................................................................ 18

Warranty............................................................................................................. 20

4 CPE-325 Operation Manual

www.centerpointe-equipment.com

CENTERPOINTE EQUIPMENT

CPE-325

Meter-Mix Dispense System

Operating Instructions

1) SYSTEM REQUIREMENTS

• Air Supply - approximately 80 (psi) @ 15 CFM.

• 120 Volt single phase 20-amp power supply.

• For optional Solvent Flush System - Solvent for ush cleaning the gun head and static

mix tubes. (Recommended solvent – SC-105 available at BJB)

2) INITIAL START-UP

• Your unit was shipped with ushing uid in the hoses and pumps. This must be removed

and not allowed to mix with resin. Remove tank lids and make sure tanks are free of any

uid. Wipe dry with a clean rag.

• Fill solvent tank with recommended solvent. (BJB SC-105)

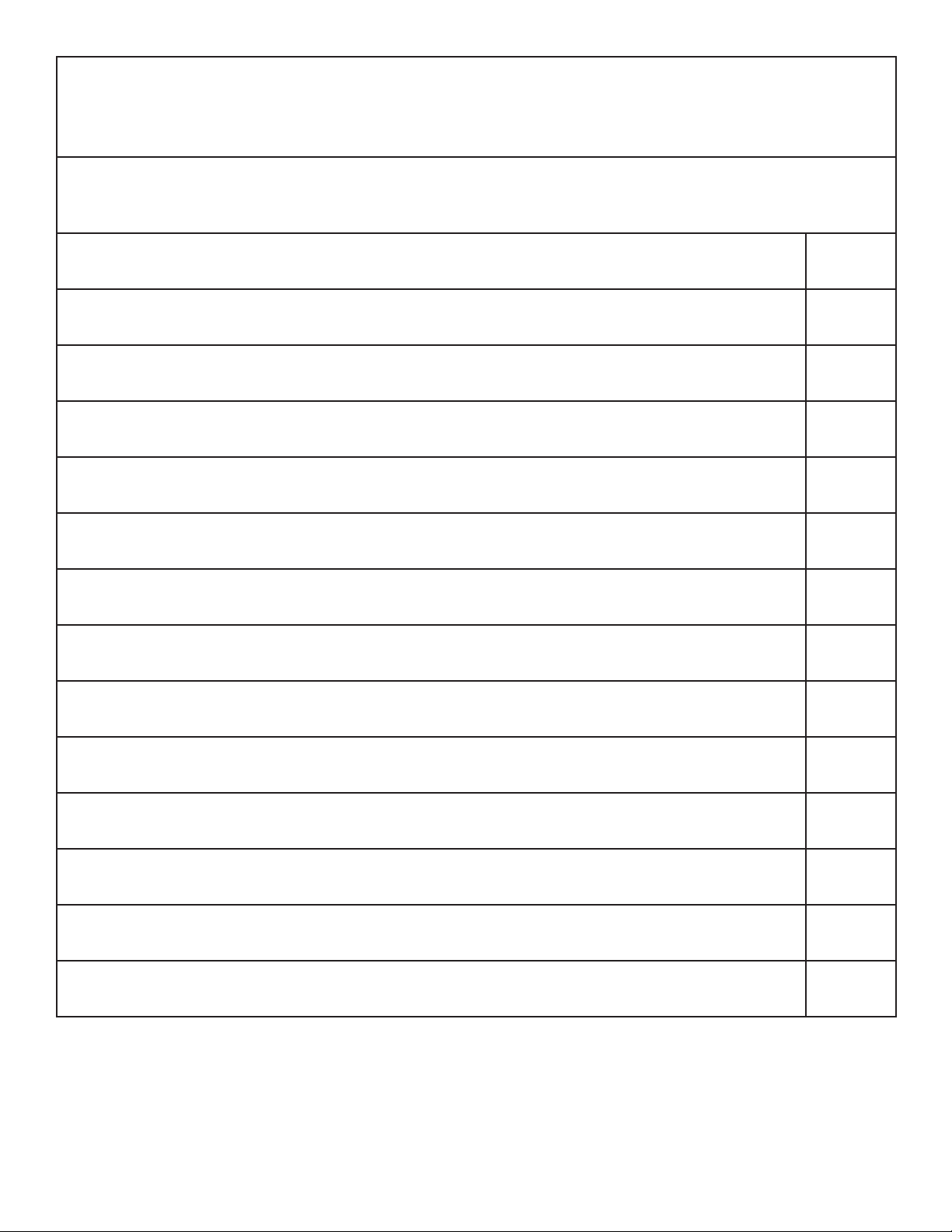

• Connect Air supply. (see g. 2.1)

• Connect Power supply.

• Put a drop of air tool oil in air inlet on lid mixers. (see g. 2.2)

CPE-325 Operation Manual 5

714.734.8450

Fig. 2.1

Fig. 2.2

6 CPE-325 Operation Manual

www.centerpointe-equipment.com

3) LOADING MATERIAL

• Place the ball valves under the tanks in the closed position. (see g. 3.1)

• Remove the lids.

• Pour the selected resin system into the feed tank. Do not ll tank while other tank is

un-covered. Material may splash from one tank into the other, causing particles to form

which will eventually be drawn into the pump. Make sure that the ‘A’ and ‘B’ components

are poured into the appropriate tanks.

• Leave enough space for material to rise during vacuum process (1/2 to 2/3 full).

• A minimum of one gallon should be poured into each tank to prevent the heaters from

scorching the material.

• Replace the lids and begin stirring the material. The lid mixers should turn slowly so as not

to introduce more air into the material. (see g. 3.2)

• Set the control knob on the heater bands to a low setting and increase gradually to

desired temperature. (see g. 3.3)

• Follow procedures in Section 5 for degassing material.

• Open the desiccant tube valves located on the lids. During machine operation, air must

be allowed to enter the tanks as the liquids are drawn out to prevent a vacuum lock. The

air going into the tanks should enter via the desiccant tubes. (see g. 3.4)

• Remove lids and place over waste containers (see g. 3.5). To purge any remaining solvent

or previous material from the lines, open ball-valves under tanks and start pumps (see

section 6 to run pumps). Run until a steady, clean stream of material ows from re-

circulation tubes on tank lids.

CPE-325 Operation Manual 7

714.734.8450

Fig. 3.1 Fig. 3.2

Fig. 3.3 Fig. 3.4

Fig. 3.5

8 CPE-325 Operation Manual

www.centerpointe-equipment.com

4) HEATER CONTROLS

• The ‘A’ and ‘B’ tank heaters are adjusted by the temperature control knobs on the heater

bands, and can be accessed through the front panel. Do not adjust heater controls while

pumps are running and chain is in motion.

• Check material temperatures frequently to prevent over heating. 80°-90° F is normal for

material temperatures.

• Mixers should be turning slowly to prevent uneven heating.

5) DE-AIRING MATERIAL

• Make sure the ball valves under the tanks are in the closed position.

• Turn o lid mixers.

• Attach the vacuum line to vacuum port on the lid. (see g. 5.1)

• Close desiccant tube valve on lids.

• Open the ball valve on the vacuum port, and proceed to pull a vacuum. Monitor level

of material constantly through the viewport while under vacuum. Using a ashlight,

shine light through one viewport while observing material in the other viewport. If the

material level approaches the top of the tank, you must close the vacuum port valve to

avoid the material being drawn into the vacuum hose. With the yellow cap removed

from the desiccant tube (see g. 3.3), open the air valve to allow bubbles to settle. Repeat

process until material settles on its own. Some materials with high viscosities may require

opening the air valve on the tank two to three times before the material level drops on its

own. BJB’s anti-foam products may help dissipate the bubbles in the tanks more easily.

• When vacuuming is complete, close the vacuum port valve, remove the vacuum line and

open the desiccant tube valve.

CPE-325 Operation Manual 9

714.734.8450

Fig. 5.1

10 CPE-325 Operation Manual

www.centerpointe-equipment.com

6) SETTING SPEED AND RATIO

Setting the Speed

• Adjusting the speed on the CPE-325 is accomplished by adjustments made to the speed

control knob located on the front panel of the unit. (see g. 6.1)

• When the knob is turned clockwise the pump speed will increase. When the knob is

turned counter-clockwise the pump speed will decrease.

Setting the Ratio

• Adjusting the ratio is accomplished by changing the sprocket size on the pumps. Addi-

tional sprockets can be purchased from BJB.

• Loosen locking bolt on chain idler to relieve chain tension and change pump sprocket as

necessary. Re-adjust chain for proper tension (chain should have approximately 1/2” up

and down play). (see g. 6.2)

Checking the Ratio

• It is recommended to insure the ratio is within tolerance (check with your material manu-

facturer).

• Attach supplied ratio head by removing the mix tube nut and aligning the smaller slot on

the ratio head with the n on the gun head manifold (see g 6.3). Tighten the ratio head

nut snuggly.

• Straddle the ratio head over the rims of two cups. (see g 6.4)

• Dispense enough material to provide an accurate weight measurement (typically 100

grams of combined material).

• Weigh each cup; divide the smaller weight by the larger weight to acquire the ratio. For

example, if you have 43 grams ‘A’ and 78 grams of ‘B’, your ratio would be 43/78 or 55/100

by weight. If you have 92 grams ‘A’ and 56 grams ‘B’ then you ratio would be 92/56 or

100/60.

• If the ratio is not within tolerance refer to “Setting the Ratio”.

CPE-325 Operation Manual 11

714.734.8450

Fig. 6.1 Fig. 6.2

Fig. 6.3 Fig. 6.4

12 CPE-325 Operation Manual

www.centerpointe-equipment.com

7) DISPENSING MATERIAL

• At start-up, always dispense at a low speed. Cold viscous material can cause high

pressures. High pressures can cause relief valve to discharge or gun seals to fail.

• Open the ball valves under the tanks, and open the desiccant tube valves on the lids.

• If the ratio head was used to determine the proper machine setting, remove it and replace

it with a mix tube.

• Dierent material systems generally have their own unique handling characteristics. Run

some test shots before lling a mold. Check for correct pot life, nal cured hardness, and

the complete mix of components.

• When nished dispensing material, point the gun in a downward position, remove the

static mix tube, and wipe the end of the gun-head manifold clean. This will prevent any

material reaction in the manifold orices.

8) SOLVENT FLUSH SYSTEM (OPTIONAL)

• When dispensing is complete, ush mix tube immediately.

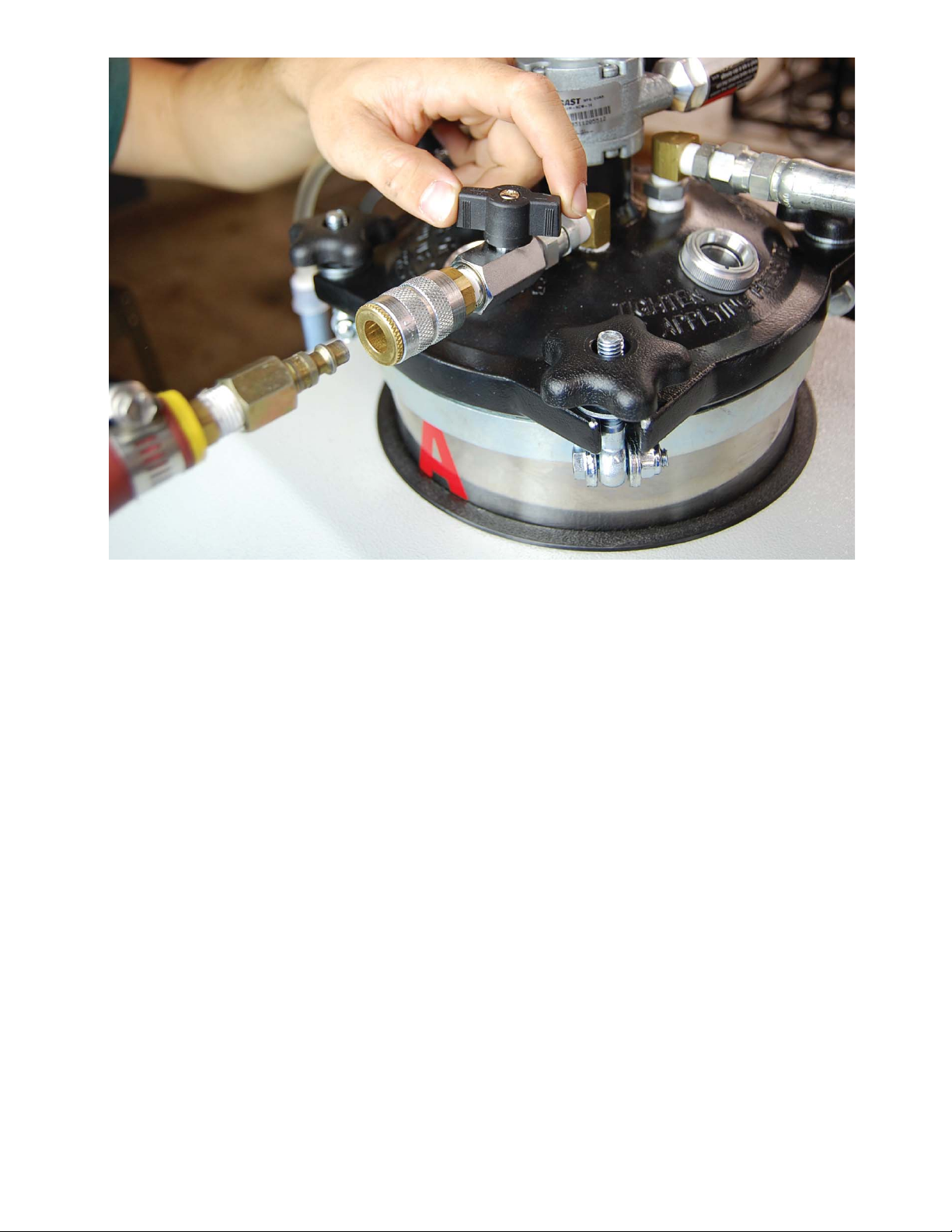

• The valves for air and solvent are located behind the gun head assembly (g. 8.1), turning

the valve to the right, towards the clear hose, will allow air to ow through the gun head

manifold; to the left, towards the black hose, will allow solvent to ow.

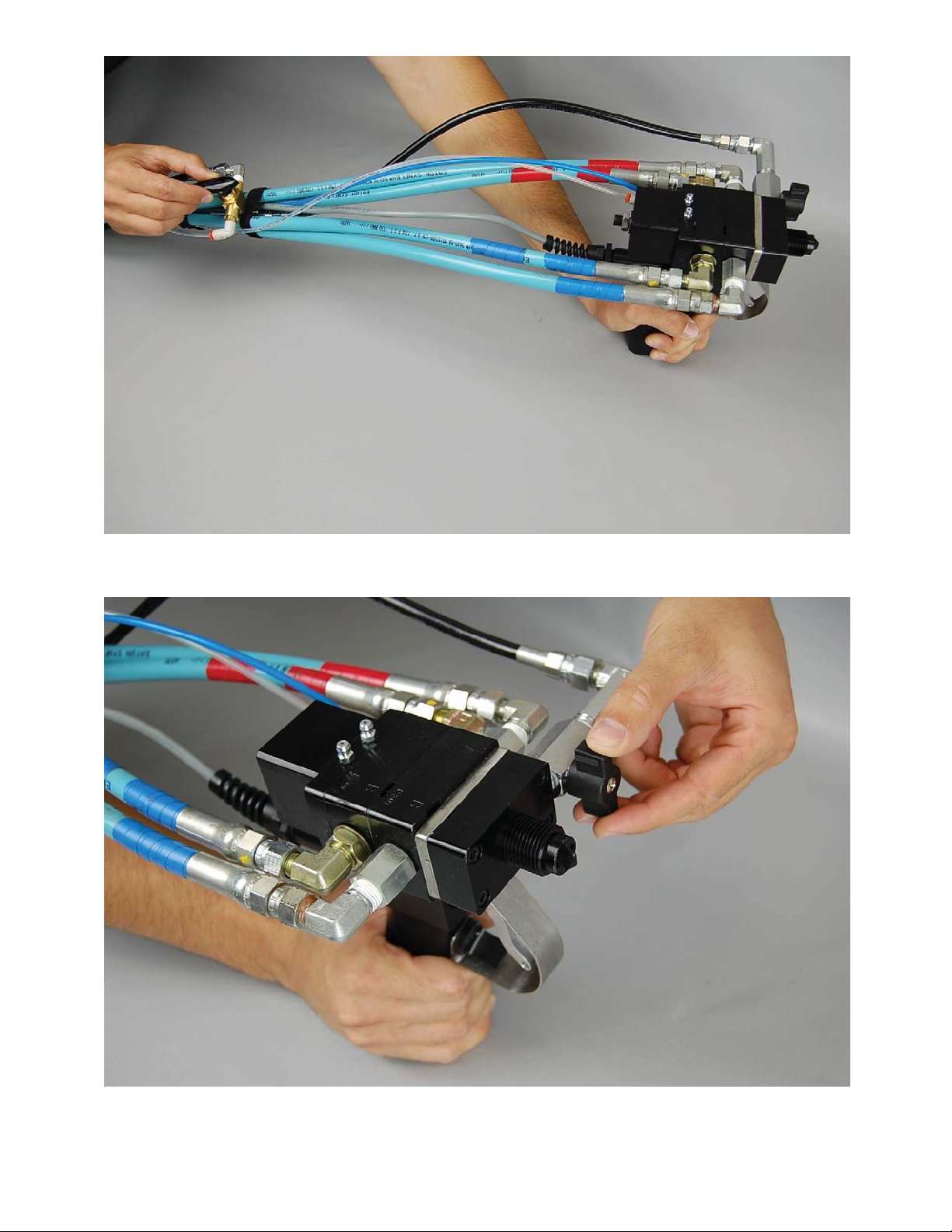

• Open the ball valve on the gun head manifold (g 8.2) to allow solvent or air to ow

through the A side port and through the mix tube. Alternate ushing with solvent and air

and repeat until the gun head manifold and mix tube are thoroughly clean.

• When nished with the solvent ush close the ball valve on the gun head manifold so

that material will not back ow into the solvent tank.

CPE-325 Operation Manual 13

714.734.8450

Fig. 8.1

Fig. 8.2

14 CPE-325 Operation Manual

www.centerpointe-equipment.com

9) DAILY SHUT DOWN

• Close the ball valves under feed tanks.

• Cap o desiccant tubes and close the valves.

• Disconnect the air supply and power supply.

• Purge tanks with dry nitrogen or evacuate air by vacuum. Replace lids and secure hold

downs.

• Do not relieve pressure on system, this will cause air to enter material lines, and harden

material in hose.

• Remove nozzle end from gun and ush both ‘A’ and ‘B’ orices with solvent. Wipe gun face

clean. Replace nozzle and install night cap. (see g. 9.1)

• Apply small amount of APG#2 grease to gun valve grease ttings. (see g. 9.2)

• Put a drop of air tool oil in each air mixer inlet.

CPE-325 Operation Manual 15

714.734.8450

Fig. 9.1

Fig. 9.2

16 CPE-325 Operation Manual

www.centerpointe-equipment.com

10) WEEKLY MAINTENANCE

• Check tanks for any hardening of material and re-apply dry nitrogen and tighten lids.

• Check chain and sprockets for tension, lube chain with small amount of lithium grease.

• Open bleed valve screw located on bottom center of pump, (it may be necessary to hold

main body of bleed valve to prevent entire valve from turning). Apply APG#2 grease to

tting until small amount of grease escapes from small hole in bleed valve body, repeat

for other pump. (see g. 10.1)

Fig. 10.1

CPE-325 Operation Manual 17

714.734.8450

11) LONG TERM STORAGE

• The ‘A’ component of urethane materials are moisture sensitive and will“skin”or harden in

the tanks, pumps, and hoses if left unchecked for extended periods of time. All tank lids

must be kept tightly sealed, purged with Dry Nitrogen or kept under vacuum. Fluid pres-

sure must not be allowed to dissipate. Systematic care of equipment and material will

insure proper operation, and minimize expensive parts replacement and downtime.

• If system will not be used for an indenite period of time, removal of material and com-

plete ushing is necessary.

• To ush system, shut o heating systems. Remove tank lids and suspend over clean,

separately marked containers. (see g. 3.4) Start pumps slowly and allow material to ow

from lid recirculation down tubes. When tank levels are just below the ball valve, stop

the pumps and close the tank ball valves. Wipe tanks clean of any residue. Fill tanks with

approximately one half to one gallon of SC-105 solvent. Open tank ball valves. Suspend

lids over waste container and start pumps until steady stream of solvent is present at

the lid recirculation down tube. Stop pumps, replace lids on respective tanks. Start

pumps and allow solvent to recirculate for approximately 20-30 minutes. Repeat process

replacing solvent each time (approximately 2-3 times).

• When satised with solvent ush of the system, close all ball valves. Leave clean solvent in

system. Disconnect air supply and electrical supply. Remove gun head manifold. Clean

gun head face and manifold thoroughly with solvent.

18 CPE-325 Operation Manual

www.centerpointe-equipment.com

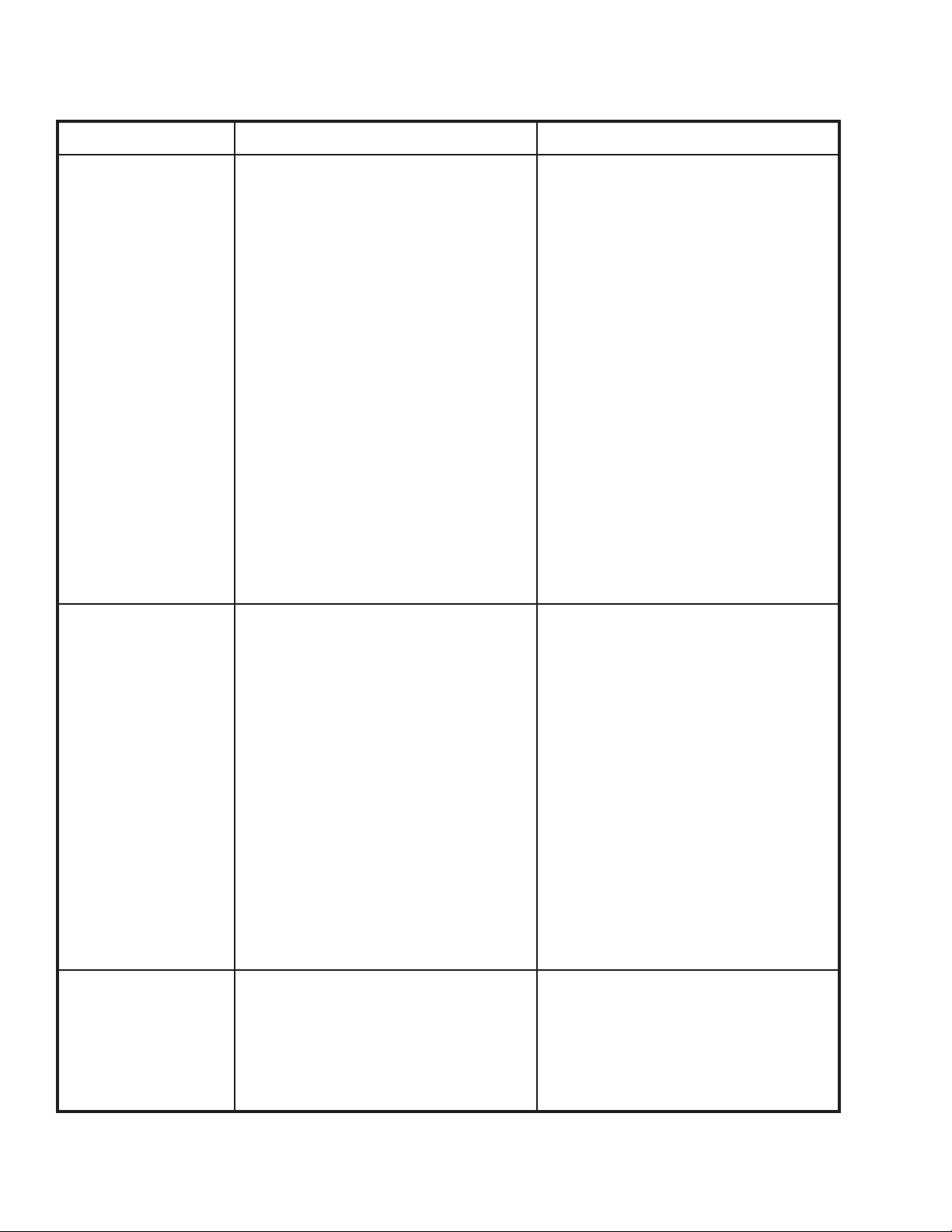

CPE-325 TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE RECOMMENDATION

Parts remain

sticky or blister.

A. Material is not being de-

livered to mix nozzle at prop-

er ratio.

B. Insucient material pres-

sure into mix nozzle.

C. Material has settled in

tank and not been re-mixed

or heated properly.

D. Solvent has not been

completely ushed from mix

nozzle.

E. First shot of material con-

tained unmixed material.

A. Install ratio head on gun

and check for proper A-B

ratio.

B. Increase pumps RPM.

C. Heat material and op-

erate mixers for 30 minutes

or until all ingredients have

been thoroughly re-blended.

D. Completely ush noz-

zle with air and solvent after

each use.

E. Always dispense small

amount into waste container

to insure mix nozzle contains

only mixed material.

Incorrect Ratio A. Clog in hoses or gun

passages.

B. Material not heated

properly.

C. Air in hoses.

D. Solvent valve is open.

A. Check all hoses and gun

for blockages.

B. Heat material to recom-

mended temperature before

dispensing. Viscosity will

aect ratio.

C. Purge all air from materi-

al hoses before dispensing or

if tanks have been emptied.

D. Flush solvent line of

backed up material, close

solvent valve.

Gun leaks

material.

A. Worn seals, o-rings

B. Improper adjustment of

snu back.

A. Replace worn packing

and o-rings.

B. Adjust snu back per gun

manual.

CPE-325 Operation Manual 19

714.734.8450

PROBLEM POSSIBLE CAUSE RECOMMENDATION

Air entrapped in

nished parts.

A. Air not evacuated from ma-

terial prior to dispensing.

B. Air in material hoses.

C. Air ush valve leaking or

partially open.

D. Air trapped in pump cham-

ber.

A. Evacuate air from material

before dispensing.

B. Attach ratio head and

dispense material into separate

containers until material ow is

air free.

C. Make sure air ush valve is

completely o or replace valve

if necessary.

D. Open purge valve on top

of pump to release air.

Pumps are turning

but no material is

being dispensed.

A. Ball valves under tanks are

closed.

B. Valves for desiccant tube

are closed.

C. Tanks are empty.

A. Open ball valves under

tanks.

B. Make sure desiccant tube

valves are open and caps

removed.

C. Replenish tanks and purge

air.

Pressures are

dierent on A and

B gauges

A. Viscosity and Ratio will

cause pressures to vary; howev-

er, a minimum pressure is need-

ed to achieve a thorough mix.

A. Dierent manifolds and

manifold orices can help

bring pressures into better

alignment.

Gun valve will not

open, Pumps will

not operate.

A. No air or inadequate air

supply

A. Check air supply/ pressure

to unit.

20 CPE-325 Operation Manual

www.centerpointe-equipment.com

BJB ENTERPRISES, INC.

NEW EQUIPMENT WARRANTY

The Company warrants that the equipment manufactured by it and delivered hereunder will be free

of defects in material and workmanship for a period of 6 months from the date of delivery. The Purchaser

shall be obligated to promptly report any failure to conform to this warranty, in writing to the Company in

said period, whereupon the Company shall, at its option, correct such nonconformity, by suitable repair to

such equipment or, furnish a replacement part F.O.B. point of shipment, provided the Purchaser has stored,

installed, maintained and operated such Equipment in accordance with good industry practices and has

complied with specic recommendations of the Company. Accessories or equipment furnished by the

Company, but manufactured by others, shall carry whatever warranty the manufacturers have conveyed to

the Company and which can be passed on to the Purchaser. The Company shall not be liable for any repairs,

replacements, or adjustments to the Equipment or any costs of labor performed by the Purchaser or others

Without Company’s prior written approval.

The eects of normal use and wear are specically excluded. THE COMPANY MAKES NO OTHER

WARRANTY OR REPRESENTATION OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF

TITLE, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE,

ARE HEREBY DISCLAIMED.

Correction by the Company of nonconformities whether patent or latent, in the manner and for the

period of time provided above, shall constitute fulllment of all liabilities of the Company for such non-

conformities whether based on contract, warranty negligence, indemnity, strict liability or otherwise with

respect to or arising out of such Equipment.

The purchaser shall not operate Equipment, which is considered to be defective, without rst no-

tifying the Company in writing of its intention to do so. Any such Equipment will be at Purchaser’s sole risk

and liability.

Limitation or Liability

The remedies of the Purchaser set forth herein are exclusive, and the total liability of the Compa-

ny with respect to this contract of the Equipment and services furnished hereunder, in connection with

the performance or breach thereof, or from the manufacture, sale, delivery, installation, repair or technical

direction covered by or furnished under this contract, whether passed on contract, warranty negligence,

indemnity, strict liability or otherwise, shall not exceed the purchase price of the unit of Equipment upon

which such liability is based.

The Company and its suppliers shall in no event be liable to the Purchaser, any successors in

interest or any beneciary or assignee of this contract for any consequential, incidental, indirect, special

or punitive damages arising out of this contract or any breach thereof, or any defect in, or failure of, or

malfunction of the Equipment hereunder, whether based upon loss of use, lost prots or revenue, interest,

lost goodwill, work stoppage, impairment of other goods, loss by reason of shutdown or non-operation,

increased expenses of operation, cost of purchase of replacement power or claims of Purchaser or custom-

ers of Purchaser for service interruption whether or not such loss or damage is based on contract, warranty,

negligence, indemnity, strict liability or otherwise.

August 22, 2012

Table of contents